Professional Documents

Culture Documents

Refinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur Distribution

Uploaded by

marraezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur Distribution

Uploaded by

marraezCopyright:

Available Formats

July August 1999

Number 263

The Magazine for the World Sulphur and Sulphuric Acid Industries

European oil refining conference report

Indian sulphur production

US Gulf refinery sulphur

Claus furnace and burner modelling

Liquid sulphur distribution

SO2 scrubbing processes

TS

PECIAL

R

U

H

P

L

U

S

REFINERY

EP OR

LIQUID SULPHUR DISTRIBUTION

Maintaining the flow

Experience at a shipping terminal taught sulphur distributor

Martin Gas Sales that a bolt-on thermal maintenance system can have

important life cycle advantages over gut tracing or welded jacketed pipe.

Henry P. Gaines, PE, VP of Controls Southeast, Inc. tells the story.

ajor sulphur distributor Martin

Gas Sales markets and transports liquefied petroleum gas

and sulphur, and processes sulphur for

dry and liquid fertilizer. Martin Gas is

the largest independent distributor of

sulphur in the USA with over one million tons handled every year. It now

operates three US Gulf liquid sulphur

terminals with docks connected to

massive holding tanks. The Neches

River terminal near Beaumont, Texas,

went into operation in August 1992.

The Tampa, Florida, terminal became

operational in January 1996, and the

new Stanolind Cut terminal, also near

Beaumont, Texas, opened in 1999.

At all three locations, long pipelines transfer liquid sulphur from ships

and barges to and from the holding

tanks. More piping carries sulphur

from trucks to the tanks. Between all

the heated storage and transport vessels, thermal maintenance in the pipes

and valves is essential to keep the sulphur flowing and the entire operation

moving.

Sulphur stays molten only within

a temperature range of 246-320F

(119C to 160C). Outside that tight

temperature band, its viscosity increases rapidly and soon becomes totally immovable. To keep the product flowing, a thermal maintenance

system is required to make up the

heat lost to the environment. We try

to maintain everything from 260 to

280F, explains Martin Gas project

engineer Keith West.

The Neches River terminal originally stored 27,000 long tons of sulphur in three heated tanks and had

around 1,000 feet (305 m) of 10 inch

(25.4 cm) pipe running from the barge

dock to the tanks. Another 500 ft (152

m) of 4 to 6 inch (10-15 cm) pipe

July . August 1999

linked the tanks to trucks. The sulphur

terminal was originally designed with

inexpensive gut tracing in all the transfer pipes. It also used fabricated jackets and tube tracing to maintain the

temperature of more than 50 valves

controlling sulphur flow.

Cross-contamination

Gut-traced pipe was simple to install.

A 2 inch (5 cm) steam line inside a 10

inch product pipe kept the surrounding sulphur hot and flowing. Unfortunately, a leak in the hidden steam

pipe caused big cross-contamination

problems for the entire system. Mr

West explains, If your steam line

breaks, you get water in the sulphur

line. If the pressure in the product line

is greater than that in the tracing line,

you get sulphur in the steam line.

Water in the sulphur pipe could

possibly ruin the product and create

corrosive and potentially hazardous

fumes. Conversely, sulphur in the

steam line clogged the steam traps,

and the sulphur in the product

line inevitably cooled. The sulphur

soon formed an insulating plug 4 or

5 ft long.

Now youve got a barge or ship

sitting there and no way to get product on or off, says Mr West. The

amount of money saved by gut tracing

is nothing compared to money you

could lose in customer disappointment and missed schedules.

Sulphur lines at the Neches River

terminal froze once or twice a year.

Restoring process flow with electric

blankets could take anywhere from a

few hours to a full week. It could be

a nightmare, admits Mr West. The

audible steam leak had to be found by

cutting access windows in the big sul39

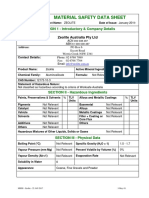

At Martin Gas new Beaumont facility,

ControHeat bolt-on jackets, like the ones

pictured on the Flowserve Mark III centrifugal pump, the 12 inch Tufline butterfly and

plug valves adjacent to the sulphur storage

tank, and the Hyspan ball joints will be used

to maintain temperature on all the process

equipment. All of the 6 in., 10 in. and 12 in.

transfer lines will be heated with a

ControTrace thermal maintenance system.

