Professional Documents

Culture Documents

Tuercas Disc Lock

Uploaded by

edwiariasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tuercas Disc Lock

Uploaded by

edwiariasCopyright:

Available Formats

THE WORLDS

SAFEST WHEEL NUT

THE DISC-LOCK

SAFETY WHEEL NUT

with NEW environmentally friendly, anti-corrosion coating

I N T E R N A T I O N A L

Vehicle Safety Invention Award

www.disc-lock.com

Disc-Lock Safety Wheel Nut

The vibration and shock-proof

wheel nut for trucks, trailers and buses

which eliminates the risk of wheel loss.*

*As confirmed by MIRA Tests (see back page)

The Disc-Lock Safety Wheel Nut:

maintains wheels on axles

is approved by vehicle and axle

manufacturers

is fitted by major fleet operators

worldwide

is as simple to install as a standard

two-piece wheel nut

What is the Disc-Lock Safety Wheel Nut?

The Disc-Lock Safety Wheel Nut is specifically designed to prevent wheel loss from commercial vehicles such as trucks, trailers

and buses. Disc-Lock Safety Wheel Nuts have proven to be far

superior in terms of safety than standard two-piece wheel nuts.

The combination of lateral, bending forces on the road-wheels

due to cornering, and torsional forces due to braking and acceleration which result in settling and looseness of normal bolted

assemblies cause Disc-Lock Safety Wheel Nuts to maintain the

clamping force and to lock. thus keeping the wheels secure on

the axle.

How does the Disc-Lock Safety Wheel Nut work?

1

Unlike a standard two-piece wheel nut, the Disc-Lock

Safety Wheel Nut is split into three sections, comprising

a nut (1), a hexagon-flanged washer (2) and a flat faced

cup washer (3). These sections are joined together to

form a one-piece assembly with a C-clip.

The top two sections (1 & 2) have interlocking cams.

When subjected to road shock or vibration, the most

common causes of wheel nut loosening, the interlocking cams of the Disc-Lock Safety Wheel Nut attempt to

rise against each other.

DL

The angle of the cam (DL) is greater than the pitch

angle of the thread on the stud (T).

DL>T

As the angle of the cam is greater than the pitch

angle of the thread on the stud, a wedging action

takes place and the Disc-Lock Safety Wheel Nut

locks and will not come loose, thus maintaining

the clamp load and keeping the wheel on the axle.

New features for 2006

Disc-Lock is always working hard to find ways in

which to improve its products. Main new features of

this latest version of the Disc-Lock Safety Wheel

Nut are:

Indestructible - The nut has been strengthened considerably to overcome the problems

caused by impact wrench abuse. Though, it

should be noted, that while the Disc-Lock

Safety Wheel Nut can now withstand such

abuse, the same cannot be said of the stud.

This could experience untold damage, in particular stretching of the stud, if the wheel nut is

severely over torqued.

Better socket engagement - The height of

the middle hexagon-flanged washer (see section 2 in diagram on left) has been increased to

give better socket engagement.

New, environmentally-friendly coating GEOMET. The Disc-Lock Safety Wheel Nut

is now coated with a new, environmentallyfriendly, anti-corrosion protection, GEOMET,

which is chrome free, ensuring it is compliant

with European Union Directive 2002/95/EC

(Restriction of Hazardous Substances). This

new coating has passed a 720 hours salt spray

test.

www.disc-lock.com

The patented Disc-Lock system is approved by vehicle and axle

manufacturers throughout the world and the Disc-Lock Safety

Wheel Nut is installed by many truck and bus fleets worldwide who

recognize the Nut as an essential safety device.

What the experts say: The Disc-Lock nut should be encouraged and publicized because practical experience shows that it

does make a major contribution to road safety and it is the most

significant improvement to wheel security for years.

Eur Ing Don H Wright, Bsc (Eng), CEng, FI MechE.

All of the vehicles pictured here

have Disc-Lock Safety Wheel Nuts installed on their wheels.

