Professional Documents

Culture Documents

ADEC™ - Advanced Diesel Engine Controller For Genset Application - 2007 - MTU® PDF

Uploaded by

pevareOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ADEC™ - Advanced Diesel Engine Controller For Genset Application - 2007 - MTU® PDF

Uploaded by

pevareCopyright:

Available Formats

ADEC

Advanced Diesel Engine Controller

for Genset Application

MTU Friedrichshafen

27.08.2007

MAP-O

Engine Control Unit ECU-7 (ext. Design)

Plug X1

LED (red)

System Cable / Connection to Plant Side

Connection to External Controller

- OFF (No Power Supply)

- ON (Normal Operation)

- Flashing slow (Incorrect Data Set /MPS, APS)

- Flashing fast (Internal Error, e.g. defective RAM)

(CAN, ANA-IN/OUT, BIN-IN/OUT)

Plug X2

Sensor Harness

(e.g Pressure, Temp., Speed

Sensors, High Pressure Pump)

Plug X3

Power Supply

Plug X4

Injector Harness

27.08.2007

Engine Control Unit ECU-7

(Differences MDEC/ADEC)

Overview of the main differences to the ECU-4 (Service View):

- No internal exchangeable fuse.

- No exchangeable modules EDM and IDM.

- No internal Failure Code Display.

- No serial interface to the Dialogue Unit, only communication via CAN

(attention: new tools are necessary).

- Parameter set is divided in engine parameters (MPS) and application

parameters (APS) update via EPROM.

- New parameter structure (ZKP numbers).

- Extended failure code list.

27.08.2007

ADEC / MDEC differences

ADEC (ECU7)

MDEC (ECU4)

Injection

Injektor voltage

triple

24 - 48 V

single

24 V

Computing velocity

I/O

Vibration

max. housing temperature

Box-Selftest

800 %

90

4 grms (goal)

105 C

yes

100 %

75

1,3 grms

75 C

no

Features

CAN-Bus for future extensions

Engine monitoring parametrable

Safetysystem parametr

Torque based Engine management

27.08.2007

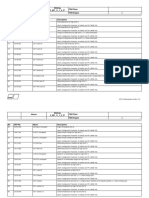

ECU 7 In/Out Genset 4000

TOP

TOP11 yellow

yellowalarm

alarm

TOP

TOP22 red

redalarm

alarm

TOP

3

lube

oil

TOP 3 lube oilstop

stop

DIDI11 Engine

EngineStop

Stop

DIDI22 Droop

Droop22

DIDI33

DIDI44

Idle

IdleMode

Mode

Alarm

AlarmReset

Reset

DIDI55

DIDI66

Speed

SpeedUp

Up

Speed

SpeedDown

Down

DIDI77

DIDI88

Start

StartEngine

Engine

Override

Override

Trans. Outputs

+24V switch

Digital Input

speed

speedwindow

window

+24V switch

Analoger Output

AI1

AI1 Speed

SpeedDemand

DemandI I

Speed

SpeedDemand

DemandUU

TOP

TOP44 starter

starteron

on

engine

enginerunning

running

0-10V

0-10V

4-20mA

4-20mA

AO 1 coolant temp.

AO 1 coolant temp.

AO

AO22 lube

lubeoiloilpressure

pressure

0-10V

0-10V

0-10V

0-10V

Analog Input

AI 2 Engine Torque Demand (LSG) 0-10V

AI 2 Engine Torque Demand (LSG) 0-10V

CAN1

CAN1

CAN2

CAN2

PCS 5

27.08.2007

ECU 7 In/Out Genset 2000 PLD

TOP

TOP11 yellow

yellowalarm

alarm

TOP

TOP22 red

redalarm

alarm

TOP

3

lube

oil

TOP 3 lube oilstop

stop

DIDI11 Engine

EngineStop

Stop

DIDI22 Droop

Droop22

DIDI33

DIDI44

Idle

IdleMode

Mode

Alarm

AlarmReset

Reset

DIDI55

DIDI66

Speed

SpeedUp

Up

Speed

SpeedDown

Down

DIDI77

DIDI88

Start

StartEngine

Engine

Override

Override

Trans. Outputs

+24V switch

Digital Input

speed

speedwindow

window

+24V switch

Analoger Output

AI1

AI1 Speed

SpeedDemand

DemandI I

Speed

SpeedDemand

DemandUU

TOP

TOP44 starter

starteron

on

engine

enginerunning

running

0-10V

0-10V

4-20mA

4-20mA

AO 1 coolant temp.

