Professional Documents

Culture Documents

Esferas Congeladas

Uploaded by

Leslie QuintanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esferas Congeladas

Uploaded by

Leslie QuintanaCopyright:

Available Formats

Heat transfer characteristics during air precooling of strawberries

D. R. Giiemes, M. E. Pirovani and J. H. Di Pentima

Instituto de Tecnologia de Alimentos, Universidad Nacional del Litoral, C. Correos 428,

3000 Santa Fe, Argentina

Received 6 January 1988; revised 18 July 1988

Heat transfer characteristics during air precooling of strawberries were studied. Effective surface heat transfer

coefficients were determined and a Nu-Re correlation which includes the effect of moisture evaporation was

developed. The mean value of film coefficients obtained for strawberries were 16 to 25 ~ higher than those

predicted by the correlation of McAdams for spheres cooled only by convection. Furthermore, a geometry

analysis for strawberries was carried out when determining surface heat transfer coefficients. It was concluded

that for practical applications strawberries may be acceptably considered as spheres, since correction for

anomalous shape does not cause significant differences.

(Keywords:food products;heat transfer;precooling;strawberries)

Caracteristiques du transfert de chaleur au cours de la

prrr frigrration par air des fraises

On a btudib les caract~ristiques du transfert de chaleur au cours de la prbrbfrigbration par air des fraises. Les

coefficients effectifs de transfert de chaleur superficiel ont btb d~terminbs et une corrblation Nu-Re comprenant

l'influence de l'~vaporation d'eau a btb btablie. La valeur moyenne des coefficients pelliculaires obtenus pour les

fraises btait supbrieure de 16 ~ 25 % ~ celle pr~vue par la corrblation de Mc Adams pour des sphbres refroidies par

convection pure. De plus, une analyse gbom~trique des fraises a ~tb effectube en dbterminant les coefficients de

transfert de chaleur superficiel. On a conclu que pour les applications pratiques les fraises pouvaient ~tre

considbrbes de fafon acceptable comme des sphbres puisque la correction pour les formes anormales ne donne pas

de diffbrences significatives.

(Mots cl~s: produits alimentaires; transfert de chaleur; prrr6frigrration;fraises)

The freezing of strawberries by IQF technology

(individually quick freezing) presents some difficulties due

to the tenderness and high perishability of these fruits 1.

Therefore, there is a trend to precool them in order to

increase their firmness, to produce a high quality product.

Precooling improves efficiency of the freezing operation,

and freezer capacity is increased due to shorter dwell

times.

A way to attain that purpose is to use a tunnel where air

is forced up through the strawberries moving

continuously on a belt conveyor. When fruits are

precooled by this method, heat is removed by convective

heat transfer from the product surface to the cooling

medium while moisture evaporation produces an

additional cooling effect2-4.

Heat transfer characteristics during air-cooling of

strawberries are important for a proper design and

operation of such systems. Empirical equations to predict

surface heat transfer coefficients are only valid when heat

transfer is by convection 5.

The best way to account for the evaporation cooling

effect is through a separate function based on the

evaporation coefficient for the product and the

temperature and humidity of the air. However, this is

more complicated and is harder to communicate to the

refrigeration industry. Hence, effective surface heat

transfer coefficients which include the effect of moisture

evaporation were proposed. A problem with the effective

'h' is that it changes with the humidity level of the cooling

0140--7007/89/030169~)5503.00

1989 Butterworth & Co (Publishers) Ltd and IIR

air. This is not as critical with single products as it is with

products in bulk or large containers.

Effective values of surface heat transfer coefficients (h)

or N u - R e type correlations for the cooling of many fruits

and vegetables have been reported 6-a. However, data

referred to strawberries in particular are scarce.

Therefore, the objectives of this study were to determine

the effective values of surface heat transfer coefficients

during air precooling of strawberries and the effect of

moisture evaporation on them, to develop a N u - R e

correlation which includes the effect of moisture

evaporation and to perform a geometric analysis using

acrylic plastic models, in order to consider anomalous

strawberry shapes.

Materials and methods

Theoretical considerations

Correlation

coefficients.

to

estimate

surface

heat

transfer

To

estimate

surface heat

transfer

coefficients (h) in forced-air cooling of a sphere, the wellknown relationship of McAdams was used:

Nu=0.37 R e '6

(1)

where N u is the Nusselt number (hD/ka) and R e is the

Reynolds number (Dvap~/1~).

