Professional Documents

Culture Documents

Stir Casting Method

Uploaded by

satish448Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stir Casting Method

Uploaded by

satish448Copyright:

Available Formats

International Journal of Engineering and Advanced Technology (IJEAT)

ISSN: 2249 8958, Volume-3, Issue-2, December 2013

Preparation of Aluminium Matrix Composite by

Using Stir Casting Method

Rajeshkumar Gangaram Bhandare, Parshuram M. Sonawane

.

Abstract The composite material is composed of a discrete

reinforcement & distributed in a continuous phase of matrix, In

Aluminium matrix composite (AMC) one constitutes is

aluminium which forms network i.e. matrix phase and another

constitute serve as reinforcement which is generally ceramic or

non metallic hard material. The basic reason of metals

reinforced with hard ceramic particles or fibers are improved

properties than its original material like strength, stiffness etc.

Stir casting process is mainly used for manufacturing of

particulate reinforced metal matrix composite (PMMC).

Manufacturing of aluminum alloy based casting composite by

stir casting is one of the most economical method of processing

MMC. Properties of these materials depend upon many

processing parameters and selection of matrix and

reinforcements. This paper presents an overview of stir casting

process, process parameter, & preparation of AMC material by

using aluminium as matrix form and SiC, Al 2O3, graphite as

reinforcement by varying proportion.

Fig1.1 Composite Material

These advantages can be used to achieve better properties.

For example, elastic modulus of pure aluminium can be

enhanced from 70GPa to 240GPa by reinforcing with 60 vol.

% continuous aluminum fiber. On the other hand

incorporation of 60 vol% alumina fiber in pure aluminium

leads to decrease in the coefficient of expansion from 24

ppm/C to 7 ppm/C. Similarly it is possible to process

Al-9% Si-20 vol% SiCp composites having wear resistance

equivalent or better than that of grey cast iron [1]. All these

examples illustrate that it is possible to alter several physical

properties of aluminium/aluminium alloy by adding two or

three appropriate reinforcement in suitable volume fraction.

Reinforcing the matrix with whiskers, short fibers or

particulates of ceramics could give a composite improved

properties compared to monolithic base alloy. Further, the

attractive feature is the isotropic nature of the properties.

Even though the property improvements are not as high as

those achievable with continuous fiber ones, they are

sufficiently attractive enough for most of the intended

engineering applications.[2]. The cost of the component

production by solid state processing route was still high and

hence large scale commercialization of wide spectrum of

engineering component did not take place .

The commonly used reinforcement is silicon carbide

particulates (SiCp) in cast alloy matrix (modified

compositions of 356 and 357 Al alloys) and alumina

particulates in wrought alloy matrix (6061/2024). Even

though the possibilities of using different kinds of

reinforcement in Al alloys as reinforcements, except SiCp

and A1203 others have not shown any commercial potential

[2]

Jokhio, Panhwar & Mukhtiar Ali investigate the effect of

elemental metal such as Cu-Zn-Mg in aluminum matrix on

mechanical properties of stir casting of aluminum composite

materials reinforced with alpha "Al2O3" particles using stir

Index Terms Stir casting process, Aluminum Matrix

composite, Reinforcement, Mixing and Agitation.

I. INTRODUCTION

Now days with the modern development need of

developments of advanced engineering materials for various

engineering applications goes on increasing. To meet such

demands metal matrix composite is one of reliable source.

Composite material is one of the reliable solutions for such

requirement. In composites, materials are combined in such a

way as to enable us to make better use of their parent material

while minimizing to some extent the effects of their

deficiencies. The simple term composites gives indication

of the combinations of two or more material in order to

improve the properties. In the past few years, materials

development has shifted from monolithic to composite

materials for adjusting to the global need for reduced weight,

low cost, quality, and high performance in structural

materials. Driving force for the utilization of AMCs in areas

of aerospace and automotive industries include performance,

economic and environmental benefits[1].

In AMC one of the constituent is aluminum, which forms

percolating network and is termed as matrix phase. The other

constituent is embedded in this aluminum and serves as

reinforcement, which is usually non-metallic and commonly

ceramic such as SiC, Al2O3 etc

Manuscript received December, 2013.

Rajeshkumar Gangaram Bhandare, Mechanical (Automotive)

Engineering, Pune University, Sinhgad Academy Of Engineering , Pune,

Maharashtra, India,

Parshuram M. Sonawane, Mechanical Engineering, Pune University,

Sinhgad Academy Of Engineering, Pune, Maharashtra, India.

61

Preparation of Aluminium Matrix Composite by Using Stir Casting Method

casting they found increase in tensile strength. Also they

found that Mg has pronounced effect on aluminum cast

composites up to 2.77% Mg contents which increases

wetability, reduces porosity and develops very good bonding

with Al2O3 [3].

