Professional Documents

Culture Documents

CCC White Paper A Total Integrated Approach 2012

Uploaded by

rodruren010 ratings0% found this document useful (0 votes)

73 views9 pagesCCC White Paper a Total

Original Title

CCC White Paper a Total Integrated Approach 2012

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCCC White Paper a Total

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

73 views9 pagesCCC White Paper A Total Integrated Approach 2012

Uploaded by

rodruren01CCC White Paper a Total

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Expertise in Turbomachinery Controls

WHITEPAPER

A Total Integrated Approach

Total Integrated Approach

Conventional Approach

Publish Date: 1/18/2012

Author: Shaun Branley,

Conoco Phillips, Australia PTY LTD

A case study describing how total plant

turbomachinery control was used to maximize

production at the ConocoPhillips Bayu-Undan

project.

Visit our website to learn more about CCC

www.cccglobal.com

WHITEPAPER | A Total Integrated Approach

Introduction

The Bayu-Undan platform is a unique world-scale

offshore gas processing platform handling over 1.1

billion cubic feet per day of gas. The platform extracts

over 115,000 barrels per day of combined condensate,

propane, and butane and produces over 950 MMSFCD

of dry natural gas.

The project was implemented in two phases. Phase 1,

achieving production in early 2004, involved

processing the wet gas to separate and store

condensate, propane, and butane; and reinjecting dry

gas back into the reservoir. Phase 2, realizing

production in early 2006, involved exporting the gas

via pipeline to a liquefied natural gas (LNG) facility

near Darwin, Australia.

Process Overview

Gas from the wellheads is fed to the production

separator where heavier hydrocarbons drop out as

liquids. The glycol contactors remove water entrained

in the gas stream. The gas is further processed by the

cold process trains to remove condensate. The liquid

from the production separator feeds the second stage

separator, where light hydrocarbons flash out and

feed the second stage of the flash gas compressor and

the remaining liquid is further processed by the

fractionators. Light gas from the fractionators is

compressed by the flash gas compressors and sent

back to the production separator. Gas from the recompressors is compressed for reinjection into the

reservoir and/or export to the pipeline.

www.cccglobal.com

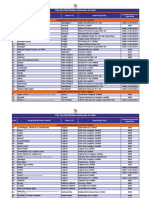

Figure 2: Process Flow Diagram

The critical turbomachinery driving the process

include the following:

Two parallel single-stage turbo-expander/recompressor trains

Two parallel gas turbine-driven two-stage

compressors (7.5 megawatts each)

Three parallel gas turbine-driven three-stage

compressors (23 megawatts each)

Turbomachinery Control System

The performance of any compressor is limited by

several constraints. Typical constraints include surge

limit, process limit, minimum speed, maximum speed,

power limit and sometimes stonewall or choke limit.

By added control margins the actual available

operating zone is shown in Figure 3.

The better the control system the closer you can

operate without sacrificing reliability. Conventional

control systems are typically based on simplistic

algorithms with programmable logic control

(PLC)-based hardware. These generic control systems

require extra control margins and thus further reduce

the compressors operating envelope. Advanced

compressor control systems, on the other hand, are

based on application specific algorithms in purpose

built hardware. By utilizing adaptive open-loop and

closed-loop techniques, such systems are able to

reduce the control margins without sacrificing

reliability and thus maximize the compressors actual

available operating zone.

WHITEPAPER | A Total Integrated Approach

between anti-surge and performance loops must be

utilized to minimize process disturbances.

Conventional Approach

The conventional approach to designing multiple

turbomachinery control systems is to either resort to

original equipment manufacturer (OEM)-supplied

control systems or to implement the turbomachinery

controls in the distributive control system (DCS).