Rev. Int. Froid 1 989 Vol 1 2 Mai

169

Air precooling of strawberries: D. R. Gilemes et al.

-1

Nomenclature

A

B

Bi

C

C,(x)

D

Fo

G

h

k

/

M~

Nu

r

R

Dimensionless distance ratio, (Area 1)/hi 2

Dimensionless distance ratio, (Area 2)/hi 2

Biot number

Function from the general equation presented by Smith et al.

Function of the geometry, position and Biot

number

Diameter for spheres or (2.l) for anomalous

shapes (m)

Fourier number

Geometry index

Surface heat transfer coefficient

(Wm -2 C -1)

Thermal conductivity (W m - 1 o c - 1)

Characteristic length (m)

Square of the first root of the transcendental equation appropriate to the given

geometry

Nusselt number

Correlation coefficient

Outside radius of spheres (m)

Experimental method to determine surface heat transfer

coefficients. A method which involves the measurement

of the temperature variation during the transient cooling

of a body was used. The temperature response as a

function of time at any position within a sphere

undergoing transient heat exchange takes the following

Re

R~q

t

T

v

W

x

Reynolds number

Equivalent radius (m)

Temperature (C)

Dimensionless temperature ratio as a function of time and position within the solid

Velocity (m s- t )

Water content (~o by weight)

Generical position

Greek letters

Thermal diffusivity (m 2 s- ~)

0

Time (s)

2,

nth root of the transcendental equation

kt

Viscosity (kg m - 1 s- l)

p

Density (kg m - 3)

Subscripts

a

Air

acr

Acrylic plastic

s

Strawberries

i

Initial uniform temperature of the product

Iv

Constant temperature of surrounding

environment

(a)

form 9 :

T - t-too _ ~, C.~.,exp(-Az.)~O/R z

ti--too .= t

~orthogonat area 1

(2)

where the transcendental root equation is:

Bi= 1 - 2 . cot 2.

(3)

After Fo = 0.20 the series solution converges rapidly,

and the temperature ratio can be evaluated accurately by

the use of the first term only. The technique to evaluate h

from cooling curves involves the assumption that the

second and higher terms in the summation of Equation (2)

are negligible after some time has elapsed. Therefore, the

equation becomes:

t-too-Cl,xeXp(-2~)o~O/R2

(4)

(b)

orthocjonalarea 2

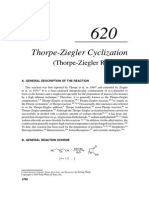

Figure 1 Cross-section of a typical strawberry in the (a) polar plane

and (b) equatorial plane

Figure 1 Coupe transversale d'une fraise type dans (a) le plan polaire et

(b) le plan bquatorial

length' (1), which is originated by two orthogonal planes

that pass through the point of maximum temperature

('thermal centre') of the fruit (Figure 1).

They also define a geometry index, G, which is

calculated by Equation (5)

ti --t~

A straight line with a slope of -22ct/R 2 is obtained by

plotting this equation on semi-log paper. Then, the

experimental cooling curve is also plotted on semi-log

paper. From the slope of this line and the properties of the

product, 22 can be evaluated. From 21 and Equation (3),

the Biot number and h can be calculated.

For those cases in which water loss occurs, the heat

transfer coefficients will be 'effective', because they will

include evaporative cooling.

Geometry analysis. The correction for non-spherical

shape of strawberries was made by applying the

procedure developed by Smith et al.l o,a 1. It is based on a

dimensional parameter defined as the 'characteristic

170

Int. J. Refrig. 1989 Vol 12 May

1

3

G=~+~-~

3

8B z

(5)

where A = orthogonal area 1/nl 2 and B = orthogonal area

2/nl 2. The geometry index for a sphere is 1, decreasing as

the sphere becomes eccentric.

Furthermore, the procedure involves a first term

approximation of the infinite series solutions, where

temperature versus time relation during transient heat

transfer is given by Equation (6):

T= C e x p ( - M ~ Fo)

(6)

Smith et al. ~'1~ developed a monograph which

Air precooling of strawberries: D. R. GOemes et al.

electronic thermometer with an accuracy of 0. IC. Each

thermocouple wire was inserted near the centre of the

sample. Thermocouple entrance was sealed appropriately. Samples were allowed to equilibrate in air to a

uniform temperature of about 30C. Cooling tests

continued until the sample had cooled to within IC of air

temperature. Air flow rates were measured with a hot wire

anemometer. The experimental air velocities were 1.3, 3.0

and 4.5 m s - 1 and temperature ranged from 0 to 2C.

The relative air humidity was determined from drybulb and wet-bulb temperature values. Experimental

values ranged from 88 to 90 ~o.

Thermal properties of the strawberries and acrylic

plastic model were determined in a previous study 12 by

the transient method 1 3. They were: ks = 0.46 W m - ~C- 1;

k a c r = 0 . 2 0 8 W m - l o c l; ~ s = l . 2 6 x 1 0 - V m 2 s - X ; and

cq~r= 1.207 x 10- 7 m 2 s - 1. These values agree with data

found in the literature s, 14,1s.

Moisture content of strawberries was determined by

drying the sample in air at 60C until constant weight was

obtained. Specific gravity was measured by water

displacement. Weight losses in the samples were

determined from values of their weights before and after

the cooling tests.

correlates M~ with G and Bi. M 1 can be calculated from

thermal diffusivity and the slope of the logarithmic

temperature ratio versus time plot during cooling tests.

R a w material

Strawberries (var. Tufts) from Coronda district (Santa Fe

province), were used. The fruits were selected to obtain

samples of uniform characteristics and size.

E x p e r i m e n t a l procedure

The heat transfer coefficients (h) and Nusselt numbers

were evaluated from properties of the product and the

acrylic model, according to the following procedure.

For the spherical shape:

1. The characteristic length of each test specimen

assumed to be the radius of a sphere of equivalent volume,

was determined;

2. 2~2 from experimental cooling curves and the

respective Bi number from tables 9, were obtained; and

3. the surface heat transfer coefficient h from the value of

Bi number, was calculated.

For the anomalous shape:

1. The geometry index (G) and the characteristic length

(1) of each test specimen were determined;

2. M~ from the semi-log plot of temperature versus time

was evaluated; and

3. using the nomograph, the reciprocal of the Biot

number and the value of the respective surface heat

transfer coefficient were obtained.

Results and discussion

Table 1 shows average surface heat transfer coefficients h

obtained from the three different air velocities. The values

of h for spheres (from Equation (1)) are averages of the

single values corresponding to each experimental

condition. Values predicted by Equation (1) of McAdams

for spheres and those obtained for the acrylic plastic

model with similar dimensions were not found to be

significantly different (P~<0.05). Values obtained for

strawberries assumed as spheres and those obtained by

correction for anomalous shape were neither found to be

significantly different (P ~<0.05).

On the other hand, significant differences (P~<0.05)

were found between predicted values for spheres or

experimental values for the acrylic model and the mean

values from strawberries. The latter were 16 to 25 ~o higher

than those predicted by Equation (1) of McAdams for

spheres and the experimental values for the acrylic plastic

model. The difference may be mainly attributed to the

Cooling tests were performed in a tunnel where air was

forced up through the strawberries or acrylic model,

placed on a wire belt. Both strawberries and acrylic model

were cooled singly. In commercial practice strawberries

are placed close together, so that higher effective h values

than the experimental values obtained are expected, as

actual air velocities at the surface are greater than the

approaching velocity used in the tests.

The acrylic plastic model was turned on a lathe so that

its shape and size were as similar as possible to the

strawberries (characteristic length, l = 0 . 0 1 2 m and

equivalent radius, R~q = 0.0145 m).

Temperature was measured using type K - A W G No. 30

thermocouples connected to a multichannel digital

Table 1 Surfaceheat transfer coefficients(h) obtained from forced-aircooling of acrylicplastic model and strawberries(eachvalue is an averageof 4 to

6 runs)

Tableau 1 Coefficients de transfert de chaleur superficiel (h) obtenus it partir du refroidissement par courant d'air force d'un modble en matikre plastique

acrylique et de fraises (chaque valeur reprbsente une moyenne de 4 it 6 essais)

Air velocity (m s- 1)

1.3

Spheres (predicted by Equation 1)

Acrylic plastic model

Strawberries

assumed as spheres

corrected for anomalous shape

3.0

4.5

h

(W m-2 oc-~)