Sulphur

No 263

LIQUID SULPHUR DISTRIBUTION

phur pipe. Once the steam line was repaired, the windows in the sulphur

pipe had to be welded shut, leaving

several potential leak points in the

product line. In a worst-case scenario,

sulphur in the steam line could reach

the boiler and require a costly boiler

teardown.

Jacketed valves

Maintaining temperature within sulphur valves was equally important,

and equally difficult. Some valves at

the Neches River facility were specially

jacketed by the manufacturer, while

others were heat-traced in the field by

Martin Gas. Mr West recalls, In

Beaumont, we wrapped steam tubing

around the valves. It didnt work at all.

The valves were constantly freezing

up. Replacing valves jacketed by the

manufacturer imposed additional

penalties in money and time. A typical

3 inch manufactured jacketed valve

could cost $600 while a standard unjacketed valve might cost only $300 to

$400. In addition, waiting time for a

manufactured jacketed valve is sometimes 16 to 20 weeks, so several expensive jacketed valves had to be kept

in inventory to prevent lengthy downtime. Martin Gas was not alone in its

thermal maintenance problems. Mr

West recalls another companys Texas

sulphur terminal fared even worse

with gut-traced lines.

Expensive welded jacketed pipe

offered few advantages. Mr West explains, With jacketed pipe, the heating source is on the outside and the

product on the inside. Once again,

youve got the possibility of cross-contamination. Labour-intensive blister

pipe, where a split steam pipe is

welded all along a process line, is

more reliable but very expensive.

Bolt-on barges in

Martin Gas

Engineers found a cost effective solution to their thermal maintenance

problems in another of its sulphur

transport applications. Around the

time when the Neches River facility

opened, Martin Gas commissioned the

inland liquid sulphur barge MGM

101, which had a bolt-on thermal

maintenance system from Controls

Southeast Inc (CSI). Sulphur lines on

Sulphur

No 263

the barge are surrounded by ControTrace bolt-on pipe heating elements,

and valves are kept hot by ControHeat

jackets. Unlike gut-tracing or welded

jacketed pipe, the bolt-on jackets on

sulphur lines eliminated the risk of

cross-contamination. Youd have to

rupture both the product line and the

ControTrace at the same spot to have

a chance of getting product into the

heating medium. That is very unlikely,

if not impossible, explains Mr West.

The bolt-on thermal maintenance system aboard the barge used hot oil instead of steam as a heat transfer

medium. In service, the bolt-on system

on the MGM 101 was trouble-free.

Beaumont terminal retrofit

In 1994, Martin Gas retrofitted its

facility near Beaumont, Texas, with

ControTrace pipe elements and

40

ControHeat valve jackets and eliminated stoppages due to cross-contamination and line freezes.

Martin Gas engineers connected

the bolt-on thermal maintenance system to the 110 psi saturated steam system at the Neches River facility and

abandoned the gut tracing lines

altogether. Standard valves at the

Texas facility were also jacketed with

bolt-on jackets. The bolt-on valve and

pipe jacketing avoided the need to install expensive welded jacket or blister

pipe and to stock costly jacketed

replacement valves.

We discovered by using bolt-on

jackets, access to the valve for service

was much faster and easier. Also because the jackets bolt onto the component, we could install the equipment before the arrival of the jackets,

which really helped us meet start-up

deadlines, recalls Mr West.

July . August 1999

LIQUID SULPHUR DISTRIBUTION

Some 1400 ft of 12 inch sulphur transfer

line from the storage tanks to the barge

loading area is jacketed with a ControTrace

thermal maintenance system from Controls

Southeast, Inc. in Charlotte, N.C.

New terminals

The performance of the bolt-on thermal maintenance system in the existing terminal and aboard the barge led

Martin Gas to specify bolt-on thermal maintenance systems for its new

Florida and Texas facilities. Since

we installed this system at our first

Beaumont terminal, weve never had

a problem, concludes Mr West. He

estimates maintenance costs for the

bolt-on system at the first Texas terminal were less than half those associated with simple gut tracing.

Sulphur lines were installed at the

new Tampa Marine Terminal in late

1995. The terminal has two 15,000

long ton sulphur tanks connected to

the docks by a 12 inch (30 cm) pipe.

The 660 ft (201 m) long pipeline is

covered with steam-heated ControTrace panels. Each 40 ft (12 m) long

panel is made up of two elements buttJuly . August 1999

welded end to end with a steam inlet

at one end and an outlet at the other.

