Professional Documents

Culture Documents

Workshop Inspection Checklist January 2012

Uploaded by

Sundara MoorthyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop Inspection Checklist January 2012

Uploaded by

Sundara MoorthyCopyright:

Available Formats

How to use this workshop

inspection checklist

Use this checklist to inspect engineering

workshops used for research, teaching

or maintenance, and any associated

storage areas.

Include associated

corridors, stairs and communal areas

such as toilets and kitchenettes/tea

rooms.

Inspections should be carried out at

least twice per year and preferably once

per term. Inspections should be done

when workshops are occupied by staf

and students, to get a true picture of

conditions and practices.

Consider getting a team together to help

you. The team should be limited to four

people and could include specialist staf

in electrical, laser or radiation hazards if

needed.

Carry out inspections in manageable

chunks. If you have a large workshop

area to inspect, divide it into diferent

areas, e.g. welding bay, paint spraying,

woodworking

machinery,

stores.

Otherwise, use one checklist per

workshop and record details of faults or

weaknesses.

found,

report

to

your Head

of School or

Office,

together

with

your

comments

and

recommend

ations

for

action.

Keep a copy

of

each

completed

inspection

checklist

and record

action taken

to

correct

the

faults

you

have

reported.

Work

When you have carried out an inspection

and recorded any faults or weaknesses

safetyunit@gre.ac.uk

January 2012

Page 1 of 13

WORKSHOP INSPECTION CHECKLIST

The answer to all these questions should be yes. If no you should note the location and brief details and investigate the

problem further to identify actions.

Areas

inspected

Inspected

by

Date

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Space and Layout

Is there enough space to move around safely?

(minimum of 11 cubic metres per person)

Is there enough space for storage of materials &

equipment? (on shelves, cupboards, benches)

Is there enough clear bench space to use

materials & equipment safely?

Are unauthorised people excluded from the

workshop?

Housekeeping

Are floors in a safe condition?

(no cracks, slippery or uneven patches etc)

Are floors free of boxes, swarf, of-cuts & other

trip hazards?

Are surfaces clean?

(including benches, shelves, equipment)

Are there separate waste bins for :

general waste?

wood dust?

sharp waste?)

(e.g. glass, swarf, metal)

Are bins emptied often enough?

Ventilation

Is there enough fresh air, without draughts?

Is local exhaust ventilation (LEV) provided to

remove fumes & dust? (e.g. wood dust, welding

or solder fumes)

-1-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Are ventilation systems tested annually?

(including fume cupboards & fume hoods)

Environment

Is the room temperature comfortable? (at least

16C)

Are windows in clean and safe condition?

Are blinds fitted to reduce glare or temperature?

Is lighting adequate in all areas?

(in working order, clean and free of flicker or

glare)

Is extra lighting provided for close work where

needed?

Manual Handling

Are stepladders or footstools used to reach high

shelves?

Are heavy & awkward items stored at waist

height where possible?

Are lifting aids available for moving heavy or

large loads? (manual handling assessments

needed for handling heavy or awkward loads)

Toilet and Handwashing Facilities

Are handwashing & drying facilities available in

the workshop?

Are there enough toilets for men & women

within reasonable distance?

Are toilets & washbasins clean & in working

order?

Are hot and cold (or warm) running water, soap

and towels (or other cleaning hand/drying

facilities) provided in the toilets?

Kitchenettes/Tea Rooms

Are staf & students warned & supervised to

ensure there is no eating, drinking or smoking in

the workshop?

Are rest & eating facilities provided outside the

workshop?

Are floor and surfaces clean and tidy?

-2-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Is drinking water available?

Are power points & cables a safe distance from

wet areas?

Are microwave oven door seals clean &

undamaged?

Is the fridge clean & defrosted?

Is a fire blanket provided where electric cookers

are used?

Fire - contact Campus Facilities Manager if problems with fire doors, extinguishers or notices

Are flammable substances used and stored

safely?

Are fire exits and escape routes free of

obstructions?

Are fire doors clearly marked and kept closed?

