Professional Documents

Culture Documents

Discontinuity Spacings in Rock

Uploaded by

Gisber Mamani ColcaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discontinuity Spacings in Rock

Uploaded by

Gisber Mamani ColcaCopyright:

Available Formats

Int. J. Rock Mech. Min. Sci. & Geomech. Abstr. Vol. 13, pp. 135-148. Pergamon Press 1976.

Printed in Great Britain

Discontinuity Spacings in Rock*

S. D. PRIEST,

J. A. HUDSON

The possible distributions of discontinuity spacings along a straight line

through a rock mass are considered. Unless there is a large predominance

of evenly spaced discontinuities, any combination of evenly spaced, clustered

and randomly positioned discontinuities leads to a negative exponential form

of frequency vs spacing value curve. The negative exponential form was confirmed by field discontinuity scanline surveys in three tunnels.

Utilizing the negative exponential distribution, a relation between the Rock

Quality Designation (RQD*) and mean discontinuity frequency per metre

(2) is established: R Q D * = 100e-'tx(0.12 + 1). The agreement with actual

RQD was within 5% at 27 survey locations mainly in chalk and mudstone.

Recommendations are made concerning the method of presenting discontinuity spacing data, the scanline length necessary for reasonable estimates

of discontinuity frequency and the number of sample values required in a

discontinuity survey.

INTRODUCTION

It is also important, however, to obtain data on discontinuity intensity in addition to discontinuity orientation. In the-case of tunnelling, for example, it is

necessary to examine the ratio between discontinuity

intensity and excavation dimensions [8, 9].

Rock discontinuities in engineering

Faults, joints, bedding planes, fractures, fissures and

microfissures are of widespread occurrence in rocks

encountered in engineering practice. The purpose of

this paper is to discuss the spacings between these inter- Indices of discontinuity intensity

ruptions in the rock continuum. The general term 'disThe form of the index adopted to describe disconticontinuity' is used here, avoiding any genetic conno- nuity intensity is often influenced by the nature of the

tations, to describe any mechanical break or interrup- exposure and the survey technique. Skempton et

tion of the properties of a rock [1].

al. [10] described discontinuity intensity in the London

Discontinuity characteristics play a major role in Clay in terms of the number of discontinuities per unit

controlling the mechanical behaviour of a rock volume of material. The values were obtained by dismass [2-4]. The following characteristics were listed by secting blocks of clay. Using a similar technique on

Piteau [5"] as having particular engineering significance: Cretaceous sediments in south-east England, Fo0kes

(a) Nature of their occurrence--i.e, whether members and Denness [1] expressed intensity as discontinuity

of sets or isolated; (b) Orientation and position in area per unit volume.

space; (c) Continuity; (d) Intensity; (e) Surface geoPiteau [5] used a scanline survey technique (measurmetry; (f) Genetic type; (g) Nature and thickness of ing tape) on rock faces and expressed discontinuity inthe joint fill.

tensity as the number of discontinuities per unit disThere are many engineering situations in which a tance normal to the strike of a set of sub-parallel disknowledge of the discontinuity characteristics of a rock continuities.

mass is of importance and a variety of approaches can

The results of a scanline survey or the quality of

be adopted to analyse the stability and behaviour of rock cores recovered during a site investigation proa given rock mass utilizing discontinuity characteristics. gramme can be described using the method proposed

A commonly used technique is that applied to slope by Deere [11]. The Rock Quality Designation (RQD)

stability, based on considerations of discontinuity is the proportion of scanline or borehole core that conorientation viewed in terms of factors of safety against sists of intact lengths that are 0.1 m (4 in) or longer.

failure along critical discontinuity surfaces [6,7].

To calculate the RQD value, these intact lengths are

summed and expressed as a percentage of the total

length:

t Crown copyright 1975. Any views expressed in this paper are

not necessarily those of the Department of the Environment. Extracts

from the text may be reproduced, except for Commercial purposes,

provided the source is acknowledged.

Higher Scientific Officer, Transport and Road Research Laboratory, Dept. of the Environment, Crowthorne, Berks, U.K.

Principal Scientific Officer, Transport and Road Research Laboratory, Dept. of the Environment, Crowthorne, Berks, U.K.

a.r~.M.s. 13 5 A

RQD = 100

~ x,/L,

(1)

i=1

where 3q is the length of the ith length 1>0.1 m, n is

the number of intact lengths >/0.1 m, L is the length

135

136

S.D. Priest and J. A. Hudson

of scanline or boreh01e along which the RQD value

is required. Thus, the RQD can be calculated for

various sections or the complete length of the scanline

or borehole.

Deere et al. [12] suggested that a scanline, which can

be used to measure discontinuity intensity at a face,

may be regarded as directly analogous to a borehole

core since the RQD can be found in both cases. This

is important because the site investigation results can

be compared with conditions actually experienced during excavation.

Otstonce from A to the ith

discontinuity :d~

Spocing values (x) given

as x i :d i-dill for i = I ~ n

(o) Discontinuity intersection points along a

straight line (A8)through the rock mOSS

I

I I.

-',,

,l'}

If-B

Af

(b)Sconiine(rr~sorinq tape)on exposed

rock face

IJJll

till(

}/Ill

Ill((

Purpose and content of this paper

The purpose of this paper is to present a theoretical

approach to discontinuity spacings and RQD based on

the statistical distributions of spacing values that could

occur along scanlines and to compare these results with

experimental data obtained in field discontinuity surveys.

In the theoretical section, the influence of spacing

distributions on the RQD value is explained, and the

sensitivity of the RQD value to mean discontinuity

spacing is illustrated. In the experimental section, the

scanline measurement technique for assessment of discontinuity spacing distributions in rock is explained.

Experimental results are then presented for three different tunnels in the U.K. and compared with theoretical

values.

Finally, the usefulness of this interpretation of discontinuity spacings and the geotechnicai implications

are discussed.

THEORY

Possible spacing distributions

The discontinuity spacings will be considered with

reference to the distances between points where discontinuities intersect a straight line through the rock

mass--as shown in Fig. l(a). This is equivalent to the

scanline or measuring tape that is used for field determinations of discontinuity spacing or to a thin borehole

core. The spacing values, .xl for i = 1 to n, are shown

in Fig. l(b). The discontinuity intersection points can

be evenly spaced, clustered, random or some combination of these.

If the discontinuities are fairly evenly spaced with

a normal distribution of spacing values, the frequency

distribution shown in Fig. l(c) will be appropriate. This

type of distribution will tend to occur in, say, a uniform

columnar jointed basalt or evenly bedded sandstone

with the standard deviation reflecting the uniformity

of jointing and bedding respectively.

In the case of clustered discontinuities, a high frequency of low spacing values occurs within clusters and

a low frequency of high spacing values occurs between

clusters. This frequency distribution is shown in Fig.

l(d). Clustering can develop as a result of spalling near

a free face or around joints due to stress or weathering

effects. In addition, cyclic variation in lithology such

Discontinuity spacing values, x

Discontinuity spacing values,

(c}Fairly evenly sP~:ed distribution

/ -.\

,

B

(d)Clustered distribuhon

A_ I lIMIt \1 /I.',

I I~

I ~1(

I B_

I~/ I " \ I CIl~,(/ I

Clustered and random

Li \

f(x)=ke_X,

. f ~ - ' ~ distributions mutually---- 1

notiva e, -iol

I ~ e i n f o ~ ~t~w spocms I

II

I|

~.~ I

Discontinuity spacing values,

(e) Random distribution

Evenly spaced ond

rondom distritxJtions

mutually interfere at

Discontinuity s0oeing values, x

(f}Combirmtion of distributions

Fig. 1. Theoretical discontinuity spacing distributions.

as alternating layers of sandstone and highly fractured

siltstone could produce this distribution.

For randomly positioned discontinuities, the discontinuity-scanline intersection points are here defined as

random if the presence of one intersection point does

not affect the chance of another occurring in its neighbourhood. In other words, there is no interaction

between discontinuities. This could occur in a homogeneous rock mass where the formation of discontinuities has not been dominated by lithological or structural variability. In Appendix A, from standard statistical theory it is explained that if each small segment

of scanline has an equal but small chance of containing

a discontinuity intersection point, the points are a Poisson process and the associated spacings follow a negative exponential distribution as shown in Fig. l(e).

The negative exponential distribution is mathematically expressed as

f(x) = 2e -a~,

(2)

where f(x) is the frequency of a discontinuity spacing

x, and ). is the average number of discontinuities per

metre. This is a one parameter (2) distribution with

the mean and S.D. both equal to 1/2.

In a geologically complex rock mass with a varied

mechanical history, it is likely that a combination of

the evenly spaced, clustered and random distributions

will be present. This will result in the type of distribution shown in Fig. l(f) which will be similar to the

negative exponential distribution. If, however, the mean

spacing of the superimposed random distribution is

Discontinuity Spacings in Rock

The total number of discontinuities in a scanline =

2L, where 2 = mean number of discontinuities/metre,

L = scanline length.

Thus, neglecting end effects, there are (2L - 1) spacing values just below 0.1 m and the rejected length of

scanline is approximately 0.1 ( 2 L - 1) giving, from

equation (1)

large compared with that of the evenly spaced distribution, the latter will be largely unaffected and consequently dominate. In all other combinations, the clusters are largely unaffected whilst the even spacings are

broken up by superimposed random discontinuity patterns. It is important to note that the orientation of

discontinuities, relative to that of the scanline, in general controls the number of discontinuities intersected

per unit length and not the overall pattern of the discontinuity spacing distribution.

RQD,,In ~- 100[L - 0.1(2L - 1)]/L

"" 10011 - 0.12 + 0. l/L].

For a scanline which is long compared with the 0.I m

threshold value, the term O.1/L can be ignored and

Influence of spacin9 distributions on the RQD

The Rock Quality Designation (RQD) is the percentage of scanline or borehole core that consists of intact

lengths over 0.1 m. Theoretical RQDs can therefore be

determined directly from distribution curves of the type

shown in Fig. 1 by considering the frequency of spacing

values above the 0.1 m threshold value. This leads to

the concept of maximum and minimum values of RQD

for the clustered and evenly spaced distributions and

a relation between discontinuity frequency and RQD

for the random distribution.

The maximum possible value of the RQD for any

mean discontinuity spacing value is always close to

100% because:

(a) if the mean discontinuity spacing is less than

0.1 m, an RQD value close to 100% is obtained when

the discontinuities are very clustered with large intact

lengths between the clusters;

(b) if the mean discontinuity spacing is greater than

0.1 m, an RQD value close to 100% can be obtained

either by clustering or even spacing.

The minimum possible value for the RQD is 0 for

an average spacing less than 0.1 m if the discontinuities

are evenly spaced. When the average spacing is greater

than 0.1 m, the minimum RQD occurs when all but

one of the spacing values are just below 0.1 m with

one high remaining spacing value. This leads to the

linear relation derived below between the minimum

possible RQD value (RQD.,i.) and the discontinuity fiequency.

70

5o

I

/

~ 40

/

IO

i

0

0.1'2) for

2 <~ 10/m.

RQD,* = 100

I:

, Lxf(x) rt' /L

and with a negative exponential distribution of spacing

values, equation (2),

RQD? = 10022

f:

x e -~x dx:

, 7

~

I /

! /

?'

0.1

I

RQD

RQI3P"I~ I-xflxldx/L

0.1

-x,

l

t

\mmolnin(jWtQhspocing~,,OlUe/

,

(3)

This relation is plotted in Fig. 2 in terms of RQDmi,

vs mean discontinuity spacing (1/2).

To calculate the RQD value for a rock having random discontinuity positions, the percentage of scanline

length containing intact lengths greater than 0.1 m is

found by integrating the spacing values from 0.1m to

L for the negative exponential distribution as shown

in Fig. 2. The relation between RQD and discontinuity

frequency for this case is derived below:

The probability of discontinuity spacings occurring

between x and x + dx is given by f(x)dx, where x is

a spacing value, dx is an increment of spacing, f(x)

is the probability density distribution of x.

For a long total length of scanline, L, the total

number of discontinuities is 2L. Thus, the number of

intact lengths between x and x + dx is 2Lf(x)dx and

the length of these is 2Lxf(x)dx. From the definition

of RQD, equation (1), and in the continuous case, the

theoretical RQD (RQD*) with an arbitrary threshold

value, t, is given by:

I ~.~"~'~'~'~r~om discordir~uty

positions

~CP =lOOe'~(O'l

k+i)7

60

RQDm;. " 10011

MaximumpossibleRQDvalue(all discontinuitiesclusteredin smallregionsalongscanline)

I

I001

90 ~

8o

.

137.

I""

I

I

0.2

0.:5

Meondiscontinuityspocin~ I/Mrn)

i ^ ~ ~

_u,Im . . . . .

;

0.4

0.,.5

Threshold volue

Fig. 2. Maximum and minimum possible RQD values and RQD vs mean discontinuity spacing for randomly positioned

discontinuities.

138

S.D. Priest and J. A. Hudson

~oo

95 % of the scanline consists of intact lengths I>0. I m

"%

" o~

90

7O

N 6O

5O

3O

1 6 0 of the sconlineconsists

of intact lengths >~l.Om

20

tO

0

0,1 0.2

Fig. 3. Variation of

03

0.4 0.5 0.6 0.7 0.8 0.9 1.0 I.I 1,2 1.3

Mean discontinuity spacing, m

RQD with

mean discontinuity spacing for a range of

For a long scanline, terms containing e -zL can be

ignored and

1.4 1.5

1,6 1.7

1.8 1.9 2D

RQD threshold

values t.

Precision of the discontinuity frequency and RQD esti.mates

Assuming a negative exponential distribution of

spacing values, it is possible to study the effect of scanFor the conventional RQD, with a threshold value of

line length on the precision of the discontinuity fret = 0.1 m, the theoretical value is

quency (2) estimate. A short scanline, say 10 times the

RQD* = 100e-1~(0.12 + 1).

(5) mean discontinuity spacing, might give a bad estimate

The relation given in equation (5) is also plotted in of 2 and hence the RQD value will not be a good repreFig. 2. Note that equations (4) and (5) only apply if sentation of the rock mass. In fact, widely different

the discontinuity spacing values follow a negative RQD values measured over metre or two metre lengths

of a borehole can simply be a reflection of the random

exponential distribution.

positioning of the discontinuities.

Variation of RQD with the threshold value

The method for studying the precision of the 2 estimate

is explained in Appendix B. Examination of Table

In the conventional RQD, the percentage of scanline

BI

reveals

that if, say, 50 discontinuities are measured

consisting of intact lengths above 0.1 m gives the RQD

along

a

scanline

length of 5 m, the true 2 (i.e. 2L/5)

value. However, it is possible to examine the magnitude

is

within

7.79/m

and

12.66/m at the 90% confidence

of the RQD value for a variety of threshold values, t.

By the same arguments presented earlier, the maxi- level. The estimated 2 of 10/m (i.e. 50/5) gives the

mum RQD value remains close to 100% and the mini- RQD* as 74% from equation (5) but, from the 2 varimum is found by substituting t for 0.1 in equation (3). ationS" at the 90% confidence level, the true RQD*

The intermediate case is the suite of curves generated varies between 82% and 64%. An alternative approach

by equation (4) for various values of t. These are shown is to determine the probability of estimating the disin Fig. 3 with RQD* plotted against the mean discon- continuity frequency (2) to within +20% or + 10% for

different sample lengths; graphs of the resulting probatinuity spacing, 1/2.

The curves in Fig. 3 show that, with the negative bilities are shown in Fig. B1. For example if the sample

exponential assumption, the conventional RQD is sensi- length is 50 times the mean discontinuity spacing, the

tive for mean discontinuity spacings between zero and estimated 2. will lie within + 20% of the true 2 86 times

approximately 0.3 m; above 0.3 m, the RQD is always out of 100.

In Fig. 4, the effect of the sample length on the RQD*

above 95%. The RQD value can be made more sensitive

for high mean discontinuity spacing values by increas- error band is shown. For the specific case of 5 discontinuities per metre encountered in sample lengths

ing the threshold value.

From scanline measurements made in a rock mass ranging from 1 m to 10 m, the RQD* error band varies

with a mean discontinuity spacing of 0.3 m, the conven- from 98%-72% to 94%-87% respectively.

tional RQD is 95%--i.e. 95% of the scanline contains

intact lengths greater than 0.1 m. From equation (4),

FIELD DISCONTINUITY SURVEYS

however, the percentage of scanline containing intact

lengths above any required theshold can be found. For Measurement technique

example, from the vertical line in Fig. 3, 16% of the

In the field surveys, discontinuity characteristics were

scanline contains lengths greater than 1 m when the

measured along scanlines (measuring tapes) set up on

conventional RQD = 95~.

exposed faces. Wherever possible, equal lengths of scanline were established in orthogonal directions to obtain

f 2 is the true population parameter; ;. is the estimate obtained

a true three-dimensional characterisation of the rock

by sampling.

RQD* = 100 e-~'(2t + 1).

(4)

Discontinuity Spacings in Rock

I m sample length

I00

80

,~

4o

5m sample length

I00

80

90% Confidence band

T', \

~ 60

139

60

ROD*=91%

Error bond

95%-84%

.Error band

20

900/.-720

~' ~

'~" ,~

2O

- "~ . . . . . ~ . . . . . . ~ .

I

I

, -- ~ ~ i ~

I0

20

30

40

Obser~<l number of discontinuities

0

0

50

I0

20

30

40

IOta sample length

2m sample length

I00

50

Observed number of discontinuities

;,

t

=o ,o r

o 60

80 I

40

20

0

0

I0

20

30

40

50

Observed number of discontinuities

I0

20

:30.

40

50

Observed number of discontinuities

Fig. 4. Effect of sample length on the

mass [5,13]. In addition to other measurements (such

as orientation and trace length) at points where discontinuities intersected the scanline, the distance along the

scanline was recorded (Fig. i). Discontinuity spacing

values were subsequently calculated by subtraction of

consecutive intersection distances along the measuring

tape.

Experimental results

(a) Chinnor tunnel. Detailed assessment of chalk discontinuity characteristics formed an intrinsic part of

the rock cutting experiments in the Lower Chalk carried out during the full scale tunnelling trials at Chinnor, Oxfordshire. A total of seven thousand discontinuity spacing values was processed for a total scanline

length of approximately 750 m taken in the 23 m deep,

3 m dia shaft and in the 5 m dia tunnel.

Figure 5 shows a discontinuity spacing histogram for

all measurements taken in the shaft, and Fig. 6 a spacing histogram of measurements taken at selected faces

during the first 85 m of tunnelling. The distribution of

measured discontinuity spficing values is not strictly

RQD* error band (90% confidence band).

continuous because the spacing is measured to the

nearest 0.01 m on the measuring tape; parallax and

angle of discontinuity to the tape do not allow greater

measurement precision. For this reason the histograms

have been plotted as single line columns. Figures 5 and

6 include tabulated values of mean spacing and standard deviation together with total scanline length and

number of observed values. In addition, the negative

exponential probability density distribution is drawn

on each histogram, using the parameter ~. equal to the

reciprocal of the mean discontinuity spacing.

The probability density distributions corresponding

to Figs. 5 and 6 are replotted on a logarithmic scale

in Figs. 7 and 8. The fitted negative exponential probability density distribution is a straight line (cf. equation 2):

lnf(x) = In ~. - 2x.

Examination of Figs. 5-8 shows that there is close

agreement between the theoretical and measured form

of the distribution curve. In addition, for each distribution, the value of the mean spacing is approximately

Ol3

.c_

II

Total sconline length 253.81m

Mean discontinuity spacing(~) O . I I 4 m

Standard deviation O.107m

Number of values 2221

~,o

Y9

8

Fitted negative exponential

/ probability density distribution, ~,=8.749/rn

"-- 4

"6

g3

]TITrFrrl-TT ,,

~o

0.01

0.C~

0.10

0.15

020

0.25

0.30

0.35

Discontinuity spacing, m

Fig. 5. Discontinuity spacing histogram. Sum of all scanlines in the

3m

>o5o .

0.40

0.45

0.50

dia shaft (Lower Chalk, Chinnor, Oxfordshire).

140

S. D. Priest and J. A. Hudson

llTotal scanline length 514.57m

Mean discontinuityspacing(~) O,105m

Standard deviation 0,I I 3m

Number of values 4 8 8 4

tO

_=

.,3 6 -

~5>.

"~. 4 c

o

"6

~ d F i t t e d negative exponential

3-

istribution, X: 9.488/m>0,50 ......b~

I-

o;o,

0.05

0.10

0.15

O.aO

0.25

'i''l-:

0.30

0.35

. . . . . .

0.40

0.45

0.50

Discont"inui'fy spacing, rn

Fig. 6.

Discontinuity spacing histogram. Sum of all scanlines in the first 85 m of tunnel (Lower Chalk, Chinnor. Oxfordshire).

equal to the standard deviation; this is a theoretical

characteristic of the negative exponential distribution

and serves to confirm the conclusion based on visual

comparison.

(b) Kielder experimental tunnel. The Kielder experimental tunnel, Rogerley Quarry, Co. Durham, was

excavated in rocks belonging to the Carboniferous

Limestone sequence. The tunnel was driven at three

levels: in sandstone, limestone and mudstone horizons.

During tunnel excavation, a detailed assessment of rock

quality at selected faces in the sandstone and mudstone

horizons was undertaken by the authors. A part of this

rock quality assessment included an examination of

rock discontinuity characteristics using measurement

techniques described earlier.

10

9

8 )o

Discontinuity spacing histograms for the sandstone

and mudstone horizons are presented in Figs. 9 and

10 together with the corresponding negative exponential probability density distributions plotted for the

appropriate value of mean discontinuity spacing. Figs.

9 and 10 show that there is good agreement between

the theoretical and measured distributions. In addition,

for each distribution there is close agreement between

the mean spacing and standard deviation. This serves

to verify the applicability of the negative exponential

distribution in describing the real discontinuity spacing

distribution for these Carboniferous rocks. It is important to note that Figs. 9 and 10 illustrate that the negative exponential distribution is equally applicable to the

highly fractured mudstone as the less fractured sandstone.

7 ~oo Fitted negative exponential

6

~o Fitted negative exponential

~..^r~oabil~ density dimibution,

~Al~obobiiity densify distribution,

5 ~ i / m

.c

o>

.E

0.9

0.8

~ 0.7

21

._ 0.7

0.6

0.5

~ 0.5

i .

0.5

0.3

e o

ooo

0.2

02

0.1

..i..,.i.,,,

O. I _..~....,....,....,....~....,....,....,....,...o.,o.._

0.10 0.20 0.30 0.40 0.50

Discontinuityspacing, m

I.,.,h.,,I,...I..,,I.,,,I..,,I.,..I.,,

O.lO 0.20 0.30 040 0.50

Discontinuity spacing, m

Sample probability density distribution of discontinuity spacing values, plotted on a logarithmic scale. Sum of all scanlines in

the 3 m dia shaft. 2221 Values (Lower Chalk, Chinnor, Oxfordshire).

Fig. 7.

Sample probability density distribution of discontinuity spacing values, plotted on a logarithmic scale. Sum of all scanlines in

lirst 85m of tunnel. 4884 Values (Lower Chalk, Chinnor,

Oxfordshire).

Fig. 8.

Discontinuity Spacings in Rock

141

Total sconlinelength 37.22m

Meandiscontinuityspacing(~) O. 129m

Standarddeviation O. 116m

Numberof values 249

tO .

~ 9 -

.~ 7

=g6Fitted negative exponential

^

~robability density distribution, X=7.-F;'8/rn

4

3

2

>0.50--.-~I

OOI

0.05

O.10

0.15

0.20

0.25

0.30

Discontinuity spocincj, rn

ne

....

0.40

0.35

,,..I

0.45

0.50

Fig. 9. Discontinuity spacing histogram. Rogerley Quarry tunnel. Sum of all scanlines in the sandstone.

In the section dealing with the theoretical approach construction programme provided an additional opporit was stated that a feature of the negative exponential tunity for examining in situ Lower Chalk. Assessment

distribution is that the mean spacing is equal to the of discontinuity characteristics was carried out using

standard deviation. Fig. 11 is a graph plotting the mean the scanline techniques described earlier. Figure 12

discontinuity spacing against the standard deviation of shows a histogram of discontinuity spacing values, for

the spacing for separate survey locations at Chinnor a 0.5 m class interval. The fitted negative exponential

and Rogerley Quarry. The data have been divided into probability density distribution indicates a reasonably

two groups based on the sample size: <200 values and good agreement between actual and theoretical distri> 200 values. The straight line in Fig. 11 indicates the butions considering the small sample size.

idealised relation for which the mean discontinuity

spacing is equal to the standard deviation. It is clear General considerations

from this figure that the experimental results conform

In searches of published data only two papers, Mahwell to the theoretical line, particularly for the larger tab et al. [14] and McGown et al. [15], were found

samples where sampling error is lower. Agreement is giving the results of measurements of discontinuity

within 20~o for samples containing more than 200 spacing in histogram form. Although the class interval

values. It is worth noting that in other distributions, was rather wide the indications are that the distribufor example the normal distribution, the mean and tions tended to follow the negative exponential form.

standard deviation are totally independent.

In view of the tunnel data presented in this section,

(c) Channel tunnelt. Excavation of the machine erec- it is felt that the negative exponential probability dention chamber during Phase II of the Channel tunnel sity distribution provides a good approximation to the

Totalscanline length

Mean discontinuity spacing (~)

Standard deviation

Number of values

60.75m

O.O=,L3rn

O.O~.rn

1828rn

0.22

Number of values

in sample

<200 >200

values values

Lower chalk Chionor

O

Sandstone Rooerley uorry -

ML~stone Rogerley cluarry a

0.20

50

~28

0. 18

-G 26

24

O

/

O. 16

2-00

E 0.14

;o

.~ 18

'-

16

~ 1.4

12

O

o O

./.:

e4'

oO

o,0

0.08

IO

~

r ~

Fitted negativeexponential A

obability der

~E

p!!"