Preparation and characterization of aluminum metal matrix

composites reinforced with aluminum nitride was carried out

by M. N. Wahab, A. R. Daud and M. J. Ghazali they found

considerable significant increase in hardness of the alloy

matrix [4].

Cast A356/SiCp composites were produced using a

conventional stir casting technique by S. Tzamtzis, N. S.

Barekar, N. Hari Babu, J. Patel, B. K. Dhindaw they found a

good combination of improved Ultimate Tensile

Strength(UTS) and tensile elongation is obtained [5].

Experiments have been conducted by varying weight fraction

of SiC, graphite and alumina (5%, 10%, 15%, 20%, 25%,

and 30%), while graphite weight fraction 2%, 4%, 6%, 8%

and 10% keep all other parameters constant by Dunia Abdul

Saheb they found that an increasing of hardness and with

increase in weight percentage of ceramic materials [6]

Method

Stir casting

Squeeze

casting

Range of

shape and size

wide range of

shapes; Larger

size; up to 500

kg

limited by pre

form

shape Up to 2cm

height

Powder

metallurgy

wide range;

restricted size

Spray

casting

Limited shape,

large shape

Range of

vol.

fraction

Damage to

reinforcem

ent

Cost

Up to 0.3

No

damage

Least

expansive

Up to 0.5

severe

damage

Moderate

expansive

reinforcem

ent

fracture

Expansive

0.3-0.7

Expansive

Table-2.1: A comparative analysis of different technique

used for fabrication [4]

C. Stir casting:

In a stir casting process, the reinforcing phases are

distributed into molten matrix by mechanical stirring. Stir

casting of metal matrix composites was initiated in 1968,

when S. Ray introduced alumina particles into an aluminum

melt by stirring molten aluminum alloys containing the

ceramic powders. Mechanical stirring in the furnace is a key

element of this process. The resultant molten alloy, with

ceramic particles, can then be used for die casting,

permanent mold casting, or sand casting. Stir casting is

suitable for manufacturing composites with up to 30%

volume fractions of reinforcement [7].

The cast composites are sometimes further extruded to

reduce porosity, refine the microstructure, and homogenize

the distribution of the reinforcement. A major concern

associated with the stir casting process is the segregation of

reinforcing particles which is caused by the surfacing or

settling of the reinforcement particles during the melting and

casting processes. The final distribution of the particles in the

solid depends on material properties and process parameters

such as the wetting condition of the particles with the melt,

strength of mixing, relative density, and rate of solidification

.The distribution of the particles in the molten matrix

depends on the geometry of the mechanical stirrer, stirring

parameters, placement of the mechanical stirrer in the melt,

melting temperature, and the characteristics of the particles

added [7].

An interesting recent development in stir casting is a

two-step mixing process. In this process, the matrix material

is heated to above its liquids temperature so that the metal is

totally melted. The melt is then cooled down to a temperature

between the liquids and solidus points and kept in a

semi-solid state. At this stage, the preheated particles are

added and mixed. The slurry is again heated to a fully liquid

state and mixed thoroughly. This two-step mixing process

has been used in the fabrication of aluminum.

Among all the well-established metal matrix composite

fabrication methods, stir casting is the most economical. For

that reason, stir casting is currently the most popular

commercial method of producing aluminum based

composites.

II. PROCESSING OF AMC

A key challenge in the processing of composites is to

homogeneously distribute the reinforcement phases to

achieve a defect-free microstructure. Based on the shape, the

reinforcing phases in the composite can be either particles or

fibers. The relatively low material cost and suitability for

automatic processing has made the particulate-reinforced

composite preferable to the fiber-reinforced composite for

automotive

applications.

Primary

processes

for

manufacturing of AMCs at industrial scale can be classified

into two main groups.

A. Liquid state processes:

Liquid state processes include stir casting, compo casting

and squeeze casting spray casting and in situ (reactive)

processing, ultrasonic assisted casting [4].

B. Solid state processes:

Solid state process include Powder blending followed by

consolidation (PM processing), high energy ball milling,

friction Stir Process, diffusion bonding and vapors deposition

techniques. The selection of the processing route depends on

many factors including type and level of reinforcement

loading and the degree of micro structural integrity desired

[4].

Among the variety of manufacturing processes available

for discontinuous metal matrix composites, stir casting is

generally accepted as a particularly promising route,

currently practiced commercially. Its advantages lie in its

simplicity, flexibility and applicability to large quantity

production.

It is also attractive because, in principle, it allows a

conventional metal processing route to be used, and hence

minimizes the final cost of the product. This liquid

metallurgy technique is the most economical of all the

Available routes for metal matrix composite production and

allows very large sized components to be fabricated.

III. OBJECTIVE OF THE PAPER

The main objective of this paper is to study the operating

parameter of the composite as its control the properties of the

composite material. Second objective is manufacture the

62

International Journal of Engineering and Advanced Technology (IJEAT)

ISSN: 2249 8958, Volume-3, Issue-2, December 2013

particulate aluminum metal matrix composite (PAMC) with

varying compositions of reinforcement particles of graphite,

Al2O3 and SiC by using stir casting method.