Figure 3: Compressor Performance Envelope

Integrated Turbomachinery Control

System (ITCS)

The primary objectives of an ITCS are given below:

1) Provide maximum reliability of the

machinery and process by:

Preventing unnecessary process trips and

downtime

Minimizing process disturbances

Preventing surge, over-speed and associated

damage

Automating startup and shutdown

2) Provide maximum efficiency of the machinery

and process by:

Operating at lowest possible energy level

Minimizing anti-surge recycle

Optimizing load-sharing of multiple units

In order to achieve the above, the ITCS consists of

integrating at minimum the anti-surge control and

capacity control loops.

The ideal ITCS consists of integrating the compressor

and driver controls. However, in some cases, such as

with new gas turbine driven compressors, it may not

be practical to integrate governor control system.

An ITCS should be implemented by using deterministic

hardware platforms in order to satisfy the desired

execution requirements such as 40 milliseconds for

anti-surge control. Advanced control algorithms using

adaptive open-and closed loop responses must be

employed to prevent surge. Dynamic decoupling

www.cccglobal.com

Another approach is to integrate the turbomachinery

control system with the emergency shutdown (ESD)

system. All three approaches have inherent

deficiencies as discussed below.

(PLC)-based systems have been proven inadequate for

anti-surge and performance control. With different

OEMs for each set of machines, the result is different

PLC systems utilizing various algorithms and control

strategies. This makes integration between the

systems virtually impossible.

Figure 4: Conventional Approach

Utilizing the DCS for anti-surge control has also proven

to be inadequate. Despite this, the DCS approach

appears attractive as it greatly reduces the number of

control interfaces. However, the success of this

approach relies heavily on DCS engineers limited

turbomachinery experience.

2

WHITEPAPER | A Total Integrated Approach

The last approach is to integrate the turbomachinery

control system with the ESD system. This approach is

being promoted as economically attractive but has

several flaws. Firstly, this approach violates the

practice of keeping basic process control systems and

ESD systems separate. Process control systems are

designed to keep process running while ESD systems

are designed to trip the plant. Typically, this approach

utilizes triple modular redundant (TMR) systems and

the perception being promoted is that the highest

availability is realized. In reality the ESD system, while

achieving the desired safety level of the system,

sacrifices the process availability by causing

unnecessary process trips. Often too much focus is

given to control system hardware and not the quality

of control. These systems fall short in adequately

integrating anti-surge, load-sharing and performance

control to maximize availability of the turbomachinery.

A properly designed ITCS (as described in the following

sections) actually minimizes the safety integrity level

requirements through improved basic process

control1.

Total Integrated Approach

This approach involves determining the overall

process control needs with respect to turbomachinery

control for all machines. This involves providing an

ITCS for each service focused on meeting the

performance control objectives for the process. For

practical purposes the ITCS for both flash gas and

reinjection services included the anti-surge and

performance control loops while the governor control

loops remained with the OEM.

As the machines are interconnected in the process, it is

prudent to look at how further integration between

machines can be beneficial. Such systems can be

integrated with each other by internal controller

communication to allow for feed forward control

actions where necessary.

This approach requires extensive field-proven

experience in designing, engineering and

commissioning various turbomachinery control

systems for different applications.

www.cccglobal.com

This integrated approach served the basis for

Compressor Controls Corporation (CCC) design when

supplying ITCS solutions for all machines.

Figure 5: Total Integrated Approach

Project Execution

The design phase for the facility involved

ConocoPhillips experts, EPC TIGA (joint venture

between Fluor Daniel and WorleyParsons), the OEMs

(Sulzer, Dresser Rand and GE Rotoflow), and the ITCS

provider (CCC). The execution of the project required

CCCs design effort to include:

Review preliminary process control philosophy

Provide preliminary control system design

report

Participate in setting up the dynamic

simulation effort

Review preliminary dynamic simulation test

results

Provide final control system design report

Review final dynamic simulation results

Provide final ITCS engineering manual

Commissioning recommendations

Ideal interaction between all parties driven by

ConocoPhillips was instrumental in developing and

testing the ITCS strategies.

WHITEPAPER | A Total Integrated Approach

Overall Turbomachinery Control Design

Basis

method of optimized performance control ensured

that unnecessary recycling was avoided.

The basis for each ITCS design focused on meeting the

overall process control objectives.

The primary control objectives identified during the

preliminary engineering phase were:

Provide maximum protection for each

machine

Maximize liquids production

Maintain gas for reinjection/export

The secondary control objectives that were identified

included:

Necessary limiting control loops for each

machine

Balance the load between the machines to

provide equal protection

The final control elements available to the ITCS were

identified to be:

Flash gas compressors speed and anti-surge

valves

Turbo expanders inlet guide vanes (IGV)

Turbo expanders Joules Thomson (JT) valves

Re-compressors anti-surge valves

Reinjection/export compressors speed and

anti-surge valves

Flash Gas Compressor ITCS

The primary objective of the flash gas compressor is to

compress gas from the de-ethanizer and gas from the

second stage separator. In order to maximize liquids

production the first stage suction pressure and the

interstage pressure of the flash gas compressor

needed to be precisely controlled. This could only be

done by a combination of operation of the anti-surge

valves and the gas turbine speed. The challenge in real

time is determining which pressure will be controlled

by speed while the remaining one via the anti-surge

valve. As the flow from the de-ethanizer and flow from

the second stage are both very dynamic the need for

optimized performance control was identified. The

performance control loops within the ITCS were

required to control speed and the anti-surge valve to

meet the suction and interstage pressures based on

efficiency, or in other words, least recycle. This

www.cccglobal.com

Figure 6: ITCS for Flash Gas Compressors

In summary, the flash gas compressors ITCS objectives

were as follows:

Provide invariant anti-surge control

Optimized first stage and interstage pressure

control

Equidistant to surge load-sharing

Decoupling between anti-surge and

performance control loops

Decoupling between anti-surge control loops

Limiting control loops

Turbo-Expander/Re-Compressor ITCS

The primary objective of the cold part of the process

(turbo-expander/re-compressor trains) is to maximize

liquids production.

In conventional expander control systems speed is not

typically controlled. Therefore during an upset turboexpander speed may exceed allowable limits.

Conventional control systems prevent over-speed

based on primitive and often indirect methods, such

as limiting the IGV position, limiting differential

pressure across the expander or split range control

between IGV and JT valve. These methods sacrifice

liquids production.

4

WHITEPAPER | A Total Integrated Approach

Conventional control systems also ignore the

importance of providing adequate anti-surge control

for the re-compressor. However protecting the recompressor against surge is just as critical as for any

other compressor.

optimized load-sharing strategy was developed,

providing equal surge protection across the recompressor when in the vicinity of surge and equal

efficiency across the turbo-expanders when far away

from surge.

CCCs patented ITCS for

turboexpander/recompressors provides maximum

protection and utilizes control strategies that

maximize liquids production2. The JT valve is

therefore used when absolutely necessary.

Unnecessary turbo-expander trips, in practice, greatly

affect the process. CCCs patented JT valve

prepositioning algorithm reduces the severity of the

trip on the process. CCC prepositions the JT valve

based on the capacity equivalent the turbo-expanders

throughput immediately prior to trip. This strategy

keeps the process online and minimizes temperature

excursions in the low temperature separator (LTS) and

in effect maximizes liquids production. The loss of one

turboexpander requires the running train to take as

much load as possible. The running train switches to

flow control while the JT valve controls the production

separator pressure to minimize loss of liquids

production. This in effect minimizes loss of liquids

production.

CCCs patented over-speed prevention strategy is

based on direct control of speed, as well as acting on

the re-compressors antisurge valve to load up the

train, then closing the IGV if speed continues to

increase. This strategy maximizes utilization of the

expander and minimizes use of the JT valve, thereby

maximizing liquids production.

Load-sharing between turbo-expander/ recompressor

trains is also critical. Operating close to surge

demands equal protection (i.e. equidistant to surge

load-sharing). However, operating far away from surge

demanded shifting the load-sharing focus from the

recompressor to the turbo-expander.