Do fire door closing mechanisms operate

properly?

Are vision panels in doors unobstructed?

Are fire extinguishers provided and tested

annually? (check last test date on label)

Are up to date fire action notices displayed in

offices or corridors? (what to do in event of fire

& fire assembly points)

Have fire wardens been appointed and trained

for this area?

Can fire alarms be heard in all areas?

Are smoking rules followed?

Is spark proof equipment used if necessary?

People With Disabilities

Is there access for people with impaired

mobility?

(e.g. wheelchair users)

Is there access to disabled toilets within

reasonable distance?

Do emergency evacuation procedures include

people with disabilities? (eg those who have

impaired mobility, or cant hear fire alarms or

see fire exits)

Are there up-to-date Personal Emergency

-3-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Evacuation Plans (PEEPS) for individual staf and

students, if necessary?

First Aid - contact occupational health service if problems regarding first aid

Are up to date posters displayed with names &

locations of trained first aiders?

Are first aid boxes clearly marked & kept fully

stocked?

Do staf and students know how to obtain blank

copies of the Accident Report Form at all times?

(download from H&S pages

http://www.gre.ac.uk/policy/safety/policy/arr)

Hazardous Substances

Are up to date hazardous substances risk

assessments available in the workshop, for work

in progress?

(COSHH assessments needed for chemicals with

hazard warning labels on container)

Are suitable warning signs in place:

in the workshop?

at the entrance to the workshop?

on containers and equipment?

Are all containers correctly labelled?

(name of chemical; hazard warnings)

Are incompatible chemicals segregated?

Are corrosive or flammable chemical containers

kept in spillage trays?

Are suitable containers used for temporary

storage?

Are guards provided to protect against splashes?

Is cutting oil & coolant regularly changed,

according to manufacturers instructions?

Personal Protective Equipment (PPE)

Is protective clothing worn properly & in good

condition?

Is suitable eye protection worn if needed?

(e.g. face shield; goggles; safety glasses)

Are suitable gloves worn if needed?

(against sharp objects, chemicals, heat or

-4-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

sparks etc)

Is respiratory protection suitable & worn if

needed?

(e.g. respirators; air-fed helmets)

Is all PPE stored in a clean, uncontaminated

area?

Is suitable PPE available for emergency use?

(e.g. chemical spillages or radioactive

contamination)

Furniture and Fittings

Are furniture & fittings in good condition?

(e.g. chairs, desks, shelving etc.)

Machine Guarding

Dangerous parts of machinery can cause

serious injuries:

rotating parts can entangle hair or clothing

machine parts which move together or to a

fixed point can cause crushing injuries

parts which move past one another can

cause shearing injuries

people can be struck by moving parts on a

machine

sharp edges can lead to cuts or severing

injuries

operators can be injured by material being

ejected from the machinery

parts of the body can be drawn into, or

become trapped, between running parts in

rollers, belts and pulley drives

stabbing injuries or skin punctures can be

caused by sharply pointed parts

friction injuries and abrasions can arise from

the operator coming into contact with rough

surfaces on the machine

if a machine becomes very hot it can lead to

burns or scalds

Do machine guards prevent these injuries?

-5-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Are guards always used?

Are guards fixed e.g. by screws or nuts and

bolts?

If fixed guards impracticable, are guards

interlocked, so that the machine cannot start

before the guard is closed & cannot be opened

while the machine is moving?

Where guards cannot give full protection, are

work holders, jigs or push sticks used?

Are computer-controlled machines also properly

guarded?

Do guards allow for safe cleaning &

maintenance of the machine?

Do all machine users & maintenance staf know

that guards must be used and how to operate

them?

Are all guards & other safety devices inspected

& tested regularly?

Machine Design

Are emergency stop buttons or pedals easily

identifiable & within easy reach?

Are operating controls clearly marked to show

what to do?

Are operating controls designed & placed to

avoid accidental operation?

(e.g. by shrouding start buttons or pedals)

Can the machine be isolated from its energy

source?