CSI provided its engineering expertise to help Martin Gas design

and install the thermal maintenance

system. The system specifies steam

traps between each 40-ft panel. We

could go 200 ft between traps, acknowledges Mr West, but we felt it

was better to go with extra traps and

fittings rather than risk problems.

The ControTrace panels are

bolted in place around the sulphur line

but cover only a small portion of the

pipe surface. Heat is transferred to the

product pipe wall to keep the sulphur

molten. Two bolt-on panels cover just

8 inches (20 cm) of the pipes 40 inch

(102 cm) circumference.

CSI uses finite difference modelling techniques. These techniques determine the required surface area coverage specific to the process require41

ments and ensure the resulting design

is capable of melt-out in the event of

an unscheduled outing. Unlike jacketed pipe, the thermal maintenance

system itself is easy to maintain, according to Mr West. With the

ControTrace panels, you can just take

the insulation off for service. The panels are easily repairable, and installation-wise, its a lot cheaper to trace the

lines. A bolt-on thermal maintenance system typically costs about

25% less than jacketed pipe and significantly less than blister pipe.

The Tampa terminal has around

25 valves ranging from 4 to 12 inches

(10 to 30 cm) in size, each with

ControHeat jacketing. These jackets

enable Martin Gas Sales to use standard valves available from any

industrial supply house. The unmodified valve and its bolt-on jacket

generally cost less than manufactured jacketed valves.

Initially, you may save a little

money with the ControHeat jacket

and a regular valve. But youre going

to have to replace a valve at some

point, and when you do, youre going

to save a lot of time and money.

Because of the success of the

bolt-on thermal maintenance system

at the Neches River and Tampa terminals, it was part of the original

plans for the newest Martin Gas facility. The new Stanolind Cut terminal in Texas has two 15,000 long ton

sulphur tanks connected to a dock by

1,400 ft of 12 inch pipe. Another 400

ft of 6 inch pipe ties the tank to

trucks. The new facility also has

about 25 valves and several pumps.

The new sulphur terminal started operations in 1999. All the pipes and

valves are kept operating by a bolt-on

thermal maintenance system.

Martin Gas has come to rely on

bolt-on thermal maintenance technology in its sulphur operations. The

removable system has matched the

performance of fabricated pipe and

valve jackets at lower installed cost,

and maintains a temperature-sensiS

tive product in transit.

Sulphur

No 263

You might also like

- Maintain FlowDocument4 pagesMaintain Flowkrishna_pipingNo ratings yet

- LNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsDocument16 pagesLNG - Growing Challenges of Heat Exchanger's Operation & Maintenance in LNG PlantsR P SinghNo ratings yet

- Alstom Process Gas CoolerDocument12 pagesAlstom Process Gas Coolerrajaramc100% (1)

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- Smith Industries WaterBath Indirect Heater PDFDocument29 pagesSmith Industries WaterBath Indirect Heater PDFcassindromeNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- 01 - Chemetics Converter InfoSheetDocument2 pages01 - Chemetics Converter InfoSheetWeb LogueandoNo ratings yet

- 1.1 OverviewDocument5 pages1.1 OverviewOdofin GbengaNo ratings yet

- Case Stydy 1Document2 pagesCase Stydy 1vishnunair27No ratings yet

- CTI Feed WaterheaterDocument9 pagesCTI Feed WaterheaterИринаNo ratings yet

- Smithery And: IrxonmongeryDocument1 pageSmithery And: IrxonmongeryreacharunkNo ratings yet

- Boiler EfficiencyDocument2 pagesBoiler EfficiencycyruskuleiNo ratings yet

- Name Baxteyar Waly Jamel Dept.: Petrochemical Mini Project: Transportation LPG To Power PlantDocument14 pagesName Baxteyar Waly Jamel Dept.: Petrochemical Mini Project: Transportation LPG To Power PlantShex Shapur Shex WalyNo ratings yet

- Depliant Brochure Marine en PDFDocument9 pagesDepliant Brochure Marine en PDFFadzil NorNo ratings yet

- Galvanization: in Hot Dip Galvanizing Lines, Which Also Have Usual EntryDocument20 pagesGalvanization: in Hot Dip Galvanizing Lines, Which Also Have Usual EntryJaypratik GoswamiNo ratings yet

