Professional Documents

Culture Documents

11 188 144463948720 28

Uploaded by

anon_5731027Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 188 144463948720 28

Uploaded by

anon_5731027Copyright:

Available Formats

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

Volume-3, Issue-10, Oct.-2015

REVIEW OF DESIGN AND PERFORMANCE OF PERMANENT

MAGNET SYNCHRONOUS MOTOR

1

A.S. ARORA, 2GURMEET SINGH

1

Professor, 2Associate Professor,

Department of Electrical and Instrumentation Engineering,

Sant Longowal Institute of Engineering and Technology- Longowal, Punjab, INDIA

E-mail: 2gsgsgrewal@yahoo.com

Abstract: Permanent magnet synchronous motor(PMSM) is a exceedingly efficient motor and is successfully operated in a

wide range of speed. Various types of permanent magnet synchronous motors are accessible in the market offering

advantages of direct on line starting as induction motor and effectively running on synchronous speed. Major disadvantages

of PMSM is uncertainty of successfully synchronization, loading capability during asynchronous as well as synchronous

period. The present market potential for motors places a high value of operating efficiency , reliability, variable speed

operation, low running temperature, quiet operation and minimum cost. In comparison to induction motor , PMSM provides

the peculiarity of consumer prerequisite along with high power density and high power factor. The advancement in the

design technologies and magnetic material allows the achievement of souk ambition at even higher temperature without

much more permanent magnetization loss. This paper presented the investigations of new structures appearing in scientific

literature carried out by the researchers to obtain multi-objective optimal design for PMSM.

Index Terms - Permanent Magnet Synchronous Motors, Axial Flux Geometry, Radial Flux Geometry, Torque, Efficiency

Power Factor And Hybrid Models

provide an overview of the present-day advancement

in the design of PMSM.

I. INTRODUCTION

Huge amount of electric energy drawn by the electric

derives is gone astray in the form of heat due to

nonefficient performance of the drives. In the family

of line start motors, the prolific induction motor is

one, of which operation is unhealthy and not fit in

todays

market trends. The permanent magnet

synchronous motor is the only alternative to

overcome this disadvantages of line start induction

motor [1].The operation of the permanent magnet

synchronous motor comprises

two modes,

asynchronous mode during which the machine runs

as induction motor and synchronous mode during

which the motor run at synchronous speed [2].

Certainty of successful synchronization is an

important undertaking

of researchers and

asynchronous torque and magnetic braking torque are

deciding factor of success rate. Hybrid electric

vehicles(HEV) especially preferred for high speed

application ranging from 7000rpm to 16000rpm and

faster acceleration are favourable due difficulties of

batteries and current lack of an electric vehicles[27].

Design considerations divides permanent magnet

synchronous motor into various categories.

Fig.1 Axial Flux geometry[5]

II. CLASSIFICATION

On the basis of flux linkage two types of machines

are reported - radial flux PMSM and axial flux

PMSM shown Fig. 1 & 2 [5]. Two more types of

PMSM depending upon the rotor structure available

in the market are Line start interior permanent magnet

synchronous motor (LSIPMSM) and surface mounted

Permanent magnet synchronous motor (LSSPMSM)

[14]. This paper is devoted to

Fig.2 Radial Flux Geometry[5]

III. DESIGN CONSIDERATIONS

Out of the main parts of the motor the stator has not

reported much more variety. Two main stator

designs slotted and slotless are used in general these

days [5]. The slotted stator geometry has the

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

20

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

advantages of reduction in amount of PMs

needed[18]. The slotless type machine is not

recommended for traction applications because it is

subjected to number of stresses[20]

Volume-3, Issue-10, Oct.-2015

and predictions of computer based model shown in

fig. 3 & 4 [8] is less convincing .

The V curves produced by conducting no load

testing differ from calculated as presented in fig. 4[8]

The Geometry offers leakage flux reduction to large

extent even rotor slot leakage is totally eliminated

but only stator slot leakage and stator coil end

leakage remains[22].

A. Axial Flux Geometry :

The axial flux permanent magnet motor(AFPM) is a

better choice in some applications such as in wheel

motors of electric vehicles as compared to radial flux

machine[6]. The comparison of output parameters

presented in the table - I [7] validated the choice of

Axial flux motor of its in wheel motors in electric

vehicles. The axial flux disc motor proved to be

reliable and efficient in applications of low speed and

high torque

Table I: AFPM and RFPM in wheel motors[7]

Fig. 3 Torque vs stator current[8]

The skewing of permanent magnets has proved

fruitful in reducing cogging torque effect.[8]

An axial flux permanent magnet motors have disc

shaped stator and rotor cores with single rotor disc

sandwiched in two stator discs or single stator disc in

between two rotor discs. The flux crosses the air gap

axially and passes through the core in the

circumferential direction[8]. The m.m.f has the form

of quassi square wave. The advent of high field rare

earth permanent magnets has opened new doors for

novel

machine

topologies

with

improved

performance[18]. The AFPM motors can be an

alternative to conventional radial flux PM motors

particularly for low speed and high torque electrical

drives.

