Professional Documents

Culture Documents

F:M and F:V

Uploaded by

sirilakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F:M and F:V

Uploaded by

sirilakCopyright:

Available Formats

12/24/2015

Online MBR Info

Like

Search

Share 126 people like this. Sign Up to see what your friends like.

Processdesign

F/M and F/V

Organic loading rate is an important design and controlling parameter in biological wastewater treatment process. It is

measured by the amount of food provided to a unit amount of biomass (or reactor volume) for a unit period of time. Food-tomicroorganisms (F/M) ratio is based on the amount of biomass while Food-to-volume (F/V) ratio is based on reactor volume.

The F/M and the F/V are calculated using the following equations.

-----------------------------------(1)

Historical Lesson

Flux & membrane area

-----------------------------------(2)

Pretreatment

where

Organic loading (F/M)

OUR/SOUR

= food-to-microorganism ratio (g BOD/g MVLSS/day)

HRT/SRT

=food-to-volumeratio(gBOD/gMLVSS/day)

Biosolids yield

Oxygen demand

= influent flow rate (m3/day)

Specific Air Demand

Design - Spread Sheet

= influent BOD (mg/L)

Design - IWA model

= MLSS in aeration tank (mg/L)

CSTR vs Plug Flow

Blower system

= tank volume (m3)

Air scouring system

Peak flow handling

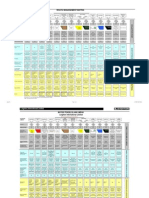

Four different F/M ratio exist depending on the unit used for food and microorganisms.

Energy optimization

OTE

Theory

Factors affecting OTE

- Pore size and air flow

- Diffuser fouling

- MLSS and viscosity

- SRT and F/M

- Foaming

- Others

OTE measurement

- Non-steady state

absorption method

- Non-steady state

desorption method

- Steady state method

Those four are inter-convertible using

the ratio of COD/BOD and MLVSS/MLSS as shown in Table 1, where COD/BOD and MLVSS/MLSS were assumed at 2.0

and 0.8, respectively, for municipal wastewater.

Typically MBR runs at lower F/M ratio than conventional activated sludge (CAS) process in order to mitigate membrane

fouling and maintain high oxygen transfer efficiency. The preferred F/M ratio range in MBR is approximately a third to a half

of that in CAS, i.e. 0.05-0.15 g BOD/g MVLSS/day or 0.1-0.3 g COD/g MLVSS/day in municipal MBR.

It is noticeable that nitrogen is not taken into consideration when F/M and F/V are calculated, but it contributes to the oxygen

demand significantly. One example for municipal wastewater here shows the oxygen demand for COD removal approximately

equals to that for nitrogen oxidation (nitrification) before considering the oxygen recovery (or credit) from denitrification.

Table. 1. Comparison of preferred ranges of operating parameters in MBR and CAS

Design

Unit

MBR

CAS

Parameter

g BOD/g MLSS/day

0.04-0.12

0.16-0.24

Membrane

g COD/g MLSS/day

0.08-0.24

0.32-0.48

Longevity

1),

2)

g

BOD/g

MLVSS/day

0.2-0.3

F/M

0.05-0.15

-Manufacturer'sdata

3)

g COD/g MLVSS/day

0.4-0.6

0.1-0.30

-Thirdparty'sdata

g BOD/L/day

0.5-1.5

0.6-0.9

-Influencingfactors

F/V

g COD/L/day

1.0-3.0

1.2-1.8

1)

Traceorganics

MLSS

g/L

2-4

8-12

-Removalmechanism

MLVSS

g/L

6-10

1.7-3.4

-Removalefficiency

SRT

days

10-30

5-10

-ComparisonwithCAS

4)

mg

O

/g

MVLSS/hr

SOUR

6-12

2

2-5

mg

O

/L/hr

OUR

15-50

20-40

Oilywastewater

2

-Pretreatment

DO

mg/L

1-2

1-2

-Producedwater

1) Judd, 2006

-Refinerywastewater

2) Brepols, 2010

3) Converted from the BOD based F/M assuming COD/BOD=2.0 for municipal wastewater

Practicalissues

4) Ng,2006

Reference

2011 by S. Yoon. All rights reserved.

