Professional Documents

Culture Documents

Mnetman A1

Uploaded by

Hubert Maraza JaliriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mnetman A1

Uploaded by

Hubert Maraza JaliriCopyright:

Available Formats

g

GE Multilin

Power Management

Lentronics

MULTINET

Serial to Ethernet Converter

Instruction Manual

Manual P/N: 1601-0117-A1

Copyright 2003 GE Multilin

NORTH AMERICA / WORLDWIDE

215 Anderson Avenue, Markham, ON

Canada L6E 1B3

Tel: (905) 294-6222

Fax: (905) 201-2098

E-mail: gemultilin@indsys.ge.com

Web: www.GEindustrial.com/multilin

EUROPE / MIDDLE EAST / AFRICA

Avenida Pinoa 10 48710,

Zamudio (Vizcaya) Spain

Tel: +34 94 485 88 00

Fax: +34 94 485 88 45

E-mail: gemultilin_euro@indsys.ge.com

Web: www.GEindustrial.com/multilin

MULTINET

Table of Contents

TABLE OF CONTENTS

FEATURES............................................................................................................................................. 3

DESCRIPTION ....................................................................................................................................... 3

RS485 SERIAL PORT............................................................................................................................ 4

10BASE-F FIBER OPTIC PORT ............................................................................................................ 5

INPUT POWER TERMINALS................................................................................................................. 5

MOUNTING ............................................................................................................................................ 5

GETTING STARTED WITH ENERVISTA TO SETUP MULTINET........................................................ 7

CONFIGURATION.................................................................................................................................. 9

EXAMPLE: Connecting MultiNet to a PQM.......................................................................................... 10

EXAMPLE: Configuring a Laptop to communicate to MultiNet over crossover cable.......................... 13

DIMENSIONS ....................................................................................................................................... 15

ORDER CODE ..................................................................................................................................... 15

SPECIFICATIONS................................................................................................................................ 16

WARRANTY ......................................................................................................................................... 17

http://www.GEindustrial.com/multilin

MULTINET

Page 3 of 19

FEATURES

Converts Modbus RTU over RS485 into

Modbus TCP/IP over Ethernet.

Supports both 10BaseT Ethernet and

10BaseF fiber connections.

Connect up to 32 RS485 serial devices to

an Ethernet network.

Modbus TCP/IP allows multiple SCADA

masters to simultaneously connect and

communicate to the same IED.

Industrially hardened product for utility and

industrial applications.

Simple "plug and play" device setup with

enerVista software.

DESCRIPTION

The MultiNet Serial-to-Ethernet converter is a communications module that provides GE Multilin serial

Modbus IEDs with Modbus TCP/IP communications over Ethernet. MultiNet has the capability to

connect up to 32 serial Modbus devices, eliminating complex wiring and additional communications

converters, as well as providing a streamlined and economical Ethernet hub. Unlike most

communications converters designed for commercial use, MultiNet is environmentally hardened to

withstand severe utility and industrial conditions.

MultiNet can be used to connect an existing Modbus RTU network over RS485 onto a LAN in order to

support multiple SCADA masters or advanced HMI systems. Additionally, the use of MultiNet greatly

facilitates the setup and wiring of any serial device to a communications center since it avoids costly

RS485 cable runs. Finally, large RS485 networks are slow and have a typical limit of 32 devices.

MultiNet allows customers to expand that limit as well as improving network performance by

separating large RS485 networks into smaller groups.

http://www.GEindustrial.com/multilin

MULTINET

Page 4 of 19

Figure 1: Connections

RS485 SERIAL PORT

RS485 data transmission and reception is accomplished over a single twisted pair with transmit and

receive data alternating over the same two wires. Using this port, continuous monitoring and control

to a PLC, protection relay or any serial Modbus IED is possible.

Connect the +, and common terminal of MultiNet to the +, and common terminals of all the

IEDs. Correct polarity must also be observed. For instance, the IEDs must be connected with all

RS485 + terminals connected together, and all RS485 terminals connected together.

To minimize errors from noise, the use of shielded twisted pair wire is recommended. The COM

terminal should be connected to the common wire inside the shield, when provided. To avoid loop

currents, the shield should be grounded at one point only. Each relay should also be daisy-chained to

the next relay in the link. A maximum of 32 relays can be connected in this manner without exceeding

driver capability.