Graphite: - Addition of graphite particle results in low

friction of composite as it is good dry lubricant hence reduces

wear and abrasion.

A. Composite Material:For composite material selection of Matrix and

reinforcement are of prime importance. For this research

work we had selected material as follows.

IV. PROCESS PARAMETER

For manufacturing of composite material by stir casting

knowledge of its operating parameter are very essential. As

there is various process parameters if they properly

controlled can lead to the improved characteristic in

composite material.

B. Matrix:Aluminium alloy 2000, 6000 and 7000 series are used for

fabrication of the automotive parts. PAMC under study

consist of matrix material of aluminium alloy Al6061 whose

chemical composition is shown in the Table. An advantage of

using aluminium as matrix material is casting technology is

well established, and most important it is light weight

material. Aluminium alloy is associated with some

disadvantages such as bonding is more challenging than

steel, low strength than steel and price is 200% of that of

steel. But with proper reinforcement and treatment the

strength can be increased to required level.

Table3.1 Chemical composition of Al (6061)

Si

0.4

0.8

Fe

00.7

Cu

0.15

- 0.4

Mn

0.0 0.15

Mg

0.81.2

Cr

0.040.35

Zn

0.0 0.25

Ti

0.0 0.15

A. Stirring speed:-

Stirring speed is the important process parameter as

stirring is necessary to help in promoting wetability i.e.

bonding between matrix & reinforcement. Stirring speed will

directly control the flow pattern of the molten metal. Parallel

flow will not promote good reinforcement mixing with the

matrix. Hence flow pattern should be controlled turbulence

flow. Pattern of flow from inward to outward direction is

best. In our project we kept speed from 300-600 rpm. As

solidifying rate is faster it will increase the percentage of

wetability [8].

Al

B. Stirring temperature:It is an important process parameter. It is related to the

melting temperature of matrix i.e. aluminium. Aluminium

generally melts at 650 C. The processing temperature is

mainly influence the viscosity of Al matrix. The change of

viscosity influences the particle distribution in the matrix.

The viscosity of liquid decreased when increasing processing

temperature with increasing holding time stirring time [8]. It

also accelerates the chemical reaction b/w matrix and

reinforcement. In our project in order to promote good

wetability we had kept operating temperature at 630C which

keeps Al (6061) in semisolid state.

Bal

C. ReinforcementParticles of Al2O3, SiC and graphite of mesh size 320 are

used as reinforcement.

SiC:-Silicon carbide particulates have attained a prime

position among the various PAMC. This is due to the fact

that introduction of Sic to the aluminum matrix substantially

enhances the strength, the modulus, the abrasive wear

resistance and thermal stability. The density of Sic (3.2g/cm)

is nearer to that of aluminum alloy AA6061 (2.7g/cm3). The

resistance of Sic to acids, alkalis or molten salts up to 800

degree Celsius makes it a good reinforcement candidate for

aluminum based MMC. Furthermore, Sic is easily available

and has good wetability with aluminum alloys. Addition of

alumina particle results in good wear properties and

compatibility. Addition of Silicon carbide particle results in

Excellent Mechanical properties this produces a very hard

and strong material.

Alumina: - Addition of alumina particle has shown increase

in tensile strength and it has good compatibility with

aluminium alloy.

C. Reinforcement preheat temperature:Reinforcement was preheated at a specified 500 C

temperature 30 min in order to remove moisture or any other

gases present within reinforcement. The preheating of also

promotes the wetability of reinforcement with matrix [7].

D. Addition of Mg:Addition of Magnesium enhances the wetability. However

increase the content above 1wt. % increases viscosity of

slurry and hence uniform particle distribution will be

difficult [6].

E. Stirring time:Stirring promotes uniform distribution of the particles in

the liquid and to create perfect interface bond b/w

reinforcement and matrix. The stirring time b/w matrix and

reinforcement is considered as important factor in the

processing of composite. For uniform distribution of

reinforcement in matrix in metal flow pattern should from

outward to inward.