- OTC 13994 Brutus Export Pipelines - Improvement Opportunities and Challenges in Deepwater Pipeline InstallationDocument12 pagesOTC 13994 Brutus Export Pipelines - Improvement Opportunities and Challenges in Deepwater Pipeline InstallationBalan14No ratings yet

- Nh3 Plant FailuresDocument18 pagesNh3 Plant FailuresMurugappan PalaniappanNo ratings yet

- Boiler OverhaulDocument9 pagesBoiler OverhaulHemant PatilNo ratings yet

- Conocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentDocument9 pagesConocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentvengielNo ratings yet

- Pack Firetube BoilersDocument5 pagesPack Firetube BoilersNath BoyapatiNo ratings yet

- MaintenanceDocument2 pagesMaintenanceṂṏḣḁṃṁḝḋ Ṃḝtwḁlly ṎṂḁrNo ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Marine Machinary CourseDocument452 pagesMarine Machinary CourseMc Liviu100% (1)

- Marine Machinery CourseDocument452 pagesMarine Machinery CourseMerrel Ross100% (1)

- JPT1999 06 Surface ProdJPTDocument4 pagesJPT1999 06 Surface ProdJPTHossein AbbassiNo ratings yet

- Bycast Folder 1106 LRDocument20 pagesBycast Folder 1106 LRmarloplenNo ratings yet

- Surface Condenser: Applications of Surface Condensers and Requirement of Surface CondenserDocument17 pagesSurface Condenser: Applications of Surface Condensers and Requirement of Surface Condenserdroffilcz27100% (1)

- Dryplus EvaporatorDocument24 pagesDryplus EvaporatorsreekanthchemiNo ratings yet

- 4 Nubcounem: Margi S ARE Captured C+ST 1 6% RES SafetyDocument2 pages4 Nubcounem: Margi S ARE Captured C+ST 1 6% RES SafetyIllustrious PotentateNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- Down Hole Heat Ex ChangersDocument11 pagesDown Hole Heat Ex ChangersSaudah ShaikhNo ratings yet

- ControTrace Benefits SummaryDocument2 pagesControTrace Benefits SummaryYoung-seok Hwang100% (1)

- Brian LadeDocument36 pagesBrian LadeMatteo CafieroNo ratings yet

- Energy Solutions Heat RecoveryDocument4 pagesEnergy Solutions Heat RecoveryyaserbadrNo ratings yet

- EN12845Document4 pagesEN12845asdthu100% (1)

- Siri Jack-Up PlatformDocument7 pagesSiri Jack-Up Platformnaren_013No ratings yet

- PlumbingDocument19 pagesPlumbingJefford C. ObañaNo ratings yet

- Engineering Letter: IndustrialsteamheatingsystemsDocument8 pagesEngineering Letter: Industrialsteamheatingsystemsmontie3No ratings yet

- 9 Pipeline TransportationDocument4 pages9 Pipeline TransportationMhiaBuenafeNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Air CannonDocument9 pagesAir Cannonkarthikraja21100% (1)

- Corrosion Problems in The Oil IndustryDocument8 pagesCorrosion Problems in The Oil IndustryUNIISCRIBDNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Heating, Home Inspection Course and Exam - North America, CanadaDocument56 pagesHeating, Home Inspection Course and Exam - North America, CanadaAli Noroozi100% (1)

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- Ensuring Efficient Reliability For Marine Thermal Systems: Industry OverviewDocument24 pagesEnsuring Efficient Reliability For Marine Thermal Systems: Industry Overviewpetar petar100% (1)

- Surface Condenser HEIDocument7 pagesSurface Condenser HEIJesús Santiago QuijadaNo ratings yet

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- Coil Catalog Version 09 - 01ADocument28 pagesCoil Catalog Version 09 - 01AblindjaxxNo ratings yet

- The Sture TerminalDocument5 pagesThe Sture TerminalSteffano BouttoreNo ratings yet

- Dryicekillscoalpile: Fires. - (Heating and VentilatingDocument1 pageDryicekillscoalpile: Fires. - (Heating and Ventilatingjuan carlos molano toroNo ratings yet

- TLEbrochure09 2005Document27 pagesTLEbrochure09 2005Arun Kumar KarNo ratings yet

- Aker Solutions (Wacker) - PAPER (10183) PDFDocument7 pagesAker Solutions (Wacker) - PAPER (10183) PDFElsherif AlyNo ratings yet