A number of configurations have been proposed[1019] . Such as internal rotor[13], internal stator[11],

multidisc type, slotted or slotless and rotors with

interior or surface mounted permanent magnets[6] are

also available. Various design parameters such as

outer diameter, inner diameter, inner to outer

diameter ratio, number of slots magnet pitch and

skewing affect the performance of the machine and

the careful choice of the values of these parameter is

the main justification of the suitability of an AFPM

motors[21]

The travelling wave modelling of AFPM motor with

slotted stator geometry and analysis

including

saturation in stator iron and effects of slot leakage

reveals that square flux wave in teeth produces a

triangular wave in the yoke which lead to higher flux

density in yoke(1.9wb/m2) as compared to

teeth(1.6wb/m2)[8]. The laboratory machine results

Fig.4 V Curves for Slotted stator AFPM motor[8]

Slotted stator axial flux geometry suffers from a

major drawback of under utilization of stator winding

due to end winding length [18]. The slotless axial flux

motors proved good interest in high performances

drives [10][11][23] and particularly designed

preferred for applications characterised by low speed

and high torque to weight ratio[12][24]. The slotless

axial flux machine

having two rotor discs

sandwiching one stator shown in fig.5[18] has

advantages of utilization of both working surfaces of

stator core as compared to conventional machine. The

stator has toroidal winding placed on iron strip[25].

The rotating rotor discs acting natural fans serving for

cooling and thereby lowering the working

temperature and permitting higher permissible

electric loading. The machine torque as presented by

equation (1) is function of outer diameter[18]

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

21

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

Where A is coefficient that depends upon thermal

and structural parameters and R0 is outer diameter of

machine that will be significant design parameter to

Volume-3, Issue-10, Oct.-2015

conductors are subjected to different conditions of

magnetic field along the radial length[25]. From the

electromagnetic considerations, the magnets side

edges should sweep the stator conductors during the

motion all along the height, this involves annular

sector shapes of permanent magnets. A typical three

phase 8-pole with one coil per pole per phase is

shown in fig.8[25]. The left part shows cut view of

stator and right shows one of the rotors The Z- axis

coincides with radial axis and active parts of

conductors parallel to r- axis.

Fig. 5 Two rotor discs sandwiching one stator[18]

obtain higher torque to weight ratio principally

applicable in electric vehicles. The variation of torque

at rated current and 50% loading with outer radius is

shown in fig. 6[18]

Fig.8 Radial variation of magnet pitch [ 25]

Radial sections of the conductors are not in same

electromagnetic conditions, the fact can be realized

from the flux lines for two sections inner and outer

radius[25]. The influence of radial variations of

magnet pitch on the torque value for converter fed

axial flux machine is shown in table-II[25].

The powder iron metallurgy core is used in axial flux

geometry

for minimizing the cogging torque

disturbance [26]. The 2D results of cogging torque

with

and without modified geometry without

considering edge factor of permanent magnets is

shown in fig. 9[26]

Fig.6 Variation of torque at full and half load with outer

radius [18]

There is another factor Kr, the ratio of inner to outer

radius of machine on which the machine dynamic

characteristics depends[24]. The choice of value of

Kr is used to maximise torque, torque to weight ratio

and efficiency. The variation of these performance

parameters with Kr

shown

in

fig.7[18]

Table II [ 25] Effect of radial variations of magnetic

pitch on torque[25]

fig.7 Variation of performance parameters with Kr[18]

Due to radial variation of magnet pitch in the slotless

permanent magnet axial flux motor, the active

Fig.9 Cogging torque with and without modified geometry [26]

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

22

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

Inspite of disadvantages of decrease in output torque,

the short pitched stator winding design has been used

to reduce both harmonic component and length of end

windings[27]. 150 magnet span and one slot pitch

skewing of magnet resulted in ripple free torque and

decrease in losses preferably in high speed

applications.

In stator core, M-4 grain oriented silicon steel is used

to reduce stator core losses. Moreover magnet

excitation is kept low around 0.73T and low flux

density in stator core about 1.2T is preferred. The

steinmetz equation given by (2) describes the specific

core loss in W/kg [28]

= 0.014492 . + 0.00004219

-----(2)

The difference in the measured and predicted stator

core losses are due to unepredected hystersis loss

caused by anisotropy of M-4 steel.