0.01

0.0,$

0.05

0.07

0.09

0.11

Discontinuity spacing, m

te: if the

~di~:onti~i~

0.04

=//

0.02

0.13

0.15

Fig. 10. Discontinuityspacing histogram. RogerleyQuarry tunnel.

Sum of all scanlinesin the mudstone.

t The Channel tunnel project was cancelled in January, 1975.

r,

0

0

0.02

~ing

distribution follows the

neojative eq)onentiol distribution

the means0ac~,g =

the standard deviation

0.04

0.06

ODe

0.I0

0.12

0.14

0.16

Standard deviation,

0.18

rn

Fig. l l. Mean discontinuity spacing and standard deviation

measuredin the shaftand tunnelat Chinnor,and in the experimental

tunnel, RogerleyQuarry.

142

S.D. Priest and J. A. Hudson

Total scanlinelength 50.65m

Mean discontinuityspacing(i) 0.378m

Standard deviation 0.585m

Number of values 134

2O

t9

of rock types. It is hoped that, in the future, further

work will shed light on the validity of wider application

of the negative exponential distribution.

18

DISCUSSION

Validity of the negative exponential discontinuity spacing

distribution assumption

._~

.-~ I0

:=

]

(Spacing >1.5 m)

Fitted negative exponential

/ ~ o b a b i l i t y densitydistribution, Jl

5 ~

0 0.1 0.2 0.3 0.4 0.5 0,6 0.7 0.8 0.9 1.0 I.I

1.2 1.3 1.4 1.5

Discontinuity spocinq, rn

Fig. 12. Discontinuity spacing histogram. Channel tunnel. Sum of

vertical and horizontal scanlines (Lower Chalk).

distribution of discontinuity spacings measured in the

field. The applicability of the negative exponential has

only been verified at a few locations for a limited range

The validity of the negative exponential distribution,

verified for the available experimental data, indicates

that equation (5) can be used to calculate the RQD

for a rock given the mean discontinuity spacing (1/2).

Table I summarises values of RQD, calculated from

measurements using equation (l), and RQD* calculated

from theory using equation (5) for the measurement

locations discussed earlier. This table, presented graphically in Fig. 13, demonstrates the close agreement

between RQD and RQD*.

The good agreement between the measured and

theoretical RQD values is not a confirmation of equation (5) but a measure of how closely the discontinuity

spacing values follow the negative exponential distribution in each location. The implication is that a value

of RQD, accurate to within 5~, could have been

obtained at each of the twenty-seven locations by

simply counting the discontinuities and calculating the

discontinuity frequency, 2.

TABLE 1. COMPARISON BETWEEN MEASURED AND THEORETICAL

Rock formation,

location

Lower Chalk

Chinnor shaft

Lithology

Chalk

RQD ",,

RQD* %

Scanline

configuration

(from

equation 1)

(from

equation 5)

Average

number of

discontinuities

per m,

/.

Horizontal

scanlines

Vertical scanline I

Vertical scanline II

79

67

7(/

81

70

75

7.9

11.0

9.5

91

87

80

83

82

78

78

72

60

66

79

64

71

64

65

63

89

87

81

87

81

81

81

74

64

69

79

65

73

68

69

63

5.6

6.3

7.9

6.4

7.9

8.0

8.0

9.9

12.5

11.3

8.5

12.3

10.1

11.7

11.3

12.8

Vertical plus

horizontal scanlines

83

82

7.8

Vertical plus

horizontal scanlines

100

98

2.0

Chainage =

Lower Chalk

Chinnor tunnel

Chalk

Sandstone

RQD

Horizontal

plus

vertical

scanlines

for

each face

9.9m

ll.5m

12.1m

14.0m

18.1m

20.4m

35.9m

55.4m

57.5m

60.5m

65.2m

70.2m

72.7m

73.9m

79.3m

85.0m

Measured

Theoretical

Carboniferous

Limestone

Rogerley

tunnel

Limestone

Mudstone

Vertical plus

horizontal

scanlines at

selected faces

12

32

14

22

12

31

17

26

37.0

23.8

32.5

26.3

Lower Chalk

Channel tunnel

Chalk

Vertical plus

horizontal scanlines

99

88

99

90

1.2

5.3

143

Discontinuity Spacings in Rock

Chinnor,Lowef Chalk

discontinuities already present in the rock mass and

to results obtained from scanlines set up on rock faces.

If, however, the discontinuity spacings are obtained

LO0

from a borehole core, there is a possibility that additional discontinuities may have been introduced by

9O

the sampling process---i.e, drilling the borehole [3].

Figure 15 summarises data presented by Deere et

80

al. [12] from cores and scanlines in a variety of rock

70

types. Figures 15(a--d) show the comparison between

RQD* and the measured values of Deereet al., broken

6O

down into the four rock types. These figures indicate

50

that for a given ~., equation (5) predicts an RQD* higher

than the measured value. The effect causing RQD to

be <RQD* (in particular for 2 >i 10/m) is a tendency

3O

for the discontinuities to be more evenly spaced than

predicted by the negative exponential distribution (cf.

20

J

RQD=TheoreticolRQOlfrom equotion 51

Fig. 14). Most of the data in Fig. 15 relate to NX

I0 /

core; it is possible, therefore, that the process of rotary

drilling added a more evenly spaced component of dis~

I

I

I

0 /~

I

I

I

I

0

I0

20 30

40

50

60

70

80

90

I00

continuities to the recovered core, though this could

RQD, %

only be confirmed by detailed surveys on freshly

Fig. 13. Comparison between measured and theoretical RQD.

exposed rock faces.

Experience at Chinnor has shown that lengths of inFigure 14 shows a graph of equation (5) relating

RQD* to 2 together with the experimental data points tact core can snap near the centre during drilling; this,

presented earlier. Between values of 2 = 6/m and together with the phenomenon of discing due to high

2 = 16/m the relation between ;t and RQD* is approxi- field stresses could lead not only to an artificially lowmately linear. The curve in Fig. 14 has an inflection ered RQD but also to an artificially imposed discontipoint P at 2 = 10/m; at this point the curve has a slope nuity spacing distribution. These effects must be borne

equal to dRQD*/d2[~=lo = - 1 0 e -1 = -3.68 m. The in mind and allowed for when interpreting results constraight line drawn through P, tangential to the curve cerning rock quality obtained from boreholes referring,

ideally, to the results of scanline surveys taken on

defined by equation (5) is therefore described by

freshly exposed faces.

RQD* = -3.682 + 110.4.

This line, shown in Fig. 14, gives a good approximation

Geotechnical implications

of RQD between values of 2 = 6/m and 2 = 16/m.

The RQD, commonly adopted as a rock quality index

Bieniawski [16], by reference to Deereet al. [12] sugis

here regarded as having two major drawbacks when

gested that the relation between 'fracture frequency' (i.e.

viewed

in the light of the present approach:

2) and RQD is linear; this statement is generally in

(a)

Calculating

RQD is a time consuming process

agreement with Fig. 14 within the stated range of 2.

which, when applied to borehole cores, can give results

Discontinuities imposed by sampling

unrepresentative of the rock mass.

In both the theoretical and experimental sections of

(b) The conventional RQD is insensitive to variations

this paper, the discussion has been with reference to in rock quality when the average discontinuity spacing

Ro~ey, sondstom |

# R o ~ I w , limestone} Corboniferous Limes~ae

Rol~ey, mudstone J

o Channel tunneI,LowefCholk

I00

Linear approximation RODe=- 3.68), + I 10.4

# .~for6<X<16

90

U'l"e,~

80

~"-~

L~

9w ~

" ~

70

Experimental doto points

ChinnortLowerChalk

Inflection point P

I'lk.

. . . . . .

I.)eVlOTIOn aue to

clustered discontinuities

.~

#RoQerley,limestone]

CarboniferousUmestone

a RogerlElYtmu~mne---J-L--I

J

0 Chores, tunneltLower Chalk

~g 6o

~ /

/ '

c$5o

Theoreficol curve

.-~1

RQ~-IOO. x (O. I X + I )

~ 40

:50

20

I0

0

0

I

2

I

4

I

8

I

I

I

I

I

I

I

I

I ~1

I0 12 14 16 18 20 22 24 26 28 30

Averoge number of discontinuities per m, X

Fig. 14. R e l a t i o n b e t w e e n

R.MM.S 13 5 a

RQD a n d

I

32

I

34

mean discontinuity frequency.

I

36

I

38

40

144

S.D. Priest and J. A. Hudson

I O0

r~~l

II B

50

100

ROD.