Lightning strikes and ground surge currents can cause large momentary voltage differences between

remote ends of the communication link. For this reason, surge protection devices are internally

provided at the communication port. An isolated power supply with an opto-coupled data interface

also acts to reduce noise coupling. To ensure maximum reliability, all equipment should have similar

transient protection devices installed.

Both ends of the RS485 circuit can be terminated with impedance as shown in Figure 2: Typical

Configuration. Termination networks should only be applied if long cable runs are used

between RS485 connections. A typical load value for a terminating network is a 120-ohm resistor in

series with a 100-pF capacitor.

http://www.GEindustrial.com/multilin

MULTINET

Page 5 of 19

10BASE-F FIBER OPTIC PORT

The fiber optic communications port allows for fast and efficient communications with Modbus TCP/IP

at 10 Mbps. Fiber optic transmissions provide an ideal solution for areas where RS485

communications or Ethernet via a twisted pair have traditionally caused problems. Fiber is immune to

electrical interference and provides complete isolation.

Optical fibers may be connected to the MultiNet supporting a wavelength of 820 nm in multimode.

Optical fiber is only available with the MultiNet-FE option (see the Order Code for details). The

MultiNet-FE has a 10BaseF transmitter/receiver for optical fiber communications and supports optical

fiber sizes of 50/125 m, 62.5/125 m, and 100/140 m. The fiber optic port is designed such that the

response times will not vary for any core 100 m or less in diameter. For optical power budgeting,

splices are required every 1 km for the transmitter/receiver pair (the ST type connector contributes for

a connector loss of 0.2 dB). When splicing optical fibers, the diameter and numerical aperture of each

fiber must be the same. Only a quarter turn of the coupling is required to engage or disengage the ST

type connector.

The 10BaseT Ethernet port and the 10BaseF Fiber port are internally linked and should not be used

together.

CAUTION

Ensure the dust covers are installed when the fiber is not In use. Dirty or

scratched connectors can lead to high losses on a fiber link.

Observing any fiber transmitter output may cause injury to the eye!

CAUTION

INPUT POWER TERMINALS

The input power terminals are located on the left side of the green terminal block. MultiNet may be

connected to either 90 to 265 V AC at 50/60 Hz or 90 to 300 V DC supply power. The terminals are

labeled "+" and "" for DC positive and negative input power and "L" and "N" are for AC line and

neutral input power. The GND terminal must be connected to ground to ensure adequate protection

against transients.

CAUTION

Control power supplied to the MultiNet must be connected to the matching power

supply range. If the voltage is applied to the wrong terminals, damage may occur!

MOUNTING

MultiNet is DIN rail mountable and ships with two DIN rail clips attached on the rear of the unit. The

DIN rail clips can attach the unit onto a standard 35 mm DIN rail. Place the top hooks of the clip

against the DIN rail and apply a downward force until an audible click is heard. In order to remove the

unit, place a standard slotted screwdriver between the unit and the DIN rail and apply an upward

force.

Each clip is held onto the unit using a standard 4-40 Phillips head screw. If the DIN rail option is not

used, remove the DIN rail clips by unscrewing the six screws. Once the clips have been removed rescrew the six screws back into their original positions. Do not substitute screws, since the wrong

length of screw may damage the internals of the product and void the warranty.

http://www.GEindustrial.com/multilin

MULTINET

Page 6 of 19

SCADA

Viewpoint

HMI

Modbus

TCP/IP

Modbus

TCP/IP

Modbus

TCP/IP

LAN/WAN

Modbus

TCP/IP

Terminating

Network

(120R Resistor

and 100pF

Capacitor)

Modbus

RTU

Modbus

RTU

Terminating

Network

(120R Resistor

and 100pF

Capacitor)

+ - Shield

+ - Shield

+ - Shield

RS485 COMPORT

RS485 COMPORT

RS485 COMPORT

IED #1

IED #2

IED #32

Figure 2: Typical Configurations

http://www.GEindustrial.com/multilin

MULTINET

Page 7 of 19

GETTING STARTED WITH ENERVISTA TO SETUP MULTINET

The MultiNet setup software is provided to edit settings and configure the unit. The setup software

connects to the unit through either the 10BaseT (RJ45) port or the 10BaseF (fiber) port.

The following requirements must be met to ensure correct operation of the MultiNet setup software:

Pentium class or higher processor (Pentium II 300 MHz or higher recommended)

Windows 95, 98, 98SE, ME, NT 4.0 (Service Pack 4 or higher), 2000, XP

64 MB of RAM (256 MB recommended)

40 MB of available hard drive space (100 MB recommended)

Video capable of displaying 800 600 or higher in High Color mode (16-bit color)

An Ethernet communications port.

To download MulitNet directly, go to http://www.geindustrial.com/multilin/software/multilin.htm

To download MulitNet through enerVista (suggested), follow the procedure outlined below.

1. Download enerVista

a) From the Web:

i)

Direct your web browser to the enerVista website at http://www.enerVista.com. Click on

the Downlaod Now button.

ii)

Run the enerVista installation program and follow the on-screen instructions.

b) From the enerVista CD:

i)

Insert the enerVista CD into your computers CD drive and it will automatically open the

welcome page. Click on the Install Now button.

ii)

Run the enerVista installation program and follow the on-screen instructions.

http://www.GEindustrial.com/multilin

Page 8 of 19

MULTINET

2. Setup the MultiNet Software:

i)

On the main enerVista page, select IED SetUp from the LaunchPad window.

ii)

Click on the Install Software button at the top of the screen.

iii) Select MultiNet from the product list. Indicate whether you are installing the software from

CD or the Web, then click Check Now.

iv) Check off the MultiNet Setup program from the Downloads screen and click Download

Now.

v) Once the download is complete, the MutiNet installation file will be shown on screen. Doubleclick this file to run the installation program.

vi) Run the installation program and follow the on-screen instructions.

x) Once the installation is complete, click on IED Setup on the left panel of the screen. You will

see a Multinet icon on the IED screen. Double click on it to launch the MulitNet setup

application.

http://www.GEindustrial.com/multilin

MULTINET

Page 9 of 19

CONFIGURATION

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on

MultiNet. To connect MultiNet directly to the Ethernet port of a PC or laptop, use a crossover cable; to

connect MultiNet directly to an Ethernet network, use a regular pass-through RJ-45 cable.

To setup MultiNet for Ethernet communications use the following procedure:

1. Install and start the latest version of the MultiNet setup software (available from the GE Multilin

Products CD or online from http://www.GEindustrial.com/multilin; see the previous section:

Getting Started with MultiNet Software).

Figure 3: MultiNet Setup Software Main Screen

1. Select the Communications > Device Setup menu item to open the Device Setup window.

2. The left pane shows the currently configured MultiNet Devices. Click the Add Device button to

add a new MultiNet device to the device list.

3. Enter the desired name in the Device Name field and a description (optional) of the device.

http://www.GEindustrial.com/multilin

MULTINET

Page 10 of 19

4. The MAC address is used to identify and configure the unit. Fill in the MAC address field with the

address found on the back of MultiNet (for example, 00-20-4A-62-AE-66).

Figure 4: Device Setup Screen

5. Under network settings, enter the IP address, Subnet and Gateway of the MultiNet network

interface. If these values are not known, consult your network administrator.

6. Under port settings, enter the Baud Rate and Parity bit for the MultiNet serial interface.

7. Once the serial and network settings have been entered, click [SAVE] to save the changes. The

message success saving settings to MultiNet device will appear in the status window when

complete. Additional devices may be added to the list by following the same procedure.

8. Click [OK] to close the device setup screen.

EXAMPLE: Connecting MultiNet to a PQM

The following steps detail how to use MultiNet in order to connect a PQM to an Ethernet network.

1. Wire COM1 on the back of the PQM to the RS485 terminals on MultiNet. The wiring is detailed in

Figure 2: Typical Configuration. Since for this example short cable runs are used, terminators are

not necessary.

2. Check the settings within the PQM, noting the Baud rate, Parity Bit and Slave Address. For the

sake of this example the values of 19200, none (or N), and 254 will be used for the baud rate,

parity bit, and slave address respectively.

http://www.GEindustrial.com/multilin

MULTINET

Page 11 of 19

3. Note the MAC address of the MultiNet unit. For this example, a MAC address of 00-20-4A-62-AE00 will be used. The MAC address is located on the rear of the unit.

4. Connect MultiNet to the network LAN. Consult your IT administrator to determine a suitable IP

address, subnet, and gateway setting for the unit. For this example we will use 192.168.1.2 as the

IP address, 255.255.255.0 as the Subnet and 192.168.1.1 as the Gateway.