The eddy current loss is major component of total

rotor core losses. It has further divided into three

parts, no load eddy current loss due to the existence

of slots, on load eddy current loss caused by mmf

winding harmonics and on load eddy current losses

induced due the presence of time harmonics of supply

system in inverter fed motors[29]. The rotor losses

can be calculated from static FE solutions [30] using

the positional magnet flux density waveforms. The

concentrated windings produce large amount of

current linkage harmonics passing across the

permanent magnets causing large eddy currents. The

large slot opening causes flux density variations that

turn out eddy current losses in permanent

magnets[31]. The analytical methods [32][33] used to

calculate losses in radial flux permanent magnet

machine ignore the effect of slot opening whereas in

axial flux machines losses are estimated by taking

into account the slot opening using Heller and

Hamats equation [34]. The eddy current losses

evaluated using three method are no load method for

stator

slot

opening

losses

magneto

dynamic(unmagnetized magnets) method for losses

due to stator mmf space harmonics and load method

for both components simultaneously without

considering influence of skin effect and

saturation[29][31-41]. The effect of

sintered

segmentation is shown in fig.10 [31]

Volume-3, Issue-10, Oct.-2015

The relation used to estimate eddy current losses in

magnets using FEA [31] is given (3)

=

-------(3)

where

material resistivity V the volume and j

current density

The windage and frictional losses contribute the

major portion of total losses in high speed machines

and magnitude of these losses increases with speed as

shown in fig.11[27]. These losses are calculated by

the method recommended in[33].

Fig. 11 Windage and friction losses v/s speed[27].

The second problem in high speed machines is

significant mechanical vibrations and stresses

experienced by permanent magnets .These produced

by attractive forces

between rotor permanent

magnets and stator core and centrifugal forces. The

glue used for fixing permanent magnets in low speed

machines can withstand maximum force density

around 5N/mm2.[27].The testing upto 120oC showed

the impossibility of protection of permanent magnets.

The adhesive force of glue is increased by nickel

coating of the magnets and protection is provided by

placing fibre glass rim over rotor magnets. By doing

this the stress value is increased to 1G Pascal[27]

Thermal conductivity of NdFeB is relatively poor

(9W/mk)[31] which is problematic for surface

mounted magnet geometry because of large eddy

current losses in the permanent magnets. High power

loss density leads to fatal temperature rise and hence

demagnetization and lower the efficiency of sintered

NdFeB bulky permanent magnet machines. The

difficulty is shorted out by replacing sintered NdFeB

permanent magnet by plastic bonded magnets

operated above 1000C [37] but suffer at the same time

from smaller remnant flux density (0.65T) and

coercive force force(403KA/m) compared to sintered

NdFeB 1.05T and 800KA/m[36]. Also energy

product of plastic bonded magnets is lower (40-90

KJ/m3 ) whereas sintered NdFeB permanent magnets

have 190-380 KJ/m3 [29].This leads to increase in

size of machine and there by centrifugal forces.

B. Radial flux Geometry:

The line start permanent magnet motor combines the

features of both permanent magnet rotor for

synchronous motor operation and squirrel cage

induction motor during the asynchronous motor

operation and the machine has the ability to direct

line start therefore.[42].The proper volume ratio

Fig. 10 Effect of sintered segmentation[31]

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

23

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

between permanent magnets and squirrel cage is the

best response to the challenge of reduced construction

and running cost along with better performance[43].

Further

with elimination of magnetizing current

resulted into improvement of operating power factor

and reduction in stator windings losses[44]. Two

design of LSPMM recorded in the literature are

surface mounted permanent magnet machine and

interior permanent magnet machine shown in fig.12

a&b [45]. The challenge of high efficiency motoring

over the world has been responded by the LSPMM

which has boosted by the dramatic improvement in

the magnet properties of the permanent magnets used

and tone motor energy efficiency class globally [4647]. The possibility of high temperature operation

without demagnetizing of the PMs, the LSPMM

gained the popularity

Volume-3, Issue-10, Oct.-2015

asynchronous and synchronous operations. There

exists wide trade off between the two operations and

then techno- economic feasibility of the machine is

evaluated [53]. The various rotor structures based on

the permanent magnet arrangements [54-55] is shown

in the fig.13[1/4]

C. Interior Permanent Magnet structure:

The interior magnet design as shown in fig.12.a[45]

has embedded magnets [46-47]. This type of

configuration suffer less from demagnetization

problem. This design is also called convex design[50]

During asynchronous period from standstill to just

reaching synchronous speed , the accelerating torque

is the resultant of two torques- cage torque and

braking torque[51] given by the equations(4&5) [45]

Fig.13 Rotor topologies of IPM [54]

The results showing the comparative performance of

these six models simulated in Maxwell has been

demonstrated in table III & IV[54]. The radial

arrangement provided better output parameters

Table III Results of rotor topologies of IPM[54]

Fig.12 Interior Permanent Magnet Motor [45]

Table IV Results of rotor topologies of IPM[54]

During synchronous period the braking torque almost

reduced to zero value and the main torque is

alignment torque of permanent magnets and

reluctance torque produced due to the saliency factor

of rotor structure, both the torque are given by

equations(6&7)[52]

The IPM suffers from serious drawback of higher

leakage flux and thereby less air gap flux density.