Theorei'icol curve

:....-;,<

Theoreticol curve

RQD*

~

75

50

or~

O

e.

25

25

J)NX core, Hockensock Siltstone

0

= I I = I I I I I

0 2 4 6 8 I0 12 14 16 18 20

b) NX core, John Day Basalt

0

AverSe number of discontinuities per m,

I00

ff--u,,,~,~

I

2

t

4

I

6

= I I I I I

8 10 17' 14 16 18 20

Avero, ~ number of discontinuities per m, ~,

I00 ~

o

Theoretical curve

T t ~ o r e t i c a l curve

- "~

.-

ROD~

75

d 50

o

e~

50

0

w"

Average number of discontinuities per m, ~,

between measured

O

n

6 8 I0 12 14 16 18 20

Fig. 15. C o m p a r i s o n

25

25 ,:) NXcore, Dworshok Darn,

granite gneiss

Tunnel woll, scanli ne

o across discontinuities

Tunnel wall,sconline

parallel to discontinuities

t) Climax Stock Granite

0

2 4

o

I

a NX core

1~3.4~

6 8 I0 12 14 16 18 20

/&verage number of discontinuities per m,

and theoretical

exceeds 0.3 m. For example, for a large excavation,

transition from 'favourable' to 'unfavourable' conditions may be represented by a variation in RQD of

only 3%, from 98% to 95%.

RQD has, however, an advantage over simple indices

which express, say, an average discontinuity frequency

per metre (2) in that it makes statements about the

distribution of block sizes. If the negative exponential

distribution is accepted as valid, from a simple knowledge of ~. additional data concerning RQD can be calculated if required. Moreover a two-tier RQD index

can be produced by adopting a pair of threshold values

at, say, 0.1 m and 1.0 m. The selection of the second

threshold value, 1.0 m, ensures sensitivity of the two-tier

RQD for mean spacing values up to 2.5 m for use when

considering particularly large excavations. The suggested rock quality index would therefore be, for

example: ).= 3.3/m, RQD&I=95%, RQD*.o= 16%,

which gives information on discontinuity frequency,

percentage of rock containing spacing values greater

than 0.1 m and percentage of rock containing spacing

values greater than 1.0 m.

Acceptance of the negative exponential distribution

allows calculations to be made concerning the precision

of the discontinuity frequency estimates made from any

given scanline. In this way, it is possible to determine

the minimum scanline length, expressed as a multiple

of the mean discontinuity spacing, required to produce

a rock quality index at a specified precision. For

example, if the sample length is 50 times the mean discontinuity spacing, the estimated 2 will lie within

-t-20% of the true 2, 86 times out of 100.

A knowledge that the distribution of discontinuity

spacings follows a negative exponential form can be

of use in rockbolt design. Rockbolt design criteria may

embody requirements that the bolt should be of sufficient length to penetrate, say, at least the third joint

block back. The probability of intersecting three joint

RQD (RQD

values from Deere

et al.,

1967).

blocks for a given rockbolt length can be calculated

directly from the statistical theory.

The distribution of discontinuity spacings in a borehole is of critical importance when measuring mass permeability using packer test methods. In order to obtain

a precise picture of mass permeability, minimising variations caused by sampling error, it is necessary to

design the packer test length with regard to mean discontinuity spacing. Thus, a similar approach to that

used when considering the effect of sample length on

the precision of the ). estimate can be used to determine

effective packer permeability test lengths.

Snow[17,18] described a method for determining

discontinuity frequency from the proportion of zero

discharge packer permeability tests that occur. He

made the basic assumption that the occurrence of open

discontinuities in a given length of borehole obeys the

Poisson distribution. A corollary of the Poisson process

is that the discontinuities follow a negative exponential

distribution. The assumptions in Snow's work, though

dealing with the particular case of open, water bearing

discontinuities, may therefore be valid for the rocks

examined here.

SUMMARY AND CONCLUSIONS

The possible distributions of discontinuity spacings

along a straight line through a rock mass were considered. The effects of evenly spaced, clustered and randomly positioned discontimJities were examined from

a theoretical standpoint. It was found that, unless there

is a large predominance of evenly spaced discontinuities, any combination of evenly spaced, clustered and

randomly positioned discontinuities will lead to a negative exponential form of frequency vs spacing value

curve.

Analysis of field results obtained from scanline

measurements carried out by the authors indicated that

Discontinuity Spacings in Rock

a negative exponential distribution of discontinuity

spacing values is a good approximation to the true distribution patterns. Deviations from negative exponential form in other rocks, though possibly a reflection

of the true discontinuity characteristics of the rock

mass, could in some cases result from data compiled

from a small number of measurements (sampling error),

or data obtained from borehole core (discontinuities

superimposed by drilling).

Using the negative exponential distribution of discontinuity spacing values, a relation was established

between the theoretical Rock Quality Designation

(RQD*) and the average number of discontinuities per

metre:

RQD*= 100e-'l;(0.12 + l).

With this formula it was possible to compare the theoretical RQD, obtained from the discontinuity frequency

alone, with the actual RQD calculated from the spacing

values. This was done for all measurement locations.

The maximum error was 5%, indicating that the RQD

could have been found to within 5% simply by counting

the number of discontinuities along the scanline and

using the formula. In addition, the formula shows that

the conventional RQD with a threshold value of 0.1 m

is insensitive when the mean discontinuity spacing is

above 0.3 m.

The authors recommend presenting discontinuity

spacing data obtained from scanlines in the following

form:

(a))., the mean number of discontinuities.per metre,

or ~ the mean discontinuity spacing (~ = 1/2).

Since RQD is a commonly used method of expressing

discontinuity spacing data in site investigation, a twotier RQD may be used:

(b) RQDo.I, the conventional RQD.

(c) RQDLo, the RQD with a threshold value of

1.0 m.t

If the theory outlined earlier is applicable, (b) and (c)

can be calculated directly from (a).

It was also found that to estimate the number of

discontinuities per metre to within a reasonable precision requires a scanline length at least fifty times the

mean discontinuity spacing. Thus, if there are about

five discontinuities every metre, the scanline must be

at least ten metres long. Moreover, at least two

hundred measurement values were generally required

before the negative exponential distribution form

became clear on a histogram. One of the features of

this distribution is that theoretically the mean and standard deviation are equal: this was found to be the case

to within 20% for the nineteen measurement locations

in Lower Chalk and Carboniferous Limestone where

greater than two hundred readings were taken.

These sampling factors are relevant to packer permeability tests where water flow occurs essentially

through the discontinuities. Very large variations of

t" A threshold value of 1.0 m is recommended for general use; however any value can be used to suit particular conditions.

145

water flow should be expected if the test lengths are

only of the order of ten times the mean discontinuity

spacing, implying that correlation of permeability

values from borehole to borehole should not then be

attempted.

It is suggested that discontinuity surveys should be

carried out in a variety of rock types to assess the wider

applicability of the concepts presented in this paper.

These surveys should be carried out on freshly exposed

faces, with sample sizes consistent with the recommendations detailed above.

Acknowledgements--The work described in this paper forms part of

the programme of the Transport and Road Research Laboratory

and is published by permission of the Director. The authors wish

to thank the following organisations for their help: Rugby Portland

Cement Co; Mort Hay and Anderson; Sir Robert McAlpine and

Sons Ltd; Soil Mechanics Ltd; Rio Tinto Zinc; Cross Channel Contractors and the Steering Committee for the Kidder Water Scheme

Experimental Tunnel.

The research was carried out under the general direction of Mr.

M. P. O'Reilly, Head of Tunnels Division, Transport and Road

Research Laboratory, Dr. P. B. Attewell and Dr. I. W. Farmer, both

of the Engineering Geology Laboratories, University of Durham. The

authors would like to thank Dr~ F. Garwood for helpful statistical

advice and Dr. E. T. Brown, Imperial College of Science and Technology, Mr. J. B. Boden, Mr. C. McCaul and Mr. G. H. Alderman

of TRRL for help in obtaining and recording discontinuity spacing

data.

Received 29 September 1975.

REFERENCES

1. Fookes P. G. & Denness B. Observational studies on fissure

patterns in Cretaceous sediments of south-east England. Geotech.

19. 493-497 (1969).

2. Trollope D. H. The mechanics of discontinua or elastic

mechanics in rock problems. In Rock Mechanics in Engineering

Practice. (Edited by Stagg K. G. & Zienkiewicz O. C.), Chap.

9. pp. 275-320 (1968).

3. Jaeger J. C. & Cook N. G. W. Fundamentals of Rock Mechanics.

p. 513. Methuen, London (1969).

4. Hock E. & Bray J. W. Rock Slope En~lineeriml. p. 309. Inst. Min.

Mctall. (1974).

5. Piteau D. R. Geological factors significant to the stability of

slopes cut in rock. S. Af Inst. Min. Met., Syrup. Planning Open

Pit Mines, Johannesburg. 33-53 (1970).

6. AtteweU P. B. & Woodman J. P. Stability of discontinuous rock

masses under polyaxial stress systems. In Stability of Rock Slopes.

13th Syrup. Rock Mech. (Edited by Cording E. J.) pp. 665-683.

ASCE, NY. (1971).

7. Hock E., Bray J. W. & Boyd J. M. The stability of a rock slope

containing a wedge resting on two intersecting discontinuities.

Q. J. Engng Geol. 6, 1-55 (1973).

8. Watkins M. D. Terminology for describing the spacing of discontinuities of rock masses. Q. J. Engng Geol. 3, 193-195 (1971).

9. Barton N., Lien R. & Lunde J. Analysis of rock mass quality

and support practice in tunneling, and a guide for estimating

support requirements. Norwegian Geotechnical Institute, Internal report, 19 June (1974).

10. Skempton A. W., Schuster R. L. & Petley D. J. Joints and fissures

in the London Clay at Wraysbury and Edgware. Geotech. 19,

205-217 (1969).

11. Dcere D. U. Technical description of rock cores for engineering

purposes. Rock Mech. Eng. Geol. 1, 17-22 (1964).

12. Dcere D. U., Hendron A. J., Patton F. D. & Cording E. J. Design

of surface and near surface construction in rock. In Failure and

Breakage of Rock (Edited by Fairhurst C.), pp. 237-302. AIME,

NY. (1967).

13. Terzaghi R. D. Sources of error in joint surveys. Geotech. 15,

287-304 (1965).

14. Mahtab M. A., Boistad D. D. & Kendorski F. S. Analysis of

the Geometry of Fractures in San Manuel Copper Mine, Arizona. U.S. Department of the Interior, Bureau of Mines. No.

RI 7715, 24 (1973).

146

S.D. Priest and J. A. Hudson

15. McGown A., Saldivar-Sali A. & Radwan M. Fissure patterns

and slope failures in till at Hurlford, Ayrshire. Q. d. Engng Geol.

7, 1-26 (1974).

16. Bieniawski Z. T. 13ngineering classification of jointed rock masses.

The Civil Engineer in South Africa 15, 335-343 (1973).

17. Snow D. T. Rock fracture spacings, openings, and porosities. J.

Soil Mech. Found. Div. ASCE, 94, SMI Proc. Paper 5736, 73-91

(1968).

18. Snow D. T. The frequency and apertures oi' fractures in rock.

lnt J. Rock Mech. Min. Sci. 7, 23-40 (1970).

19. Lindley D. V. Introduction to Probability and Statistics--l. Probability, p. 259. Cambridge University Press, London (1965).

20. Garwood F. Fiducial limits for the Poisson distribution. Biometrika, 28. Parts 3 and 4, 437-442 (1936).

21. Pearson E. S. & Hartley H. O. Biometrika Tables for Statisticians.

Vol. I. Cambridge University Press, London (1954).

APPENDIX A

The Poisson and negative exponential distributions

In practice, the probability of a small unit length

of scanline being intersected by a discontinuity need

not be one half as for the unbiased coin. Thus, the

analogy becomes direct for a biased coin1" with a different probability value for tails producing a random

sequence such as

HHHTHHHHTHTH

HHH

HTTH

HT.

The probability of k tails occurring in n tosses, or

k discontinuities in a length n units, is given.by the

binomial distribution as:

p~k

tails io~ = (n!/(n -- k)!k!)qkp"-k,

x n losses /

(A1)

where P(x)= probability of x occurring, p = probability of a head (or an intact unit), q = 1 - p = probability of a tail (or a unit containing a discontinuity).

The probabilities associated with encountering a certain number of discontinuities in a given length of scanline can be calculated from equation A I given q the

probability of a discontinuity intersecting a unit length

of scanline. The mean and standard deviation of the

binomial distribution are np and x/npq respectively.

However, we are also interested in the distribution

of spacings between successive tails and, by analogy,

the distribution of spacings between discontinuities. In

this case, the probability of each sequence is considered.

Assuming that a tail has just occurred, the sequences

in Table A1 can follow:

Using the scanline technique, discontinuity spacings

are measured by setting up a measuring tape across

the rock face and noting the tape positions where discontinuities are present. If it is assumed that each small

section of scanline has an equal chance of containing

a discontinuity, the discontinuity positions are random

and the spacing distribution can be studied in two

ways:

(a) the discrete case--a unit length of rock (say

10 mm) is considered intact if no discontinuity is present, and fractured if a discontinuity is present; the total

scanline length must then be an integral multiple of

TABLE A 1 . SPACING SEQUENCES BETWEEN SUCCESSIVE TAILS

the unit length;

(b) the continuous case--the unit lengths become inNo. of heads

Probability for

finitely small and the total scanline length can have

(spacing between

unbiased coin

Sequence

tails)

Probability

(p = I/2)

any value.

In the discrete case, the binomial and geometric dis- T-T

0

q

1/2

tributions provide the probabilities associated with fre- T-HT

1

pq

1/4

2

ppq

1/8

quency of occurrence and spacing values respectively. T-HHT

3

pppq

1/16

In the continuous case, the equivalent distributions are T-HHHT

T-HHHHT

4

ppppq

1/32

the Poisson and negative exponential functions. The

discrete case is explained via a coin tossing analogy

This probability density distribution is called the

and the continuous case as a limit to the discrete case

geometric distribution because the probability is

when the number of units becomes infinite. The coin

reduced by the constant factor p for each unit increase

tossing analogy is useful because it provides an intuitive

o f spacing.

understanding of why the most likely spacing value is

Thus

zero when the discontinuities are randomly positioned.

p / k heads between'~

~

~suessive tails ) = pkq

pk(l

p).

(A2)

(a) Discrete case. Consider, in analogy, an unbiased

coin tossing sequence of heads and tails where a head This distribution is plotted in Fig. A1 for a specific

represents a unit length of intact rock and a tail rep- value of p (19 = 0.91): for p = , the coin is unbiased;

resents a unit length containing a discontinuity. For for other p values, the coin is biased but the coin tossing sequence is still random. Note that for all p values,

example:

the most frequently occurring spacing value is zero. The

Coin sequence:

THHTHHTHTTTHHTHT

THT

I(I I Ill I h i I/IIKI I I/I I / l l l I/1

mean of the geometric distribution is equal to p/(1 - p).

Scanline:

I

~

~. ', ~,

/

t ~ /

(b) Continuous case. In the coin tossing analogy, the

There is an analogy between the number of tails that coin can only be thrown an integral number of times

will occur in n tosses and the number of discontinuities and hence the scanline length can only be an integral

that will occur along a scanline of length n units. In multiple of the unit length. The equivalent distribution

addition, the spacings between successive tails and the that characterises the number of events occurring in

spacings between successive discontinuities are analo- a continuous interval x is the Poisson distribution. The

gous.

probability of k events occurring in the interval x is

t Although biased, the result is still random--similar to selecting given by

a ball from a bag containing different numbers of black and red

pek

.... ts xi,~] ~ e - xx(2x)k/k!,

(A3)

~interval

balls,

147

Discontinuity Spacings in Rock

Geometric

0.IO~

distribution

Nc~jofi~ e~oon~t~l

O. lO

heads between~_^k q ~',

pL~ __~'

K )"" ~ -v,

~/s_ive toils

Where P(Head) : p

P(Tail) = l-p=q

Mean spacing

= p/(l - p] Heads

0.08 I

~0.06

X = O . I/unit length

i, Mean spacing

value= I 0 heads

:~

"~

0.

004

I I

0 1

10

15

o.o~ I-

Meonspecing

value= IOunits

',

O/

0

25

20

0.02 I-

f(x)=Xe-x=

whereh =nunt~ of events/unitlength

Mean spacing=l/X units

\

X

0.08

p= 0.91

~ 0.06

distribution

t

i

5

tO

15

20

Spacing value,x, arbitrary units

Spacing value, K heads

25

Fig. A1. Geometric and negative exponential distributions.

where 2 is the mean number of events occurring in

a unit interval. In the Poisson distribution, the values

of the mean and variance are both 2.

Since we are interested in the discontinuity spacing

probability density distribution, consider the distance

/ from one discontinuity to the next:

APPENDIX B

Precision of the mean discontinuity frequency estimate

P(d <<,x ) = t - P(d > x)

= 1-

accidents follow a Poisson distribution. In the discontinuity context, an apparent clustering of discontinuities

will occur as a natural consequence of the random positions.

P(no discontinuities in distance x)

and from equation (A3), with k = 0

P(t' ~ x) = 1 - e-xx.

(A4)

This is a negative exponential cumulative probability

distribution. The probability density distribution (f(x))

is the derivative of equation (A4) with respect to x:

f(x) = 2e -xx.

(A5)

This spacing distribution (equation A5) is plotted in

Fig. A1 for a specific value of 2 (2 = 0.l/m). The mean

and standard deviation are both equal to 1/2.

In both the geometric and negative exponential distributions, the most likely spacing value is zero. Lindley [19] suggests that this is the reason for the phrase

"it never rains but it pours" since rare events such as

The parameter 2 in the negative exponential distribution (cf. equation 2) is estimated by counting the

number of discontinuities intersecting a scanline and

then dividing by the scanline length: The estimated

number of discontinuities per metre (2) is given by

n/L,

(B1)

where n is the number of discontinuities encountered;

and L is the scanline length. We wish to know the

probability of estimating 2 within a certain error band

as a function of the scanline length.

For example, if the true 2 = 10/m and a scanline

length of one metre is taken, then 10 discontinuities

must occur for 2 to be within 59/o of the value 10/m;

if 9 or 11 discontinuities occurred, 2 would be 10%

in error.

Curves ore upper envelopes of probability

The actual curve has a saw tooth shape becausethe error bonds ore artificial (c. Appendix B)

It is only passible to measure an integral number of discontinuities.Thus,if XL =3.4,it is not

,ossibleto estimate within IO%-i.e. measureo numberof discontinuitiesbetween 3.06-3.74

1.0

"""'"""""*20/~r~--"~--

E'~ 0.8

=g

/

~ OA

""'~

~:to%etror bond

-- -- --

-- -- Ex~ple:To estimate X to within :1:10%, either 18,19,20,21 or 22 discontinuities

must occur in the samplelength20 times the mean dsoontindty spaci~

Fromequation AS,the pmpabili~ is given as

x

0

"1

K=I8

I0

15

20

25

30

~20~/Kt =0.42

I

35

-I

40

45

50

XL-Numl~r of times the sample length is91mtetfhanthe mean dsco~inuity spacing

(for either sconline,borehole or packer permeability test length)

Fig. B1. Graph for determining the probability of estimating the discontinuity frequency (2) to within +20% or + 10%

for different sample lengths.

148

S.D. Priest and J. A. Hudson

Equation (A3) gives the probability of k events occurring in an interval x as

p t k ,nts in~

I,inlcr',al x }

e- ;x(~.x)k/k!

(B2)

Thus, for the example above

pOO

di. . . . tinuitics] = e-1o 101o/10! = 0.125.

~in one metre

In this case, for a true ). of 10/m and taking a scanline

length of 1 m, the probability of estimating ). within

5 ~ is only 0.125. Note that the use of 5 ~ is arbitrary

here because the same probability applies to estimating

2 to within any percentage less than 10~--i.e. when

ten discontinuities are measured, ). will be exactly equal

to 2.

In general for ~ to lie within a certain error

band, + ~,

2(1 - E) ~< 2 ~< 2(1 + E)

(B3)

and, from equation (B1)

2L(1 - ~) ~< n ~< 2L(1 + e).

(B4)

From equation (B2), the probability of this occurring

20, 21, n2 = 22. The probability of this occurring is

0.423---calculated from equation (B5).

However, because of the arbitrary error band, it is

preferable to use the upper and lower limits of 2L from

the observed number of discontinuities at, say, the 98~o

or 90~o confidence limit [20] as in Table B I below. A

larger table is available in Pearson and Hartley [21].

TABLE B I . VARIATION OF 2 L AT 98% AND

900o CONFIDENCE LEVELS GIVEN THE OBSERVED

NUMBER

OF

DISCONTINUITIES,

FROM

GARWOOD [20]

Possible variation of 2L

n

98% confidence

90% confidence

0

1

5

10

15

20

25

30

40

50

0-4.61

0.01-6.64

1.28-13.11

4.13-20.14

7.48-26.74

11.08-33.10

14.85-39.31

18.74-45.40

26.77-57.35

35.03-69.07

0-3

0.05-4.74

1.97-10.51

5.43-16.96

9.25-23.10

13.25-29.06

17.38-34.92

21.59-40.69

30.20-52.07

38.96--63.29

is

k= a2

e-aL(2L)k/k!,

(B5)

k=nt

for integral values of nt to n2, satisfying inequality (B4).

If, for example, the scanline length is 20 times the mean

discontinuity spacing (2L = 20) and a 10~o error band

is allowed (e = 0.1), n can take the values nt = 18, 19,

If 50 discontinuities are observed in a scanline length

of 5 m, 2L varies from 38.96 to 63.29 at the 90~o confidence level (Table BI); i.e. 2 varies between 7.79/m and

12.66/m. From equation (5), the theoretical RQD* value

then varies from 82~o to 64?/0. This illustrates the high

sampling error in using short scanlines or borehole

lengths for RQD determinations.

You might also like

- Geological Strain Analysis: A Manual for the Rf/Ø MethodFrom EverandGeological Strain Analysis: A Manual for the Rf/Ø MethodRating: 4 out of 5 stars4/5 (1)

- Atlas of Structural Geological Interpretation from Seismic ImagesFrom EverandAtlas of Structural Geological Interpretation from Seismic ImagesAchyuta Ayan MisraNo ratings yet

- Risk Assessment and Prediction of Rock Fragmentation Produced by Blasting Operation A Rock Engineering SystemDocument13 pagesRisk Assessment and Prediction of Rock Fragmentation Produced by Blasting Operation A Rock Engineering SystemW N Nan FajarNo ratings yet

- Radial Basis Functions and Kriging - A Gold Case StudyDocument8 pagesRadial Basis Functions and Kriging - A Gold Case StudyHamid KorNo ratings yet

- Stability Analysis of Open Pit Slope by Finite Difference MethodDocument9 pagesStability Analysis of Open Pit Slope by Finite Difference MethodInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Russo 2007 - Improving The Reliability of GSI EstimationsDocument6 pagesRusso 2007 - Improving The Reliability of GSI EstimationsPauly FernándezNo ratings yet

- JRU Rock Mechanics Lab ManualDocument20 pagesJRU Rock Mechanics Lab ManualgizeaNo ratings yet

- Slope Mass Rating (SMR) Geomechanics Classification Thirty Years ReviewDocument10 pagesSlope Mass Rating (SMR) Geomechanics Classification Thirty Years ReviewMiguel Angel Painenahuel Garces100% (1)

- Slope Inclinometers For Landslides-1Document13 pagesSlope Inclinometers For Landslides-1godbugNo ratings yet

- Palmström A. (2001) - Measurement and Characterization of Rock Mass JointingDocument46 pagesPalmström A. (2001) - Measurement and Characterization of Rock Mass Jointingmassimo.bochioloNo ratings yet

- Waste Dumps Active Passive FailureDocument24 pagesWaste Dumps Active Passive FailurechrisoldroydNo ratings yet

- Rock Mass Characterization Using RMR SystemDocument18 pagesRock Mass Characterization Using RMR SystemJoseph AbrahamNo ratings yet

- Barton, N. and N. Bar 2015 Q-Slope. Salzburg EurockDocument6 pagesBarton, N. and N. Bar 2015 Q-Slope. Salzburg EurockAliAl-naqa100% (1)

- BasRock Trajec3D ManualDocument21 pagesBasRock Trajec3D Manualcajimenezb8872No ratings yet

- Rock Mass Strength For TunnelDocument21 pagesRock Mass Strength For TunnelShwan R AhmadNo ratings yet

- Handbook No 2Document266 pagesHandbook No 2Z ANo ratings yet

- General Snowden Logging ProceduresDocument115 pagesGeneral Snowden Logging ProceduressawhlaayeNo ratings yet

- K 0 OCR ClayDocument7 pagesK 0 OCR Clayrlo_azNo ratings yet

- Evaluating The Effect of Slope Curvature On Slope StabilityDocument9 pagesEvaluating The Effect of Slope Curvature On Slope StabilityLaura GonzalezNo ratings yet

- Debris Flow PDFDocument12 pagesDebris Flow PDFAntonio Castillo RualesNo ratings yet

- Dearman1974-Weathering Classification in The Characterisation of Rock For Engineering PurposesDocument10 pagesDearman1974-Weathering Classification in The Characterisation of Rock For Engineering PurposesJose AleNo ratings yet

- Design in Rock Engineering PDFDocument25 pagesDesign in Rock Engineering PDFBrayan González CarvajalNo ratings yet

- Barton 1974Document48 pagesBarton 1974Jael Araya100% (1)

- Scanline Sampling Techniques For Rock Engineering Surveys: Insights From Intrinsic Geologic Variability and UncertaintyDocument5 pagesScanline Sampling Techniques For Rock Engineering Surveys: Insights From Intrinsic Geologic Variability and UncertaintyRivaiNo ratings yet

- Evaluation of Engineering Properties of Rock Using Ultrasonic Pulse Velocity and Uniaxial Compressive StrengthDocument7 pagesEvaluation of Engineering Properties of Rock Using Ultrasonic Pulse Velocity and Uniaxial Compressive StrengthAzeNo ratings yet

- Estimating Soil Unit Weight From CPTDocument8 pagesEstimating Soil Unit Weight From CPTGerald TanNo ratings yet

- ArmstrongDocument9 pagesArmstrongronan2000No ratings yet

- Stability Analysis of Cut Slopes Using Empirical, Kinematical, Numerical and Limit Equilibrium MethodsDocument27 pagesStability Analysis of Cut Slopes Using Empirical, Kinematical, Numerical and Limit Equilibrium MethodsBYRON BRAVONo ratings yet

- RockEng09 ProceedingsDocument258 pagesRockEng09 Proceedingsdafo407No ratings yet

- Geoethic EducationDocument8 pagesGeoethic EducationEricNo ratings yet

- PSM Geotechnical Report Appendix EDocument68 pagesPSM Geotechnical Report Appendix EsaviodebritoNo ratings yet

- Engineering Geology For Infrastructure Planning in EuropeDocument10 pagesEngineering Geology For Infrastructure Planning in EuropeAdeshola FunmilayoNo ratings yet

- Suitability of Conventional Data For Blast DesignDocument18 pagesSuitability of Conventional Data For Blast DesignOkta ChristalNo ratings yet

- GeoEng2000 Conference Proceedings/TITLEDocument59 pagesGeoEng2000 Conference Proceedings/TITLESidharth MahajanNo ratings yet

- Pore Pressure Profiling of Impounded Tailings DamsDocument16 pagesPore Pressure Profiling of Impounded Tailings DamsLuciano JuniorNo ratings yet

- Rock Mechanics and Rock Engineering FundamentalsDocument69 pagesRock Mechanics and Rock Engineering FundamentalsTengku Tantoni YahyaNo ratings yet

- General Slope Stability Concept PDFDocument25 pagesGeneral Slope Stability Concept PDFfaidNo ratings yet

- Diederichs 2007 SSRDocument8 pagesDiederichs 2007 SSRanarNo ratings yet

- Effect of Blast Load on Slope Stability Analysis Using FLACDocument4 pagesEffect of Blast Load on Slope Stability Analysis Using FLACKaram MiniNo ratings yet

- Priest - Hemispherical Projection Methods in Rock Mechanics PDFDocument132 pagesPriest - Hemispherical Projection Methods in Rock Mechanics PDFBoris Leal MartinezNo ratings yet

- Rock-Engineering Tutorials Solutions BBDDocument7 pagesRock-Engineering Tutorials Solutions BBDSandip PaudelNo ratings yet

- Evaluation of Open Pit Mine Slope Stability Analysis - Verma Dkk.Document12 pagesEvaluation of Open Pit Mine Slope Stability Analysis - Verma Dkk.ramatrisNo ratings yet

- Geotechnical Aspects of Landfill Design and ConstructionDocument121 pagesGeotechnical Aspects of Landfill Design and ConstructionBenjamín Aguilar100% (1)

- Considerations in The Optimisation of Bench Face Angle and Berm Width Geometries For Open Pit MinesDocument22 pagesConsiderations in The Optimisation of Bench Face Angle and Berm Width Geometries For Open Pit MinesPaula OliveiraNo ratings yet

- Basic Rock MechanicsDocument8 pagesBasic Rock Mechanicslopi98llkj55No ratings yet

- RMRDocument22 pagesRMRgrsadowskiNo ratings yet

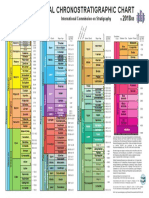

- International Chronostratigraphic Chart: International Commission On Stratigraphy V /08Document1 pageInternational Chronostratigraphic Chart: International Commission On Stratigraphy V /08Leonardo Xavier DornelasNo ratings yet

- Geotechnical Investigation of Upper Keng Tawng DamDocument6 pagesGeotechnical Investigation of Upper Keng Tawng DamEditor IJTSRDNo ratings yet

- Stability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionDocument12 pagesStability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionHas TomoNo ratings yet

- Debris Flow ClassificationDocument11 pagesDebris Flow ClassificationIoana Vieru100% (2)

- Casm A Unified State Parameter Model For Clay and SandDocument33 pagesCasm A Unified State Parameter Model For Clay and SandMarcus ViniciusNo ratings yet

- Ground - Improvement - and - Ground - Control - in FUll PDFDocument226 pagesGround - Improvement - and - Ground - Control - in FUll PDFDipendra AwasthiNo ratings yet

- Week 02 - Stress Distribution in Rocks PDFDocument24 pagesWeek 02 - Stress Distribution in Rocks PDFRAJAT PURWARNo ratings yet

- Rock Mass Properties For Underground MinesDocument20 pagesRock Mass Properties For Underground MinesJuanPerezRooneyNo ratings yet

- (Bieniawski Z) Engineering Rock Mass ClassificationDocument250 pages(Bieniawski Z) Engineering Rock Mass ClassificationNopia HarpianNo ratings yet

- GSI From Different MethodsDocument13 pagesGSI From Different MethodsNathan VincentNo ratings yet

- Slope Stability Analysis in Cohesive and Frictional SoilDocument10 pagesSlope Stability Analysis in Cohesive and Frictional SoilSimonferezNo ratings yet

- What Is Static Liquefaction Failure of Loose Fill Slopes?Document12 pagesWhat Is Static Liquefaction Failure of Loose Fill Slopes?samuel200879No ratings yet

- Mkaj 1093 - Unsaturated Soil Mechanics Project SEMESTER II, SESSION 2020/2021Document3 pagesMkaj 1093 - Unsaturated Soil Mechanics Project SEMESTER II, SESSION 2020/2021Lingeswarran Numbikannu0% (1)

- Revisión de EstudiosDocument30 pagesRevisión de EstudiosGisber Mamani Colca100% (1)

- Time Prediction of Slope Failures by The Inverse Velocity MethodDocument17 pagesTime Prediction of Slope Failures by The Inverse Velocity MethodGisber Mamani ColcaNo ratings yet

- Time Prediction of Slope Failures by The Inverse Velocity MethodDocument17 pagesTime Prediction of Slope Failures by The Inverse Velocity MethodGisber Mamani ColcaNo ratings yet

- Time Prediction of Slope Failures by The Inverse Velocity MethodDocument17 pagesTime Prediction of Slope Failures by The Inverse Velocity MethodGisber Mamani ColcaNo ratings yet

- Modeling of Landslide Volume EstimationDocument11 pagesModeling of Landslide Volume EstimationGisber Mamani ColcaNo ratings yet

- Manual de MuestreoDocument83 pagesManual de MuestreoOmarhersan100% (3)

- Blasting in Relation To Strength IndexDocument13 pagesBlasting in Relation To Strength Indexaksh28No ratings yet

- Anderson, E.M., 1905 The Dynamics of FaultsDocument17 pagesAnderson, E.M., 1905 The Dynamics of FaultsGisber Mamani ColcaNo ratings yet

- OralsDocument1 pageOralsGisber Mamani ColcaNo ratings yet

- Resultado SismograficoDocument1 pageResultado SismograficoGisber Mamani ColcaNo ratings yet

- Coversion de CoordenasDocument1 pageCoversion de CoordenasGisber Mamani ColcaNo ratings yet

- Detonadores ElectronicosDocument4 pagesDetonadores ElectronicosGisber Mamani ColcaNo ratings yet

- Form Geom SLDocument1 pageForm Geom SLGisber Mamani ColcaNo ratings yet

- Perception of Senior High School Students of Ramon Magsaysay (Cubao) High School Towards Shifting Back To Face-To-Face Classes Amidst The PandemicDocument32 pagesPerception of Senior High School Students of Ramon Magsaysay (Cubao) High School Towards Shifting Back To Face-To-Face Classes Amidst The Pandemici3No ratings yet

- UV ManualDocument693 pagesUV ManualNGUYEN Ethan100% (1)

- Hypotheses Testing ExplainedDocument93 pagesHypotheses Testing ExplainedTushar ShrimaliNo ratings yet

- IUSS Bulletin 109Document75 pagesIUSS Bulletin 109Scary CreaturesNo ratings yet

- A Study On Consumer Behaviour Towards FMCG Goods An Empirical Study With Special Reference To SPSR Nellore District of Andhra PradeshDocument7 pagesA Study On Consumer Behaviour Towards FMCG Goods An Empirical Study With Special Reference To SPSR Nellore District of Andhra PradeshHimanshu PatelNo ratings yet