(e.g. electricity, gas)

Are the machine & work pieces securely

clamped to minimise vibration, noise & risk of

pieces being ejected?

Are warning devices audible or visible & does

everyone understand what they mean?

(e.g. hooters or flashing lights)

Use of Machinery

Are risks of injury minimised by reducing need

-6-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

to go near dangerous machine parts?

(eg. machines are fed or cleaned automatically)

Are there precautions to prevent unintentional

start-up of machinery?

(e.g. by locking off machinery, Permit-to-Work

systems, portable warning signs and barriers to

prevent access)

Are operators supervised to ensure that they

use guards & other protection provided?

Is there always another member of staf nearby

when dangerous machinery is being operated,

cleaned or maintained?

Is unattended equipment in use, labelled with

details of hazards and contact person/user?

Instruction and Training

Do all machine operators know how to operate

the machine(s) they use?

(so they know the risks of injury and precautions

to be taken)

Have all operators of woodworking machines &

abrasive wheels completed approved training

courses?

Is information about safe working loads,

minimum speeds etc. clearly displayed on

equipment?

Electrical Safety

Is 110 volt or battery powered equipment used

whenever possible?

Are all machines, including cables, inspected

regularly?

Are all electrically-powered machines tested

every three years?

Are live electrical parts guarded at all times?

Is the machine disconnected or isolated from

the power supply before electrical parts are

exposed?

(e.g. for maintenance or repair)

-7-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

ACTION TAKEN or

RECOMMENDED

(with completion dates)

Visual Inspection of Electrical Equipment - Switch off and disconnect (unplug) equipment before inspecting. Then look for danger

signs

is the cable covering intact?

damage to the plug is the casing intact and

pins straight?

is the lead intact without any joins?

the outer covering of the cable is gripped

where it enters the plug or equipment

see if the coloured insulation or copper of the

internal wires are completely covered.

the plug, equipment or socket is free from

indications of overheating (eg brown burn

marks) label any faulty equipment with do

not use signs & take out of use until checked

by an electrician. Encourage other staff to

report any faults or damaged equipment

Maintenance

Is there a schedule of preventive maintenance

for all machines?

Are guards & safety devices tested &

maintained in working order?

Are all inspections, tests, maintenance & repairs

recorded in a machine log?

Is there a safe system of work for maintenance

( e.g. isolating from power supply, warning

signs, locking-off controls?)

Have maintenance staf (including contractors)

been warned about the dangers & precautions

to be taken?

Noise

Can you hear someone two metres (approx. six

feet) away talking in a normal voice, while

machines are in use?

Are ear defenders provided and worn if needed?

Gases

Are gas taps easy to reach & turn on & of?

-8-

HAZARD

YES/N

O

COMMENTS

(location & brief details)

Are gas cylinders attached to a support or

trolley?

Are gas cylinder valves & tubing in good

condition?

Are gas cylinders clearly labelled with contents

& hazards?

Are the correct regulators fitted?

Are gas lines & isolators clearly labelled?

Are portable gas cylinder kits stored in a locked

external enclosure when the workshop is not in

use?

Pressure Vessels

Are pressure vessels tested regularly?

Are instructions for use displayed nearby?

Are door seals & locks free from wear or

damage?

Are pressure gauges easily readable?

Radiation

all work involving radioactive substances must

be approved by the Radiation Protection

Supervisor and follow local rules

Are there clear instructions for the use of

radioactive materials?

Is there a safe method of storage?

Is there a safe method of disposal?

Are all radioactive substances correctly labelled?

Are workers familiar with local rules?

Are workers adequately trained?

Are the following available & being used when

necessary

double containment?

shielding?

remote handling facilities?

Are workers health checks, if necessary, up to

date?

Are unauthorised people excluded from the

area?

-9-

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

(e.g. cleaning staff etc.)

Is there an up to date list of emergency contact

numbers displayed?

Lasers

Is access to lasers of Class 3R or above,

restricted to trained users?

Are lasers correctly labelled with class and

hazard warning?

