Professional Documents

Culture Documents

Seafastening Design Check

Uploaded by

Bolarinwa100%(2)100% found this document useful (2 votes)

1K views3 pagesSeafastening design check

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSeafastening design check

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

1K views3 pagesSeafastening Design Check

Uploaded by

BolarinwaSeafastening design check

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

11/27/2014

1.0

ATTACHMENT 1

Designed by : AO

Checked by : AO

CPF2 SEAFASTENING

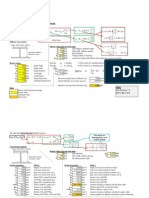

The CPF2 is transported on the Jascon 17A and sea-fastened using grillage and stoppers. The

following sketch shows the CPF2 transportation on the barge deck

CP2.xmcd

Page 1 of 3

11/27/2014

ATTACHMENT 1

Designed by : AO

Checked by : AO

1.1 Input Data

1.11 Mechanical Properties

Maximum cargo weight: Ps 683tonne

Spacing of seafastening roll 1 & 2, y s 17080mm

Spacing between pitch seafastening 1 and 2 x s 16500mm

COG height of CP2 h s 7736mm

Horizontal distance of roll seafastening 1 and 2 from the COG

a 8542mm

b 8542mm

acceleration due to roll : ars 0.6

acceleraion due to heave : ahs 0.3

acceleraion due to pitch : aps 0.4

Force on CP2 due to roll : frs Ps ars 409.8 tonne

Force on CP2 due to pitch : fps Ps aps 273.2 tonne

Longitudinal Force on Seafastening 1

frs

Force on seafastening due to roll : frs1

40.98 tonne

10

fps

Force on sefatening due to pitch : fps1

45.533 tonne

6

Transverse and Longitudinal Force on Seafatening 2

frs

Force on seafastening due to roll : frs2

40.98 tonne

10

fps

Force on seafastening due to pitch : fps2

45.533 tonne

6

CP2.xmcd

Page 2 of 3

11/27/2014

ATTACHMENT 1

Designed by : AO

Checked by : AO

1.2 Uplift Check

Uplift of the container exsits if:

f rs h s P 1 ah.s

0

ys

2

frs h s Ps 1 ahs

53.44 tonne

ys

Hence, there is no uplift, stoppers are sufficient to stabilize the cargo.

1.3 Stopper Check

The maximum load applied on 1 ROLL stopper

Fws frs1 40.98 tonne

The analysis of the seafastening has been carried out using SAC5.4

1.4 Stopper Check

The maximum load applied on 1 PITCH stopper

Fps fps2 45.533 tonne

The analysis of the seafastening has been carried out using SAC5.4

CP2.xmcd

Page 3 of 3

You might also like

- SpreadsheetDocument219 pagesSpreadsheetLit Phen TuNo ratings yet

- Sea Fastening Desig MannualDocument36 pagesSea Fastening Desig Mannualjamesmec20013588100% (2)

- Grillage&Seafastening DesignExampleDocument66 pagesGrillage&Seafastening DesignExamplefelipecmello100% (1)

- Seafastening Holding Down BracketDocument1 pageSeafastening Holding Down BracketRohan Karande50% (2)

- Load OutDocument239 pagesLoad OutDeepak Kumar100% (2)

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoDocument4 pagesMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelNo ratings yet

- Dog Plate & Tubular Support Subsea Template DesignDocument4 pagesDog Plate & Tubular Support Subsea Template DesignAkhmad Syahroni100% (1)

- Seafastening Calculations Transit ModifiedDocument380 pagesSeafastening Calculations Transit ModifiedUtkarsh RamayanNo ratings yet

- Cargo acceleration calculation sheetDocument2 pagesCargo acceleration calculation sheetiw2fualNo ratings yet

- MOORING CALCULATIONS (S)Document6 pagesMOORING CALCULATIONS (S)halimNo ratings yet

- Seafastening Design CalculationsDocument82 pagesSeafastening Design CalculationsInhake AutechreNo ratings yet

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDDocument2 pagesB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- Barge motion calculation sheetDocument7 pagesBarge motion calculation sheetSiva ShankarNo ratings yet

- Jacket Launching AnalysisDocument7 pagesJacket Launching Analysisiw2fualNo ratings yet

- Grillage Seafastening DesignExampleDocument66 pagesGrillage Seafastening DesignExampleeNo ratings yet

- Sea FasteningDocument2 pagesSea FasteningOlanrewaju Tope100% (1)

- Stopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Document6 pagesStopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Karthik36100% (2)

- Seafastening DesignDocument14 pagesSeafastening DesigntristanxpNo ratings yet

- DANA-Technical Note (TN)Document8 pagesDANA-Technical Note (TN)Samsul Imran BahromNo ratings yet

- Ground Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneDocument6 pagesGround Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneTran Van DaiNo ratings yet

- Ballast PlanDocument2 pagesBallast Planseadog100% (1)

- Aj30 Reporttow, SeafasteningDocument64 pagesAj30 Reporttow, Seafasteningsabah8800100% (7)

- SEAFASTENING DESIGN CALCULATION FOR TRANSPORT LOADSDocument1 pageSEAFASTENING DESIGN CALCULATION FOR TRANSPORT LOADSlkc 8100% (1)

- LGS Seafastening Design - Revision 3Document2 pagesLGS Seafastening Design - Revision 3ksangeeth2000No ratings yet

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- Longitudinal Strength Analysis of Barge During CPP2 Jacket LoadoutDocument106 pagesLongitudinal Strength Analysis of Barge During CPP2 Jacket LoadoutSanieBurhan100% (3)

- Sea TransportationDocument8 pagesSea TransportationMark Samsel RohanNo ratings yet

- Ballasting Calculation For The Transportation of PLEMsDocument17 pagesBallasting Calculation For The Transportation of PLEMsBolarinwa100% (1)

- 8E.3 - Barge - Deflection - Sea - TransDocument11 pages8E.3 - Barge - Deflection - Sea - TransSiva ShankarNo ratings yet

- OCIMF Environment Forces CalculatorDocument9 pagesOCIMF Environment Forces Calculatorshahjada100% (1)

- Seafastening Design Calculation - Transportation LoadsDocument1 pageSeafastening Design Calculation - Transportation LoadsBolarinwa100% (5)

- Seafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3Document17 pagesSeafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3JackNo ratings yet

- Sacs-Basics PDFDocument113 pagesSacs-Basics PDFanilNo ratings yet

- Barge 180Ft Deck Load Capacity & Strength-Rev1Document52 pagesBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- SACS Motion StabilityDocument64 pagesSACS Motion Stabilityramy abazaNo ratings yet

- Transportation Analysis Dynamic Forces Calculation: + Roll Heave (Load Case 101)Document2 pagesTransportation Analysis Dynamic Forces Calculation: + Roll Heave (Load Case 101)Booraj DuraisamyNo ratings yet

- V1 0 PDFDocument8 pagesV1 0 PDFnap_carino100% (1)

- Acceleration Calculations TeoryDocument3 pagesAcceleration Calculations TeoryBolarinwaNo ratings yet

- Cargo Acceleration Forces WWW - Thenavalarch.com V2.0 SIDocument9 pagesCargo Acceleration Forces WWW - Thenavalarch.com V2.0 SIPaulo BrunoNo ratings yet

- PDFDocument5 pagesPDFSameera JayaratneNo ratings yet

- 0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFDocument38 pages0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFMark InnesNo ratings yet

- Mathcad - Laydown Area Deck PlateDocument3 pagesMathcad - Laydown Area Deck PlatePradeep ChitluriNo ratings yet

- Mooring Forces Port or STBD On Quay WWW - Thenavalarch.com Rev 1Document10 pagesMooring Forces Port or STBD On Quay WWW - Thenavalarch.com Rev 1Mohamed Elfawal100% (1)

- Lift (Skew & Cog Shift) MethodsDocument18 pagesLift (Skew & Cog Shift) MethodsManoj Kumar Pal100% (1)

- Innovative Seafastening for Offshore Wind TurbinesDocument164 pagesInnovative Seafastening for Offshore Wind Turbinese_taubNo ratings yet

- Hosei 8 TC DescriptionDocument2 pagesHosei 8 TC Descriptionbill duanNo ratings yet

- Design Methodology of Strength Verification of Platform During Load Out of The Arkutun Dagi SE-TOPSIDE 43.800 MTDocument12 pagesDesign Methodology of Strength Verification of Platform During Load Out of The Arkutun Dagi SE-TOPSIDE 43.800 MTSHARATHNo ratings yet

- Grain Stability ManualDocument173 pagesGrain Stability Manualpraveen100% (1)

- Revision List: No. Para. / Section No. Items Explanation / ReasonDocument17 pagesRevision List: No. Para. / Section No. Items Explanation / ReasonnpwalNo ratings yet

- RC Pier TabaDocument20 pagesRC Pier TabaAbera MamoNo ratings yet

- Bourbon Borgstein PDFDocument2 pagesBourbon Borgstein PDFswapneel_kulkarniNo ratings yet

- (38GC) TC Des-KSL Chaoyang (Updated 20201005)Document3 pages(38GC) TC Des-KSL Chaoyang (Updated 20201005)Edy GunawanNo ratings yet

- Giulio Verne Cable Laying ShipDocument9 pagesGiulio Verne Cable Laying ShipGaetan Dufour100% (1)

- Pondasi Conveyor C-1 - Rev A (02!12!2011)Document40 pagesPondasi Conveyor C-1 - Rev A (02!12!2011)Barita JonBos SilalahiNo ratings yet

- Ballast Plan and CalculationDocument18 pagesBallast Plan and Calculationspgkumar7733No ratings yet

- Mathcad - Gravity PlatformDocument3 pagesMathcad - Gravity PlatformGadde BhagyasriNo ratings yet

- MV Toronto TraderDocument3 pagesMV Toronto TraderPapitas FritasNo ratings yet

- Fleet Management Cargo Loading PlanDocument6 pagesFleet Management Cargo Loading PlantenederoNo ratings yet

- FA-18 Pocket Check ListDocument16 pagesFA-18 Pocket Check Listmad_mitch376100% (1)

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDocument23 pages"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionBolarinwaNo ratings yet

- Risk AssessmentDocument8 pagesRisk AssessmentBolarinwaNo ratings yet

- Equipment Numeral Calculator For A ShipDocument16 pagesEquipment Numeral Calculator For A ShipBolarinwaNo ratings yet

- 1000 Business IdealsDocument43 pages1000 Business IdealsBolarinwaNo ratings yet

- ANSYS Manual StudentDocument215 pagesANSYS Manual StudentBolarinwaNo ratings yet

- Ballasting Calculation For The Transportation of PLEMsDocument17 pagesBallasting Calculation For The Transportation of PLEMsBolarinwa100% (1)

- Onbottom ThailandDocument30 pagesOnbottom ThailandBolarinwaNo ratings yet

- Afes StripDocument27 pagesAfes StripBolarinwaNo ratings yet

- Crosby Shackles G-2130 PDFDocument2 pagesCrosby Shackles G-2130 PDFBolarinwaNo ratings yet

- 101 Ways To Make Money in Africa PDFDocument17 pages101 Ways To Make Money in Africa PDFBolarinwaNo ratings yet

- Ffs Su 5221Document12 pagesFfs Su 5221BolarinwaNo ratings yet

- Scaffolding Bin Structural Integrity ReportDocument27 pagesScaffolding Bin Structural Integrity ReportBolarinwaNo ratings yet

- BS Civil EngineeringDocument138 pagesBS Civil EngineeringBolarinwaNo ratings yet

- Mac Su 7.03Document8 pagesMac Su 7.03BolarinwaNo ratings yet

- Ffs-pu-5116-A-transportation of Cargo by Barge or ShipDocument28 pagesFfs-pu-5116-A-transportation of Cargo by Barge or ShipBolarinwaNo ratings yet

- Mac Su 7.02Document10 pagesMac Su 7.02BolarinwaNo ratings yet

- Ffs Su 5221Document12 pagesFfs Su 5221BolarinwaNo ratings yet

- Civ-su-1.28-A Helidecks On Offshore InstallationsDocument12 pagesCiv-su-1.28-A Helidecks On Offshore InstallationsBolarinwaNo ratings yet

- Ffs Su 5218Document33 pagesFfs Su 5218BolarinwaNo ratings yet

- Ffs-su-5217-A - Design of Fixed Platform StructuresDocument134 pagesFfs-su-5217-A - Design of Fixed Platform StructuresBolarinwa100% (1)

- Civ-su-1.10-A Design and Installation of Living QuartersDocument86 pagesCiv-su-1.10-A Design and Installation of Living QuartersBolarinwa100% (1)

- StruCalc 80 ManualDocument124 pagesStruCalc 80 ManualBolarinwaNo ratings yet

- Ffs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsDocument28 pagesFfs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsBolarinwaNo ratings yet

- Mac-Su-7.01 - Offshore Lattice Boom Pedestal CranesDocument31 pagesMac-Su-7.01 - Offshore Lattice Boom Pedestal CranesBolarinwaNo ratings yet

- Gen-Su-5227 - Units of MeasurementDocument4 pagesGen-Su-5227 - Units of MeasurementBolarinwaNo ratings yet

- Civ-Su-6001-C - Design of BuildingsDocument37 pagesCiv-Su-6001-C - Design of BuildingsBolarinwaNo ratings yet

- Civ Du 5009 H Structural Design CriteriaDocument28 pagesCiv Du 5009 H Structural Design CriteriaBolarinwaNo ratings yet

- Civ-su-1.24-A - Design and Fabrication of BuildingsDocument35 pagesCiv-su-1.24-A - Design and Fabrication of BuildingsBolarinwaNo ratings yet

- BS 2X 33 Two Part EpoxyDocument13 pagesBS 2X 33 Two Part EpoxyBolarinwaNo ratings yet

- THIELE Lifting Products: Grade 100 (XL-Program)Document44 pagesTHIELE Lifting Products: Grade 100 (XL-Program)Dejan KostadinovicNo ratings yet

- Motivation Letter by Farooq AhmadDocument3 pagesMotivation Letter by Farooq AhmadAisha shakeelNo ratings yet

- Detailed Lesson Plan ScienceDocument17 pagesDetailed Lesson Plan ScienceShine Rain Ponsal RoldanNo ratings yet

- Exhibition Stand - REV 0Document12 pagesExhibition Stand - REV 0shibu4321No ratings yet

- Beamforming in Multi-Path Channels at 28 GHZ: Creating The Antenna ElementsDocument7 pagesBeamforming in Multi-Path Channels at 28 GHZ: Creating The Antenna ElementsHafiz Rahmat UllahNo ratings yet

- 5th Sem Syllabus DseuDocument8 pages5th Sem Syllabus DseuSachin KumarNo ratings yet

- EVSU Structural Theory I Assignments CompilationDocument2 pagesEVSU Structural Theory I Assignments CompilationTejay TolibasNo ratings yet

- Blowroom: Basic OperationsDocument13 pagesBlowroom: Basic OperationsNeelakandan D100% (1)

- Pages From 0625 - s16 - QP - 42 - 06Document2 pagesPages From 0625 - s16 - QP - 42 - 06lelon ongNo ratings yet

- Analysis of Simply-Supported Orthotropic Plates Subject To Static and Dynamic LoadsDocument16 pagesAnalysis of Simply-Supported Orthotropic Plates Subject To Static and Dynamic LoadsKevin LeeNo ratings yet

- Physics SampleDocument4 pagesPhysics SampleSourajit DasguptaNo ratings yet

- CQQQQQDocument21 pagesCQQQQQanshumanbadgujarNo ratings yet

- 09.roof SupportsDocument22 pages09.roof SupportsLavudiya RajkumarNo ratings yet

- ASTM D 3107 - 03stretch Properties of Fabrics Woven From Stretch YarnsDocument6 pagesASTM D 3107 - 03stretch Properties of Fabrics Woven From Stretch YarnsZiauddin QureshiNo ratings yet

- Freund-Dynamic Fracture MechanicsDocument583 pagesFreund-Dynamic Fracture MechanicsRavi Sankar H50% (2)

- API Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIADocument7 pagesAPI Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIAtraining6156No ratings yet

- Period of a Pendulum LabDocument5 pagesPeriod of a Pendulum LabKhysval WalkerNo ratings yet

- Design Guide For SHSCFCDocument73 pagesDesign Guide For SHSCFCDebajit SahaNo ratings yet

- NSCP Provisions For Design of Main Reinforcements of BeamsDocument7 pagesNSCP Provisions For Design of Main Reinforcements of BeamsAllenNo ratings yet

- Unit Ii-Fourier SeriesDocument53 pagesUnit Ii-Fourier SeriesDheenã SagařNo ratings yet

- Rules of Thumb in Geotechnical EngineeringDocument13 pagesRules of Thumb in Geotechnical EngineeringAndreas Giannakogiorgos100% (2)

- ASPE-45 Siphonic Roof Drainage 2013 DraftDocument49 pagesASPE-45 Siphonic Roof Drainage 2013 DraftSusan LamNo ratings yet

- CON4338A2TO180829BL Ch4 PrestressedConcreteDocument26 pagesCON4338A2TO180829BL Ch4 PrestressedConcretelau lauNo ratings yet

- Section Study Guide: Teacher Notes and AnswersDocument4 pagesSection Study Guide: Teacher Notes and Answersmahsan abbasNo ratings yet

- CFD Analysis of Helical Tube RadiatorDocument4 pagesCFD Analysis of Helical Tube RadiatorpugazhNo ratings yet

- FEA-Based Mathematical Modeling and Simulation For IPMSM Drive With Consideration of Saturation and Cross-Coupling InfluenceDocument5 pagesFEA-Based Mathematical Modeling and Simulation For IPMSM Drive With Consideration of Saturation and Cross-Coupling Influencealaref elhajNo ratings yet

- Aiton, The Concept of ForceDocument15 pagesAiton, The Concept of ForceSamuel Le GendreNo ratings yet

- EIM212 16 EIM212Nov2013Document6 pagesEIM212 16 EIM212Nov2013Priviledge MuzotaNo ratings yet

- Module 3 - Physics of Photonic DevicesDocument33 pagesModule 3 - Physics of Photonic DevicesAditi KeshavamurthyNo ratings yet

- Design Procedure for Switched-Reluctance Motors: A Step-by-Step GuideDocument6 pagesDesign Procedure for Switched-Reluctance Motors: A Step-by-Step GuideSuman SahaNo ratings yet