Professional Documents

Culture Documents

SSE501 1.0 - 1.2 - Executive Summary - Building Services Design - r3

Uploaded by

KCFUNGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSE501 1.0 - 1.2 - Executive Summary - Building Services Design - r3

Uploaded by

KCFUNGCopyright:

Available Formats

Contract No.: SS E501 (Programme No.

: 185GK)

Design and Construction of Transport Departments Vehicle Examination Centre

at Sai Tso Wan Road, Tsing Yi, New Territories

1.2 Executive Summary of Key Value-added Design Provisions and Highlights

of Building Services Design

The overall design objectives, directives and considerations for E&M systems to be installed in

the Tsing Yi Vehicle Examination Centre (TYVEC) is aimed at designing a vehicle examination

centre identified for the three VECs currently operated by Transport Department (TD), namely

the Kowloon Bay VEC (KBVEC), the New Kowloon Bay VEC (NKBVEC) and To Kwa Wan

VEC (TKWVEC) that creates safe and secure environment, concerns on staff needs and be

staff friendly, ensures functional alignment and efficiency, be a green and energy conservative

construction, can accommodate operational flexibility and will incorporate (or able to

accommodate) future advanced technology.

The building services and M&E required for the different functions of the TYVEC have been

closely integrated with the architectural and structural planning to ensure compatibility. Risk of

failure in one service having an adverse effect on another or on the building operation has

been minimized by careful planning of the building services design. Wet and dry services have

been designed to be routed independently of each other, and plant rooms / risers have been

strategically located to service various accommodations with provisions for easy expansion

and maintenance. The building services infrastructure has been designed to provide adequate

back-up capability, standby redundancy, and future expansion and to capitalize operating cost

saving in line with low life cycle strategy. All systems have been designed to achieve quick

recovery from system failure.

Section 1.0 Executive Summary

1.0

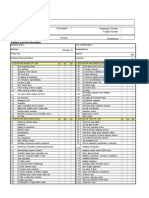

1.2.1

Operation Efficiency

1.2.1.1

1.2.1.2

1.2.1.3

Provision of Durable Building Services Equipment

Central Battery System serves as Back-up Power for Emergency Lighting

Raised Flooring Arrangement for Hub Rooms, Server Rooms, UPS Rooms and

Offices

Clean Electricity Design by Elimination of Electromagnetic Interference

Application of Intelligent Addressable Lighting Control System

Extra Lift Capacity to Enhance Operational Lift Traffic for 1 Goods Lift and 2

Passenger Lifts

Provision of Travelling Cable for Mobile Phone System for Lift Cars

Use of Compression Type Copper Pipe Fitting

Nuisance Free Plant Room Arrangement

Electro-magnetic Type Descaling System for the Boiler and Cooling Tower

Provision of Water Hammer Arrestor for Urinal and Wash Basin Sensor

Standardization of EC Plug Fans for AHU / PAU

Adequate Maintenance and Access Space for MEP Plant Rooms

1.2.1.4

1.2.1.5

1.2.1.6

1.2.1.7

1.2.1.8

1.2.1.9

1.2.1.10

1.2.1.11

1.2.1.12

1.2.1.13

The following table outlines a total of 51 value-added building services design provisions and

highlights of Overall Building Services and M&E Design covering the aspects of Operation

Efficiency, Safety and Reliability, Environmental Considerations, Sustainability and Energy

Efficiency that are best representing the merits and technical know-how offered in the building

services and M&E design. The detailed key value-added design provisions and highlights have

been explained and illustrated in the Section 2.1d.

Provision of Duty/ Standby PAU

Contract No.: SS E501 (Programme No.: 185GK)

Design and Construction of Transport Departments Vehicle Examination Centre

at Sai Tso Wan Road, Tsing Yi, New Territories

Section 1.0 Executive Summary

1.0

1.2.2

Environmental Considerations

1.2.4

Sustainability and Energy Efficiency

1.2.2.1

1.2.2.2

High Efficiency PV Panels c/w 327Wp output at R/F

Strategic Major Plant Room Location Planning and Arrangement to Minimize the

Noise Impact to NSR

Adoption of Natural Ventilation for Inspection Floors

Application of Sustainable & Renewable Solar Energy

Application of Light Pipe

Use of IMMS Central Control & Monitoring System for Automatic Irrigation System

Adoption of Heat Pipes in air ductworks for heat recovery of exhaust air

Adoption of Heat Pump for generating hot water by waste heat recovery

A/C Condensate Water Recycling System to pre-cool fresh air in PAU

1.2.4.1

1.2.4.2

Integrated Building Services Installation Approach

Variable Speed Drive (VSD) for all PAU, AHU, EAF, Chillers, Cooling Towers and

Water Pumps

Energy Efficient Lighting Design with LED Down Light

Adoption of Induction Lamps in Carpark Areas

Provision of Staircase Lighting Integrated with Motion Sensor

Energy Reclaim of Lift Regenerating Power

Water Efficiency Labeling Scheme (WELS)

Sustainable Building Energy Management System

BEAM Gold Grade, IAQ Excellent Class and Extra Low OTTV (5.19 W/m2)

Estimated Annual CO2 Reduction by Building Services Installation Equipment

Use of EC Plug Fan for PAU / AHU

A/C Condensate Water Recycling System to pre-cool fresh air in PAU Rainwater /

A/C Condensate Water Recycling System.

Use of Task Lighting at Open Plan Office

Provision of high efficiency oil-free water-cooled chillers

Provision of variable refrigerant volume (VRV) system with high COP

Provision of DC Brushless Type Fan Coil Units for variable speed control

Thermostatic controlled mechanical ventilation system for all plant rooms

Strategic Zoning of the Mechanical Ventilation System on inspection floors

1.2.2.3

1.2.2.4

1.2.2.5

1.2.2.6

1.2.2.7

1.2.2.8

1.2.2.9

1.2.4.3

1.2.4.4

1.2.4.5

1.2.4.6

1.2.4.7

1.2.4.8

1.2.4.9

1.2.4.10

1.2.4.11

1.2.4.12

1.2.4.13

1.2.4.14

1.2.4.15

1.2.4.16

1.2.4.17

1.2.4.18

Pre-cooling system by condensate recycling

Energy efficient water-cooled chillers

1.2.3

Safety and Reliability

1.2.3.1

1.2.3.2

Reliable Emergency and Essential Lighting Design

Tri-generation of Hot Water Sources by Heat Pump, Solar Panel and Unvented

Type Electrical Water Heater to Central Hot Water Supply System

Reliable AHU / PAU by using EC Plug Fans

Reverse Return Arrangement for Chilled Water System

Provision of duty and standby PAU with 100% standby capacity

Duty/ Standby arrangement for CRAC units for Server Rooms

1.2.3.3

1.2.3.4

1.2.3.5

1.2.3.6

BEAM

Plus

GOLD

IAQ Excellent

Class

BEAM Gold Grade, IAQ

Excellent Class and Extra Low

Contract No.: SS E501 (Programme No.: 185GK)

Design and Construction of Transport Departments Vehicle Examination Centre

at Sai Tso Wan Road, Tsing Yi, New Territories

1.2.5

Indoor Environmental Quality

1.2.5.1

1.2.5.2

Strategic Air Intake and Exhaust Locations

Demand Controlled Ventilation feature for AHUs by carbon dioxide sensors in the

duct return paths

Gas monitoring devices including carbon monoxide, sulphur dioxide and nitrogen

dioxide will be provided to control the mechanical ventilation system in inspection

lanes

Application of Indirect Reflector for Lighting Luminaire at Office Areas

Positive Pressure will be maintained inside inspection pits to prevent infiltration of

exhaust air from vehicles

1.2.5.3

1.2.5.4

1.2.5.5

Section 1.0 Executive Summary

Strategic Air Intake and Exhaust Locations

CFD Simulation For Inspection Hall

1.0

You might also like

- Basic Ice Rink Building Design Scope: OverviewDocument5 pagesBasic Ice Rink Building Design Scope: OverviewKCFUNGNo ratings yet

- PUBLICATION - A - 2358 - GN On Competition Law (English and Chinese)Document36 pagesPUBLICATION - A - 2358 - GN On Competition Law (English and Chinese)KCFUNGNo ratings yet

- Client Brief-New Competition Ordinance in Hong Kong A4 4pp March 2013 PDFDocument4 pagesClient Brief-New Competition Ordinance in Hong Kong A4 4pp March 2013 PDFKCFUNGNo ratings yet

- Active Silencers For Air-Conditioning Units: Welcome - Contents BackDocument15 pagesActive Silencers For Air-Conditioning Units: Welcome - Contents BackKCFUNGNo ratings yet

- AS 2118.4 - 2012 Residential SprinklersDocument54 pagesAS 2118.4 - 2012 Residential SprinklersKCFUNGNo ratings yet

- AS 2890.6-2009 Parking FacilitesDocument18 pagesAS 2890.6-2009 Parking FacilitesKCFUNG100% (5)

- Modern Plumbing IllustratedDocument458 pagesModern Plumbing IllustratedKCFUNGNo ratings yet

- BocaPCM-TES Job Reference 2014-FebDocument2 pagesBocaPCM-TES Job Reference 2014-FebKCFUNGNo ratings yet

- Mitsubishi - Air Conducting FanDocument4 pagesMitsubishi - Air Conducting FanKCFUNGNo ratings yet

- AKE Temperature & Pressure Relief ValveDocument2 pagesAKE Temperature & Pressure Relief ValveKCFUNGNo ratings yet

- Wolter Induction Fans A08.5 R2Document17 pagesWolter Induction Fans A08.5 R2KCFUNGNo ratings yet

- Apricus Collector Installation ManualDocument68 pagesApricus Collector Installation ManualKCFUNGNo ratings yet

- By Emaux: Your Solution in Water TechnologyDocument4 pagesBy Emaux: Your Solution in Water TechnologyKCFUNGNo ratings yet

- SE Series Centrifugal Pump Installation & Operating InstructionsDocument2 pagesSE Series Centrifugal Pump Installation & Operating InstructionsKCFUNGNo ratings yet

- Joya CatalogueDocument20 pagesJoya CatalogueKCFUNGNo ratings yet

- CQM TaikooDocument20 pagesCQM TaikooKCFUNGNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 4.6 Metre Class 4 Recessed 4 Post Lift Mot Bay DimensionsDocument1 page4.6 Metre Class 4 Recessed 4 Post Lift Mot Bay DimensionsWahidul Alam SrijonNo ratings yet

- Caterpillar 966HDocument28 pagesCaterpillar 966HMarcelo Cardozo80% (5)

- ALE Newsletter FEB AWLRsingleDocument12 pagesALE Newsletter FEB AWLRsinglesabah8800No ratings yet

- R2102011CHECKLIST For ElevdumbwaiterDocument2 pagesR2102011CHECKLIST For ElevdumbwaiterAlim Ur RahmanNo ratings yet

- Maintenance Manual: Vehicle Lift VL 30 & VL 35Document9 pagesMaintenance Manual: Vehicle Lift VL 30 & VL 35Anton LyakhovNo ratings yet

- Catalog - BVMDocument28 pagesCatalog - BVMAlexsandro CordeiroNo ratings yet

- Ansi - Itsdf B56-11-1 (2005) PDFDocument16 pagesAnsi - Itsdf B56-11-1 (2005) PDFAlain AñamuroNo ratings yet

- CGDCR-2017 Part-Iii Performance Regulations PDFDocument55 pagesCGDCR-2017 Part-Iii Performance Regulations PDFHakimNo ratings yet

- 1-Ship Lifts and Ro-Ro Ferry RampsDocument34 pages1-Ship Lifts and Ro-Ro Ferry RampsRhn RhnNo ratings yet

- Sais Inspector Guide En81-20Document94 pagesSais Inspector Guide En81-20Ali DiabNo ratings yet

- Guide-Forklift SafetyDocument21 pagesGuide-Forklift SafetyGUILLERMO VAZQUEZNo ratings yet

- The Complete Range of Pillar and Wall Jib Cranes For Loads Up To 6.3 TonnesDocument13 pagesThe Complete Range of Pillar and Wall Jib Cranes For Loads Up To 6.3 Tonnesabhibho12345No ratings yet

- Mop HongDocument31 pagesMop HongChâu Vĩnh LợiNo ratings yet

- Structural DesignDocument108 pagesStructural DesignPrasanna PandianNo ratings yet

- Allmand Night-Lite PRO II Operators Manual PDFDocument66 pagesAllmand Night-Lite PRO II Operators Manual PDFLuis Alberto Perez MoralesNo ratings yet

- Doosan Lift Truck d35s 5 d40s 5 d45s 5 d50c 5 d55c 5 Maintenance ManualDocument20 pagesDoosan Lift Truck d35s 5 d40s 5 d45s 5 d50c 5 d55c 5 Maintenance Manualashley100% (46)

- Bihar Building BylawsDocument13 pagesBihar Building BylawsAakanksha NidhiNo ratings yet

- GTE Company Profile Gulf TechDocument14 pagesGTE Company Profile Gulf TechMega MegaNo ratings yet

- RS-60-R200S 3-22-2016 MpartesDocument46 pagesRS-60-R200S 3-22-2016 MpartesEvert Vargas Torrez100% (1)

- BL L1000e 01 PDFDocument32 pagesBL L1000e 01 PDFJitheshbabu BabuNo ratings yet

- ASME Training and Development-Autumn-CalenderDocument7 pagesASME Training and Development-Autumn-CalenderLeon HernandezNo ratings yet

- 2M Tek TOP TEKDocument2 pages2M Tek TOP TEKamghardjillali_44923No ratings yet

- Specs CASE 821E SeriesDocument6 pagesSpecs CASE 821E SeriesDian SikumbangNo ratings yet

- Install Sensor Lsi Fl061Document14 pagesInstall Sensor Lsi Fl061AlterSon Grafi KalayNo ratings yet

- 99790-87100-02 - Know Your Lift TruckDocument48 pages99790-87100-02 - Know Your Lift TruckBARRENECHEA DELGADO ISAACNo ratings yet

- Manual Maintenance Interval Cat 416d 420d 42d 428d 430d 432d 442d Backhoe LoadersDocument47 pagesManual Maintenance Interval Cat 416d 420d 42d 428d 430d 432d 442d Backhoe LoadersManuel Canaza Ancasi77% (13)

- TDM 100 Mechanical Systems Manual Revision March 2010Document63 pagesTDM 100 Mechanical Systems Manual Revision March 2010Chaouki BoukhamlaNo ratings yet

- SpecDocument1 pageSpecBrad SalasaNo ratings yet

- Lift Truck Gear From DTAUTO - CADocument32 pagesLift Truck Gear From DTAUTO - CAGregGGHNo ratings yet

- Lifts and Escalators 3: Third Year B.Arch, Building Services Sulakshana BhanushaliDocument20 pagesLifts and Escalators 3: Third Year B.Arch, Building Services Sulakshana BhanushaliVenkat MuraliNo ratings yet