Table 3.2 Properties of Matrix and Reinforcement

63

Preparation of Aluminium Matrix Composite by Using Stir Casting Method

Table 4.1Uniform dispersion time for 10% SiC particles for

different stirrer types and stirring speeds in glycerol/water

solution of viscosity 300mPas2

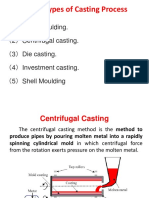

Fig. 5.1 Stir Cast apparatus

This is the layout of the stir casting apparatus. It consist of

conical shaped graphite crucible is used for fabrication of

AMCs, as it withstands high temperature which is much

more than required temperature [680C].Along that graphite

will not react with aluminum at these temperature. This

crucible is placed in muffle which is made up of high ceramic

alumina. Around which heating element of wound. The coil

which acts as heating element is Kanthol-A1. This type of

furnace is known as resistance heating furnace. It can work

up to 900C reach within 45 min. Aluminium, at liquid stage

is very reactive with atmospheric oxygen. Oxide formation

occurs when it comes in contact with the open air. Thus all

the process of stirring is carried out in closed chamber with

nitrogen gas as inert gas in order to avoid oxidation. Closed

chamber is formed with help of steel sheet. This reduces heat

loss and gas transfer as compare open chamber. A K type

Temperature thermocouple whose working range is -200C

to 1250C is used to record the current temperature of the

liquid. Due to corrosion resistance to atmosphere EN 24 is

selected as stirrer shaft material. One end of shaft is

connected to 0.5 hp PMDC motor with flange coupling.

While at the other end blades are welded. 4 blades are

welded to the shaft at 45C. A constant feeding rate of

reinforcement particles is required to avoid coagulation and

segregation of the particles. This can be achieve by using

hopper . Aluminium alloy matrix will be formed in the

crucible by heating aluminium alloy ingots in furnace. A

stirring action is started at slow rate of 30 rpm and increases

slowly in between 300 to 600 rpm with speed controller. A

mixture of reinforcements (Al2O3 + SiC + Graphite) is to be

incorporated in the metal matrix at semisolid level near

640C. Dispersion time is to be taken as 5 minutes. After

that slurry is reheated to a temperature above melting point to

make sure slurry is fully liquid and then it is poured in mould.

Procedure:Stir casting process starts with placing empty crucible in the

muffle. At first heater temperature is set to 500C and then it

is gradually increased up to 900C. High temperature of the

muffle helps to melt aluminium alloy quickly, reduces

oxidation level, enhance the wetability of the reinforcement

particles in the matrix metal. Aluminium alloy Al6061 is

F. Blade Angle:The blade angle and number of blades are prominent

factor which decides the flow pattern of the liquid metal at

the time of stirring. The blade with angle 45 & 60 will give

the uniform distribution. The number of blade should be 4.

Blade should be 20mm above the bottom of the crucible [8].

Blade pattern drastically affect the flow pattern

G. Inert Gas:As aluminium melt it start reacting with environment

oxygen and will produce an oxide layer at the top. This oxide

layer will avoid further oxidation but along that it will

difficult to brake. So such layer will be big trouble for

reinforcement mixture with metal. So in order to avoid this

we had used inert gas like nitrogen.

H. Preheated Temperature of Mould:In casting porosity is the prime defect. In order to avoid

these preheating the permanent mould is good solution. It

will help in removing the entrapped gases from the slurry in

mould It will also enhance the mechanical properties of the

cast AMC. While pouring molten metal keep the pouring rate

constant to avoid bubble formation.

I. Powder Feed Rate:To have a good quality of casting the feed rate of powder

particles must be uniform. If it is non-uniform it promotes

clustering of particles at some places which in turn enhances

the porosity defect and inclusion defect, so the feed rate of

particles must be uniform.

V. EXPERIMENTAL SETUP AND PROCEDURE:-

64

International Journal of Engineering and Advanced Technology (IJEAT)

ISSN: 2249 8958, Volume-3, Issue-2, December 2013

used as Matrix material. Required quantity of aluminium

alloy is cut from the raw material which is in the form of

round bar. Aluminium alloy is cleaned to remove dust

particles, weighed and then poured in the crucible for

melting. During melting nitrogen gas is used as inert gas to

create the inert atmosphere around the molten matrix.

Powder of alumina (Al2O3), silicon carbide (SiC) and

graphite are used as reinforcement. 1% by weight of pure

magnesium powder is used as wetting agent. At a time total

700 gram of molten composite was processed in the crucible.

Required quantities of reinforcement powder and

magnesium powder are weighed on the weighing machine.

Then it is thoroughly mixed with each other with the help of

blending machine for 24 hour. This mixture is kept ready 1

day before the test has to carry out. Prior to conducting the

test this mixture is kept for heating in another heater.

Reinforcements are heated for half hour and at temperature

of 500C. When matrix was in the fully molten condition,

Stirring is started after 2 minutes. Stirrer rpm is gradually

increased from 0 to 300 RPM with the help of speed

controller. Temperature of the heater is set to 630C which is

below the melting temperature of the matrix. A uniform

semisolid stage of the molten matrix was achieved by stirring

it at 630C.Pouring of preheated reinforcements at the

semisolid stage of the matrix enhance the wetability of the

reinforcement, reduces the particle settling at the bottom of

the crucible. Reinforcements are poured manually with the

help of conical hopper. The flow rate of reinforcements

measured was 0.5 gram per second. Dispersion time was

taken as 5 minutes. After stirring 5 minutes at semisolid

stage slurry was reheated and hold at a temperature 900C to

make sure slurry was fully liquid. Stirrer RPM was then

gradually lowered to the zero. The stir casting apparatus is

manually kept side and then molten composite slurry is

poured in the metallic mould. Mould is preheated at

temperature 500C before pouring of the molten slurry in the

mould. This makes sure that slurry is in molten condition

throughout the pouring. While pouring the slurry in the

mould the flow of the slurry is kept uniform to avoid trapping

of gas. Then it is quick quenched with the help of air to

reduce the settling time of the particles in the matrix.