But the cogging torque developed is less and

subjected to less vibrations so less noisy operation.

The synchronizing capability of IPM is better but it

hand has small synchronous loading capability[45]

Numerous rotor topologies of IPM are proposed in

literature in last about 30 years for improving both

The effect of shape of magnets using arc, rectangular

and parallelogram type of magnets has been

evaluated and observed that spoke arc magnet

combination is superior in comparison to

others[54].The proposed arrangement is shown in

fig.14[54] The prototype has drawn 13% lower full

load current and deliver 16% more output.

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

24

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

Volume-3, Issue-10, Oct.-2015

The comparison of various output parameters shown

in fig. 17[48] with radial bonded spoke type and new

geometry verifies the better performance of new

geometry

The new hybrid rotor geometry of permanent magnet

synchronous motor used both ferrite and bonded rare

earth magnets with the objective to increase air gap

flux density and thereby output power[63]. About

30% higher flux density is achieved as compared to

conventional circumferentially magnetized rotor for

same magnet volume. The effect of magnet size,

location and angle of inclination evaluated using

FEM and Maxwell. Best compromise between cost

and performance has been achieved

Super premium efficient line start up permanent

magnet synchronous motor design [64] shows

increased efficiency level with reduced size and

Fig.14 Spoke arc magnet shape [54]

Repeated five full load tests of duration 8 hours each,

shows no deterioration of the magnets. The little

decrease in open circuit voltage has been recovered

when machine resumed normal temperature[54]. The

model has better power factor, less rated current and

high energy saving prospective. Double layer magnet

arrangement in interior permanent magnet motor with

flux weakening control adopted to increase speed

range of motor [56].The arrangements Itype[57],

Vtype [58-59] and double layer [60-62]shown in

fig.15[56] are generally used to increase the

reluctance torque

Fig.15 Magnet arrangements inIPM[56]

The results clarified that type arrangement has wide

range of speed with high efficiency and maximum

torque at low speed due to lower Ld and high Lq is

acceptable[56].

The new rotor geometry in fig.16[48] has combined

advantages of conventional radial and circumferential

geometries. It shows a good potential of energy

saving and improvement in power factor.

Fig. 17 Synchronous performance of IPM a)Efficiency, b)

Power Factor, c) Torque and d) Line current Vs. Load angle

for 1. Radialy magnetized with bonded, 2 Radialy magnetized

with ferrite, 3 Spoke type with ferrite and 4. New geometry

with ferrite[48]

Fig.16 Combination of radial and circumferential

geometries[48]

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

25

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

weight. Three rotor configurations namely parallel

magnet path, series magnetic path and combined

magnetic path shown in fig. 18[64] have been

principally investigated with the help of FEA.

Comparison of results from table-VI[64]) verified the

improvement in design.

Volume-3, Issue-10, Oct.-2015

material used for reducing size and cost of the

machine has been analyzed. For instance, the axial

flux motor has developed high working torque,

higher torque to weight ratio for same number poles

and slots however these are not suitable for high

speed drives, on the other hand the radial flux

geometry

with surface mounted magnets has

advantages of high air gap flux density and high

synchronous loading capacity though it suffers from

large vibration and noisy operation Similarly interior

permanent magnet synchronous motor is less

subjected to cogging torque and demagnetizing

problem but has the weakness of low synchronous

capability and high leakage flux. The very little

efforts has been made to combine the features of two

or more machines in the literature. The hybrid model

using two types magnets yield better results in

comparison to conventional model. We are working

on the newly proposed model that will combine the

features of axial flux geometry as well as radial

geometry to improve the asynchronous and

synchronous loading capability of the machine. The

model mingle the feature of interior permanent

magnet motor and surface mounted geometry that

will yield better solution to cogging torque reduction.

The results of combining the features will certainly

give the birth to new generation of synchronous

motor

Table .VI Comparison of LSPMSM(IE4) and

IM(IE3)[64]

The magnets are mounted on the surface of the

rotor[65-66][45] . The geometry offers less leakage

flux and reluctance consequently air gap flux

density is high in comparison to IPM of same size

therefore delivers large output power. But regrettably

suffers from increased cogging torque more vibration

and noisy operation due to bigger reluctance forces

developed. The machine with surface mounted design

has smaller asynchronous loading capability but large

synchronous loading capability

REFERENCES

[1]

A.H. Isfahani and S.Vaez-Zadeh, Line start permanent

synchronous motors: Challenges and opportunities

Elsevier J. Energy, vol.34 no.11,pp1755-1763,Nov.2009

[2] W. H. Kim, K. C. Kim. D.W. Kang,S.C. Go,H.W. Lee,

Y.D. Chun and J. Lee A study on the rotor design of

LSPM considering starting torque and efficiency IEEE

Trans. Magn. vol.45 no. 3 pp. 1808-1811,Mar.2009

[3] Edouard Bomme et al Double air-gaps permanent

magnets synchronous motors analysis Proceedings of the

International Conference on Electrical Machines 2008, pp.