Are there up-to-date laser registration forms,

risk assessment forms, laser survey forms, and

laser user registration forms for all lasers of

Class 3R or above?

Have completed forms been copied to the

University Laser Safety Adviser?

Are written procedures for use of lasers of Class

3R or above kept in the same area as the lasers?

Are warning signs displayed at entrances to the

room/areas?

Are there suitable interlocks on all access points

with risk of exposure to lasers of Class 3B or

Class 4?

Lasers

Is access to lasers class 2 or above, restricted to

trained users?

Are warning signs displayed at entrances to the

rooms/areas?

Are there suitable interlocks on all access points

with risk of exposure to lasers class 3B** or

class 4?

Are lasers correctly labelled with class & hazard

warning?

Is there an up to date register of lasers and laser

users?

Other Hazards/Notes

- 10 -

ACTION TAKEN or

RECOMMENDED

(with completion dates)

HAZARD

YES/N

O

COMMENTS

(location & brief details)

- 11 -

ACTION TAKEN or

RECOMMENDED

(with completion dates)

You might also like

- Is 4923 1997Document19 pagesIs 4923 1997Akhil GargNo ratings yet

- A-ONE TECHNIQUES Safety Calendar 2012Document1 pageA-ONE TECHNIQUES Safety Calendar 2012Anonymous 5F2C52vNo ratings yet

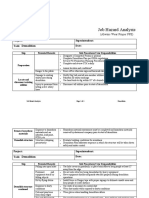

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Weekly Progress Report 21 To 27 OCT2017Document2 pagesWeekly Progress Report 21 To 27 OCT2017Mehdi MessNo ratings yet

- Audit ChecklistDocument25 pagesAudit ChecklistMaria Luciana GusmãoNo ratings yet

- Risk Assessment ActivityDocument5 pagesRisk Assessment ActivityHarthwell CapistranoNo ratings yet

- 3 SOP - Emergency Procedure - Final Sent To Zones Without PhotDocument20 pages3 SOP - Emergency Procedure - Final Sent To Zones Without PhotVijayNo ratings yet

- Director Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzDocument2 pagesDirector Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzNeilSchwartzNo ratings yet

- Site Safety OrientationDocument19 pagesSite Safety OrientationKrischaEverNo ratings yet

- l22 PDFDocument84 pagesl22 PDFRauf HuseynovNo ratings yet

- Accident Investigation: Introduction To EffectiveDocument28 pagesAccident Investigation: Introduction To EffectiveBabbooNo ratings yet

- Toolbox Talk CylindersDocument1 pageToolbox Talk CylindersAdel SukerNo ratings yet

- UTA AST-Fall Protection SafetyDocument72 pagesUTA AST-Fall Protection SafetyNyoman SaktiNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

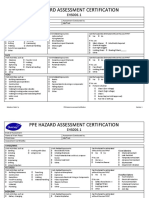

- Ppe Hazard AssessmentDocument4 pagesPpe Hazard AssessmentNeha PatelNo ratings yet

- Safety Park BungeDocument37 pagesSafety Park BungeRavi Sankar VenkatesanNo ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- Assignment Safety Report WALTON Factory Mahmudul HaqueDocument28 pagesAssignment Safety Report WALTON Factory Mahmudul Haquepunter07No ratings yet

- CartridgeSelectionPoster English HRDocument1 pageCartridgeSelectionPoster English HRTg TarroNo ratings yet

- Safe Use of Hand Gloves: Aromatics ProjectDocument1 pageSafe Use of Hand Gloves: Aromatics Projectpl_rajaNo ratings yet

- Check Hard Hat Expiry Dates Before UseDocument1 pageCheck Hard Hat Expiry Dates Before UsetimbulNo ratings yet

- Mechanical Workshops Health and Safety File W105, W106, W108 - April 2016 - 1Document152 pagesMechanical Workshops Health and Safety File W105, W106, W108 - April 2016 - 1Shuhaib MDNo ratings yet

- Safe Manual Handling BookletDocument17 pagesSafe Manual Handling Bookletbilo1984No ratings yet