VI. CONCLUSION

In present study the aim is study the various operating

parameter of stir casting process. And to prepare AMC with

help of stir casting process. For this Aluminium (6061) is

selected as matrix phase while SiC, Alumina and Graphite

act as reinforcement. With the help of stir casting process we

had successfully manufactured AMC at less cost. While

manufacturing AMC we come to know that process

parameter are platy a major role for uniform distribution of

reinforcement. We had some following conclusion

1) For uniform dispersion of material blade angle should

be 45 or 60 & no of blade should be 4.

2) For good wetability we need to keep operating

temperature at semisolid stage i.e. 630 for Al (6061). At

full liquid condition it is difficult uniform distribution

of the reinforcement in the molten metal.

3) Preheating of mould helps in reducing porosity as well

as increases mechanical properties.

For further study we are going to check its mechanical

properties.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Fig. 5.2 AMC Specimen

65

M K SURAPPA, ALUMINIUM MATRIX COMPOSITES:

CHALLENGES AND OPPORTUNITIES, Sadhana Vol. 28, Parts 1

& 2, February/April 2003, pp. 319334

B.C. PAI, R.M.PILLAI AND K.G.SATYANARAYANA LIGHT

METAL MATRIX COMPOSITES - PRESENT STATUS AND FUTURE

STRATEGIES

Muhammad Hayat Jokhio, Muhammad Ibrahim Panhwar, And

Mukhtiar Ali Unar MANUFACTURING OF ALUMINUM

COMPOSITE MATERIAL USING STIR CASTING PROCESS

Mehran University Research Journal Of Engineering & Technology,

Volume 30, No. 1, January, 2011 [Issn 0254-7821]

M. N. Wahab, A. R. Daud and M. J. Ghazali PREPARATION AND

CHARACTERIZATION OF STIR CAST-ALUMINUM NITRIDE

REINFORCED ALUMINUM METAL MATRIX COMPOSITES

International Journal of Mechanical and Materials Engineering

(IJMME), Vol. 4 (2009), No. 2, 115-117

J Hashim, L Looney, M.S.J. Hashim THE ENCHANCEMENT OF

WETABILITY SIC PARTICLE IN CAST ALUMINIUM MATRIX

COMPOSITE Journal of material processing technology 119(2001)

329- 335

Dunia Abdul Saheb ALUMINUM SILICON CARBIDE AND

ALUMINUM GRAPHITE PARICULATE COMPOSITES ARPN

Journal of Engineering and Applied Sciences VOL. 6, NO. 10,

OCTOBER 2011 ISSN 1819-6608

PradeepSharma, Gulshan Chauhan, Neeraj Sharma PRODUCTION

OF AMC BY STIR CASTING- AN OVERVIEW International Journal of

Contemporary Practises Vol.2 Issue1

S. Naher, D. Brabazon, L. Looney SIMULATION OF THE STIR

CASTING PROCESS Journal of Materials Processing Technology

143144 (2003) 567571

G. G. Sozhamannan1*, S. Balasivanandha Prabu2, V. S. K

Venkatagalapathy1 EFFECT OF PROCESSING PARAMTERS ON

METAL MATRIX COMPOSITES: STIR CASTING PROCESS

Journal of Surface Engineered Materials and Advanced Technology,

2012, 2, 11-15

You might also like

- MOULDINGDocument35 pagesMOULDINGsumitNo ratings yet

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- 3475331Document41 pages3475331Nguyen Trong TanNo ratings yet

- Diamond Chemical Vapor Deposition: Nucleation and Early Growth StagesFrom EverandDiamond Chemical Vapor Deposition: Nucleation and Early Growth StagesNo ratings yet

- Sand Casting and Other Casting ProcessesDocument74 pagesSand Casting and Other Casting ProcessesRashid KareemNo ratings yet

- Mf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreDocument2 pagesMf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNo ratings yet

- Foundry Sand TypesDocument4 pagesFoundry Sand TypesMohamed WahidNo ratings yet

- Isostatic PressingDocument4 pagesIsostatic PressingBelma HasanovicNo ratings yet

- Gating & RiserDocument8 pagesGating & Riserhegdemahesh1No ratings yet

- Steel CastingsDocument50 pagesSteel CastingsVijayakumar TNo ratings yet

- Casting ProcessesDocument18 pagesCasting ProcessesvelavansuNo ratings yet

- Casting ProcessDocument53 pagesCasting ProcessSenthilKumar SubramanianNo ratings yet