In summary, the turbo-expander/re-compressors ITCS

objectives were as follows:

Maintain production separator pressure

Optimized load-sharing strategy

Equidistant to surge load-sharing

Decoupling between anti-surge and

performance control loops

Limiting control loops

Reinjection/Export ITCS

Figure 7: ITCS for Turboexpander/Recompressors

Equal efficiency across the expanders was desired

when operating away from surge. As a result, an

www.cccglobal.com

The primary objective of the reinjection/export

compressors is to deliver gas at a suitable pressure

and flowrate for either reinjection or export. More than

six operating modes were identified depending on

whether the upstream expander/recompressors were

online and the export requirements. This required CCC

to translate these operating modes into control modes

for each individual compressor. The control modes

were defined as follows:

Mode A. Participates in a load-sharing scheme

based on controlling suction manifold

pressure, applicable when thecompressor

operates in either high speed mode (discharge

pressure = 310 barg) or low speed mode

5

WHITEPAPER | A Total Integrated Approach

(discharge pressure= 190 barg). One, two or all

three compressors may operate in this mode.

Mode B. Non-load-sharing (stand-alone) choke

control scheme, applicable only when the

compressors operate in lowspeed mode

(discharge pressure = 190 barg). One or a

maximum of two export/reinjection

compressors may operate inthis mode.

Mode C. Non-load-sharing (stand-alone)

compressor suction pressure control scheme,

applicable when the compressoroperates in

low- or high-speed mode. Only one

compressor at a time may operate in this

mode.

and experience were utilized to determine whether

independent anti-choke control was required or

integration within the anti-surge controllers was

adequate. Anti-surge controllers with integrated antichoke control were provided.

Using one of the operating modes as an example the

control modes were defined as show in Figure 8,

whereby onemachine is dedicated for export while the

other machines for reinjection.

In summary, the reinjection/export compressors ITCS

objectives were as follows:

Maintain suction pressure

Provide integrated anti-surge and anti-choke

control for each stage

Optimized load-sharing strategy

Decoupling between anti-surge and

performance control loops

Limiting loops

Based on the complex operating modes, unique

challenges for the reinjection/export compressors ITCS

were observed. The importance of not only anti-surge

control but also operating one or more of the

machines in choke region was of significant concern.

The anti-surge control requirements for each

compressor required providing adequate surge

protection for each stage while utilizing one anti-surge

valve. CCCs experience in multiple anti-surge

controllers sharing a single valve was utilized.

The integrated anti-surge and anti-choke control

required an optimized load-sharing strategy. When the

machines are close to surge, the equidistant to surgeload-sharing was desired; yet when away from surge,

or in other words close to choke, equidistant to choke

was required. This optimized load-sharing strategy

and provided maximum protection for all parallel

machines.

The Role of Dynamic Simulation

Dynamic simulation played a pivotal role during the

design phase of the project. The design simulation

package used was Hysys, which included models of

CCC controls.

With the help of CCC the project, team refined the

CCC models to ensure that models emulated the ITCS

system in this project. Once the system was setup, the

dynamic simulation was instrumental in testing the

control strategies listed above.

Figure 8: Reinjection/Export Compressor Normal

Export Mode

The requirements for anti-choke control were

identified early in the design phase. CCCs knowledge

www.cccglobal.com

The dynamic simulation exercise provided a starting

point for setting up each ITCS and the necessary

interactions. The control strategies developed in the

ITCS for each machine were tested and verified

throughout the simulation process.

The extensive testing provided a benchmark for

system performance. The overall dynamic simulation

process provided no surprises during commissioning

and contributed to shorter startup time.

6

WHITEPAPER | A Total Integrated Approach

Figure 10: Total Plant Turbomachinery Control for

Bayu-Undan Platform

Feedback from the Field

Figure 9: ITCS for Reinjection/Export Compressors

Total Integrated Approach in Action

The total integrated approach proved extremely

beneficial. Figure 10 illustrates the total plant

turbomachinery control, consisting of the ITCS for

flash gas, turbo-expander and reinjection/export

services.