AO 1 coolant temp.

AO

AO22 lube

lubeoiloilpressure

pressure

0-10V

0-10V

0-10V

0-10V

Analog Input

AI 2 Engine Torque Demand (LSG) 0-10V

AI 2 Engine Torque Demand (LSG) 0-10V

CAN1

CAN1

CAN2

CAN2

PCS 5

27.08.2007

S.2000/4000 for Genset Application

Engine Sensors

Serie 4000_03

Serie 2000 PLD

coolant

coolantwater

waterlevel

level

coolant

coolantwater

waterlevel

levelintercooler

intercooler

FF33

33

coolant

coolantwater

watertemp.

temp.

charge

chargeair

airtemp.

temp.

BB66

BB99

rail

railfuel

fueltemp.

temp.

coolant

coolanttemp.

temp.intercooler

intercooler

BB33

33

BB26

26

lube

lubeoiloiltemp.

temp.

fuel

fuelpressure

pressureafter

afterfilter

filter

BB77

BB34

34

fuel

fuelhigh

highpressure

pressure

lube

oil

pressure

lube oil pressure

BB48

48

BB55

charge

chargeair

airpressure

pressure

crankshaft

crankshaftspeed

speed

BB10

10

BB13

13

camshaft

camshaftspeed

speed

B1

B1

FF57

57

coolant

coolantwater

waterlevel

level

FF33

33

coolant

coolantwater

watertemp.

temp.

BB66

charge

chargeair

airtemp.

temp.

fuel

fueltemp.

temp.

BB99

BB33

33

lube

lubeoiloiltemp.

temp.

BB77

lube

lubeoiloilpressure

pressure

charge

chargeair

airpressure

pressure

BB55

BB10

10

crankshaft

crankshaftspeed

speed

camshaft

camshaftspeed

speed

BB13

13

B1

B1

27.08.2007

ADEC for Genset Application

Technical leadership

Torque based Engine management

Robust and simple design

Easy Diagnostics and service features

Flexible Customer Interface and plant adaption via a Service and

Automation Module (SAM)

27.08.2007

ADEC for Genset Application

Technical leadership

Programmable Injectors

(one Box for 4 different Injector Typs)

Pre and Post Injection Possible

42 V Injectors

Optimised Engine Emission and Consumption Values

20 Injectors with one Governor Box

Easy handling of Power Adjustment

27.08.2007

ADEC for Genset Application

Robust and simple design

9Increased Temperature range

from 40C up to +105C

within the specified accuracy

9Shock and vibration stressability

up to 3,6 G RMS

9Protection class: IP69K

Note:

ADEC was designed to

withstand a harsher environment

than the previous MDEC/DDEC.

27.08.2007

10

ADEC for Genset Application

Easy Diagnostics

The ADEC performs a selftest during

power initialisation and during

operation. The result is indicated via the

Diagnostic lamp (DILA).

Permanent light

Flashing light

No light

ADEC is ok.

ADEC is defect.

Power is off

Internal faults can be detected with

power on at disconnected harness

27.08.2007

Box Tausch

Diagnostic lamp

11

You might also like

- Square D Wiring Diagram BookDocument109 pagesSquare D Wiring Diagram BookVieruth Pascua Paet100% (10)

- Fault Finding Manual For Stamford AC Generators - July 2009 - CUMMINS Generator Technologies PDFDocument29 pagesFault Finding Manual For Stamford AC Generators - July 2009 - CUMMINS Generator Technologies PDFpevare78% (9)

- Error Code MTU ADEC ECU 7Document24 pagesError Code MTU ADEC ECU 7Sudiono Ajb92% (12)

- SensorsDocument9 pagesSensorsGiang DoNo ratings yet

- System Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Document198 pagesSystem Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Minh Le100% (1)

- P158LE - P180LE - P122LE Doosan PDFDocument162 pagesP158LE - P180LE - P122LE Doosan PDFroyert80100% (2)