- 2 - 2 Fundamentals of CastingDocument172 pages2 - 2 Fundamentals of CastingColorgold BirlieNo ratings yet

- Metal-Casting Process and EquipmentDocument18 pagesMetal-Casting Process and EquipmentZulfikarUdenNo ratings yet

- Casting Slides 103-130Document28 pagesCasting Slides 103-130Swaraj PrakashNo ratings yet

- Dr. Babasaheb Ambedkar Technological University, LonereDocument36 pagesDr. Babasaheb Ambedkar Technological University, LonereNikhil PawarNo ratings yet

- Types of CastingDocument14 pagesTypes of CastingRamoji Aditya Chary100% (1)

- Conventional CastingDocument7 pagesConventional CastingEmyl SantosNo ratings yet

- Unit-1 Metal Casting ProcessDocument261 pagesUnit-1 Metal Casting ProcessDharun PrakashNo ratings yet

- Cast Iron BMEDocument2 pagesCast Iron BMEsahitya karaheNo ratings yet

- Permanent Mold CastingDocument10 pagesPermanent Mold Castingroronoa zoroNo ratings yet

- Special CastingDocument24 pagesSpecial CastingManohara ErlaNo ratings yet

- Casting ProcessesDocument20 pagesCasting ProcessesVv4HNo ratings yet

- Centrifugal Casting: A Metallurgical Manufacturing Process by CastingDocument43 pagesCentrifugal Casting: A Metallurgical Manufacturing Process by CastingMuhammad AgilNo ratings yet

- Casting Visual InspectionDocument60 pagesCasting Visual InspectionSaravanan SaranNo ratings yet

- Casting Processes Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Document59 pagesCasting Processes Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Kanav GoyalNo ratings yet

- Analysis of TIG Welding Process On Mechanical Properties and Microstructure of Aa6063 Aluminum Alloy JointsDocument4 pagesAnalysis of TIG Welding Process On Mechanical Properties and Microstructure of Aa6063 Aluminum Alloy JointsEditor IJRITCCNo ratings yet

- Gating and Risering PDFDocument16 pagesGating and Risering PDFpericharla ravivarmaNo ratings yet

- Chapter 10 Casting IDocument38 pagesChapter 10 Casting IMinhaj UllahNo ratings yet

- M - I U - 1 C P: Anufacturing Processes NIT Asting RocessesDocument246 pagesM - I U - 1 C P: Anufacturing Processes NIT Asting RocessesMahesh SalotagiNo ratings yet

- Valery Marinov, Manufacturing TechnologyDocument168 pagesValery Marinov, Manufacturing TechnologyAbir Roy100% (3)

- Introduction To Metal Casting ProcessDocument8 pagesIntroduction To Metal Casting ProcessRiya PanwarNo ratings yet

- 10 Rules For CastingDocument2 pages10 Rules For CastingBijendra PrajapatiNo ratings yet

- GTU B. E. Mech Sem V MP II Topic 2 Foundry Technology NeDocument401 pagesGTU B. E. Mech Sem V MP II Topic 2 Foundry Technology NebmdbmdbmdNo ratings yet

- Yield Improvement Steel Castings PDFDocument321 pagesYield Improvement Steel Castings PDFMy Dad My WorldNo ratings yet

- Silicon NitrideDocument2 pagesSilicon NitrideNishanth ShannmugamNo ratings yet

- Grains Structure of IngotsDocument6 pagesGrains Structure of Ingotshayder1920No ratings yet

- Internship Presentation in Grupo AntolinDocument19 pagesInternship Presentation in Grupo AntolinRavi GowdaNo ratings yet

- Study of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessDocument8 pagesStudy of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessIJRASETPublicationsNo ratings yet

- Casting, Welding, Machine Tools, Material SC PDFDocument240 pagesCasting, Welding, Machine Tools, Material SC PDFSanjay Kajal0% (1)

- Centrifugal CastingDocument2 pagesCentrifugal Castingfarooqshah007No ratings yet

- Ingot StructureDocument5 pagesIngot StructureklawsisNo ratings yet

- Manufacturing Process-I (Casting)Document25 pagesManufacturing Process-I (Casting)Rahul Deb PalNo ratings yet

- 09 Cast IronDocument34 pages09 Cast IronyogeshmangulkarNo ratings yet

- 1 - Intro To MetllurgyDocument37 pages1 - Intro To Metllurgyapi-342177144No ratings yet

- Silicon Nitride CeramicDocument43 pagesSilicon Nitride CeramicSukmaSuciNo ratings yet

- 08 - Advanced Metal FormingDocument12 pages08 - Advanced Metal FormingAdityaRamaNo ratings yet

- Powder Metallurgy: Basics & Applications Powder MetallurgyDocument11 pagesPowder Metallurgy: Basics & Applications Powder MetallurgyVivek BajpaiNo ratings yet