5. Open the MultiNet setup software. Use the procedure detailed in the Configuration section to

configure the unit. For this example the following settings will be used:

Device Name: MultiNet 1

IP Address:

192.168.1.2

Subnet:

255.255.255.0

Gateway:

192.168.1.1

Baud Rate:

19200

Parity Bit:

None

NOTE

The baud rate and parity bit are identical to those set within the PQM. Additionally, the

MAC address from step 3 is needed to configure the Network settings.

6. Close the MultiNet setup software and open enerVista Viewpoint.

7. From the main screen of enerVista Viewpoint, click Device Setup to open the Device Setup

window.

Figure 5: Device Setup Screen within Viewpoint

8. On the left is the device list showing the Quick Connect default site. Click on the plus sign next

to the Quick Connect site to reveal the Quick Connect default device. Selecting this device

allows parameters to be entered in the right pane.

http://www.GEindustrial.com/multilin

MULTINET

Page 12 of 19

9. For this example, we are going to configure the Quick Connect device as our PQM. Select

Ethernet as the interface and fill in the IP address and slave address of the PQM.

10. Click Read Order Code. Viewpoint will locate the PQM device and connect to it. Once this order

code has been read, click OK to save the configuration.

11. Select the Plug & Play > Create Schema menu item to open the Plug and Play Device dialog

box. Ensure that PQM is selected within the drop down selection. Click Create to automatically

create plug and play screens for the PQM.

Figure 6: Dialog Box for Creating plug and play Screens

12. When finished, the plug and play menu will appear, showing our PQM labeled as Quick

Connect. Click the Dashboard button below the PQM icon to view the device information. We

have now successfully accessed our PQM through MultiNet.

Figure 7: Plug and Play Menu Showing Attached PQM.

http://www.GEindustrial.com/multilin

MULTINET

Page 13 of 19

EXAMPLE: Configuring a Laptop to communicate to MultiNet over crossover cable.

This procedure details how to configure MultiNet for use with a crossover cable. Using a crossover

cable allows for a direct local connection to a MultiNet device, bypassing the network. The following

procedure is based upon the Windows 2000 operating system; variations of this procedure will work

other windows operating systems, as they are all fairly similar.

NOTE

This example uses sample values for IP address, subnet and gateway. Please

substitute these values with your own.

1. Connect a CAT5 crossover Ethernet cable between the laptop running the MultiNet setup

software and the MultiNet unit. Since the 10BaseT connection is being used, the 10BaseF

connection must be disconnected.

2. Right click on My Network Places and select properties from the pop down menu.

3. Click on the Local Area Connection icon and select properties.

4. Select Internet Protocol (TCP/IP) and click Properties.

5. Record the current settings of the Internet Protocol (TCP/IP) properties window.

6. Select the Use the following IP address button. The laptop must be configured with the same

settings as the MultiNet. For example, if an IP address of 192.168.1.2 has been assigned to the

MultiNet, use that address as the gateway for the laptop. Similarly, set the IP address of the

laptop to the gateway IP of the MultiNet. For example, set the laptop IP address to 192.168.1.1

if the gateway IP of the MultiNet is 192.168.1.1. The subnet mask is to remain the same. Fill in

the corresponding fields:

IP address: 192.168.1.1

Subnet: 255.255.255.0

Gateway address: 192.168.1.2

NOTE

The laptop has been configured as the gateway for MultiNet do not connect the

laptop back to the network without first restoring the settings for the IP address.

Again, the IP address, Subnet and gateway supplied here are for this example

only. Please change these values so that they correspond to the values assigned

in your network.

7. Click OK to save the changes. Depending on your operating system, you may wish to restart your

PC.

http://www.GEindustrial.com/multilin

MULTINET

Page 14 of 19

Figure 8: Setting the IP Address on a Laptop.

8. Open the MultiNet setup program and follow the procedure detailed within the CONFIGURATION

section. For this example use the IP address of 192.168.1.2, subnet of 255.255.255.0 and a

gateway of 192.168.1.1.

9. Once the configuration of the MultiNet device is complete, return the laptop to its previous

settings using the recorded values from step 5. If the MultiNet device was configured properly,

communications may be tested on the connected network using enerVista, as shown in the first

example.

http://www.GEindustrial.com/multilin

MULTINET

Page 15 of 19

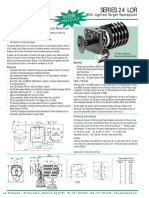

DIMENSIONS

Figure 6: MultiNet Dimensions

ORDER CODE

There are two order codes for the GE Multilin MultiNet converter: MULTINET-E and MULTINET-FE.

MULTINET

Modbus RTU to Modbus TCP/IP converter with RS485

communications

10BaseT Ethernet Port

FE

10BaseT Ethernet Port, and 10BaseF fiber optic port.

http://www.GEindustrial.com/multilin

MULTINET

Page 16 of 19

SPECIFICATIONS

ETHERNET:

TYPE TESTS:

Version 2.0/IEEE 802.3

10BaseT: RJ45 connection

10BaseF: 820 nm, multi-mode, fiber optic with ST

connector

Modbus TCP/IP

EMC Test Levels:

Test Conditions:

ESD:

RS485 PORT:

RS485 2-wire, half duplex, isolated

Baud Rate: 300 bps to 115.2 Kbps

Protocol: Modbus RTU

INSTALLATION:

Configuration through enerVista setup software

ENVIRONMENTAL:

Humidity: 95% non-condensing

Operating Temperature: 20C to 70C

Storage Temperature: 40 to 85C (40 to 185F)

IP rating: IP 40

POWER INPUT:

DC power: 90 to 300 V DC

AC power: 90 to 264 V AC at 50/60 Hz

APPROVALS:

ISO: Manufactured to an ISO9001 registered program

UL: Listed for US and Canada under E83849 - Vol. 1

Sec.10.

FCC: PART 15

MECHANICAL SPECIFICATIONS:

Material: Metal enclosure

Dimensions: 6.6 3.98 1.46

Shipping box: 12.9 9 3.25

Ship weight: 2 lbs.

http://www.GEindustrial.com/multilin

EN 50263

IEC60255-6

IEC60255-22-2

(IEC 61000-4-2)

IEEE/ANSI C37.90.3

Surge Immunity:

*IEC 60255-22-5

(IEC 61000-4-5)

Fast Transient:

IEC 60255-22-4

(IEC 61000-4-4)

IEEE/ANSI C37.90.1

Oscillatory:

IEEE/ANSI C37.90.1

*IEC 60255-22-1

Dielectric Strength:

IEC 60255-5

Insulation Resistance:

IEC 60255-5

Impulse Voltage:

IEC 60255-5

Power Fr. Magnetic Field:

IEC 61000-4-8

Pulse Magnetic Field:

IEC 61000-4-9

Voltage Dip/ Interruption:

IEC 61000-4-11

RF cond. & radiated emission: IEC 60255-25

RF Conducted Immunity:

IEC 60255-22-6

(IEC 61000-4-6)

RF Radiated Immunity:

*IEC 60255-22-3

(IEC 61000-4-3)

IEEE/ANSI C37.90.2

Digital Port. Tel. Immunity:

IEC 50204

Temperature:

(Cold)

IEC 60068-2-1,

(Hot)

IEC 60068-2-2

Relative humidity:

IEC 60068-2-30

Ingress Protection:

IEC 60529

Mechanical Stress:

2G

* RJ-45 not supported for marked tests

MULTINET

Page 17 of 19

WARRANTY

GE Multilin Product Warranty

General Electric Multilin Inc. (GE Multilin) warrants each

product it manufactures to be free from defects in

material and workmanship under normal use and

service for a period of 24 months from date of shipment

from factory.

In the event of a failure covered by warranty, GE Multilin

will undertake to repair or replace the product providing

the warrantor determined that it is defective and it is

returned with all transportation charges prepaid to an

authorized service center or the factory. Repairs or

replacement under warranty will be made without

charge.

Warranty shall not apply to any product that has been

subject to misuse, negligence, accident, incorrect

installation or use, not in accordance with instructions

nor any unit that has been altered outside a GE Multilin

authorized factory outlet.

GE Multilin is not liable for special, indirect or

consequential damages or for loss of profit or for

expenses sustained as a result of a product malfunction,

incorrect application or adjustment.

For complete text of Warranty (including limitations and

disclaimers) refer to GE Multilin Standard Conditions of

Sale.

http://www.GEindustrial.com/multilin

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- NT538Document15 pagesNT538Hubert Maraza JaliriNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Rockwell Automation Service ContactsDocument2 pagesRockwell Automation Service ContactsHubert Maraza JaliriNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Operating Manual: High Voltage Isolated Gate Driver Power SupplyDocument8 pagesOperating Manual: High Voltage Isolated Gate Driver Power SupplyHubert Maraza JaliriNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Safety Guidelines For The Application, Installation and Maintenance of Solid State ControlDocument24 pagesSafety Guidelines For The Application, Installation and Maintenance of Solid State ControlLinda SanchezNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Frontline: Frontline Gold Frontline Blue Frontline Green Frontline RedDocument2 pagesFrontline: Frontline Gold Frontline Blue Frontline Green Frontline RedHubert Maraza JaliriNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Superior Key InterlocksDocument4 pagesSuperior Key InterlocksHubert Maraza JaliriNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- BrochuredigsilentDocument28 pagesBrochuredigsilentsuresh.rajanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Current Transformer Excitation CurveDocument6 pagesCurrent Transformer Excitation CurveHubert Maraza JaliriNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Manual de Transformadores Pad MoutedDocument12 pagesManual de Transformadores Pad MoutedAlbertoCedeñoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lab5 DialuxDocument5 pagesLab5 DialuxHubert Maraza JaliriNo ratings yet

- Allen-Bradley Medium Voltage Bus Support: Product Data Bulletin IDocument2 pagesAllen-Bradley Medium Voltage Bus Support: Product Data Bulletin IHubert Maraza JaliriNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Manual PQM IIDocument8 pagesManual PQM IILuis Eugenio Hernandez QuijaiteNo ratings yet

- Application of Surge Protection To Vacuum Contactors - Bulletin 1502Document1 pageApplication of Surge Protection To Vacuum Contactors - Bulletin 1502Hubert Maraza JaliriNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- MotorDocument10 pagesMotorHubert Maraza JaliriNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- E560 Et23 DBDocument4 pagesE560 Et23 DBHubert Maraza JaliriNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DiodoDocument3 pagesDiodoLaura Lizeth Rodriguez RodriguezNo ratings yet

- Aero FloDocument7 pagesAero FloHubert Maraza JaliriNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- D-MWH: Information OnlyDocument2 pagesD-MWH: Information OnlyHubert Maraza JaliriNo ratings yet

- Free Software License For Binary Distributions: Proconx Pty LTD, Brisbane/Australia, Acn 104 080 935Document2 pagesFree Software License For Binary Distributions: Proconx Pty LTD, Brisbane/Australia, Acn 104 080 935Hubert Maraza JaliriNo ratings yet

- Instruction DataDocument1 pageInstruction DataHubert Maraza JaliriNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2.33. - Electroswitch 7803gDocument6 pages2.33. - Electroswitch 7803gHubert Maraza JaliriNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Abb Utilities GMBH: Application CharacteristicsDocument2 pagesAbb Utilities GMBH: Application CharacteristicsHubert Maraza JaliriNo ratings yet

- Certificacion Tapones 3MDocument3 pagesCertificacion Tapones 3MHubert Maraza JaliriNo ratings yet

- E560 Mod81 DBDocument2 pagesE560 Mod81 DBHubert Maraza JaliriNo ratings yet

- E560 IEC60870-5-103 SubDocument46 pagesE560 IEC60870-5-103 SubHubert Maraza JaliriNo ratings yet

- BAS16/MMBD4148/MMBD914: Surface Mount Switching DiodeDocument3 pagesBAS16/MMBD4148/MMBD914: Surface Mount Switching DiodeHubert Maraza JaliriNo ratings yet

- Field Device Rio Panel: 3220-TE-03211-A C2-3200-IO-033Document1 pageField Device Rio Panel: 3220-TE-03211-A C2-3200-IO-033Hubert Maraza JaliriNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Field Device Rio Panel: C2-3240-PC-346 C2-3200-IO-045Document1 pageField Device Rio Panel: C2-3240-PC-346 C2-3200-IO-045Hubert Maraza JaliriNo ratings yet

- E560 Psu81 CSDocument6 pagesE560 Psu81 CSHubert Maraza JaliriNo ratings yet

- A230-A230s Camile BauerDocument11 pagesA230-A230s Camile BauerHubert Maraza JaliriNo ratings yet

- UCCN1004 - Lab 03 - Network RoutingDocument9 pagesUCCN1004 - Lab 03 - Network RoutingZHEN-HONG LEENo ratings yet

- Iot Imo SmartDocument22 pagesIot Imo SmartRaj kumarNo ratings yet

- SDS13784 Z Wave Network Protocol Command Class SpecificationDocument206 pagesSDS13784 Z Wave Network Protocol Command Class SpecificationsamcurranNo ratings yet

- Hype Cycle For The Telecommu 260996Document102 pagesHype Cycle For The Telecommu 260996Enrique de la RosaNo ratings yet

- How To Connect MyPBX To TA FXO Gateway enDocument12 pagesHow To Connect MyPBX To TA FXO Gateway endodikNo ratings yet

- Movitools ManualDocument12 pagesMovitools ManualdarkblackredNo ratings yet

- Oci Q&aDocument33 pagesOci Q&aSwatiNo ratings yet

- User - Manual GW-DLMS-485-SL7 - 5.59 - enDocument14 pagesUser - Manual GW-DLMS-485-SL7 - 5.59 - enIkhwan Firdaus NurgumilarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ConfigDocument37 pagesConfigJennifer TaylorNo ratings yet

- SPA9000userguide PDFDocument129 pagesSPA9000userguide PDFrigofsNo ratings yet

- Ficha Tecnica Nodo de Cuerda VibranteDocument3 pagesFicha Tecnica Nodo de Cuerda VibranteCARLOS HUMBERTO AGUILERA MOLINANo ratings yet

- A100K10602 Alphacom XE User GuideDocument119 pagesA100K10602 Alphacom XE User GuideAlberto R PerezNo ratings yet

- Global VPN Client 4. 7 Administrator's Guide: Dynamic Security For The Global Network™Document70 pagesGlobal VPN Client 4. 7 Administrator's Guide: Dynamic Security For The Global Network™NVNo ratings yet

- Intel IXP2350 Network Processor: Enables Access and Edge Applications To 2 GbpsDocument8 pagesIntel IXP2350 Network Processor: Enables Access and Edge Applications To 2 Gbpscatsoithahuong84No ratings yet

- SmartPTT File Transfer User's GuideDocument19 pagesSmartPTT File Transfer User's GuideSmartPTTNo ratings yet

- Marconi NND 410Document38 pagesMarconi NND 410chandanNo ratings yet

- IN03、IN04 User Manual V1.0Document82 pagesIN03、IN04 User Manual V1.0Edd PONo ratings yet

- Modbus GWDocument2 pagesModbus GWKhaled KadryNo ratings yet

- ZXSS10 SS1b: Data Configuration Guide Global ConfigurationDocument76 pagesZXSS10 SS1b: Data Configuration Guide Global ConfigurationAmar TuladharNo ratings yet

- Commissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingDocument6 pagesCommissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingT S VirdiNo ratings yet

- MOIA Technical ProposalDocument72 pagesMOIA Technical Proposalvadavada100% (1)

- Netscaler Gateway 12 0Document658 pagesNetscaler Gateway 12 0Haidar MaghrifaNo ratings yet

- CompTIA Network PlusDocument28 pagesCompTIA Network PlusFirstNames Surnames100% (5)

- AppGate SDP For GCP - Reference Architectures - 042020Document26 pagesAppGate SDP For GCP - Reference Architectures - 042020Trường NgôNo ratings yet

- Non-VLSM Guide NotesDocument3 pagesNon-VLSM Guide NotesJOEMARIE A VALIENTENo ratings yet

- APH RTLS-Netzwerkkonfiguration-V2.12.0.0 76Document38 pagesAPH RTLS-Netzwerkkonfiguration-V2.12.0.0 76Marcone Marques TeixeiraNo ratings yet

- Lab4 - Packet TracerDocument3 pagesLab4 - Packet TracerNikita LoharNo ratings yet

- 553 3001 156 - 14.00Document134 pages553 3001 156 - 14.00bobfuestNo ratings yet

- How To Implement Cisco Unified SRST and MGCP Fallback - Cisco Support CommunityDocument3 pagesHow To Implement Cisco Unified SRST and MGCP Fallback - Cisco Support CommunityRamakrishnan PisharodyNo ratings yet

- SMP Gateway User ManualDocument269 pagesSMP Gateway User ManualgusfajNo ratings yet