1-5.

[4] P.W. Huang et al Investigation of Line Start Permanent

Magnet Synchronous Motors with Interior-Magnet Rotors

and Surface-Magnet Rotors International Conference on

Electrical Machines and Systems (ICEMS) 2008, pp. 28882893.

[5] Duane C. Hanselmen Brusless permanent magnet motor

design M Graw Hill,Inc. pp. 106, 1995

[6] A. Parviainen, M. Niemela, and J. Pyrhonen, 2D Fem

and 3D Fem modelling of axial frux machine,

proceedings of 10th power electronics and application

conference, EPE 2003, Toulouse, sept. 2003

[7] C.Versle at el. Analytical Design of an Axial Flux

Permanent Magnet In-Wheel Synchronous Motor for

Electric VehiclePower electronics and applications,EPE2009 pp1-9

[8] D. Platt Permanent Magnet Synchronous Motor with

Axial Flux Geometry IEEE Transactions on Magnetics,

Vol. 25, No. 4, July 1989, pp. 3076-3079.

[9] F. Caricchi et. al. Design and Construction of a WheelDirectly-Coupled Axial-Flux PM Motor Prototype for EVs

Industry Applications Society Annual Meeting 1994, pp.

254-261.

[10] E. Spooner, B. J. Chalmers, "Toroidally-wound, axial-flux,

permanent-magnet brusless DC motors, Proceedings of

the International Conference on Electrical Machines, 1988,

vol. III, pp. 81-86

a) Rotor with parallel b) Rotor with series

magnet path

magnet path

c) Rotor with combined magnet path

Fig.18 Super premium deign of PMSM[64]

The various design strategies investigated have their

own advantages and disadvantages but hybridization

showed observable effect on the performance of the

PMSM

CONCLUSION

This paper has presented an overview of various

design strategies used in the design of permanent

magnet synchronous motor developed by the

researchers in the past and the effect of variation of

geometric parameters on the performance of the

motor. Categorization on the basis of flux linkage,

magnet positions, arrangements and type of magnetic

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

26

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

[11] T.A. Lipo, C. Jensen, F. Profumo, "A low loss permanent

magnet brushless D.C. motor utilising tape wound

amorphous iron". IEEE Trans. on Industry Applications,

vol. 28, pp:646651, 1992.

[12] F. Caricchi, F. Crescimbini, A. Di Napoli, O. Honorati,

T.A. Lipo,G. Noia, E. Santini, "Development of a IGBT

inverter driven axial-flux PM synchronous motor drive",

Proceedings of the 4th European Power Electronics

Conference; 1991; vol. 3, pp. 482-487

[13] F. Caricchi. F. Crescimbini, A. Di Napoli, E. Santini,

"Optimum CAD-CAE design of axial-flux PM motors",

Proceedings of the International Conference on Electrical

Machines, Manchester(U.K.), September 1992, vol. 2, pp.

637 - 641.

[14] E. Spooner, B.J. Chalmers, "TORUS - a slotless toroidal stator, permanent magnet generator", IEE Proceedings part B, 139, November 1992, pp. 497-506.

[15] O. Honorati, F. Caricchi, F. Crescimbini, G. Noia,

"Gearless wind energy conversion system using an axialflux PM synchronous machine", Proceedings of the

European Wind Energy Conference, 1991,vol. I, pp.814818.

[16] F. Caricchi, F. Crescimbini, 0. Honorati, E. Santini.

"Performance evaluation of an axial-flux PM generator",

Proceedings of the International Conference on Electrical

Machines, 1992, vol. 2, pp.761-765

[17] F. Caricchi, F. Crescimbini, 0. Honorati, R. Vivarelli,

"Prototype of a wind turbine directly-coupled axial-flux

PM generator", Proceedings of the European Wind Energy

Conference and Exhibition,1994

[18] F. Caricchi. F. Crescimbini, E. Fedeli, G. Noia, "Design

and construction of a wheel-directly-coupled axial-flux

PM motor prototype for EVs", Proceedings of the

IEEE/IAS Annual Meeting,1994,vol.1, pp.254-261.

[19] Z. Zhang, F. Profumo, and A. Tenconi. Axial flux wheel

machines for electric vehicles Electric Machines and

Power Systems, 1996 vol. 24, pp883896

[20] F. Profumo, Z. Zhang and A. Tenconi, Axial flux

machines drives: A new viable solution for electric cars,

IEEE Transactions on Industrial Electronics, vol. 44 no. 1,

Feb. 1997

[21] F. Sahin and A.J.A. Vandenput, Design considerations of

the flywheel mounted axial-flux permanent-magnet

machine for a hybrid electric vehicle EPE99, page CD,

September 1999.