- A Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar HussainDocument23 pagesA Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar Hussainoquintero99100% (2)

- CastingDocument20 pagesCastingCHANDRAJEET AMARNo ratings yet

- Alumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsDocument3 pagesAlumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsRing MasterNo ratings yet

- Processing: Hot Forming Heat Treatments MachiningDocument32 pagesProcessing: Hot Forming Heat Treatments MachiningThân KhaNo ratings yet

- Basic Information About Metals and AlloysDocument7 pagesBasic Information About Metals and AlloysMahesh JingarwarNo ratings yet

- Casting ProcessDocument50 pagesCasting ProcessPankajNo ratings yet

- Fabrication of Microelectronic Devices Final - 2 PDFDocument30 pagesFabrication of Microelectronic Devices Final - 2 PDFAdarsh BarnwalNo ratings yet

- 8 Centrifugal & Die Casting-2Document53 pages8 Centrifugal & Die Casting-2Monsieur PoopNo ratings yet

- Casting Processes: DR Ajay BatishDocument46 pagesCasting Processes: DR Ajay BatishAlisha GuptaNo ratings yet

- Tensile Properties Analysis of Aluminium-Magnesium Alloys Produced by Modified Stir Casting MethodDocument3 pagesTensile Properties Analysis of Aluminium-Magnesium Alloys Produced by Modified Stir Casting MethodijsretNo ratings yet

- MCM AllDocument7 pagesMCM AllPalanisamy RajaNo ratings yet

- MCQ On Air Standarad CyclesDocument6 pagesMCQ On Air Standarad Cyclessatish448100% (1)

- NDTDocument80 pagesNDTsungkang92% (12)

- DX9 01 1 Why DX9 Mighty Fine PDFDocument10 pagesDX9 01 1 Why DX9 Mighty Fine PDFsatish448No ratings yet

- 278-3333 VEX Swept Away Classroom Bundle: Part Number DescriptionDocument6 pages278-3333 VEX Swept Away Classroom Bundle: Part Number Descriptionsatish448No ratings yet

- Strength of MaterialsDocument34 pagesStrength of Materialssatish44850% (2)

- Solutions To Concepts: Chapter - 1Document4 pagesSolutions To Concepts: Chapter - 1Jayanth VgNo ratings yet

- M.tech Thermal Syllabus-PtuDocument28 pagesM.tech Thermal Syllabus-Ptusatish448No ratings yet

- BROCHURE Haryana Service Commision (EB) 2014Document78 pagesBROCHURE Haryana Service Commision (EB) 2014khatrinaveenNo ratings yet

- Math 2Document5 pagesMath 2Ravi YadavNo ratings yet

- Engineering DrawingDocument240 pagesEngineering DrawingKhelly Shan C. Sta. RitaNo ratings yet

- BROCHURE Haryana Service Commision (EB) 2014Document78 pagesBROCHURE Haryana Service Commision (EB) 2014khatrinaveenNo ratings yet

- Free-Body DiagramsDocument20 pagesFree-Body Diagramssatish448100% (1)

- Heat TransferDocument32 pagesHeat Transfersatish44825% (4)

- Basics and Applications of Induction FurnacesDocument54 pagesBasics and Applications of Induction Furnacespioneerinvincible100% (4)

- Free Body DiagramsDocument25 pagesFree Body DiagramsRagerishcire KanaalaqNo ratings yet

- M.tech Thermal Syllabus-PtuDocument28 pagesM.tech Thermal Syllabus-Ptusatish448No ratings yet

- Tig MigDocument15 pagesTig Migsatish448No ratings yet

- Trafficking in Persons Report June 2012Document61 pagesTrafficking in Persons Report June 2012Beatriz TurNo ratings yet

- SOM - AssignmentsDocument15 pagesSOM - Assignmentssatish448100% (1)

- Fluid MechanicsDocument41 pagesFluid Mechanicsjmgingo1No ratings yet

- Steam TurbineDocument37 pagesSteam Turbinesatish448No ratings yet

- NDTDocument80 pagesNDTsungkang92% (12)

- Helical SpringDocument15 pagesHelical Springsatish448No ratings yet

- Biomechanics Central Nervous SystemDocument7 pagesBiomechanics Central Nervous Systemsatish448No ratings yet

- Engineering MechanicsDocument37 pagesEngineering Mechanicser_paramjeetgillNo ratings yet

- 5-Cold Working BrassDocument4 pages5-Cold Working BrassAhmed MagedNo ratings yet

- SF & BM DiagramDocument22 pagesSF & BM Diagramsatish448100% (1)

- Hot Forming MetalsDocument23 pagesHot Forming Metalssatish448No ratings yet

- Cast Iron HandbookDocument144 pagesCast Iron Handbooksachinguptachd100% (2)