One of the benefits realized by this approach was

demonstrated during the design phase, when it was

recognized that the flash gas compressors would

potentially run into overload condition while running

at maximum speed due to excessive gas coming from

the de-ethanizer. It was determined that this condition

could be alleviated by opening the turbo

expander/recompressors anti-surge valves. Since

communication between all ITCS was originally

envisaged to be beneficial, setting this up in the

system was not difficult.

www.cccglobal.com

The total plant turbomachinery control was executed

and completed to ConocoPhillips satisfaction.

Feedback provided by ConocoPhillips from the field is

given below.

With respect to the expander/re-compressors ITCS,

The trains run very well in both load-sharing, flow and

pressure control, and both pressure control (preferred).

With the improved IGV control it has meant that very

low temperatures have been achieved. This has a flow

effect of excellent recoveries. The stability of the

control has allowed the plant to operate above design

and meet both allocated and stretch targets for

volumes over the last two years.

With respect to the reinjection/export compressors

ITCS, With the compressors in export mode, this has

allowed us to increase further raw gas rates to the

facility, meaning increased volumes. The choke

control mode, discharge pressure limiting and antisurge pressure override functions all have been used

with great success.

7

WHITEPAPER | A Total Integrated Approach

References

1. A total integrated approach, Hydrocarbon

Engineering, February 2007, Islam et al.

2. Minimizing Safety Integrity Level Requirements of

Turbomachinery Process Through Improved Basic

Process Control, ISA Volume 430, Sheldon et al.

3. Gas Processing Plants: Automation of Compressors

and Expanders to Optimize Plant Performance, Mirsky

et al.

Acknowledgements

The author wishes to thank the management and staff

of ConocoPhillips at Bayu-Undan for their support and

permission to present the details of this article.

www.cccglobal.com

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- PFC500/PDC500 Series Data Sheet: FeaturesDocument4 pagesPFC500/PDC500 Series Data Sheet: Featuresrodruren01No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ex Wdr2000feDocument4 pagesEx Wdr2000ferodruren01No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument37 pagesPower Systems Protection Course: Al-Balqa Applied Universityrodruren01No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- An Introduction To IGBT Operation: Application NoteDocument5 pagesAn Introduction To IGBT Operation: Application Noterodruren01No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 4.0 Using IGBT Modules 4.1 Structure and Operation of IGBT ModuleDocument27 pages4.0 Using IGBT Modules 4.1 Structure and Operation of IGBT Modulerodruren01No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- CB76 3261Document7 pagesCB76 3261rodruren01No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Voltage Drop in A Generator System: The Ultimate Solution For Maintaining Your Nationwide Generator NetworkDocument2 pagesVoltage Drop in A Generator System: The Ultimate Solution For Maintaining Your Nationwide Generator Networkrodruren01No ratings yet

- DX Crowbar Tester 8007 - 633827455629178570Document2 pagesDX Crowbar Tester 8007 - 633827455629178570rodruren01No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 9500100990Document6 pages9500100990rodruren01No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- DECS 2100bull7Document2 pagesDECS 2100bull7rodruren01No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hy Course Description Training en DataDocument18 pagesHy Course Description Training en Datarodruren01No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DECS-250E Synchronous Motor ApplicationsDocument4 pagesDECS-250E Synchronous Motor Applicationsrodruren01No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Ex d2100 ModulesDocument4 pagesEx d2100 Modulesrodruren01No ratings yet

- CHP Control SolutionsDocument8 pagesCHP Control Solutionsrodruren01No ratings yet

- Generators: 90 AnniversaryDocument16 pagesGenerators: 90 Anniversaryrodruren01No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- z33m821 CPDocument1 pagez33m821 CProdruren01No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hci636g 312 TD en Rev ADocument9 pagesHci636g 312 TD en Rev Arodruren01No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ful Flo A SeriesDocument10 pagesFul Flo A Seriesrodruren01No ratings yet

- Fulflo FVSeriesDocument7 pagesFulflo FVSeriesrodruren01No ratings yet

- Sweet and Sour: The Curse of Oil in The Niger Delta - Michael WattsDocument10 pagesSweet and Sour: The Curse of Oil in The Niger Delta - Michael WattsPost Carbon InstituteNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Long Term Gas Supply ContractsDocument6 pagesLong Term Gas Supply ContractslupoderiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- AutoPIPE Project ShowcaseDocument36 pagesAutoPIPE Project ShowcasejangdiniNo ratings yet

- 3) Renewable and Non-Renewable Energy PPTDocument68 pages3) Renewable and Non-Renewable Energy PPTkrysfer03No ratings yet

- Shaft Furnace Technology: For Scrap and Waste RoutesDocument6 pagesShaft Furnace Technology: For Scrap and Waste RoutesernandesrizzoNo ratings yet

- Advanced Automation Technology Reduces Refinery Energy CostsDocument8 pagesAdvanced Automation Technology Reduces Refinery Energy CostsRavindra JillepalliNo ratings yet

- A Rigless Permanent Plug and Abandon ApproachDocument88 pagesA Rigless Permanent Plug and Abandon ApproachMuhammad Abubakar100% (1)

- 3index PDFDocument22 pages3index PDFdada jamdarNo ratings yet

- TerraGreen - Green PaperDocument71 pagesTerraGreen - Green PaperTerragreenNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- CGD Data For Website 7.10.2016Document3 pagesCGD Data For Website 7.10.2016arbaz khanNo ratings yet

- Learning From AiChEDocument74 pagesLearning From AiChEChuma Khan100% (1)

- Title Operate and Maintain Gas-Fired Water Bath Heater Equipment in A Gas Network Level 4 Credits 4Document4 pagesTitle Operate and Maintain Gas-Fired Water Bath Heater Equipment in A Gas Network Level 4 Credits 4BensmatElHouariNo ratings yet

- 14 Pertamina CBM Project in South SumatraDocument16 pages14 Pertamina CBM Project in South SumatraDeni Sumargono100% (1)

- Modeling of Internal Combustion Engine Based CogenerationDocument14 pagesModeling of Internal Combustion Engine Based CogenerationALEJANDRO CADENA DAZANo ratings yet

- The Bio-Based Economy in The NetherlandsDocument12 pagesThe Bio-Based Economy in The NetherlandsIrving Toloache FloresNo ratings yet

- LC News Thursday, 12th January 2012Document29 pagesLC News Thursday, 12th January 2012pigheadponceNo ratings yet

- PetrobrasDocument9 pagesPetrobrasTatiana TovarNo ratings yet

- QuestionBank Writing Sample Reports For AC Task1 Part 1Document21 pagesQuestionBank Writing Sample Reports For AC Task1 Part 1quynh ngocNo ratings yet

- 10 1016@j Chemosphere 2017 10 139Document86 pages10 1016@j Chemosphere 2017 10 139Aldehir AldehirNo ratings yet

- GGSPL Corporate PresentationDocument10 pagesGGSPL Corporate PresentationpduvvuriNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guidlines For Safety Practice For Gas LP PDFDocument64 pagesGuidlines For Safety Practice For Gas LP PDFing.valerio.ambrocioNo ratings yet

- Drilling Deeper PetrobrasDocument41 pagesDrilling Deeper PetrobrasCarolina MonteiroNo ratings yet

- Syngas ProductionDocument10 pagesSyngas ProductionOliver Everett EspinoNo ratings yet

- 2006 Annual Reports PDFDocument139 pages2006 Annual Reports PDFAlfian Fajar SamudraNo ratings yet

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocument32 pagesHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- FLNGDocument6 pagesFLNGguslohNo ratings yet

- Antony Arul Roger: Production OperatorDocument6 pagesAntony Arul Roger: Production OperatorDonNo ratings yet

- Burner Training BookDocument32 pagesBurner Training BookNguyễn Thanh Hải100% (3)

- 35 MAP and DAP Fact SheetDocument2 pages35 MAP and DAP Fact SheetsharemwNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)