CV

(%)

h

(Wm-2 of-,)

CV

(%)

h

(Wm-2 of 1)

CV

(%)

39.6

37.8

8.3

14.7

64.9

68.9

7.0

7.0

83.9

81.9

3.9

14.6

47.8

44.5

10.9

12.6

82.5

78.3

14.0

13.9

102.1

106.4

15.9

14.5

CV: Coefficient of variation (standard deviation/mean value) 100

Average air temperature during cooling tests: 1.4C

Spheres (for Eguation 1): f-=_/~q= 0.012 m; _acrylicplastic model: l= 0.012 m; Req= 0.0145 m; G = 0.76

Strawberries: l=0.0116m; Req=0.0131 m; G=0.83; jrs=952; 1~=90.5 %

Rev. Int. Froid 1989 Vol 12 Mai

171

Air precooling of strawberries: D. R. Gi)emes et al.

32

~.20

E

16

12

Air temperature

I

0

I

2

I

4

I

6

I

8

I

10

I

12

I

14

I

16

Time (minutes)

Figure 2

Temperature response curve from experimental cooling tests

(@) comparedwith that obtained by the analytical solutionfor spheres

using h values predicted by McAdams relationship (+) and the

analytical solution for a sphere using experimental h value (O) (each

temperature is an average of 4 runs). #a, 3.0ms-~; L 0.0116m; /~eq,

0.0132m; (~, 0.86; Yc/R, 0.22; &, 2.1C

Figure 2 Courbe de rkponse de la tempkrature ~ partir d'essais de

refroidissement expbrimental en comparaison de celle obtenue par la

solution analytique pour des sphbres en utilisant les valeurs de h prkvues

par la relation de McAdams (+) et la solution analytique pour une sphbre

utilisant la valeur de h expbrimentale ()(_chaque temperature represente

une moyenne de 4 essais). ~ , 3 , 0 m s - l ; 1, O,Oll6m; R~q, 0,0132m: G,

0,86; ~/R, 0,22; ~, 2,1C

additional cooling due to water evaporation from the

strawberries. Although many authors have considered

the evaporative cooling effect, little quantitative

information has been found. In this regard, Feldman 4

found that water evaporation produced an additional

cooling of 16 % (when va = 2 m s- 1) and 22 % (when va =

4 m s- ~), working with spheres made of ice (R = 0.03 m).

It should be noted that direct comparison with the data of

Feldman may not be valid because free water on the

surface evaporates more easily than from the strawberry

and the size of spheres was greater than those of

strawberries.

Besides the evaporative effect, during the forced

convection cooling of single products radiation can also

have a significant effect. In this work, experimental

conditions were such that this effect was minimized. If,

however, radiation had some influence, it would be

similar either for h obtained for strawberries or the acrylic

model.

Another reason for a higher apparent h is that the true

surface area of a strawberry might be higher than the

'nominal' surface area due to bumpiness and the small

seeds on the surface and therefore it might contribute to

the heat transfer rate at the surface and thus increase the

apparent h.

F i g u r e 2 shows the temperature response curve from an

experimental cooling test compared with that obtained by

the analytical solution for spheres, using h values

predicted by the correlation of McAdams (when Va=

3.0m s-l). Also plotted is the analytical solution for a

sphere using the h obtained from the same experimental

test.

As Ansari et al. 3 and Sastry et al. 16 have noted, the

difference between experimental and predicted cooling

172

Int. J. Refrig. 1989 Vol 12 May

rates occurs in the earlier stage of cooling. During this

period, the strawberries lose their surface moisture, and

the evaporation cooling effect becomes very important.

However, as cooling proceeds, the analytical solution for

a sphere using experimental h values compares fairly well

with the experimental data. This is because the effective h

value is an average value throughout the process, while

the evaporative effect is greater in the earlier stage of

cooling and smaller in the later stage.

Weight losses during cooling were also evaluated in

some tests. The values ranged from 0.4 to 0.9% of the

initial weight, with a mean value of 0.6 %. While the

number of runs was not sufficient to draw a definitive

conclusion, no correlation between the weight loss and

air-flow rates was found.

F i g u r e s 3 and 4 show Nusselt-Reynolds correlations

for strawberries and the acrylic plastic model,

respectively. Also plotted is the correlation proposed by

McAdams for forced-air cooling of spheres. An analysis of

the data yielded the following N u - R e relationships and

correlation coefficients.