[22] Alger, P.L. Induction Machines, Their Behaviour and

Uses Gordon and Breach, Science Publishers, New York,

Second Edition, 1970.

[23] E. Spooner, B. J. Chalmers, M. M. El-Missiry, WuWei, A.

C. Renfi-ew, "Motoring performance of the toroidal

permanent magnet machine Torus", Proc. IEE 5th

International Conference on Electrical Machines and

Drives, 1991, pp. 36 40

[24] A. Di Napoli, F. Caricchi, F. Crescimbini, G. Noia,

"Design Criteria of a Low-Speed Axial-Flux PM

Synchronous Machine'' - Proc. International Conference

on the Evolution and Modem Aspects of Synchronous

Machines, 1991, vol. 3, pp. 11 19 - 1124.

[25] F. Caricchi, F. Crescimbini, E. Santini, C. Santucci,

Influence of the Radial Variation of the Magnet Pitch in

Slotless Permanent Magnet Axial Flux Motors proc.

IEEE Industry Applications Society annual Meeting New

Orleans, Louisiana, October 5 - 9,1997 pp. 18-23 check

ieee vol

[26] Z.Zhang, F.Profumo and A.Tenconi Politecnico di Torino,

Analysis and experimental validation of performance for

axial flux permanent magnet brushless DC motor with

powder iron metallurgy cores IEEE transactions on

magnetic, sept.1997 vol. 33, no.5 pp. 4194-96

[27] F. Sahin, A. M. Tuckey, and A.J.A. Vandenput, Design,

development and testing of high speed axial flux

permanent magnet machine IEEE 2001 pp.1640-47

[28] C. Koechli and Y. Perriard, analytical model for slotless

permanent magnet axial flux motors IEEE 2013, pp. 78892

Volume-3, Issue-10, Oct.-2015

[29] P. Campell, Permanent magnet materials and applications

Cambridge university press,1994

[30] A.R.C. sekhar Babu, and K.R. Rajagopal, FE analysis of

multiphase doubly salient permanent magnet motors

IEEE transactions on magnetcis Oct. 2005, vol.41,no. 10

pp.3955-58

[31] H. Jussila, P. Salminen, A. Parviainen, J. Nerg and J.

Pyrhonen, Concentrated Winding Axial Flux Permanent

Magnet Motor with Plastic Bonded Magnets and Sintered

Segmented Magnets IEEE ,2008, pp. 1-5

[32] K. Atallah, D. Howe, P.H. Mellor and D.A. Stone,

Rotor loss in permanent magnets on brushless AC

machines IEEE Trans. Ind. App., Nov./Dec. 2000,vol.36,

no. 6, pp. 1612-1618

[33] H. Toda,Z. Xia, J. Wang, K. Atallah and D. Howe, Rotor

eddy current loss in permanent magnet

brushless

machines IEEE transaction on magnetic ,vol. 40, no. 4

July 2004

[34] J.D. Ede ,K. Atallah and G.W. Jewell, Effect of axial

segmentation of permanent magnets on the rotor loss in

modular permanent magnet brushless machines IEEE

transactions on industry applications.,Vol.43,no. 5, Sept./

Oct. 2007

[35] Z.Q. Zhu and D. Howe, Analytical predictions of air gap

field distribution in permanent magnet motors accounting

the effect of slotting In ISEF proc.,pp. 181-184, 1991

[36] Neorem magnets online available at www. Neorem.fi

[37] M. Kume \, M. Hayashi, M. Yamamoto, K. Kawamura and

K. Ihara Heat resistant plastic magnets, IEEE

transactions on magnetic, vol.41, no. 10,Oct.2005

[38] C. Deak, I. Petrovic, A. Binder, M. Mirzaei, D. Irimie,

and B. Funieru, Calculation of eddy current losses in

permanent magnets synchronous machines Prog. Of

SPEEDDAM 2008 Ischia Italy, CD ROM

[39] C. Deak, A. Binder and K. Magyari, Magnet loss

analysis of permanent magnet synchronous motors with

concentrated windings Prog. Of ICEM- 2006Chania

Creece, CD ROM

[40] J. Nerg, M. Niemela, J. Pyrhonen and J. Partanen, FEM

calculation of rotor losses in a medium speed direct torque

controlled permanent magnet synchronous motor at

different load conditionsIEEE transactions on magnetic,

vol. 38, no. 5,pp. 3255-57,Sept. 2002

[41] H. Polinder, and M. J. Hoieijmakers, Eddy current losses

in segmented surface mounted magnets of a permanent

magnet machine, IEEE proc. on electr. Power appl., vol.

146, no.46, pp. 261-266, May 1999

[42] Abdolmir Nekoubin, Design a line start synchronous

motor and analysis effect of the rotor structure on the

efficiency World academy of science, eng. and tech., vol.

5, pp. 5-9, Sept. 2011

[43] Chu, Ming Tsung et al, Rotor structure of line start

permanent magnet synchronous motor, U.S. patent no.