- Integr Ted Business Re S: at SourceDocument14 pagesIntegr Ted Business Re S: at SourcecyclopsoctopusNo ratings yet

- Commander SK Size 2 To 6 Getting Started GuideDocument80 pagesCommander SK Size 2 To 6 Getting Started GuidesunhuynhNo ratings yet

- 2 BoilersDocument58 pages2 BoilersSundara MoorthyNo ratings yet

- HHDocument2 pagesHHnaveed ahmedNo ratings yet

- July SMR RevDocument2 pagesJuly SMR RevShyam SadanandanNo ratings yet

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Ahmad Daniel: PPE Requisition/Issuance FormDocument2 pagesAhmad Daniel: PPE Requisition/Issuance Formspyrogyra2921No ratings yet

- Vijay Chemsol: R.S.No.110/5, HM Road, Industrial Area, Sedharapet, Pondicherry-605 111. IndiaDocument16 pagesVijay Chemsol: R.S.No.110/5, HM Road, Industrial Area, Sedharapet, Pondicherry-605 111. IndiaSundara MoorthyNo ratings yet

- Fiber Reinforced Plastics & Laminates GuideDocument32 pagesFiber Reinforced Plastics & Laminates GuideMercyJatindroNo ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- Everythingohs Workplace Inspection ChecklistDocument4 pagesEverythingohs Workplace Inspection ChecklistsandyskadamNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs AssessmentahmadNo ratings yet

- Generic Mechanical Workshop Risk AssessmentDocument6 pagesGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqNo ratings yet

- Ladder Safety Tips <40Document2 pagesLadder Safety Tips <40Ange JuanNo ratings yet

- HSE - Statistics - Report - Name ContractorDocument4 pagesHSE - Statistics - Report - Name ContractorDynar AnjaniNo ratings yet

- Premobilisation Wheel Loader InspectionDocument1 pagePremobilisation Wheel Loader InspectionArjun Satheesan100% (1)

- Guide to Safety and Health in Feed and Grain MillsDocument28 pagesGuide to Safety and Health in Feed and Grain MillskumarmvsnNo ratings yet

- Fire Extinguisher Training: Health, Safety & Environment DeptDocument33 pagesFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNo ratings yet

- Requirements For Checklists Before Putting A Forklift Into UseDocument11 pagesRequirements For Checklists Before Putting A Forklift Into UsekasivisanadhNo ratings yet

- Fire Evacuation PlanDocument4 pagesFire Evacuation PlanMiguel AlexandreNo ratings yet

- Hse Emergency Preparedness and ResponseDocument6 pagesHse Emergency Preparedness and ResponsenagaaNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- Self-Inspection Check List: RecordkeepingDocument11 pagesSelf-Inspection Check List: Recordkeepingernie pNo ratings yet

- Written Lockout/Tagout Program University of South Carolina (Enter Department Name Here)Document13 pagesWritten Lockout/Tagout Program University of South Carolina (Enter Department Name Here)SaidNo ratings yet

- Health and Safety & TOPdesk: A Safe CombinationDocument2 pagesHealth and Safety & TOPdesk: A Safe CombinationTOPdeskNo ratings yet

- EHS ManagerDocument3 pagesEHS Managerapi-121631565No ratings yet

- C 112574 Iso 11612Document3 pagesC 112574 Iso 11612Amr ZainNo ratings yet

- Welding Safety ChecklistDocument8 pagesWelding Safety ChecklistAli HajirassoulihaNo ratings yet

- Fall Protection PPT v-03!01!17Document31 pagesFall Protection PPT v-03!01!17Mustafa AdelNo ratings yet

- Site Safety Meeting AgendaDocument2 pagesSite Safety Meeting AgendaMohamad Hidayat Zainul Masri100% (2)

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- Induction Training ProcessDocument7 pagesInduction Training ProcessRanajit RoyNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- Safety Inspection ChecklistDocument3 pagesSafety Inspection ChecklistVivienne IrvingNo ratings yet

- Offsite Emergency PlanDocument19 pagesOffsite Emergency Planhmpathak476No ratings yet