For the acrylic plastic model:

r =0.906

Nu =0.34 Re T M

For strawberries:

Nu=0.37 R e T M

r=0.884

It should be noted that Nusselt and Reynolds numbers

for both the acrylic model and the strawberries correlate

significantly. Under experimental conditions, the value of

the Prandtl number remained constant at approximately

0.71. Therefore, it was not included in the above

mentioned correlations. Since the values of the film

coefficients obtained for strawberries assumed as spheres

and those obtained by correction for anomalous shape

were not found to be significantly different, the N u

number for each run was calculated by using the mean

value of both determinations.

200

tO0

6O

40

o

ff

/

1~o

O0 f i t "

.o s

~o

20

10

IOO0

I

2OOO

4 0 O0

Reynolds

I I I

I0000

number

20000

Figure 3 Nusselt-Reynolds correlation for forced-air precooling of

strawberries ( -) and McAdams relationship for spheres (

). Q,

Experimental data

Figure 3 Corrklation entre les hombres de Nusselt et de Reynolds pour

la prkrbfrigkration par air de fraises ( - - - ) et relation de McAdams pour

des sphbres (

). O , Rbsultats exp~rimentaux

Air precooling of strawberries: D. R. GSemes et al.

200

Acknowledgement

This work was supported by the Secretaria de Estado de

Ciencia y T~cnica de la Repfiblica A r g e n t i n a

I00

60

D

Z

References

40

1

2

20-

3

10

1000

2000

t I I

4000

10O00

Reynolds number

20000

Figure 4 Nusselt-Reynolds correlation for forced-airprecooling of the

acrylic plastic model ( - - - ) and McAdams relationship for spheres

(

). +, Experimental data

Figure 4 Correlation entre les nombres de Nusselt et de Reynolds pour

la pr~rbfrig~ration par eourant d'air forcb du modble en mati~re plastique

acrylique ( - - - ) et relation de McAdams pour des spheres (

). +,

Rbsultats expbrimentaux

4

5

6

7

8

9

Conclusions

F o r practical applications, strawberries can be acceptably

considered as spheres, because the correction for

a n o m a l o u s shape does n o t cause significant differences.

This c o m m e n t is limited to strawberries of Tufts variety

or others of similar shape because there are some varieties

that are very large a n d fiat, a n d perhaps c a n n o t be

modelled as spheres.

The air cooling of strawberries involves, to some

extent, a n e v a p o r a t i o n cooling effect. T o take this effect

into account, 'effective' surface heat transfer coefficients

must be used.

It should be interesting for future work to evaluate

moisture losses as a function of time a n d air velocity, in

order to describe the c o m b i n e d heat a n d mass transfer

process m o r e accurately.

10

11

12

13

14

15

16

Conroy,R., Ellis, R. F. Precooling berries improves quality

shortens fluidizedfreezingtime Food Processing (1981) 42 82-83

Fockens,F. H., Meffert, H. F. Moisture loss of horticultural

products during precooling with cold air 12bne Congr~s

International du Froid Madrid (1967) 731-741

Ansarl,F. A., Charan, V. Varma, H. K. Heat and mass transfer

analysis in air-cooling of spherical food products lnt J Refrio

(1984) 7 194-197

Feldrnan,C. Transfert de chaleur et de masse entre une sphere et

de l'air a basse temperature CTGREF No 6 Memoire (March

1976)

McAdams,W. Heat Transmission McGraw Hill Book Co., New

York, Toronto, London (1954)

Are, J., Sweat, V. E. Survey of published heat transfer

coefficients encountered in food refrigeration processes

ASH RAE Trans (1980) 86(2)

Kopdman, I., Blaisdell,J. L, Ptlug, !. J. Influenceof fruit sizeand

coolant velocityon the cooling of Jonathan apples in water and

air ASHRAE Trans (1966) 72(1) 209-216

Minh,T. V, Perry, J. S, Bennett, A. H. Forced air precooling of

white potatoes in bulk ASHRAE Trans (1969) 75(II) 87-94

Luikuv,A. V. Analytical Heat Diffusion Theory Academic Press,

New York and London (1968)