6844652, 2005

[44] M. Cistelecan, M. Popescu, V. nitigus, AC three phase

line start permanent magnet motor,Romanian patent RO

121623, Dec. 2007

[45] P.W. Huang et al Investigation of Line Start Permanent

Magnet Synchronous Motors with Interior-Magnet Rotors

and Surface-Magnet Rotors International Conference on

Electrical Machines and Systems (ICEMS) 2008, pp. 28882893

[46] Almeida, A. T.; Ferreira, F. J. T. E.; and Fong, J. A. C.,

Standards for efficiency of electric motors - Permanent

magnet synchronous motor technology, IEEE Ind. App.

Mag., vol.17, no.1, pp. 12-19, Jan. /Feb. 2011]

[47] X. Feng, Y. Bao, L. Liu, L. Huang and Y. Zhang,

Performance investigation and comparison of line startup permanent magnet synchronous motor with super

premium efficiency, in Proc. of XX, ICEM, 2012 Conf.,

pp. 424-429, Sep.2012.

[48] B.N. chaudhari,S. K. pillai and B.G. Fernandes, Energy

efficient line start permanent magnet synchronous motor,

IEEE Region 10 ICGC in energy, computer,

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

27

International Journal of Industrial Electronics and Electrical Engineering, ISSN: 2347-6982

[49]

[50]

[51]

[52]

[53]

[54]

[55]

[56]

communication control, New Delhi, vol. 2, pp. 379-382,

Dec. 1998

M. A. Rahman and A. M.Osheiba, Performance of

large line start permanent magnet synchronous motor,

IEEE trans. Energy conversion, vol.5, no. 1, pp. 211217,1990

S. Kim, J. K. Choi and J. Lee, Magnet shape optimization

for high performance single phase line start synchronous

motor, Journal of applied physics, vol. 93,pp. 8695-97,

May 2003.

M. Popescu, T. J. E. Miller, M. I. McGilp, G. Strappazzon,

N. Trivillin and R. Santarossa, Line start permanent

magnet motor: single phase starting performance analysis,

IEEE trans. on industrial appl. , vol.39, pp. 1021-30, July/

Aug. 2003

M. Popescu, T. J. E. Miller, , M. I. McGilp, G.

Strappazzon, N. Trivillin and R. Santarossa, C. Cossar,

Line start permanent magnet motor single phase steady

state performance analysis, IEEE trans. on industrial

application, vol. 40, pp. 516-525, March/April 200

Eike Richter, T. J. E. Miller, T. W. Neumann and T. L.

Hudson, The Ferrite Permanent Magnet AC Motor-A

Technical and Economical Assessment, IEEE Trans. on

Ind. Appl., vol.IA-21, no.4, pp.644-649, May/June 1985

R.T. Ugale et al A New Rotor Structure for Line Start

Permanent Magnet Synchronous Motor Electric

Machines & Drives Conference (IEMDC) 2013, pp. 14361442

R. T. Ugale, Gaurav Singh, S. Baka and B. N. Chaudhari,

Effwctive energy conservation for the agricultural sector

using line start permanent magnet synchronous motors

IEEE, 2009

Katsumi

Yamazaki

and

Kazuya

Kitayuguchi

Investigation of Magnet Arrangements in Double Layer

Interior Permanent-Magnet Motors Energy Conversion

Congress and Exposition (ECCE) 2010, pp. 1384-1391

Volume-3, Issue-10, Oct.-2015

[57] K. Yamazaki and Y. Seto, Iron loss analysis of interior

permanent magnet synchronous motors -Variation of main

loss factors due to driving condition, IEEE Trans. on Ind.

Appl., vol. 42, no. 4, pp. 1045-1052, 2006

[58] M. Kamiya, Development of traction drive motors for the

Toyota hybrid system, IEEJ Trans. on IA, vol. 126, no. 4,

pp. 473479, 2006

[59] K. C. Kim, J. Lee, H. J. Kim, and D. H. Koo,

Multiobjective optimal design for interior permanent

magnet synchronous motor, IEEE Trans. on Magn., vol.

45, no. 3, pp. 1780-1783, 2009.

[60] M. Sanada, K. Hiramoto, S. Morimoto, and Y. Takeda,

Torque ripple improvement for synchronous reluctance

motor using an asymmetric flux barrier arrangement,

IEEE Trans. on Ind. Appl., vol. 40, pp.10761082, 2004.

[61] S. H. Han, T. M. Jahns, and Z. Q. Zhu, Analysis of rotor

core eddy current losses in interior permanent magnet

synchronous machines, IEEE Trans. on Ind. Appl., vol.

46, no. 1, pp. 196-205, 2010.

[62] K. C. Kim, J. Lee, H. J. Kim, and D. H. Koo,

Demagnetization analysis of permanent magnets

according to rotor types of interior permanent magnet

synchronous motor, IEEE Trans. on Magn., vol. 45, no. 3,

pp. 2799-2802, 2009.