- BlueScope Steel LTD V Dongkuk Steel Mill Co, LTD (No 2) (2019) 152 IPR 195Document238 pagesBlueScope Steel LTD V Dongkuk Steel Mill Co, LTD (No 2) (2019) 152 IPR 195FionaNo ratings yet

- S and P Block Elements PDF Class 12 Chemistry NotesDocument25 pagesS and P Block Elements PDF Class 12 Chemistry NotesMuhammad QasimNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDikaAnindyajatiNo ratings yet

- Solar Cell Lecture-2Document33 pagesSolar Cell Lecture-2SUNIABHINo ratings yet

- Giới thiệu dây SAWDocument4 pagesGiới thiệu dây SAWNguyen Thanh TrungNo ratings yet

- 5070 - W1past Paper o LevelDocument20 pages5070 - W1past Paper o LevelRafayNo ratings yet

- Development and Economic Evaluation of A Reactive Distillation Process For Silane ProductionDocument11 pagesDevelopment and Economic Evaluation of A Reactive Distillation Process For Silane ProductionuvsarathiNo ratings yet

- Defects Reactions 2 PDFDocument37 pagesDefects Reactions 2 PDFPhilmona SamuelNo ratings yet

- Lichioiu IDocument6 pagesLichioiu ICristina MaierNo ratings yet

- Empanques VulcanDocument124 pagesEmpanques VulcanEduardoNo ratings yet

- Stefan Sepeur - Nora Laryea - Stefan Goedicke - Frank Groß - Nanotechnology - Technical Basics and Applications-Vincentz Network (2013)Document168 pagesStefan Sepeur - Nora Laryea - Stefan Goedicke - Frank Groß - Nanotechnology - Technical Basics and Applications-Vincentz Network (2013)Arthur ThiesenNo ratings yet

- Tips & Techniques, UltraWAVE, Rev12Document7 pagesTips & Techniques, UltraWAVE, Rev12AntWonxxxNo ratings yet

- Type RR, Silicon Carbide Heating Elements: General DescriptionDocument8 pagesType RR, Silicon Carbide Heating Elements: General DescriptionJohn Jairo CelisNo ratings yet

- Damage Analysis of Catalyst Tube of Reformer FurnaceDocument9 pagesDamage Analysis of Catalyst Tube of Reformer FurnaceAnonymous xmSWrWbUKGNo ratings yet

- Electronic Devices: EEE F214/INSTR F214 Lecture 1-6Document63 pagesElectronic Devices: EEE F214/INSTR F214 Lecture 1-6KapilAgrawalNo ratings yet

- Gantrex Technical Bulletin 43Document2 pagesGantrex Technical Bulletin 43gechaves1No ratings yet

- Semiconductor PurificationDocument15 pagesSemiconductor PurificationPratish BajracharyaNo ratings yet

- ReviewDocument7 pagesReviewsayaNo ratings yet

- The P-Block Elements (Boron and Carbon Family) 3.: (Odisha JEE 2004)Document20 pagesThe P-Block Elements (Boron and Carbon Family) 3.: (Odisha JEE 2004)RAGE pubgNo ratings yet

- STPM Chemistry Chapter 3Document20 pagesSTPM Chemistry Chapter 3Wei Shan LeeNo ratings yet

- Imds Recommendation 019 Circuit BoardsDocument13 pagesImds Recommendation 019 Circuit BoardsNeemias de Macedo FerreiraNo ratings yet

- Energy Bands in Semiconductors:) IP: 128.123.35.41 On: Thu, 04 Sep 2014 10:23:07Document16 pagesEnergy Bands in Semiconductors:) IP: 128.123.35.41 On: Thu, 04 Sep 2014 10:23:07JOSE CARLOS LEON GONZALEZNo ratings yet

- Efficient Heterogeneous Fenton-Like Catalysis of Fe-Doped SAPO-44Document9 pagesEfficient Heterogeneous Fenton-Like Catalysis of Fe-Doped SAPO-44NamNo ratings yet

- Wednesday 9 January 2019: ChemistryDocument24 pagesWednesday 9 January 2019: ChemistryWandaNo ratings yet

- Hydroponic NutrientsDocument9 pagesHydroponic NutrientsDhanraj PatilNo ratings yet

- Group 4A - Carbon FamilyDocument11 pagesGroup 4A - Carbon FamilyPaul Jhon EugenioNo ratings yet

- Ajc H2 Chem P1 QPDocument20 pagesAjc H2 Chem P1 QPclarissa yeoNo ratings yet

- Production of FerroalloysDocument39 pagesProduction of Ferroalloysozgelke100% (3)

- Materials and Design: Jung-Ting Tsai, Li-Kai Lin, Shun-Tian Lin, Lia Stanciu, Martin Byung-Guk JunDocument12 pagesMaterials and Design: Jung-Ting Tsai, Li-Kai Lin, Shun-Tian Lin, Lia Stanciu, Martin Byung-Guk JunAlya WorkerNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesFrom EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet