Professional Documents

Culture Documents

NASH VectraXL en

Uploaded by

John UrdanetaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NASH VectraXL en

Uploaded by

John UrdanetaCopyright:

Available Formats

Vectra XL Series

Liquid Ring Vacuum Pumps and Compressors

NASH Vectra XL Series

Liquid Ring Vacuum Pumps and Compressors

Industry Workhorses

Vacuum and compressor technology

for chemical processing

NASH liquid ring vacuum pumps produced by Gardner

Denver Nash have been known for more than 100 years

as tireless workhorses, designed to stand up to the

rigorous, nonstop demands of the harshest industrial

environments. Built better than industry standards,

NASH pumps are known for their reliability.

Vectra XL pumps are designed to stand up to the harsh

environments found in the chemical process Industry. They are

available in both ductile iron and stainless steel and can

accommodate a variety of mechanical seals. Key elements of the

design are the improved cone angles, which decrease the size of

the pump, and NASH patented Gas Scavenging Technology, which

dramatically improves pump performance at high vacuum levels.

Vectra XL vacuum pumps and compressors, created

specifically for the chemical process industry, combine

the highest standard of this reliability with a new level

of ingenuity. Gardner Denver Nash employs advanced

design technologies to achieve optimum performance

and unprecedented production efficiencies. As a result,

Vectra XL pumps are economical and provide great value

to our customers.

Designed from the ground up based on customer

defined market requirements; and the input from R&D,

manufacturing, marketing, and most importantly, process

engineers, Vectra XL pumps are a revolutionary line of

pumps tough enough to be branded NASH.

These pumps include technological advancements such

as a patented cone design and rotor configuration.

These machines have been specifically designed to excel

in applications that require discharging against a positive

back pressure. Vectra XL pumps meet high combustible

range standards and are ATEX certified. These vacuum

pumps and compressors are in accordance with guideline

94/9/EG, category 1 and 2 and were also designed with

API 681 specifications in mind.

Features

Benefits

Compact design

Less floor space required

External mechanical seals

Flexibility & ease of maintenance

Universal stuffing box

Accepts variety of mechanical seals

Direct drive speeds for

60 Hz and 50 Hz motors

Global product design

Extended pressure ratings

Ability to handle tough applications

where back pressure is required

Conical design

Better ability to handle water /

particulate slugs

Basic Specifications NASH Vectra XL

One moving part

Long term reliability

Vacuum range

to 33 mbar abs. (0-29 in Hg vac)

Variable port design

High efficiency

Mechanical seals*

Single, double and cartridge

Lobe purges

Reduce erosion wear

Differential pressure

capability

2 bar (30 psi)

NASH patented

Gas Scavenging

Increased performance

at high vacuum levels

Compressor pressure

3 bar abs. (30 psig)

Redesigned cone angle

Reduced pump length

Hydrotest pressure

16 bar abs. (225 psig) optional

11 bar abs. (150 psig) standard

Optimum design using

finite element analysis

Improved efficiency, performance

and value

Construction material Ductile iron, stainless steel

100% performance tested Trouble-free start-up and operation

* Mechanical seals are standard on stainless steel Vectra XL 35 - 150 models. Optional on others.

NASH Vectra XL Series

World Class Design and Performance

Performance :

Suction Capacity

Performance :

Vacuum and Compressor Range

XL 950

28

0.8

XL 750

33 160 mbar abs. 1013 1.0

1.0 4.7

in HgA

30.0 0

bar abs. 2.0

PSIG

14.5

2.5

22

3.0

30

XL 500

XL 350

XL 250

XL 150

XL 130

XL 100

XL 80

XL 60

XL 45

XL 35

m/hr 0

1000 2000 3000 4000 5000 6000 7000 8000 9000

CFM

500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500

Capacity

Vacuum pump

0 33

1

mbar abs.

in HgA

1000

30

Vacuum pump

with back pressure

Capacity

Atmospheric

Dimensions

all dimensions are approximate; technical data subject to change

XL 950

XL 750

XL 500

XL 350

XL 250

XL 150

XL 130

XL 100

XL 80

XL 60

XL 45

XL 35

mm

mm

mm

mm

mm

inches inches inches inches inches

2273 1407 1360 590

150

89.5 55.4 53.5 23.2

5.9

2070 1244 1200 520

130

81.5

49

47.3 20.5

5.1

2057 991 1041 457

89

81

39

41

18

3.5

1626 737

787

380

86

64

29

31

13

3.4

1397 660

635

292

76

55

26

25

11.5

3

1219 533

533

236

64

48

21

21

9.3

2.5

1168 483

508

203

61

46

19

20

8

2.4

1067 483

508

203

61

42

19

20

8

2.4

991

432

406

173

48

39

17

16

6.8

1.9

914

432

406

173

48

36

17

16

6.8

1.9

838

340

356

152

38

33

13.4

14

6

1.5

762

340

356

152

38

30

13.4

14

6

1.5

Inlet

Flange

Discharge

Flange

mm

inches

300

12

250

10

250

10

200

8

150

6

150

6

100

4

100

4

100

4

100

4

80

3

80

3

mm

inches

250

10

200

8

200

8

150

6

150

6

100

4

100

4

100

4

80

3

80

3

50

2

50

2

0 33 mbar abs.

1 in HgA

2 bar abs.

30 PSIA

Compressor

Capacity

Pump

Model

Atmospheric

0 bar abs. 1

PSIA

15

Inlet

XL

2

30

3

45

Discharge

B

C

D

Gardner Denver Nash is a division of Gardner Denver, Inc.

The histories of NASH and elmo provide more than

100 years of experience as the worlds leading supplier of

liquid ring vacuum pumps, compressors and systems.

Other NASH Products:

2BE4 / P2620

Large liquid ring vacuum pumps with superior corrosion resistance

Top discharge capability which eliminates need for trench

Self-recirculating seal water, reducing need for external seal water source

Capacity: 6,800 to 39,000 m3/h (4,000 to 23,000 CFM)

Vacuum: to 160 mbar abs. (25 HgV)

TC/TCM

Integral 2 stage liquid ring pumps with improved performance at

high vacuum levels

Designed to handle large amounts of liquid carryover

without difficulty

Capacity: 170 to 3,740 m3 /h (100 to 2,240 CFM)

Vacuum: to 27 mbar abs. (0.8 HgA)

Vectra SX

Liquid ring vacuum pumps and compressors

Available in monoblock or lantern design

Water handling version for large amounts of liquid carryover

Capacity: 35 to 260 m3/h (20 to 155 CFM)

Vacuum: to 33 mbar abs. (29+ HgV)

Service for

Liquid Ring

Pumps

We have the know-how, the experience and the specialists:

We provide professional service to keep your pumps running and

efficient for decades. Our Service Centers are located in:

Australia

Brazil

China

Germany

Korea

The Netherlands

Singapore

South Africa United Kingdom

USA

Steam Jet

Ejectors

Sizes range from 25mm to 2 meters (1 to 78) inlets

Capacity: 34 to 34,000 m3/h (20 to 20,000 CFM)

Vacuum: Multi-stage system pressures as low as 0.034 mbar abs.

(0.001 mm HgA)

Gardner Denver Nash

has many ISO 9001

certifications.

Order-No.: LRP:B-PB118-A1-EN

2.0/08-2011 Printed in Germany

2011 All Rights Reserved; All data subject to change

Gardner Denver Nash has an extensive network of sales offices and representatives all over the world.

Nash - Zweigniederlassung

der Gardner Denver

Deutschland GmbH

Katzwanger Strae 150

90461 Nuremberg, Germany

Phone: +49 911 1454-0

Fax:

+49 911 1454-6935

nash.de@gardnerdenver.com

www.GDNash.com

You might also like

- The Performance Meets The Promise: Vectra Series Models GL & XLDocument12 pagesThe Performance Meets The Promise: Vectra Series Models GL & XLNicolás Villarin100% (1)

- Gardner Denver Nash CL Serien BroschyrDocument8 pagesGardner Denver Nash CL Serien BroschyrjorgekichiNo ratings yet

- 905 Series Liquid Ring Vacuum Pumps & CompressorsDocument4 pages905 Series Liquid Ring Vacuum Pumps & CompressorscarlosNo ratings yet

- Características Técnicas Bombas Mark IIIDocument60 pagesCaracterísticas Técnicas Bombas Mark IIIBORISINHO2975No ratings yet

- BUSCH Original Parts Indications & Benefit (Customer Version)Document30 pagesBUSCH Original Parts Indications & Benefit (Customer Version)jojo shendy100% (1)

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- 2GDocument8 pages2GGaurav Panditrao UdanshivNo ratings yet

- Ring Blower Vacuum Pump Catalog (Total) 2 PDFDocument17 pagesRing Blower Vacuum Pump Catalog (Total) 2 PDFDSdds0% (1)

- Nash Vectra XL BrochureDocument4 pagesNash Vectra XL BrochureTorus EngenhariaNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Limits and Fits Pr1171 - 1172Document1 pageLimits and Fits Pr1171 - 1172Teguh Nugraha KusnanNo ratings yet

- Dalian DB Pump EAP-Catalogue-English-2009Document13 pagesDalian DB Pump EAP-Catalogue-English-2009Lukarsa2013100% (1)

- Elmo Pack IOMDocument61 pagesElmo Pack IOMErick Fabian Carrillo Revilla100% (1)

- What Is DampenerDocument12 pagesWhat Is DampenerReyNo ratings yet

- Bomba CPKDocument20 pagesBomba CPKPatricio Andres Silva SanzanaNo ratings yet

- Cat Vacuum Pumps V71D17C EngDocument16 pagesCat Vacuum Pumps V71D17C Enghoangvubui4632100% (1)

- Teikoku Pump Manual PDFDocument8 pagesTeikoku Pump Manual PDFWan ZahirNo ratings yet

- Resources Mechanical AESSEAL Guides AUTODocument16 pagesResources Mechanical AESSEAL Guides AUTOmanoNo ratings yet

- NTT Om PDFDocument24 pagesNTT Om PDFrpichoNo ratings yet

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- Wilden Pump p8Document47 pagesWilden Pump p8RUBERTH ALEXANDER OCHOANo ratings yet

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- Tuthill Blower Spec - 02Document8 pagesTuthill Blower Spec - 02Kari ConwayNo ratings yet

- LPHX Serie 4500 SIHIDocument11 pagesLPHX Serie 4500 SIHIJorge FernandezNo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- OBL Metering Pumps X9 BrochureDocument12 pagesOBL Metering Pumps X9 BrochureniranpaiNo ratings yet

- 3a Index PDFDocument4 pages3a Index PDFraluntitled0% (1)

- Technical Specifications of Mechanical Seal S.NO. Description Specifications Eagle Poonawala Flowserve Sanmar Roto - Seals Hi - Fab Operating DetailsDocument3 pagesTechnical Specifications of Mechanical Seal S.NO. Description Specifications Eagle Poonawala Flowserve Sanmar Roto - Seals Hi - Fab Operating Detailssushant_jhawerNo ratings yet

- Oerlikon Leybold Roots Blower Vacuum Pump CatalogDocument40 pagesOerlikon Leybold Roots Blower Vacuum Pump CatalogYasir Ali100% (1)

- TC FLS SIHI LEH 1200 1500 1800 Mag ENDocument7 pagesTC FLS SIHI LEH 1200 1500 1800 Mag ENGustavo ZavalaNo ratings yet

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Document29 pagesHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanNo ratings yet

- Catalog Serie LEMA 25 - 50Document8 pagesCatalog Serie LEMA 25 - 50Lenin MisariNo ratings yet

- 4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFDocument16 pages4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFmiguel callataNo ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- KSB - Etabloc - Iom - enDocument64 pagesKSB - Etabloc - Iom - enAnonymous cPzveVRHINo ratings yet

- Goulds AF: Axial Flow PumpsDocument11 pagesGoulds AF: Axial Flow PumpsKarthick VenkateshNo ratings yet

- Resources Mechanical Flowserve Pusher P50Document2 pagesResources Mechanical Flowserve Pusher P50Suresh Kumar MittapalliNo ratings yet

- Hi Fab Mechanical SealDocument1 pageHi Fab Mechanical SealVarun MalhotraNo ratings yet

- Xylem Guide To BlowersDocument11 pagesXylem Guide To BlowersAmal KaNo ratings yet

- Liquid-Ring Vacuum Pump L-900 SeriesDocument144 pagesLiquid-Ring Vacuum Pump L-900 SeriesReinaldo RamirezNo ratings yet

- 3196xbulletin Read 06Document20 pages3196xbulletin Read 06bryandownNo ratings yet

- Inoxpa - ManualDocument93 pagesInoxpa - ManualnikitaNo ratings yet

- CPX, CPXR, CPXN, CPXP PDFDocument44 pagesCPX, CPXR, CPXN, CPXP PDFAhunahonNo ratings yet

- Nash Liquid Ring Vacuum PumpsDocument6 pagesNash Liquid Ring Vacuum Pumpsbltzkrig100% (2)

- Multistage Pump - Kirloskar PDFDocument63 pagesMultistage Pump - Kirloskar PDFpsuvarnasNo ratings yet

- NEMO Progressing Cavity PumpsDocument24 pagesNEMO Progressing Cavity PumpsPeñaloz GustavoNo ratings yet

- CPK Pump CatalogeDocument16 pagesCPK Pump CatalogeawigaNo ratings yet

- Dry Screw Vacuum PumpsDocument12 pagesDry Screw Vacuum PumpsJitendra KadamNo ratings yet

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- TECHNICAL Layne Engineering ManualDocument34 pagesTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNo ratings yet

- MBN - E00657 Multistage Pump PDFDocument8 pagesMBN - E00657 Multistage Pump PDFAlfonso BlancoNo ratings yet

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDocument1 pageScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesNo ratings yet

- B 4600Document6 pagesB 4600sergioarrayaNo ratings yet

- Busch Instruction Manual RA 0025-0100 F ATEX en 0870155907Document52 pagesBusch Instruction Manual RA 0025-0100 F ATEX en 0870155907phucdc095041No ratings yet

- Ajustes y ToleranciasDocument1 pageAjustes y ToleranciasRay Rodriguez SanchezNo ratings yet

- NASH 2BE4 P2620 LargePumps enDocument4 pagesNASH 2BE4 P2620 LargePumps enYugmeshNo ratings yet

- TC/TCM Two Stage Liquid Ring Vacuum PumpsDocument4 pagesTC/TCM Two Stage Liquid Ring Vacuum PumpstpplantNo ratings yet

- CL Liquid Ring Vacuum Pumps and CompressorsDocument8 pagesCL Liquid Ring Vacuum Pumps and CompressorsJavier gonzalezNo ratings yet

- Vectra GL Brochure PDFDocument4 pagesVectra GL Brochure PDFpexyNo ratings yet

- Energy Efficiency in Steam Systems - CHE - Facts - 0409Document1 pageEnergy Efficiency in Steam Systems - CHE - Facts - 0409John UrdanetaNo ratings yet

- Correcting Improper Performance of Direct Fired Heaters - May 2013Document8 pagesCorrecting Improper Performance of Direct Fired Heaters - May 2013John UrdanetaNo ratings yet

- Immersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006Document5 pagesImmersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006John UrdanetaNo ratings yet

- CHE Facts - Industrial Gas Burners - July 2016Document1 pageCHE Facts - Industrial Gas Burners - July 2016John UrdanetaNo ratings yet

- CHE BP - Best Practices For The Control of Fuel Gas - May 2014Document4 pagesCHE BP - Best Practices For The Control of Fuel Gas - May 2014John UrdanetaNo ratings yet

- Che Apr 2009 - GsoDocument7 pagesChe Apr 2009 - GsoJohnUrdanetaNo ratings yet

- CHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015Document11 pagesCHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015John UrdanetaNo ratings yet

- Revista PetroleoDocument115 pagesRevista PetroleojesslpezNo ratings yet

- HP May 2014Document115 pagesHP May 2014John UrdanetaNo ratings yet

- Che Apr 2009 - GsoDocument7 pagesChe Apr 2009 - GsoJohnUrdanetaNo ratings yet

- Vizio User Manual - M321iA2Document80 pagesVizio User Manual - M321iA2John UrdanetaNo ratings yet

- Smith MN 01011Document8 pagesSmith MN 01011John UrdanetaNo ratings yet

- DHV 6a Catalogue-FinalDocument16 pagesDHV 6a Catalogue-FinalJohn UrdanetaNo ratings yet

- F-104 - SPEEDAIRE Heavy Duty Air Line - 1 of 2Document1 pageF-104 - SPEEDAIRE Heavy Duty Air Line - 1 of 2John UrdanetaNo ratings yet

- Smith Ab 01023Document24 pagesSmith Ab 01023John UrdanetaNo ratings yet

- Gaso Performace ChartDocument1 pageGaso Performace ChartJohn UrdanetaNo ratings yet

- Asco Ah2d v710Document4 pagesAsco Ah2d v710John Urdaneta0% (1)

- Alfa Laval Spiral Heat Exchanger BrochureDocument12 pagesAlfa Laval Spiral Heat Exchanger BrochureJohn UrdanetaNo ratings yet

- Spiral Heat Exchanger - Instruction BookDocument17 pagesSpiral Heat Exchanger - Instruction BookJohn UrdanetaNo ratings yet

- TDW Vantage V Cleaning PigDocument1 pageTDW Vantage V Cleaning PigJohn UrdanetaNo ratings yet

- Environmental AuditingDocument37 pagesEnvironmental AuditingParth Shah100% (1)

- Is 1593Document7 pagesIs 1593Stacy Wilson100% (1)

- Malaysia FACTORIES AND MACHINERY (STEAM BOILER AND UNFIRED PRESSURE VESSEL) REGULATIONS, 2017, Incorporating Latest Amendment - P.U. (A) 106 2017Document3 pagesMalaysia FACTORIES AND MACHINERY (STEAM BOILER AND UNFIRED PRESSURE VESSEL) REGULATIONS, 2017, Incorporating Latest Amendment - P.U. (A) 106 2017mandster1978No ratings yet

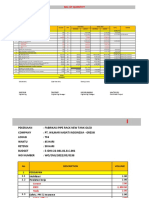

- RFQ Fabrikasi Pipe Rack New Tank OleoDocument22 pagesRFQ Fabrikasi Pipe Rack New Tank OleokamprettelanjangNo ratings yet

- Composite CatalogDocument128 pagesComposite Catalogmkwetco75% (4)

- D-11 Chapter 9 Turb Alignment and S P ClearancesDocument17 pagesD-11 Chapter 9 Turb Alignment and S P ClearancesHernan Giraut100% (2)

- Nov 2016Document104 pagesNov 2016chuchin28No ratings yet

- Oil and Gas BookDocument41 pagesOil and Gas Bookramkumar_me0% (1)

- Aspen Plus Dynamics DatasheetDocument2 pagesAspen Plus Dynamics Datasheetatsomech132206No ratings yet

- Hydrocarbon Processing - RENTECHDocument125 pagesHydrocarbon Processing - RENTECHIulian BarascuNo ratings yet

- High-Voltage Transformer Bushing Assessment Is Critical - T&D WorldDocument11 pagesHigh-Voltage Transformer Bushing Assessment Is Critical - T&D WorldwasimwalayatNo ratings yet

- LIE Proposal For Silver Oaks - ITCOT-AhmedabadDocument7 pagesLIE Proposal For Silver Oaks - ITCOT-AhmedabadVasudevan R DNo ratings yet

- M Series Manual PDFDocument141 pagesM Series Manual PDFPrestoneKNo ratings yet

- An Introduction To Turbodrills: Putting The Power To WorkDocument46 pagesAn Introduction To Turbodrills: Putting The Power To WorkHamed Gerami100% (1)

- Biomass Based Power Plant in South SudanDocument23 pagesBiomass Based Power Plant in South SudanYogendra PalNo ratings yet

- Certified Program For Electrical Engineers "Building Installation"Document23 pagesCertified Program For Electrical Engineers "Building Installation"Mohammad Al-RfoohNo ratings yet

- CIR vs. Mindanao II Geothermal Jan 2014Document7 pagesCIR vs. Mindanao II Geothermal Jan 2014Sam Leynes100% (1)

- Jinko Solar ReportDocument8 pagesJinko Solar ReportShayne RebelloNo ratings yet

- PT. Fadnov Airtech Indonesia Profile.Document18 pagesPT. Fadnov Airtech Indonesia Profile.abdur rohmanNo ratings yet

- 8194MA Baltec Proposal For PT Truba Jurong Eng 1 X V64.3A Rev4Document3 pages8194MA Baltec Proposal For PT Truba Jurong Eng 1 X V64.3A Rev4Mitha SyauzieNo ratings yet

- New - Aluminium Health, Environmental and Engineering PerspectivesDocument294 pagesNew - Aluminium Health, Environmental and Engineering Perspectivesapi-3842732100% (1)

- Summer Internship Report: Indian Oil Corporation LimitedDocument34 pagesSummer Internship Report: Indian Oil Corporation Limitedshakti shanker0% (1)

- Qatar Companies ListDocument10 pagesQatar Companies ListSyed Abbu Hurerah50% (2)

- ER5.2. How To Lose Half A Trillion EurosDocument8 pagesER5.2. How To Lose Half A Trillion EurosFahdNo ratings yet

- NEC 2015 ReportDocument20 pagesNEC 2015 ReportNew Economy CoalitionNo ratings yet

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Document1 pageHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyNo ratings yet

- WEG Three Phase Flameproof Motors w22x and Bfgc4 Series Technical European Market 125.71 Brochure EnglishDocument202 pagesWEG Three Phase Flameproof Motors w22x and Bfgc4 Series Technical European Market 125.71 Brochure EnglishVishal NarkhedeNo ratings yet

- PTD Newsletter Issue 3 Final.Document11 pagesPTD Newsletter Issue 3 Final.PavithraNo ratings yet

- Philips Report by Kashan PirzadaDocument52 pagesPhilips Report by Kashan Pirzadakashanpirzada100% (2)

- Conceptual Design of Salt Cavern Based LNG TerminalDocument25 pagesConceptual Design of Salt Cavern Based LNG TerminalNurcahyo Djati W100% (3)