- DE - Ch9 - Piping Design and SpecificationsDocument9 pagesDE - Ch9 - Piping Design and SpecificationsMy TvNo ratings yet

- IMPORTANT Boiler Repairs Problems Marine Education MarineexamDocument8 pagesIMPORTANT Boiler Repairs Problems Marine Education MarineexamEge CNo ratings yet

- Shell BoilerDocument12 pagesShell BoilerMochamad Fajar RamdaniNo ratings yet

- Heat ExchangerDocument37 pagesHeat Exchangerdhairya1725100% (5)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Scientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesFrom EverandScientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesNo ratings yet

- Zeolite MsdsDocument6 pagesZeolite MsdsmarraezNo ratings yet

- Sulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanDocument18 pagesSulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanmarraezNo ratings yet

- MD AlkyClean v2Document4 pagesMD AlkyClean v2marraezNo ratings yet

- US8105968Document24 pagesUS8105968marraezNo ratings yet

- MSDS Zeolite 25 JAN 2019Document4 pagesMSDS Zeolite 25 JAN 2019marraezNo ratings yet

- MechReaction Liu 2016Document26 pagesMechReaction Liu 2016marraezNo ratings yet

- DuplicateDocument134 pagesDuplicatemarraezNo ratings yet

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocument17 pagesK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezNo ratings yet

- US20220144724A1Document24 pagesUS20220144724A1marraezNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- Refining K-Saat 2022marDocument4 pagesRefining K-Saat 2022marmarraezNo ratings yet

- Hydro Cracking For Maximizing Middle Dis PDFDocument9 pagesHydro Cracking For Maximizing Middle Dis PDFmarraezNo ratings yet

- SNG Symp2019 KBR 2 K SAATDocument30 pagesSNG Symp2019 KBR 2 K SAATmarraezNo ratings yet

- AZ Cover Sheet For SummaryDocument1 pageAZ Cover Sheet For SummarymarraezNo ratings yet

- A Crude Distillation Unit Model Suitable Foronline ApplicationsDocument21 pagesA Crude Distillation Unit Model Suitable Foronline ApplicationsNông DânNo ratings yet

- LPG Plant ReportDocument104 pagesLPG Plant Reportmsh_jaazNo ratings yet

- PSV PDFDocument35 pagesPSV PDFJagan BoseNo ratings yet

- Petroleum Fraction at Ion OverviewDocument35 pagesPetroleum Fraction at Ion Overviewphobos2000No ratings yet

- Crude and Vacuum Unit Design ChallengesDocument24 pagesCrude and Vacuum Unit Design Challengesumeshchandra yadavNo ratings yet

- E04413040 PDFDocument11 pagesE04413040 PDFjoseNo ratings yet

- Thermodynamic Analysis: Yaşar DemirelDocument31 pagesThermodynamic Analysis: Yaşar DemirelmarraezNo ratings yet

- Refractory Nitrogen Compounds in Hydrocr PDFDocument6 pagesRefractory Nitrogen Compounds in Hydrocr PDFmarraezNo ratings yet

- CHEMICAL ENGINEERING Interview QuestionsDocument28 pagesCHEMICAL ENGINEERING Interview QuestionsNikunj PatelNo ratings yet

- Lo Que AprenderásDocument2 pagesLo Que AprenderásmarraezNo ratings yet

- Modification of Outlet Stream of The AtmDocument9 pagesModification of Outlet Stream of The AtmADEOLANo ratings yet

- Process Profits W SimulationDocument4 pagesProcess Profits W SimulationmarraezNo ratings yet

- Five Best PracticesDocument10 pagesFive Best PracticesAntHony K-ianNo ratings yet

- Ordouei Mohammad HosseinDocument159 pagesOrdouei Mohammad HosseinmarraezNo ratings yet

- Some Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilDocument22 pagesSome Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilmarraezNo ratings yet

- Process Profits W SimulationDocument4 pagesProcess Profits W SimulationmarraezNo ratings yet

- Reporter IssueDocument80 pagesReporter IssueGenetBezuNo ratings yet

- Turbine Meter Calculation FundamentalDocument10 pagesTurbine Meter Calculation FundamentalMuhammad Sa'adNo ratings yet

- The Industry HandbookDocument34 pagesThe Industry HandbookslpypndaNo ratings yet