- Form O - CPD Record - WF - V3.0 EnglishDocument5 pagesForm O - CPD Record - WF - V3.0 EnglishsasaNo ratings yet

- Check List Walmart Fire SafetyDocument33 pagesCheck List Walmart Fire SafetyMiguel MelladoNo ratings yet

- RDOS Safety Audit Executive SummaryDocument4 pagesRDOS Safety Audit Executive SummaryJoe FriesNo ratings yet

- HSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Document1 pageHSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Edwin M. MolinaNo ratings yet

- Safety Resume Without Certificate PDFDocument4 pagesSafety Resume Without Certificate PDFSAFETY RNo ratings yet

- Roles and Responsibilities of Human Resource Department - TuteboxDocument4 pagesRoles and Responsibilities of Human Resource Department - TuteboxMrityunjoy RoyNo ratings yet

- Boq For Expansion of Sohar HospitalDocument2 pagesBoq For Expansion of Sohar HospitalSundara MoorthyNo ratings yet

- Boq For 3 Sides TankDocument2 pagesBoq For 3 Sides TankSundara MoorthyNo ratings yet

- Price Fixing CalculatorDocument1 pagePrice Fixing CalculatorSundara MoorthyNo ratings yet

- Gdce Je Pway Tmo Application FormDocument1 pageGdce Je Pway Tmo Application Formnellai kumarNo ratings yet

- Boq For Royal Suite Sultan Qaboos Universirty Ambulance ParkingDocument3 pagesBoq For Royal Suite Sultan Qaboos Universirty Ambulance ParkingSundara MoorthyNo ratings yet

- Boq For L&T City HotelsDocument4 pagesBoq For L&T City HotelsSundara MoorthyNo ratings yet

- Section Properties03Document20 pagesSection Properties03xavierlthNo ratings yet

- Rolled Steel Sections - Indian (Bis) (Refr. Hanbook For Structural Engineers Sp:6 (1) - 1964 Rolled Steel BeamsDocument1 pageRolled Steel Sections - Indian (Bis) (Refr. Hanbook For Structural Engineers Sp:6 (1) - 1964 Rolled Steel BeamsSundara MoorthyNo ratings yet

- Refurbishment Goat Shed BBA SoharDocument2 pagesRefurbishment Goat Shed BBA SoharSundara MoorthyNo ratings yet

- MeDocument2 pagesMeIrshad HussainNo ratings yet

- 074 Sundus Acrylic Sign 1Document1 page074 Sundus Acrylic Sign 1Sundara MoorthyNo ratings yet

- Refurbishment Goat Shed BBA SoharDocument2 pagesRefurbishment Goat Shed BBA SoharSundara MoorthyNo ratings yet

- Project - Unitech Limited: P.No Descripition Size WT in Kgs Material Specification Length (IN 'M') QTY (NOS)Document2 pagesProject - Unitech Limited: P.No Descripition Size WT in Kgs Material Specification Length (IN 'M') QTY (NOS)Sundara MoorthyNo ratings yet

- Refurbishment Goat Shed BBA SoharDocument2 pagesRefurbishment Goat Shed BBA SoharSundara MoorthyNo ratings yet

- Dubai Customs New Registration PDFDocument46 pagesDubai Customs New Registration PDFSundara MoorthyNo ratings yet

- Steel TablesDocument33 pagesSteel TablesSundara MoorthyNo ratings yet

- Ladder PDFDocument1 pageLadder PDFSundara MoorthyNo ratings yet

- Modern India GeographyDocument24 pagesModern India GeographyAnandababucNo ratings yet

- British and U.S. systems of weights and measures conversion guideDocument4 pagesBritish and U.S. systems of weights and measures conversion guideSundara MoorthyNo ratings yet

- PFC 230Document1 pagePFC 230Sundara MoorthyNo ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- British and U.S. systems of weights and measures conversion guideDocument4 pagesBritish and U.S. systems of weights and measures conversion guideSundara MoorthyNo ratings yet