[63] B.N. Chaudhari, B.G. Fernandes and S.K. Pillai A New

Hybrid Rotor Geometry for Permanent Magnet

Synchronous Motor International conference on Power

Electronic

Drives and Energy

Systems for Industrial

Growth, Vol. 1, 1998, pp. 260-263

[64] X. Feng et al, Super Premium Efficient Line Start-up

Permanent Magnet Synchronous Motor XIX International

Conference on Electrical Machines - ICEM 2010, pp. 1-6.

[65] J. H. Boyd, Line start permanent magnet motor,U.S.

patent5952757, Sept.1999

[66] G. B. Kliman, M. A. Preston and D. W. Jones, Permanent

magnet line start motor having magnets outside the stator

cage, U.S. patent 5548172, Aug. 1996.

Review Of Design And Performance Of Permanent Magnet Synchronous Motor

28

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Am DSBFC Systems (By Larry E. Gugle K4rfe)Document9 pagesAm DSBFC Systems (By Larry E. Gugle K4rfe)rascalangelNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Single Event Effects Radiation Test ReportDocument15 pagesSingle Event Effects Radiation Test ReportRahul SushruthNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- LED Thin PAR64 User ManualDocument10 pagesLED Thin PAR64 User ManualAndy P ParsonsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- TIC106DDocument1 pageTIC106DMauricio BurgosNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RADWIN System DescriptionDocument28 pagesRADWIN System Descriptiontho2007100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- TROUBLESHOOTING AIR CONDITIONER ERRORSDocument11 pagesTROUBLESHOOTING AIR CONDITIONER ERRORSMuhamad PriyatnaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Battery Reading ProfarmaDocument1 pageBattery Reading Profarma220KVISPR2 SANGJANINo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Assignment - 4Document2 pagesAssignment - 4Hardeep SinghNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- SA100 V 14 BulletinDocument8 pagesSA100 V 14 BulletinTeepoonsab somsaiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Linear ElectronicsDocument4 pagesLinear ElectronicsGreesh MaheshwariNo ratings yet

- SENZIT USER GUIDE INSTALLATIONDocument6 pagesSENZIT USER GUIDE INSTALLATIONDaniel AyalaNo ratings yet

- Aim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpDocument8 pagesAim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpAvinash Nandakumar100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Chapter 2Document16 pagesChapter 2irvan1173No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

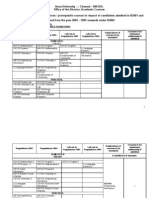

- Anna University: : Chennai - 600 025. Office ofDocument8 pagesAnna University: : Chennai - 600 025. Office ofafzalbaigsa100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Cbse Electrostatics and Current ElectricityDocument6 pagesCbse Electrostatics and Current ElectricityHimanshu KatwalNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- York Packaged Unit China (CM Brochure Ummhzcan Cooling Rooftop)Document49 pagesYork Packaged Unit China (CM Brochure Ummhzcan Cooling Rooftop)Augustine Dharmaraj100% (1)

- Atmega644Pa: 8-Bit Avr MicrocontrollersDocument16 pagesAtmega644Pa: 8-Bit Avr MicrocontrollersAngel Luciano Ramon GomezNo ratings yet

- 11 PurchaseOrder FormDocument2 pages11 PurchaseOrder FormJocelyn Nacion OrogoNo ratings yet

- Philips+Chassis+TPM18 6LDocument90 pagesPhilips+Chassis+TPM18 6LJackson FerreiraNo ratings yet

- Carrier PARTS 4 2010Document16 pagesCarrier PARTS 4 2010ricodavidNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MPPT Algorithm PDFDocument8 pagesMPPT Algorithm PDFakilaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Humidity & Temperature Datalogger: Model RHT20Document5 pagesHumidity & Temperature Datalogger: Model RHT20Calibration Abu DhabiNo ratings yet

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocument4 pagesForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjNo ratings yet

- 2014 Winter Model Answer PaperDocument25 pages2014 Winter Model Answer Papernavneet100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- S6 Sub Maths SBDocument186 pagesS6 Sub Maths SBFlorence UfituweNo ratings yet

- Altec Lansing ADA105Document7 pagesAltec Lansing ADA105Ciara Mae Waldron100% (1)

- Jabra A120s User ManualDocument51 pagesJabra A120s User Manualapi-26157899No ratings yet

- 2VAA000720R0001 A en S Control Harmony Bridge Controller With Ethernet (BRC-410) User ManualDocument95 pages2VAA000720R0001 A en S Control Harmony Bridge Controller With Ethernet (BRC-410) User ManualanbarasanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- CapacitorsDocument10 pagesCapacitorsrsrtnj100% (1)

- Arteche Mu HV Ug User+Manual enDocument17 pagesArteche Mu HV Ug User+Manual enPrime useNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)