- Amec Foster Wheeler Factsheet Web PDFDocument2 pagesAmec Foster Wheeler Factsheet Web PDFcristi_molinsNo ratings yet

- Ref Three EditionDocument9 pagesRef Three EditionDragon DangerNo ratings yet

- Chapter Two Climate ChangeDocument26 pagesChapter Two Climate ChangeLucky Pearl OkonNo ratings yet

- Materials For Roads and Pavements: Standard Terminology Relating ToDocument4 pagesMaterials For Roads and Pavements: Standard Terminology Relating ToGregorio ToroNo ratings yet

- Industrial Hose and Couplings CatalogDocument265 pagesIndustrial Hose and Couplings Catalog2643108No ratings yet

- Coal AnalysisDocument7 pagesCoal AnalysisManigandan ChinnasamyNo ratings yet

- Energy Work and Power Form 3 WorkDocument8 pagesEnergy Work and Power Form 3 WorkGcwalaNo ratings yet

- 19 - Storvik - Subsea SeparationDocument19 pages19 - Storvik - Subsea SeparationMarco Andrés Guevara LunaNo ratings yet

- Price-In-Malappuram - html#Historical+Diesel+Pric E+in+malappuramDocument3 pagesPrice-In-Malappuram - html#Historical+Diesel+Pric E+in+malappuramjafir8shangmail.com shanNo ratings yet

- Selection of Cleaning Agents For Oxygen Systems: Standard Guide For TheDocument4 pagesSelection of Cleaning Agents For Oxygen Systems: Standard Guide For TheEngr. Jahanzeb MaharNo ratings yet

- The Alphabet Soup of IOR, EOR and AOR Effective Communication Requires A Definition TermsDocument3 pagesThe Alphabet Soup of IOR, EOR and AOR Effective Communication Requires A Definition TermsWaldinho Gaucho da SilvaNo ratings yet

- Decline-Curve Analysis For Gas WellsDocument40 pagesDecline-Curve Analysis For Gas WellsjangojangoNo ratings yet

- Additional Cases Ch08Document4 pagesAdditional Cases Ch08amanraajNo ratings yet

- OMAE2016-55137: Multiphase Transient Slugging Flow in Subsea Oil and Gas ProductionDocument12 pagesOMAE2016-55137: Multiphase Transient Slugging Flow in Subsea Oil and Gas Productionthlim19078656No ratings yet

- PE 111 Assessment - 2 IV2Document4 pagesPE 111 Assessment - 2 IV2mghareebNo ratings yet

- IBM Oil and Gas Report 2030Document20 pagesIBM Oil and Gas Report 2030Aya KusumaNo ratings yet

- GHG Template enDocument165 pagesGHG Template enmetroroadNo ratings yet

- Philippine Canadian Inquirer #390Document40 pagesPhilippine Canadian Inquirer #390canadianinquirerNo ratings yet

- Indian Petrolium Industry EsseyDocument15 pagesIndian Petrolium Industry EsseyShashank BansalNo ratings yet

- Fracfit Solution Increased Post-Fracture Treatment Production 63%Document1 pageFracfit Solution Increased Post-Fracture Treatment Production 63%downbuliaoNo ratings yet

- 2022 Hibiscus Investor Presentation September R1Document57 pages2022 Hibiscus Investor Presentation September R1zamans98No ratings yet

- Business Portfolio Petro TNC Intl 1 Oct 2018Document8 pagesBusiness Portfolio Petro TNC Intl 1 Oct 2018Dante KindeverNo ratings yet

- 1629213726technology GK EbookDocument394 pages1629213726technology GK EbookDebrajNo ratings yet

- ChapterDocument37 pagesChapterSamuel Mawutor GamorNo ratings yet

- Refinery and Petrochemical Processing DistillationDocument18 pagesRefinery and Petrochemical Processing Distillationrashid1986@hotmailNo ratings yet

- Phenoline 187 VOC: Selection & Specification DataDocument4 pagesPhenoline 187 VOC: Selection & Specification Datarajiv_quantumNo ratings yet

- How To Deal With High Oil Prices and Steps To OvercomeDocument3 pagesHow To Deal With High Oil Prices and Steps To OvercomesdddNo ratings yet

![Scientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877

A Weekly Journal Of Practical Information, Art, Science,

Mechanics, Chemistry, And Manufactures](https://imgv2-2-f.scribdassets.com/img/word_document/187114288/149x198/c199ff44cf/1579708199?v=1)