- 12 Biology EMDocument121 pages12 Biology EMSundara MoorthyNo ratings yet

- John Bingham-Hall CVDocument2 pagesJohn Bingham-Hall CVJohn Bingham-HallNo ratings yet

- Importance of Writing Thesis Skills in EnglishDocument3 pagesImportance of Writing Thesis Skills in Englishdanial 96No ratings yet

- Endress KatalogDocument72 pagesEndress KatalogpnsanatNo ratings yet

- Transmission Lines-Basic Principles 01515900Document13 pagesTransmission Lines-Basic Principles 01515900Sachin1091No ratings yet

- Anixter Wire&Cable Catalog Armored Cables PDFDocument42 pagesAnixter Wire&Cable Catalog Armored Cables PDFAhmed H. HassanNo ratings yet

- Vet. Medicine Companies in PakistanDocument6 pagesVet. Medicine Companies in PakistanRAO NABEEL AKRAM100% (1)

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocument213 pagesDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNo ratings yet

- Revision Sex Death and EpicsDocument77 pagesRevision Sex Death and EpicsAshli KingfisherNo ratings yet

- User Manual SR 9797HDDocument47 pagesUser Manual SR 9797HDnavamivbNo ratings yet

- Joybook A52 Series EnglishDocument44 pagesJoybook A52 Series EnglishTudor VladNo ratings yet

- Developments in The Singapore Electricity Transmission Network - 5 Apr 2011Document8 pagesDevelopments in The Singapore Electricity Transmission Network - 5 Apr 2011Megha SharmaNo ratings yet

- EIGA Doc 04 09 EDocument34 pagesEIGA Doc 04 09 EFrancisco Campos ParadaNo ratings yet

- Circular No. 27 - Olympiad ScheduleDocument2 pagesCircular No. 27 - Olympiad Schedulerishu ashiNo ratings yet

- Air Intake AccessoriesDocument42 pagesAir Intake AccessoriesMark CarterNo ratings yet

- Kollmorgen PMA Series CatalogDocument6 pagesKollmorgen PMA Series CatalogElectromateNo ratings yet

- Physics Sample ProblemsDocument5 pagesPhysics Sample ProblemsEdin Abolencia0% (1)

- SolverTable HelpDocument13 pagesSolverTable HelpM Ibnu Aji DwiyantoNo ratings yet

- Assignment Fall2018Document2 pagesAssignment Fall2018Frans LoekitoNo ratings yet

- Unistar HR Compact: Electro-Hydraulic Point Machine For Freight, Urban and Mixed TrafficDocument2 pagesUnistar HR Compact: Electro-Hydraulic Point Machine For Freight, Urban and Mixed TrafficAmir EshaghiNo ratings yet

- Populate Data From Database Into JTable in NetbeansDocument13 pagesPopulate Data From Database Into JTable in NetbeansSam Nil100% (1)

- UPS KAISE TORRE 6-10kVA SERIES KSDocument2 pagesUPS KAISE TORRE 6-10kVA SERIES KSCARLOS QUISPENo ratings yet

- Red Ocean Vs Blue OceanDocument8 pagesRed Ocean Vs Blue Oceanbadshahkhn110No ratings yet

- Building A Two Wheeled Balancing RobotDocument120 pagesBuilding A Two Wheeled Balancing RobotCp Em PheeradorNo ratings yet

- ASHIDA Product CatalogueDocument4 pagesASHIDA Product Cataloguerahulyadav2121545No ratings yet

- VW T4 Automatic Gearbox Adapter Kit InstallationDocument2 pagesVW T4 Automatic Gearbox Adapter Kit InstallationLuke HazelgroveNo ratings yet

- Major ICT and manufacturing companies in EthiopiaDocument3 pagesMajor ICT and manufacturing companies in EthiopiafiraolNo ratings yet

- PH Probe For The PIC Temperature ControllerDocument6 pagesPH Probe For The PIC Temperature ControllerMohamad ZikriNo ratings yet

- Service QualityDocument11 pagesService QualityMang Abdul RohmatNo ratings yet