- Engine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsDocument62 pagesEngine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsGeorge Barsoum100% (3)

- ADEC™ - Error List - 2006 - MTU® PDFDocument33 pagesADEC™ - Error List - 2006 - MTU® PDFpevare100% (4)

- ADEC™ - Error List - 2006 - MTU® PDFDocument33 pagesADEC™ - Error List - 2006 - MTU® PDFpevare100% (4)

- ADEC Advanced Diesel Engine ControllerDocument49 pagesADEC Advanced Diesel Engine Controllerpevare100% (12)

- Mtu Sam & Adec E532304 - 00eDocument216 pagesMtu Sam & Adec E532304 - 00ecampioed85% (13)

- RTS Automatic Transfer Switch - Technical Manual - GENERAC PDFDocument28 pagesRTS Automatic Transfer Switch - Technical Manual - GENERAC PDFpevare100% (2)

- Mechanical and Natural VentilationDocument43 pagesMechanical and Natural VentilationSudhanshu Mandlik100% (1)

- E532304 - 00E - ADEC and SAM Connection InterfaseDocument202 pagesE532304 - 00E - ADEC and SAM Connection InterfaseAlex Robledo Olarte92% (12)

- ADEC Advanced Diesel Engine Controller For Genset Application 2007 MTU PDFDocument11 pagesADEC Advanced Diesel Engine Controller For Genset Application 2007 MTU PDFthanhhai3150% (2)

- Digital Control Panel Kerys (English)Document8 pagesDigital Control Panel Kerys (English)dbarron00No ratings yet

- Especificaciones Mtu PDFDocument11 pagesEspecificaciones Mtu PDFCeciliagorraNo ratings yet

- Operation and Maintenance Manual Automatic Transfer Switch ZTSH Series 30 - 4000 AMPSDocument37 pagesOperation and Maintenance Manual Automatic Transfer Switch ZTSH Series 30 - 4000 AMPSYassin AlkadyNo ratings yet

- Mtu Reach SVHC 2018-10-29 enDocument75 pagesMtu Reach SVHC 2018-10-29 enalawi50% (2)

- MTU and DSE Controllers Configuration GuideDocument7 pagesMTU and DSE Controllers Configuration GuideABOUDH50% (4)

- Engine Troubleshooting Guide: Shortcuts To Costly Engine DiagnosticsDocument24 pagesEngine Troubleshooting Guide: Shortcuts To Costly Engine DiagnosticssubruaNo ratings yet

- TE809-ATS - Instructions Manual - Project v1.1.3 - TECNOELETTRA® PDFDocument36 pagesTE809-ATS - Instructions Manual - Project v1.1.3 - TECNOELETTRA® PDFpevare50% (2)

- 8V 10V 12V1600 Operation & Maintenance MS150076 02EDocument138 pages8V 10V 12V1600 Operation & Maintenance MS150076 02EETGI100% (3)

- Pelton TurbineDocument5 pagesPelton Turbinegauravarora93No ratings yet

- Adec Advanced Diesel Engine Controller For Genset Application 2007Document11 pagesAdec Advanced Diesel Engine Controller For Genset Application 2007Mauro Miranda Couto100% (2)

- Accsesory 11BG For ASCO® Series 300 - Kit Installation - 381339-252 E - ASCO™ PDFDocument4 pagesAccsesory 11BG For ASCO® Series 300 - Kit Installation - 381339-252 E - ASCO™ PDFpevareNo ratings yet

- E532284 - Funcional Descrition MtuDocument42 pagesE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- MDEC Stationary DieselDocument5 pagesMDEC Stationary DieselAhmad Shahrul Mohamed100% (2)

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocument246 pagesADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocument246 pagesADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- UltrasoundDocument175 pagesUltrasoundsky rain100% (15)

- Easygen-3100 and 3200 - P1-P2 - Software Version 1.2102 or Higher - 37532E - WOODWARD® PDFDocument754 pagesEasygen-3100 and 3200 - P1-P2 - Software Version 1.2102 or Higher - 37532E - WOODWARD® PDFpevare100% (3)

- Iaw59f PinoutDocument6 pagesIaw59f PinoutHernan Fagetti0% (1)

- ECU-7 Vorstellung PDFDocument25 pagesECU-7 Vorstellung PDFRogelio Adolfo Leiva BarrazaNo ratings yet

- Serie 4000 12V 16V Engine HarnessDocument1 pageSerie 4000 12V 16V Engine Harnessrinho201367% (3)

- Adec 1600Document84 pagesAdec 1600Sudiono Ajb50% (2)

- Pandaros Workshopman-03 PDFDocument33 pagesPandaros Workshopman-03 PDFRodrigo Santibañez100% (2)

- Field Automation Level Assembly CatalogDocument254 pagesField Automation Level Assembly CatalogAbdul KhaliqNo ratings yet

- ADEC Error List: ECU7 - SoftwareDocument33 pagesADEC Error List: ECU7 - SoftwareGiang Do100% (1)

- Manual MTUDocument134 pagesManual MTUjuan pablo zuniga100% (2)

- Dvigatel Mtu 12v2000g65eDocument155 pagesDvigatel Mtu 12v2000g65eAziz Arrahal100% (1)

- ADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFDocument49 pagesADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFaup100% (3)

- 00a MTU Abreviation ListDocument12 pages00a MTU Abreviation ListJuan Rivera100% (2)

- Psychrometric Chart ReadingDocument10 pagesPsychrometric Chart ReadingEzakiman OtanimNo ratings yet

- SAM CommisioningDocument7 pagesSAM CommisioningAlex Robledo Olarte100% (2)

- Electric Motor NEMA Frame Sizes Table PDFDocument6 pagesElectric Motor NEMA Frame Sizes Table PDFpevareNo ratings yet

- ADEC Genset Functions and ParameterDocument52 pagesADEC Genset Functions and ParameterOunna PechNo ratings yet

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 pagesPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNo ratings yet

- MTU 4000 Maintenance ScheduleDocument35 pagesMTU 4000 Maintenance Schedulenereomad100% (8)

- MtuDocument464 pagesMtuDarin Hood100% (12)

- Ecu - 7 Präsentation 11 07 - C&i - eDocument40 pagesEcu - 7 Präsentation 11 07 - C&i - eRogelio Adolfo Leiva Barraza67% (3)

- 01 Introduction Bluevison NG V1 07Document60 pages01 Introduction Bluevison NG V1 07Abdul Muksith100% (1)

- ADEC Genset Functions and ParameterDocument52 pagesADEC Genset Functions and ParameterRizki Heru Hermawan83% (23)

- Option H5, H7 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK, Rev. I PDFDocument84 pagesOption H5, H7 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK, Rev. I PDFoscarafonso100% (2)

- Smart Connect: 1 © MTU TC FN / Actual State: 07/2009 Geno - Basics - MechDocument20 pagesSmart Connect: 1 © MTU TC FN / Actual State: 07/2009 Geno - Basics - MechAnonymous uEt1sNhU7l71% (14)

- Kelloggs Edition 14 SummaryDocument2 pagesKelloggs Edition 14 SummaryRitu JainNo ratings yet

- Adjustments Sam Via MinidialogDocument4 pagesAdjustments Sam Via Minidialogarcangel_pic100% (1)

- ADEC Electronics Documentation For Electronic Engine Control Unit ECU 7 2007 MTU PDFDocument246 pagesADEC Electronics Documentation For Electronic Engine Control Unit ECU 7 2007 MTU PDFVinesh VineshbNo ratings yet

- CanbuswiringforDSEcontrollers (Motores Eletrônicos)Document34 pagesCanbuswiringforDSEcontrollers (Motores Eletrônicos)Gustavo PereiraNo ratings yet

- MTU Engine 4000-Series Functional DescriptionDocument42 pagesMTU Engine 4000-Series Functional DescriptionAlex100% (1)

- KERYS Descripcion PDFDocument33 pagesKERYS Descripcion PDFHalit Yalçınkaya100% (1)

- E531827 00E CAN FieldbusDocument46 pagesE531827 00E CAN Fieldbusarcangel_picNo ratings yet

- XZ599001-200541 - Serie 2000 - ComapDocument53 pagesXZ599001-200541 - Serie 2000 - ComapGiang Do100% (1)

- ECU-7/E2/G: Advanced Diesel Engine ControllerDocument94 pagesECU-7/E2/G: Advanced Diesel Engine ControllerGláucio Quintanilha100% (1)

- ADEC Advanced Diesel Engine Controller for Series 4000/2000 Generator ApplicationDocument49 pagesADEC Advanced Diesel Engine Controller for Series 4000/2000 Generator ApplicationFERNANDO INOCENTE TRINIDAD GUERRA100% (1)

- Мануал L33 - new - MS50199 - 01EDocument16 pagesМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Error Code ECU8Document16 pagesError Code ECU8Giang DoNo ratings yet

- Series 2000 For Power GenerationDocument6 pagesSeries 2000 For Power GenerationBarham Gen BarhamNo ratings yet

- MTU BLUE VISION AdVANCED PDFDocument8 pagesMTU BLUE VISION AdVANCED PDFomar alayash100% (1)

- 02ecu 8sameDocument69 pages02ecu 8sameSudiono Ajb80% (5)

- History of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Document584 pagesHistory of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Artisan Ideas75% (4)

- 12V Mtu 4000Document248 pages12V Mtu 4000Mig Vazq100% (5)

- MTU 4000 Series Diesel Engines for Stationary PowerDocument6 pagesMTU 4000 Series Diesel Engines for Stationary PowerMohamed Naser100% (6)

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- LPG Parts Diagram BreakdownDocument43 pagesLPG Parts Diagram BreakdownناصرقوجيلNo ratings yet

- Edoc - Pub E53173000eDocument64 pagesEdoc - Pub E53173000eBayanaka TehnikNo ratings yet

- 1600 Series Parts and OverviewDocument94 pages1600 Series Parts and OverviewJorge Eraldo Albarran PoleoNo ratings yet

- Brine ZLD Process-GEDocument7 pagesBrine ZLD Process-GEvijayendra100% (1)

- EKIP Connect - User S Manual - 1SDH000891R0002 - ABB PDFDocument51 pagesEKIP Connect - User S Manual - 1SDH000891R0002 - ABB PDFpevare100% (1)

- EKIP Connect - User S Manual - 1SDH000891R0002 - ABB PDFDocument51 pagesEKIP Connect - User S Manual - 1SDH000891R0002 - ABB PDFpevare100% (1)

- Am5766 V1.6Document10 pagesAm5766 V1.6Paulo Roberto s freireNo ratings yet

- 87 Catalog Invertere Ic5Document19 pages87 Catalog Invertere Ic5vga1234No ratings yet

- PDFDocument94 pagesPDFTrần Quang TuyênNo ratings yet

- Adjustable Speed Drives TutorialDocument13 pagesAdjustable Speed Drives Tutorialapi-3765150100% (2)

- MCDGV4 Protección de GeneradorDocument1,070 pagesMCDGV4 Protección de GeneradorIngJGM100% (1)

- Transfer Switches (Manual & Automatic) - SENR2164 - June 1981 - CATERPILLAR®Document50 pagesTransfer Switches (Manual & Automatic) - SENR2164 - June 1981 - CATERPILLAR®pevareNo ratings yet

- ATS Contactor Type - 9Y-7900 - Operation & Maintenance Manual - SEBU6324-02 - January 1996 - CATERPILLAR®Document123 pagesATS Contactor Type - 9Y-7900 - Operation & Maintenance Manual - SEBU6324-02 - January 1996 - CATERPILLAR®pevareNo ratings yet

- Transfer Switches (Manual & Automatic) - SENR2164 - June 1981 - CATERPILLAR®Document50 pagesTransfer Switches (Manual & Automatic) - SENR2164 - June 1981 - CATERPILLAR®pevareNo ratings yet

- TM 55 1930 209 14 and P 9 4Document848 pagesTM 55 1930 209 14 and P 9 4moussaNo ratings yet

- Spanish Latin America Master Glossary - 2011 - CATERPILLAR® PDFDocument135 pagesSpanish Latin America Master Glossary - 2011 - CATERPILLAR® PDFpevare100% (1)

- Catalogo Sensors - For - Instrumentation 2010 VDODocument176 pagesCatalogo Sensors - For - Instrumentation 2010 VDOMilton Pazmiño BritoNo ratings yet

- ATC-300+ - Standard Schematic - Breaker Based Transfer Switch - CE231377 - January 2015 - EATON® PDFDocument2 pagesATC-300+ - Standard Schematic - Breaker Based Transfer Switch - CE231377 - January 2015 - EATON® PDFpevareNo ratings yet

- Digitrip™ 520 Trip Unit For Use Only in Magnum and Magnum DS Circuit Breaker - IL70C1037H05 - Oct 2009 - EATON® PDFDocument40 pagesDigitrip™ 520 Trip Unit For Use Only in Magnum and Magnum DS Circuit Breaker - IL70C1037H05 - Oct 2009 - EATON® PDFpevareNo ratings yet

- ATC-600 Automatic Transfer Switch Controller - Instructional Booklet - IB ATS-1005 - EATON® PDFDocument36 pagesATC-600 Automatic Transfer Switch Controller - Instructional Booklet - IB ATS-1005 - EATON® PDFpevareNo ratings yet

- O & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFDocument44 pagesO & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFpevareNo ratings yet

- Flow of Lubricating Greases in Centralized Lubricating SystemsDocument8 pagesFlow of Lubricating Greases in Centralized Lubricating SystemsFelipe LeiteNo ratings yet

- G20 Business Letter We Mean Business CoalitionDocument26 pagesG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoNo ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardARUN BNo ratings yet

- Wave Nature of The Motor Cable and Voltage Stress of The Motor in Inverter DriveDocument9 pagesWave Nature of The Motor Cable and Voltage Stress of The Motor in Inverter DrivealbertofgvNo ratings yet

- OCDE Toolkit de ConstrucciónDocument54 pagesOCDE Toolkit de ConstrucciónALBERTO GUAJARDO MENESESNo ratings yet

- Chapter 11-Homogeneous ReactionDocument55 pagesChapter 11-Homogeneous ReactionBryan ManaliliNo ratings yet

- Aluminum Extrusions in Solar Power ApplicationsDocument4 pagesAluminum Extrusions in Solar Power ApplicationsСтанислав ПодольскийNo ratings yet

- Photoassociation Spectroscopy of A Spin-1 Bose-Einstein CondensateDocument5 pagesPhotoassociation Spectroscopy of A Spin-1 Bose-Einstein Condensatee99930No ratings yet

- VolsampDocument153 pagesVolsampSonny HutomoNo ratings yet

- Safety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Document43 pagesSafety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Dimkovski Sase KazakNo ratings yet

- DC & AC Machines and Speed ControlDocument53 pagesDC & AC Machines and Speed ControlInsane Clown Prince60% (5)

- Fermentor TypesDocument33 pagesFermentor TypesFahad MukhtarNo ratings yet

- Ncom N102Document16 pagesNcom N102RixroxNo ratings yet

- Makalah Tentang AnnouncementDocument10 pagesMakalah Tentang AnnouncementBayu Grafika 2No ratings yet

- Glycerol Production, Consumption, Prices, Characterization and New Trends in CombustionDocument19 pagesGlycerol Production, Consumption, Prices, Characterization and New Trends in CombustionmkamalzamanNo ratings yet

- Cole Tarango - Research Paper 2018-2019Document5 pagesCole Tarango - Research Paper 2018-2019api-447838694No ratings yet

- Zone 22 Hazardous Locations Classification and RequirementsDocument3 pagesZone 22 Hazardous Locations Classification and RequirementsVictor TenorioNo ratings yet

- Notification 1 2017 For CGST Rate ScheduleDocument74 pagesNotification 1 2017 For CGST Rate ScheduleIti CglNo ratings yet

- CFBC Boilers & TG Set Auxillaries SpecificationsDocument18 pagesCFBC Boilers & TG Set Auxillaries SpecificationsJAY PARIKHNo ratings yet

- MATE 280 Characterization of Powders and Porous MaterialsDocument65 pagesMATE 280 Characterization of Powders and Porous MaterialsAnissa Adiwena100% (1)

- GreenTech EC Technology enDocument44 pagesGreenTech EC Technology enspscribd1No ratings yet

- Manual TW enDocument5 pagesManual TW enRobertoNo ratings yet