http://www.onlinembr.info/MBR%20Design/Organic%20loading.htm

1/1

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Cost Estimating Manual For Water Treatment FacilitiesDocument197 pagesCost Estimating Manual For Water Treatment FacilitiesSiddhu 2092100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Water Sensitive Urban Design GuidelineDocument42 pagesWater Sensitive Urban Design GuidelineTri Wahyuningsih100% (1)

- Waste Water Treatment 2014Document81 pagesWaste Water Treatment 2014ankur neogNo ratings yet

- Corn Processing Investment Feasibility PDFDocument4 pagesCorn Processing Investment Feasibility PDFfekremariam Ambaw100% (1)

- Refining Water Best PracticesDocument60 pagesRefining Water Best Practicesarini_aristia_sNo ratings yet

- STP Presentation - SBRDocument51 pagesSTP Presentation - SBRNoriel Luna100% (1)

- Waste Management MatrixDocument2 pagesWaste Management Matrixttdost100% (2)

- Aeration Solutions Comparison Chart - VlightDocument2 pagesAeration Solutions Comparison Chart - VlightprannoyNo ratings yet

- Chapter 1 Basic Design ConsiderationDocument38 pagesChapter 1 Basic Design ConsiderationAce ThunderNo ratings yet

- BLD 207 Building Services Final CombinedDocument169 pagesBLD 207 Building Services Final CombinedVietHungCao100% (7)

- 6280Document13 pages6280sanbarunNo ratings yet

- Biology ProjectDocument20 pagesBiology ProjectRohith SivakumarNo ratings yet

- Attachment at BataDocument33 pagesAttachment at BataJoseph Njuguna Kamau67% (3)

- EVS Project Report - GROUP 1Document29 pagesEVS Project Report - GROUP 1Aparna HNo ratings yet

- Rajiv Gandhi Govt Polytechnic, Itanagar A.P.: Sewerage System in Hilly RegionDocument32 pagesRajiv Gandhi Govt Polytechnic, Itanagar A.P.: Sewerage System in Hilly RegionNobin MichiNo ratings yet

- Impacts On Water Environment: Prediction and Assessment ofDocument32 pagesImpacts On Water Environment: Prediction and Assessment ofDhruv YadavNo ratings yet

- Module 5Document59 pagesModule 5Joanne Michelle B. DueroNo ratings yet

- Non Clogging PumpsDocument15 pagesNon Clogging PumpsSouvik SingharoyNo ratings yet

- The City of Calgary - Wastewater Treatment Online TourDocument4 pagesThe City of Calgary - Wastewater Treatment Online TourMagdiel ScherokiNo ratings yet

- Pre-Treatment of Hospital Wastewater by Coagulation-Flocculation and FlotationDocument9 pagesPre-Treatment of Hospital Wastewater by Coagulation-Flocculation and FlotationzizitroNo ratings yet

- Siemens Aeration Competence CenterDocument41 pagesSiemens Aeration Competence Centeryassine moujbaniNo ratings yet

- Shipboard Sewage Management Plan - Declared ShipsDocument2 pagesShipboard Sewage Management Plan - Declared ShipsparthasarathipkNo ratings yet

- SMR Manolo 1ST Quarter 2023 4Document19 pagesSMR Manolo 1ST Quarter 2023 42ry4mnp9rnNo ratings yet

- India Waste Water Treatment and Management IndustryDocument10 pagesIndia Waste Water Treatment and Management IndustryhikonariNo ratings yet

- Operation of Municipal Wastewater Treatment Plants WEF Manual of Practice No. 11 Sixth EditionDocument17 pagesOperation of Municipal Wastewater Treatment Plants WEF Manual of Practice No. 11 Sixth EditionLorenzo ValentonNo ratings yet

- Sewage Plant and IncinerationDocument19 pagesSewage Plant and IncinerationCarls EstefanNo ratings yet

- DPCC Guidelines HotelsDocument3 pagesDPCC Guidelines Hotelsjohntylee1969No ratings yet

- Ranked: With BestDocument76 pagesRanked: With BestTreatment Plant Operator MagazineNo ratings yet

- Microorganisms NotesDocument3 pagesMicroorganisms NotesjoshiNo ratings yet

- Tim Hieu Qua Trinh Loc Tach Dau KhiDocument838 pagesTim Hieu Qua Trinh Loc Tach Dau KhiNem Chua RánNo ratings yet