Disc-Lock Safety Wheel Nut Dimensional Chart

SIZE & THREAD

WIDTH ACROSS THE FLATS HEIGHT

FLANGE DIAMETER

M18 x 1.5

34.0mm

29.0mm

47.5mm

M20 x 1.5

34.0mm

29.0mm

47.5mm

M20 x 2.5

34.0mm

29.0mm

47.5mm

M22 x 1.5

38.0mm

34.0mm

52.0mm

3/4 - 16UNF

1.340

1.140

1.880

7/8 - 14UNF

1.500

1.320

2.000

How to install & remove the Disc-Lock Safety Wheel Nut

The Disc-Lock Safety Wheel Nut is easy to install and remove. Indeed, it is

installed in exactly the same way as a standard two-piece wheel nut.

To install or remove, simply place the socket over the hexagon nut and

hexagon flanged washer and tighten or loosen.

Refer to axle manufacturers instructions for torque settings.

A detailed installation instruction leaflet and workshop poster is available on request to Disc-Lock International, tel 310/944-9352 or email

info@disc-lock.com.

Disc-Lock Safety Wheel Nuts keep wheels secure if maintained and installed correctly.

To install or remove

push socket on to

fully cover both

hexes of nut

Disc-Lock Safety Wheel Nut On Test

MIRA Test

In December 2004 the Disc-Lock Safety Wheel

Nut underwent a severe performance test at the

Motor Industrial Research Association (MIRA)

Proving Ground in Nuneaton, Warwickshire, UK.

A fully-laden semi-trailer/tractor-unit combination (weight 35 ton)

was fitted with Disc-Lock Safety Wheel Nuts on the nearside and

standard two-piece wheel nuts on the offside.

Over a two-day period the vehicle was driven around a figure-of-eight

track to apply lateral bending movements to the wheels. In addition,

repeated forward and rearward emergency braking was undertaken

to induce torsional slipping forces to the wheels. At the completion of

each cycle of thirty minutes a torque check was undertaken.

Actual truck and trailer used for the MIRA Test.

These checks revealed no loss of torque on any of the Disc-Lock Safety Wheel Nuts at any

stage. The same could not be said of the standard two-piece wheel nuts, a staggering 50% of

which had come loose by the end of the test.

To obtain a detailed copy of this MIRA Test report call Disc-Lock International at 310/944-9352 or e-mail info@disc-lock.com

Junker Vibration Test

Disc-Lock Safety Wheel Nuts are tested on a Junker Vibration Test machine

which is named after its German designer Gerhard Junker. Junkers theories are

based in part on the so-called longform torque equation relating the

torque applied to a fastener to the frictional and elastic reactions to that

DISC-LOCK

INTERNATIONAL

torque. The Junker Test machine works

as follows: an eccentric cam generates

a controllable amount of transverse displacement on the joint under test. A load cell measures the

actual transverse forces exerted on the joint. One can determine the relationship between residual preload in the fastener

under test and external vibratory forces created by the test

machine as a function of time.

50,000

40,000

30,000

20,000

10,000

0

15

30

When tested against a standard two-piece wheel nut on a Junker Test machine

the Disc-Lock Safety Wheel Nut remains secure under the most severe vibration

conditions while the standard two-piece wheel nut comes completely loose.

45

60

90

105

7/8 x 11 BSF, 450 lbf.ft (610 Nm)

7/8 x 11 BSF, 450 lbf.ft (610 Nm)

Disc-Lock Nut, 515 lbf.ft (698 Nm)

Disc-Lock Nut, 450 lbf.ft (610 Nm)

For further information and prices contact Disc-Lock International

6101 W. Centinela Avenue, Suite 280, Culver City, CA 90230, USA

Tel: 310/944-9352 Fax: 310/944 9522 Email: info@disc-lock.com

www.disc-lock.com

75

120

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordDocument2 pagesView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaNo ratings yet

- Sem 638 Manual de MantenimientoDocument12 pagesSem 638 Manual de MantenimientoJhon Simanca100% (1)

- As 2812-2005 Welding Brazing and Cutting of Metals - Glossary of TermsDocument6 pagesAs 2812-2005 Welding Brazing and Cutting of Metals - Glossary of TermsSAI Global - APAC0% (1)

- ECSS E ST 50 03C (31july2008)Document43 pagesECSS E ST 50 03C (31july2008)jsadachiNo ratings yet

- DuvalTriangles1 7-29mar2016Document68 pagesDuvalTriangles1 7-29mar2016Jorgo BelloNo ratings yet

- ERJ 145 InfoDocument11 pagesERJ 145 InfoMarcus100% (1)

- 800ma Low Dropout Positive Regulator: Features DescriptionDocument12 pages800ma Low Dropout Positive Regulator: Features DescriptionmarcianocalviNo ratings yet

- Nessus 6.3 Installation GuideDocument109 pagesNessus 6.3 Installation GuideminardmiNo ratings yet

- Trial On CompresorDocument3 pagesTrial On CompresorA JNo ratings yet

- Kumbh Mela 2019 Presentation Mela AuthorityDocument35 pagesKumbh Mela 2019 Presentation Mela AuthorityBanibrataChoudhuryNo ratings yet

- Different Types of Steering Systems + ExamplesDocument0 pagesDifferent Types of Steering Systems + ExamplesAbhilash NagavarapuNo ratings yet

- Voltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFDocument58 pagesVoltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFHoward KnopfNo ratings yet

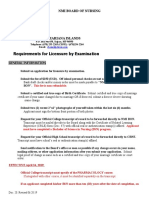

- 20 and 21. Requirements For Licensure by Examination Nclex. Revised 06.20.19 1Document2 pages20 and 21. Requirements For Licensure by Examination Nclex. Revised 06.20.19 1Glennah Marie Avenido RamosNo ratings yet

- TCE BE EEE RulesandRegulationsDocument509 pagesTCE BE EEE RulesandRegulationsAplieNo ratings yet

- A Modified Vince Gingery PlasticDocument13 pagesA Modified Vince Gingery PlasticgeppaNo ratings yet

- HL780 9SDocument583 pagesHL780 9SAnonymous yjK3peI7100% (3)

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocument1 pageDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobNo ratings yet

- Harga Jual Genset Deutz GermanyDocument2 pagesHarga Jual Genset Deutz GermanyAgung SetiawanNo ratings yet

- Mmro C 053 MD 0357 Interior PL DrawingsDocument82 pagesMmro C 053 MD 0357 Interior PL DrawingsAnonymous 4Ts8UBFwzNo ratings yet

- Photometric Design White PaperDocument5 pagesPhotometric Design White PaperScott VokeyNo ratings yet

- Operator'S Manual: E-Series Ultraviolet Hand LampsDocument9 pagesOperator'S Manual: E-Series Ultraviolet Hand LampsGuiss LemaNo ratings yet

- 6802988C45 ADocument26 pages6802988C45 AJose Luis Pardo FigueroaNo ratings yet

- PL54 PeugeotDocument3 pagesPL54 Peugeotbump4uNo ratings yet

- 2008 Signs of The Times and Screen Printing EngDocument12 pages2008 Signs of The Times and Screen Printing Engdeep431No ratings yet

- Java Lang OutOfMemoryError Handbook - PlumbrDocument28 pagesJava Lang OutOfMemoryError Handbook - PlumbrcuonglunNo ratings yet

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocument8 pagesScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityAnonymous Mdw6y7Q1No ratings yet

- BC-5000&BC-5150 - Service Training Material - V1.0 - EN (REV)Document137 pagesBC-5000&BC-5150 - Service Training Material - V1.0 - EN (REV)iisputNo ratings yet

- Summary of Change ASME 2021Document8 pagesSummary of Change ASME 2021Asep DarojatNo ratings yet

- Brochure A35g A40g t4f en 22 20050840 DDocument20 pagesBrochure A35g A40g t4f en 22 20050840 DRengga PratamaNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet