Professional Documents

Culture Documents

1 s2.0 S0957582096706262 Main

Uploaded by

MaheshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0957582096706262 Main

Uploaded by

MaheshCopyright:

Available Formats

09575820

Institution of Chemical Engineers

Open access under CC BY-NC-ND license.

BLOWDOWN OF LPG PIPELINES

S. M. RICHARDSON (FELLOW) and G. SAVILLE

Department of Chemical Engineering, Imperial College, London, UK

n order to be able properly to assess the hazards associated with the rapid

depressurization or blowdown of an oil, gas or condensate pipeline, there is a need to

be able to predict uid pressure, uid and wall temperatures and e ux rate,

composition and phase. Several computer programs have been developed to do this,

including our program BLOWDOWN. A comparison is made here of BLOWDOWN

predictions with the measurements made during eight of the tests using LPG carried out

by Shell and BP on the Isle of Grain in 1985. Four of the tests were for full-bore

depressurizations and four for depressurizations with ori ces at the open ends of the lines.

The BLOWDOWN predictions are shown to be in at least adequate, and often good,

agreement with the Isle of Grain measurements.

Keywords: blowdown; hydrocarbons; LPG; pipelines.

INTRODUCTION

The rapid depressurization or blowdown of an oil, gas or

condensate pipeline, whether deliberate or accidental, is

a hazardous operation. One part of the hazard arises

because of the very low temperatures generated within

the uid in the line. This leads to a reduction in the

temperature of the walls and possibly to a temperature

below the ductile-brittle transition temperature of the

steel from which the line is made. It can also possibly lead

to the generation of unacceptably high thermal stresses

within the line. It can in addition lead to the formation of

hydrates in cases when free water is present in the line.

Another part of the hazard arises because of the large

total e ux and high e ux rates that occur when the large

inventory of a typical line such as a sub-sea pipeline is

blown down.

In order to be able properly to assess the hazards

associated with depressurization of a pipeline containing

hydrocarbons, there is a need to be able to predict uid

pressure, uid and wall temperatures and e ux rate,

composition and phase. Several computer programs

have been developed to do this including:

pipelines containing hydrocarbon mixtures at elevated

pressures. One of the few sources of such data is the tests

using LPG carried out by Shell and BP on the Isle of

Grain89, full details of which are given elsewhere10.

Comparisons of BLOWDOWN predictions with some of

these test data are presented here.

ISLE OF GRAIN TESTS

The Isle of Grain tests were conducted in July to

September 1985. Two parallel pipelines were used, both

100 m long. The large pipeline was nominally of diameter

69 9 and the small pipeline was nominally of diameter 29 9 .

Ori ces of various shapes and sizes were used. Four

initial tests (F1-F4) were conducted using Freon-12.

Eighty-four main tests (P1-P84) were conducted using

commercial propane or LPG. The two pipelines were

extensively instrumented. Pressure transducers and

thermocouples measuring uid temperature were

attached along each line. Inventory and hold-up were

measured using load-cells and neutron back-scattering.

Video recordings were also made of the ows using

special windowed sections mid-way along and at the

open end of each line.

Two types of test were conducted: steady and

transient. Both types of test were initiated by rupture

of a disc at the downstream end of the pipeline. In the

steady tests, the ow through the pipeline was fed

steadily and continuously from an upstream reservoir. In

the transient tests, the ow was inherently unsteady and

there was no feed from the upstream reservoir. Clearly, it

is the transient tests which are of direct relevance to

depressurization. Eight of these, covering as wide a range

of conditions as possible, were selected for comparison

with BLOWDOWN predictions:

BLOWDOWN

developed

Imperial

College principally for

15

by the authors at

the simulation of the

depressurization of networks of vessels and associated

pipework on the topsides of o shore oil and gas

platforms (and extensively validated for such networks)

and extended to simulation of the depressurization of

pipelines;

OLGA developed at SINTEF for the simulation of

two-phase

ow in pipelines;

PLAC7 developed by AEA Technology also for the

simulation

of two-phase ow in pipelines.

6

One principal di culty with such predictive programs is,

however, a lack of proper validation against appropriate

experimental data for the depressurization of pipelines.

These data should preferably be for relatively large

P40, P42, P45 and P47 using the 69 9

Tests

Tests

P61, P63, P65 and P66 using the 29 9

235

line;

line.

236

RICHARDSON and SAVILLE

Table 1. Pipelines.

Line

69 9

29 9

Table 3. Initial and ambient conditions.

Length,

m

Inner

diameter,

mm

Outer

diameter,

mm

Wall

roughness,

mm

100.0

100.0

154.0

52.0

168.6

60.9

0.05

0.05

Details of the two carbon steel pipelines used in the tests

are given in Table 1.

Ori ces of various sizes (measured in terms of

equivalent diameter that is, the diameter of the circle

of the same cross-sectional area as the ori ce) and shapes

were used in the eight tests. Details are given in Table 2.

Note that tests P40, P42, P61 and P65 were for full-bore

depressurizations.

The LPG used in the tests comprised a mixture of

propane and other low molecular weight hydrocarbons,

such as butane and ethane. The approximate composition was 95 mole% propane and 5 mole% butane. The

initial pressure and temperature of the LPG and the

ambient air temperature and wind speed for the eight

tests are given in Table 3.

Ten pressure transducers and ten thermocouples (bare

metal with a response time of the order of milliseconds)

measuring temperature were attached along each line.

The thermocouples projected from the inside walls of the

lines and measured uid temperatures close to the wall.

Eight neutron back-scattering (NBS) devices were used

to measure liquid hold-up in each line. Twenty load-cells

were used to measure the inventory in each line. Details

of the precise locations of the measurement devices are

given elsewhere10.

It is di cult to make a reliable assessment of the

uncertainty in the data, mainly because no access can be

gained to the original data acquisition devices. Nevertheless, based on the nature of those devices and the

scatter in the measured data, the likely uncertainty is

estimated to be about 0.5 bar in the pressure data

(though the uncertainty is higher in test P61), 2C in the

temperature data, 5% in the load-cell inventory data

and 10% in the NBS hold-up data.

BLOWDOWN PROGRAM

The depressurization of the Isle of Grain pipelines

Table 2. Ori ces.

Test

Line

Ori ce

diameter,

mm

P40

P42

P45

P47

P61

P63

P65

P66

69 9

69 9

69 9

69 9

29 9

29 9

29 9

29 9

154.0

154.0

75.0

50.0

52.0

35.0

52.0

35.0

Shape

Circular

Circular

Circular

Circular

Circular

Circular

Circular

Equilateral

triangular

Test

Initial LPG

pressure,

bar a

Initial LPG

temperature,

C

Ambient air

temperature,

C

Wind

speed,

m s- 1

P40

P42

P45

P47

P61

P63

P65

P66

21.6

11.3

11.4

21.3

21.2

22.5

11.6

21.8

17.8

20.0

15.9

14.6

(?)

18.4

13.8

13.3

19.1

18.6

16.7

15.4

(?)

(?)

(?)

(?)

(?)

8.8

6.5

(?)

(?)

(?)

(?)

(?)

has been simulated using our computer package

BLOWDOWN4. BLOWDOWN has been developed

principally for simulation of the depressurization of

networks of vessels and associated pipework on

o shore oil and gas platforms. The distinction between

depressurization of a vessel and depressurization of a

pipeline is that there is a signi cant pressure di erence

within the latter but not within the former. Thus, for

depressurization of a vessel, the only signi cant

pressure drops are across the ori ce and between the

exit of the ori ce and the atmosphere if the ow is

choked at the ori ce. For depressurization of a

pipeline, in contrast, there are signi cant pressure

drops along the line, across the ori ce if the ori ce is

small enough (clearly, if there is a full-bore rupture,

there is no pressure drop across the ori ce) and

between the exit of the ori ce and the atmosphere if

the ow is choked at the ori ce.

The main features of BLOWDOWN are as follows.

Space and time discretization

A pipeline is divided axially into many elements, the

size of each of which is varied dynamically during the

calculation in such a way that changes in physical

properties along the element may be neglected. A vessel

is divided into three zones:

A top zone of gaseous hydrocarbon (including

evaporated

water and suspended liquid droplets which

have condensed from the gas);

A middle zone of liquid hydrocarbon (including

dissolved

water and gas bubbles which have evaporated

from the liquid);

A bottom zone of free water (including dissolved

hydrocarbons).

Depressurization is broken down into a sequence of

pressure, rather than time, steps because pressure is a

more relevant parameter thermodynamically.

Fluid mechanics

Flow (whether one-phase or two-phase) is assumed

to be quasi-steady (that is, the mass ow rate is

assumed to be the same in every element in a pipeline

at a given instant of time) and, for a two-phase ow, to

be homogeneous (that is, the gas and liquid in an

element move at the same velocity). Standard methods

are used to determine friction factor and hold-up.

Trans IChemE, Vol 74, Part B, November 1996

BLOWDOWN OF LPG PIPELINES

Thermodynamics

Experimental evidence has shown that it is most

important to model the thermodynamics of depressurization accurately since failure to do so can lead

to trajectories through phase (pressure-temperaturecomposition) space which are grossly in error. For this

reason, thermodynamic, phase and transport properties

of the multi-phase multi-component uids are calculated

rigorously by an extended principle of corresponding

states using our computer package PREPROP. The

extension is necessary in order to treat non-spherical

molecules through the use of shape factors. The idea

behind the thermodynamic calculations is to obtain an

expression for the di erence between the actual value of

a property at a given volume and temperature and the

value which a perfect gas would have at the same volume

and temperature: the properties of the mixture are then

related to those of a single reference substance, methane.

The method, when coupled with expressions for perfect

gas properties, enables one to obtain thermodynamically

consistent values for the enthalpy, pressure and fugacity

of any single-phase mixture. PREPROP uses these values

and performs phase equilibrium calculations including

dew and bubble points and isothermal, isentropic and

isenthalpic liquid-vapour ashes. Other properties such

as thermal conductivity, viscosity and surface tension

can also be predicted though these are not based on the

same rigorous thermodynamics.

Heat transfer

In a pipeline, heat transfer is assumed to be by:

convection to the uid;

Forced

Transient

insulation); conduction through the wall (including any

convection to the air or sea surroundingForced/natural

the line.

In a vessel, heat transfer is assumed to be by:

convection in the top zone;

Forced/natural

Nucleate/

lm

boiling

middle zone;

Natural convection ininthethebottom

zone;

Transient conduction through the wall

(including any

insulation);

convection to the air or sea surroundingForced/natural

the vessel.

In all cases, standard correlations are used to determine

heat transfer coe cients.

Ori ces

Because transit times through ori ces are comparable

with times for nucleation and growth of gas bubbles in a

volatile liquid, non-equilibrium ashing ow is assumed

when just volatile liquid is fed to an ori ce. Otherwise,

the ow approaching an ori ce is assumed to be in

thermodynamic and phase equilibrium.

Choking

When choking occurs, whether for a gas, liquid or twophase (gas plus liquid) ow, the mass ow rate is a

maximum.

Trans IChemE, Vol 74, Part B, November 1996

237

Balance equations

In order to close the system of equations describing

depressurization, mass and energy balances are performed. For pipelines, momentum balances are also

performed. The balances for each element of a pipeline

are linked together in an iterative scheme to satisfy the

boundary condition of ambient pressure (or choking

pressure if the ow becomes choked) at the open end of

the line or exit of the ori ce. The iterative variable is the

mass ow rate through the line.

Pressure and temperature changes

Allowance is made for the pressure change when a pipe

of one diameter joins a pipe of another diameter. In

particular, when there is a sudden enlargement of

diameter, the Borda-Carnot equation (or its two-phase

analogue) is used to determine the pressure change. No

other pressure changes (other than those arising continuously from friction at walls) are, however, allowed

for. Thus pressure changes at bends and tees, in

particular, are ignored. An energy balance is used to

determine the temperature change at expansions (or

contractions) and also tees arising from interconversion

of mechanical (kinetic) energy and thermal energy.

Allowance is also made for conversion of mechanical

(pressure) energy lost through friction at pipe walls into

thermal energy. This is especially important when the

ow in a given pipeline is fast, in particular when it is

choked or nearly choked.

METHODOLOGY

The approximate composition of the LPG used in the

tests is 95 mole% propane and 5 mole% butane.

Numerical tests using BLOWDOWN reveal that the

predictions are relatively insensitive to the precise initial

composition (the only signi cant e ect is on uid

temperatures towards the end of a depressurization).

Initial LPG pressures and temperatures are known (see

Table 3) for all tests except test P61, for which the initial

LPG temperature is unknown: a value of 17C has been

assumed. Ambient air temperatures are known for

tests P40, P42, P45 and P47 only (see Table 3). Air

temperatures of 17C have been assumed for tests P61,

P63, P65 and P66. Wind speeds are known for tests P42

and P45 only. Numerical tests made using BLOWDOWN reveal that the predictions are relatively

insensitive to the assumed wind speed: the only

signi cant e ect is on wall temperatures, which were

not measured in the tests. Accordingly, it has been

assumed that the wind speed for all tests is zero and thus

the ambient air is assumed to be freely-convecting. The

ambient air pressure (and hence the back-pressureon the

ow from the pipeline) is assumed to be 1 bar a for all

tests.

In tests P40, P42, P61 and P65 in which there is a fullbore depressurization, the equivalent ori ce diameter is

unambiguously that of the bore of the pipeline being

depressurized (assuming that the discs used to initiate the

tests ruptured fully: the evidencesuggests that they did so

for these tests) and the discharge coe cient is unity. In

tests P45, P47, P63 and P66, in which there is an ori ce at

the end of the line, the magnitude of the equivalent

238

RICHARDSON and SAVILLE

Table 4. Equivalent ori ce diameters.

Test

Nominal

ori ce

diameter,

mm

Adopted

ori ce

diameter,

mm

Adopted

discharge

coe cient

P45

P47

P63

P66

75.0

50.0

35.0

35.0

95.0

70.4

42.5

42.5

0.80

0.80

0.80

0.80

ori ce diameter is less clear. Experimental evidence3

shows that a discharge coe cient of 0.80 is appropriate

for ow of pressurized gas or gas plus liquid through an

ori ce. In order to match the measured e ux rates from

the pipelines, it has been found necessary to adopt the

values of equivalent ori ce diameters given in Table 4

instead of the nominal ones. The reason for the

discrepancy between the nominal and adopted values is

unclear. It may be associated with an assumed value of

discharge coe cient corresponding to a nominal equivalent ori ce diameter (a value of 0.61 is often quoted,

based on measurements for ow of liquid through an

ori ce: a higher value is appropriate for ows of

pressurized gas or gas plus liquid, probably because the

vena contracta becomes larger as a result of gas

expansion).

PREDICTIONS

Key predictions from the complete BLOWDOWN

simulations are given in Figures 18 to enable direct

comparison to be made with the Isle of Grain data:

Graphs P##P give the variations with time of the uid

pressure

at the closed and open ends of the line;

Graphs P##T give the variations with time of the bulk

uid

temperature at the closed and open ends of the line

(note that there are no measured temperature data for

test P61);

Graphs P##I give the variations with time of the total

uid

inventory of the line based on the load-cell data

(and not on the NBS data because they are much noisier

than the load-cell data);

where ## refers to the test number. Throughout,

solid lines refer to measurements and broken lines to

predictions.

PRESSURE

Measurements

Graphs P##P all exhibit an extremely rapid initial

decrease in pressure at the closed end of the line to a

pressure of about 8 bar a and, indeed, a slight undershoot.

The rapid decrease corresponds to a very short period of

expansion of the compressed LPG followed almost at

once by ashing of the LPG. The bubble point pressure

(or saturated vapour pressure) of the LPG used at 20C

(the approximate starting temperature for all of the tests)

is about 8 bar a. The undershoot is probably associated

with non-equilibrium arising from the rapidity of the

pressure decrease and perhaps also re ection of expansion

waves o the closed end of the line.

Figure 1. Graphs P40P/T/I: solid lines measured; broken lines

predicted.

Graphs P##P show that the pressure at the open

end of the line is always less than that at the closed

end, as is to be expected. However, the pressure at

the open end of the line is very similar to that at the

closed end in tests P45 and P47: this is because

the ori ce area is relatively small compared with the

cross-sectional area of the line and so the pressure

Trans IChemE, Vol 74, Part B, November 1996

BLOWDOWN OF LPG PIPELINES

239

Figure 2. Graphs P42P/T/I: solid lines measured; broken lines

predicted.

Figure 3. Graphs P45P/T/I: solid lines measured; broken lines

predicted.

drop along the line is negligible compared with that

across the ori ce.

The extremely rapid decrease in pressure at the closed

end of the line, corresponding to a very short period of

expansion of the compressed LPG followed almost at

once by ashing of the LPG, would be much slower in a

really long pipeline, where expansion of the compressed

liquid could not so quickly be accommodated because of

signi cant frictional and inertial e ects. Similarly, the

pressure at the open end of a really long pipeline would

not be so close to that at the closed end unless the ori ce

area were much smaller than the cross-sectional area of

the line, again because of signi cant frictional and

inertial e ects.

Trans IChemE, Vol 74, Part B, November 1996

240

RICHARDSON and SAVILLE

Figure 4. Graphs P47P/T/I: solid lines measured; broken lines

predicted.

Figure 5. Graphs P61P/T/I: solid lines measured; broken lines

predicted.

The pressure at the open end of the line in test P61 tends

to a value of about - 4 bar a when the depressurization is

complete. This is clearly impossible and re ects de ciencies in the raw pressure data for that test. It is, however,

di cult to correct the raw data: addition of 5 bar (say) to

all values seems of doubtful validity. For this reason, none

of the measured data have been modi ed in any way.

Predictions

Graphs P# #P show that there is generally at least

adequate, and often good, agreement between the

predictions and the measurements of uid pressure.

The discrepancy in pressure is less than about 2 bar at

any given instant. The corresponding discrepancy in time

is less than about 4 s at any given pressure. An exception

Trans IChemE, Vol 74, Part B, November 1996

BLOWDOWN OF LPG PIPELINES

241

Figure 6. Graphs P63P/T/I: solid lines measured; broken lines

predicted.

Figure 7. Graphs P65P/T/I: solid lines measured; broken lines

predicted.

arises at the open end of the line in test P61, for which the

measurements are clearly erroneous.

Graphs P##P show that the predictions all reproduce

the extremely rapid initial decrease in pressure corresponding to expansion of compressed liquid. They fail,

however, to reproduce any overshoot. This is because no

attempt is made in BLOWDOWN to simulate the

motion of the expansion wave from the open end of

the line to the closed end immediately after initiation of

the depressurization, or indeed to simulate any other

wave motions up and down the line, which are rather

complex but usually irrelevant.

Trans IChemE, Vol 74, Part B, November 1996

242

RICHARDSON and SAVILLE

almost certainly associated with the corresponding

pressure undershoot.

Graphs P##T all show that the temperature at the

open end of the line is less than that at the closed end, as

is to be expected. However, the temperature at the open

end of the line is very similar to that at the closed end of

the line in test P47. This is because the ori ce area is then

relatively small compared with the cross-sectional area of

the line and so the pressure drop along the line is

negligible compared with that across the ori ce, which in

turn means that conditions are relatively uniform along

the length of the line.

Graphs P##T generally show that there is a signi cant

and rapid rise in temperature at the open end of the line

towards the end of the depressurization. The exceptions

are test P45 for which the corresponding temperature rise

might in fact occur at a later time and perhaps test P47

where there is a great deal of scatter in the data (and also

perhaps test P61 for which there are no data). There is also

a signi cant and rapid rise in temperature at the closed

end of the line towards the end of the depressurization in

tests P47 and P63. These rises start at the moment when

the ow ceases to be two-phase (gas plus liquid) and

becomesone-phase (gas) instead and presumably re ects a

signi cant change in the heat transfer rate from the wall to

the uid. The slight levelling of the temperature immediately before the rise in temperature at the open end of the

line in test P42 is associated with the cessation of choking

at the open end of the line.

Graphs P##T show that the minimum temperature,

which occurs towards the end of each test, is about

- 40C, which corresponds to the bubble point temperature of LPG at 1 bar a (the bubble point temperature at 1

bar a is - 42C for a mixture of 95 mole% propane and 5

mole% butane).

Figure 8. Graphs P66P/T/I: solid lines measured; broken lines

predicted.

TEMPERATURE

Measurements

Graphs P##T, with the exception of graph P47T, all

exhibit an extremely rapid initial decrease in temperature

at the open end of the line to a temperature of about

10C and, indeed, a slight undershoot. The undershoot is

Predictions

Graphs P##T show that there is generally at least

adequate, and often good, agreement between the

predictions and the measurements of bulk uid temperature. The discrepancy in temperature is less than about

10C at any given instant. The corresponding discrepancy

in time is less than about 4s at any given temperature.

Graphs P##T show that the largest discrepancies

between the predictions and the measurements arise

towards the end of the depressurizations. The reason for

this is probably the sensitivity of the predictions to the

assumed composition of the LPG. Although adjustments

could have been made to the assumed composition to

achieve better agreement, this has not been done. Indeed,

no adjustments have been made to BLOWDOWN or to

any of the data used in the simulations (with the

exception of the equivalent ori ce diameters in tests

P45, P47, P63 and P66). The simulations are thus purely

predictive.

INVENTORY

Measurements

Graphs P63I and P66I show that the e ux from the

line is essentially una ected by the geometry of the ori ce

Trans IChemE, Vol 74, Part B, November 1996

BLOWDOWN OF LPG PIPELINES

Table 5. Residual liquid

Test

Maximum fractional

residual liquid, v/v

P45

P47

P63

0.13

0.22

0.05

(recall that test P63 is for a circular ori ce and test

P66 for an equilateral triangular ori ce of the same

area). While this result is likely to be true more generally,

it may not be true if the aspect ratio of the ori ce

becomes very large if, say, the ori ce is a narrow slit.

Unfortunately, no tests were performed with narrow slit

ori ces.

Predictions

Graphs P##I show that there is generally at least

adequate agreement between the predictions and the

measurements of uid inventory. The discrepancy in

inventory is less than about 10% of the initial inventory

at any given instant. The corresponding discrepancy in

time is less than about 4s at any given inventory, except

in test P47, when it is about 8s.

Graphs P45I and P47I show that the predicted

inventory tends to zero at the end of the depressurization

whereas the measured inventory is nite and positive.

The reason for this may be that the ori ce acts as a dam

in these tests, tending to hold liquid back in the pipeline.

Both Isle of Grain pipelines were levelled very

accurately (apparently to the order of mm). For the

full-bore tests (P40, P42, P61 and P65), there would be

no tendency for liquid to be held back and all of it

would be expected to drain out eventually (though the

drainage rate would generally be insigni cant compared with the pressure-induced e ux from the line).

For the tests in which there is an ori ce at the end of

the line (P45, P47, P63 and P66), if the liquid level at

the end of the depressurizations were to be coincident

with the bottom of the ori ce, then elementary

geometry can be used to estimate the maximum volumes

of residual liquid held back. The results of such a

calculation (based on the adopted equivalent ori ce

diameters given in Table 4, as opposed to the nominal

ones, and normalized with respect to the initial liquid

volume) are given in Table 5. Note that no estimate is

given for test P66 since a triangular ori ce was used for

that test and its orientation appears not to have been

recorded.

Clearly, it is most unlikely that the maximum residual

volume would in fact remain in the line at the end of a

depressurization. Indeed, the measurements suggest that

around half of the maximum remains in tests P45 and

P47 (that in test P63 is almost undiscernible). Such

residual liquid might have a signi cant e ect on the

temperature of the bulk uid towards the end of a

depressurization.

Graphs P# #I show that the predicted inventory is

consistently greater than the measured one (except

Trans IChemE, Vol 74, Part B, November 1996

243

toward the end of some depressurizations, when there

is considerable uncertainty in the measurements). The

predicted e ux rate is correspondingly lower than the

measured one. The reason for this is unclear but may

well be associated with the assumptions of quasi-steady

and homogeneous ow made in BLOWDOWN. Independent evidence11 based on some of the Isle of Grain

data supports this conjecture. A much more re ned

model of pipeline depressurization (recall that BLOWDOWN was developed principally for simulation of

vessel depressurization) has been developed by the

authors12,13 in which the ow is allowed to be fully

transient (thus relaxing the assumption of quasi-steadiness) and phase slip is allowed through use of a two uid model (thus relaxing the assumption of homogeneity). Much better agreement is found between

predictions and measurements for a limited set of Isle

of Grain tests so far examined. The disadvantage with

the use of the more re ned model is the signi cantly

increased computer run times. Whereas BLOWDOWN

typically requires a few hours to perform a simulation

of an Isle of Grain test on a 386 or 486 machine tted

with an 860 co-processor, the more re ned model

typically requires a few days.

CONCLUSION

The objective of the work reported here was validatory

comparison of the predictions of BLOWDOWN with

some of the Isle of Grain test data. The predictions have

been shown to be in at least adequate, and often good,

agreement with the Isle of Grain measurements, permitting increased con dence to be placed in predictions

made using BLOWDOWN.

REFERENCES

1. Haque, M. A., Richardson,S. M., Saville,G. and Chamberlain, G.,

1990, Rapid depressurizationof pressure vessels, J Loss Prev Proc

Ind, 3: 47.

2. Haque, M. A., Richardson, S. M. and Saville, G., 1992, Blowdown

of pressurevessels. I. Computer model, Trans IChemE, 70 (B1): 3

9.

3. Haque, M. A., Richardson,S. M., Saville,G., Chamberlain, G. and

Shirvill, L., 1992, Blowdown of pressure vessels. II. Experimental

validation of computer model and case studies, Trans IChemE, 70

(B1): 1017.

4. Richardson, S. M. and Saville, G., 1991, Blowdown of pipelines,

Oshore Europe 91 (Society of Petroleum Engineers, Aberdeen),

paper SPE 23070.

5. Richardson, S. M. and Saville, G., 1992, Blowdown of vessels and

pipelines, Major Hazards Onshore and Oshore, Symposium Series

No. 130, 195210 (IChemE, Rugby, UK).

6. Bendiksen, K. H., Malnes, D., Moe, R. and Nuland, S., 1991, The

dynamic two- uid model OLGA: theory and application, SPE

Production Engineering, 6: 171180.

7. Hall, A. R. W., Butcher, G. R. and Teh, C. E., 1993,

Transient simulation of two-phase hydrocarbon ows in

pipelines, European Two-Phase Flow Group Meeting (Hannover),

paper I4.

8. Cowley, L. T. and Tam, V. H. Y., 1988, Consequences of

pressurised LPG releases: the Isle of Grain full scale experiments,

GASTECH 88, 13th International LNG/LPG Conference, Kuala

Lumpur.

244

RICHARDSON and SAVILLE

9. Tam, V. H. Y. and Higgins, R. B., 1990, Simple transient release

rate models for releases of pressurised liquid petroleum gas from

pipelines, J Haz Mat, 25: 193203.

10. Richardson, S. M. and Saville, G., 1996, Isle of Grain pipeline

depressurisationtests, HSE OTI 96 ###. (HMSO, London).

11. Pots, B. F. M., 1990, Numerical simulation of multi-component

two-phasepipelineblowdowns using the homogeneousequilibrium

model, Shell Report, AMGR.90.337.

12. Chen, J-R., Richardson, S. M. and Saville, G., 1995, Modelling of

two-phase blowdown from pipelines- I. A hyperbolicmodel based

on variational principles, Chem Eng Sci, 50: 695713.

13. Chen, J-R., Richardson, S. M. and Saville, G., 1995, Modelling of

two-phase blowdown from pipelines - II. A simpli ed numerical

method for multi-component mixtures, Chem Eng Sci, 50: 2173

2187.

ACKNOWLEDGEMENTS

The experimental data upon which this paper is based have been

made available by Shell Research (Thornton). The analysis of the data

was funded by the Health and Safety Executive.

ADDRESS

Correspondence concerning this paper should be addressed to

Professor S.M. Richardson, Department of Chemical Engineering,

Imperial College, Prince Consort Road, London SW7 2BY. E-mail:

s.m.richardson@ic.ac.uk

The manuscript was received 7 June 1996 and accepted for publication

12 July 1996.

Trans IChemE, Vol 74, Part B, November 1996

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

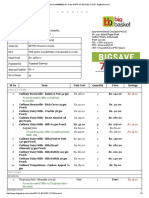

- Invoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketDocument2 pagesInvoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketMahesh0% (1)

- Top Malls in Chennai CityDocument8 pagesTop Malls in Chennai CityNavin ChandarNo ratings yet

- Pulanche Patralekhan PDFDocument1 pagePulanche Patralekhan PDFMaheshNo ratings yet

- View PDFDocument2 pagesView PDFMaheshNo ratings yet

- BOILERDocument6 pagesBOILERapi-26570979100% (3)

- Comparison To WorkbenchDocument5 pagesComparison To WorkbenchMaheshNo ratings yet

- 05.0 Operating ProceduresDocument8 pages05.0 Operating ProceduresMaheshNo ratings yet

- How To Get A Job - 57 TacticsDocument36 pagesHow To Get A Job - 57 TacticsShemin T JohnNo ratings yet

- 1101.0969 2 PDFDocument10 pages1101.0969 2 PDFMaheshNo ratings yet

- ArachchigeEJSR86 3Document12 pagesArachchigeEJSR86 3MaheshNo ratings yet

- VishakhaDocument3 pagesVishakhaMaheshNo ratings yet

- Aspen Plus Simulation of CO2 Removal From Coal and Gas Fired Power PlantsDocument9 pagesAspen Plus Simulation of CO2 Removal From Coal and Gas Fired Power Plantstaufany99No ratings yet

- OLGA Link User GuideDocument51 pagesOLGA Link User GuideekabudiartiNo ratings yet

- PH Coagulant DosageDocument6 pagesPH Coagulant Dosageromdhan88No ratings yet

- Noc - Frequently Asked QuestionsDocument6 pagesNoc - Frequently Asked QuestionsMaheshNo ratings yet

- 2012christiansen PDFDocument116 pages2012christiansen PDFMaheshNo ratings yet

- Strategic Investment Analysis - PINSDocument10 pagesStrategic Investment Analysis - PINSMaheshNo ratings yet

- Control Valve Sizing for Viscous Crude Oil FlowDocument1 pageControl Valve Sizing for Viscous Crude Oil Flowmaulana_madridistaNo ratings yet

- REfrigeration CO2 GuidelinesDocument7 pagesREfrigeration CO2 GuidelinesMaheshNo ratings yet

- Heat Transfer Excel Calculations 1Document39 pagesHeat Transfer Excel Calculations 1Sharon LambertNo ratings yet

- Rigorously Size Relief Valves For Critical FluidsDocument10 pagesRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Bendik Sen 1991Document10 pagesBendik Sen 1991MaheshNo ratings yet

- O Hydrate Formation ReportDocument10 pagesO Hydrate Formation ReportMaheshNo ratings yet

- CVGASDocument1 pageCVGASrarunr1No ratings yet

- 02 - Heat ExchangersDocument107 pages02 - Heat ExchangersMaheshNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- BOG CalDocument6 pagesBOG CalSook Thiam LeeNo ratings yet

- 05.0 Operating ProceduresDocument8 pages05.0 Operating ProceduresMaheshNo ratings yet

- GIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyDocument17 pagesGIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyJames DeanNo ratings yet

- Lifespan Development Canadian 6th Edition Boyd Test BankDocument57 pagesLifespan Development Canadian 6th Edition Boyd Test Bankshamekascoles2528zNo ratings yet

- Sewage Pumping StationDocument35 pagesSewage Pumping StationOrchie DavidNo ratings yet

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Document19 pagesMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldNo ratings yet

- Theory of Linear Programming: Standard Form and HistoryDocument42 pagesTheory of Linear Programming: Standard Form and HistoryJayakumarNo ratings yet

- The Ultimate Advanced Family PDFDocument39 pagesThe Ultimate Advanced Family PDFWandersonNo ratings yet

- Evolution of Bluetooth PDFDocument2 pagesEvolution of Bluetooth PDFJuzerNo ratings yet

- Zelev 1Document2 pagesZelev 1evansparrowNo ratings yet

- PLC Networking with Profibus and TCP/IP for Industrial ControlDocument12 pagesPLC Networking with Profibus and TCP/IP for Industrial Controltolasa lamessaNo ratings yet

- HenyaDocument6 pagesHenyaKunnithi Sameunjai100% (1)

- Tension field beams: Aircraft wing spar analysisDocument19 pagesTension field beams: Aircraft wing spar analysisPrajeesh RajNo ratings yet

- Orc & Goblins VII - 2000pts - New ABDocument1 pageOrc & Goblins VII - 2000pts - New ABDave KnattNo ratings yet

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDocument20 pagesSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyNo ratings yet

- PointerDocument26 pagesPointerpravin2mNo ratings yet

- BPL Millipacs 2mm Hardmetrics RarDocument3 pagesBPL Millipacs 2mm Hardmetrics RarGunter BragaNo ratings yet

- Report Emerging TechnologiesDocument97 pagesReport Emerging Technologiesa10b11No ratings yet

- Tigo Pesa Account StatementDocument7 pagesTigo Pesa Account StatementPeter Ngicur Carthemi100% (1)

- Liebert PSP: Quick-Start Guide - 500VA/650VA, 230VDocument2 pagesLiebert PSP: Quick-Start Guide - 500VA/650VA, 230VsinoNo ratings yet

- Archlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Document16 pagesArchlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Goh Ka WeeNo ratings yet

- Lecture02 NoteDocument23 pagesLecture02 NoteJibril JundiNo ratings yet

- 08 Sepam - Understand Sepam Control LogicDocument20 pages08 Sepam - Understand Sepam Control LogicThức Võ100% (1)

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocument12 pagesMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNo ratings yet

- Krok2 - Medicine - 2010Document27 pagesKrok2 - Medicine - 2010Badriya YussufNo ratings yet

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDocument20 pagesMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalNo ratings yet

- Book Networks An Introduction by Mark NewmanDocument394 pagesBook Networks An Introduction by Mark NewmanKhondokar Al MominNo ratings yet

- Yellowstone Food WebDocument4 pagesYellowstone Food WebAmsyidi AsmidaNo ratings yet

- Energy AnalysisDocument30 pagesEnergy Analysisca275000No ratings yet

- John Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JDocument12 pagesJohn Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JFrances Ann TevesNo ratings yet