Smith,IL E., Nelson, G. L, Henrickson, R. L. Analyses on

transient heat transfer from anomalous shapes Trans ASAE

(1967) 10 236-245

Smith,R. E., Nelson, G. L., Henriekson, R. L. Applications of

geometry analysis of anomalous shapes to problems in transient

heat transfer Trans ASAE (1968) 11 296-302

Di Pentima, J. H., Giiemes,D. R. Difusividadtrrmica de acrilico

y de frutillas preparadas de diferentesmaneras, unpublished data

(1985)

Gaffney,J. J., Baird, C. D., Eshleman,W. D. Reviewand analysis

of the transient method for determining thermal diffusivity of

fruits and vegetables ASHRAE Trans (1980) 86(2) 261-280

Sweat, V. E. Experimental values of thermal conductivity of

selected fruits and vegetables J Food Sci (1974) 39 1080-1083

Perry,R., Chilton, C. Chemical Engineers' Handbook 5th Ed.

McGraw Hill Kogakusha Ltd, Tokyo (1973)

Sastry,S. K. Zuritz, C. A., Anantheswaran, R. C. Interaction

between heat and mass transfer in foods ASHRAE Trans (1985)

91(2)

Rev. Int. F r o i d 1 9 8 9 V o l 12 M a i

173

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Zamoramartnez1995 PDFDocument8 pagesZamoramartnez1995 PDFLeslie QuintanaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Burbujeo de AireDocument6 pagesBurbujeo de AireLeslie QuintanaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Zamora Mart Nez 1995Document8 pagesZamora Mart Nez 1995Leslie QuintanaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Temperature of Convective FlowDocument7 pagesTemperature of Convective FlowLeslie QuintanaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Burbujeo de AireDocument6 pagesBurbujeo de AireLeslie QuintanaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Antioxidant Effects of Sesamol Released From Polymeric FilmsDocument8 pagesAntioxidant Effects of Sesamol Released From Polymeric FilmsLeslie QuintanaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Numerical Modelling of Cooling and HeatingDocument16 pagesNumerical Modelling of Cooling and HeatingLeslie QuintanaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Development of Air CycleDocument4 pagesDevelopment of Air CycleLeslie QuintanaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Modelo Matemático Sobre La Congelación de ManzanasDocument19 pagesModelo Matemático Sobre La Congelación de ManzanasLeslie QuintanaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Refrigeration of Food ProductsDocument9 pagesRefrigeration of Food ProductsLeslie QuintanaNo ratings yet

- Development of Air Cycle Technology For Transport RefrigerationDocument9 pagesDevelopment of Air Cycle Technology For Transport RefrigerationLeslie QuintanaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Reynol Nusselt Aire de Refirgeracion 13Document7 pagesReynol Nusselt Aire de Refirgeracion 13Leslie QuintanaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Etileno-Vidautil Manzana 06Document6 pagesEtileno-Vidautil Manzana 06Leslie QuintanaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heat Transfer During Apple CoolingDocument9 pagesHeat Transfer During Apple CoolingLeslie QuintanaNo ratings yet

- Laminar Transitional and Turbulent Flow of Yield Stress FluidDocument13 pagesLaminar Transitional and Turbulent Flow of Yield Stress FluidLeslie QuintanaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Karababa2013 PDFDocument7 pagesKarababa2013 PDFLeslie QuintanaNo ratings yet

- Turbulent Pipe Flow of Power-Law FluidsDocument12 pagesTurbulent Pipe Flow of Power-Law FluidsLeslie QuintanaNo ratings yet

- Cleland1982 PDFDocument9 pagesCleland1982 PDFLeslie QuintanaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Journal of Food EngineeringDocument7 pagesJournal of Food EngineeringLeslie QuintanaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Antioxidant Effects of Sesamol Released From Polymeric FilmsDocument8 pagesAntioxidant Effects of Sesamol Released From Polymeric FilmsLeslie QuintanaNo ratings yet

- AtomizationDocument21 pagesAtomizationLeslie QuintanaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Capitulo 11 - Thermal PropertiesDocument12 pagesCapitulo 11 - Thermal PropertiesLeslie QuintanaNo ratings yet

- Etileno-Vidautil Manzana 06Document6 pagesEtileno-Vidautil Manzana 06Leslie QuintanaNo ratings yet

- AtomizationDocument11 pagesAtomizationLeslie QuintanaNo ratings yet

- Facilities Chemical SpareDocument73 pagesFacilities Chemical SparesamuelNo ratings yet

- HDPE Production Via Slurry-Loop ProcessDocument1 pageHDPE Production Via Slurry-Loop ProcessBramJanssen76100% (1)

- Qac D 072 Kao Fabric Softener 6 ConcentrationDocument2 pagesQac D 072 Kao Fabric Softener 6 ConcentrationChemist Technologist0% (1)

- HEAT TRANSFER ANALYSIS of A FLATDocument13 pagesHEAT TRANSFER ANALYSIS of A FLATAdhish khadkaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Selective Off-Flavor Reduction by Adsorption A Case Study in Alcohol-Free BeerDocument14 pagesSelective Off-Flavor Reduction by Adsorption A Case Study in Alcohol-Free BeerSefa Yücesoy100% (1)

- Kinematics, Dynamics, and Design of Machinery 2nd Edition by Waldron Kinzel Chapter 8Document87 pagesKinematics, Dynamics, and Design of Machinery 2nd Edition by Waldron Kinzel Chapter 8JoJo11436390% (10)

- 2013 GC Test 4 1Document6 pages2013 GC Test 4 1api-246009015No ratings yet

- Static Electric FieldsDocument175 pagesStatic Electric FieldsAli Ahmad100% (1)

- Blending - IBCDocument2 pagesBlending - IBCRoyNo ratings yet

- MODIFIED Applied Chemistry-SET-2 Key - R20 RegulationDocument35 pagesMODIFIED Applied Chemistry-SET-2 Key - R20 RegulationM VAMSHI M VAMSHINo ratings yet

- 3a Lattice Vibrations PDFDocument18 pages3a Lattice Vibrations PDFGanesh NegiNo ratings yet

- Practice Quiz 1 ANSWER KEY 2017Document2 pagesPractice Quiz 1 ANSWER KEY 2017Frezeil RocheNo ratings yet

- Concentrated Aqueous Emulsions (EW) : Innovation You Can Build On™Document6 pagesConcentrated Aqueous Emulsions (EW) : Innovation You Can Build On™zoilaNo ratings yet

- Carbon and CompoundDocument39 pagesCarbon and CompoundTathagat MauryaNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ScriptDocument2 pagesScriptShelli TristanNo ratings yet

- Chemistry-12 Holiday HomeworkDocument6 pagesChemistry-12 Holiday Homeworkamansingh20022006No ratings yet

- Module 4 - Gunpowder and ExplosivesDocument11 pagesModule 4 - Gunpowder and ExplosivesJohn Carl DomingoNo ratings yet

- Simulation Chem Eng Gil Ivan Copia-A+Document537 pagesSimulation Chem Eng Gil Ivan Copia-A+Dahiyana Cristancho100% (3)

- HUBS1403 - Biomedical Science 1 - Lecture 2. Organisation of MatterDocument30 pagesHUBS1403 - Biomedical Science 1 - Lecture 2. Organisation of MatterEvelyn YongNo ratings yet

- Thermal Cracking Reaction Kinetics - Hemendra KhakharDocument21 pagesThermal Cracking Reaction Kinetics - Hemendra Khakhargolden retrieverNo ratings yet

- Guideline For Choosing A Property MethodDocument12 pagesGuideline For Choosing A Property MethodAtul JainNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary Educationzainab tamerNo ratings yet

- Industrial Automation MOTOR CLASSDocument18 pagesIndustrial Automation MOTOR CLASSAlamin SikderNo ratings yet

- CH 01 Edited PDFDocument10 pagesCH 01 Edited PDFabbyNo ratings yet

- Evaluation of The Lipophilicity of Chalcones by RP-TLC and Computational MethodsDocument9 pagesEvaluation of The Lipophilicity of Chalcones by RP-TLC and Computational MethodsArtem KulikovNo ratings yet

- Thrope Ziegler Cyclization SearchDocument4 pagesThrope Ziegler Cyclization SearchahmedramadanNo ratings yet

- Chapter - 3: Structure of The AtomDocument34 pagesChapter - 3: Structure of The AtomFozia ShaikhNo ratings yet

- Heap Leach PadsDocument72 pagesHeap Leach PadsOmar Alex Meléndez Huamán100% (1)

- Chapter 13 - DynamicsDocument54 pagesChapter 13 - DynamicsAndrew BorgNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)