Professional Documents

Culture Documents

Minimizing Angular Backlash of A Multi-Stage Gear Train

Uploaded by

Jose Ancasi EspinalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimizing Angular Backlash of A Multi-Stage Gear Train

Uploaded by

Jose Ancasi EspinalCopyright:

Available Formats

565

Minimizing angular backlash of a multistage gear

train

Y-L Hsu* and S-G Wang

Department of Mechanical Engineering, Yuan Ze University, Chung-Li, Taiwan

Abstract: An optimization model is constructed to select the optimum reduction ratios that minimize

the total angular backlash of a gear train, under constraints on the total reduction ratio and available

space. It is found that a proper layout of reduction ratios has a major eVect on the total angular

backlash of a gear train.

Keywords: gear train, angular backlash, optimization

INTRODUCTION

The prime function of gear transmission systems in many

precision machines is to accurately transmit angular displacement. In such applications , gear backlash causes an

unexpected angular position error when a rotating gear

train reverses, and it also induces a transient impact

force on the mating gear surface due to the moment of

inertia of the system.

There is an enormous amount of research literature

addressing precision gear design. Various design requirements have been considered; in particular, minimizing

the transmission error has received much attention.

Yoon and Rao [1] minimized the static transmission

error using cubic splines for a gear tooth prole. Iwase

and Miyasaka [2] modied the tooth prole to minimize

a transmission error of helical gears, while Shibata et al.

[3] tried to nd the optimum tooth prole that minimizes

transmission error for hypoid gears. Using quadrature

factorial models, Yu and Ishii [4] modied the tooth

prole to nd a robust optimum that has a minimum

expected transmission error.

However, modifying the tooth prole in order to

minimize the transmission error may not be a practical

option for many precision machine designers. Typical

design decisions faced by the designers are how to

select proper reduction ratios, gear quality grades and

tolerances, so that the required transmission precision

of a gear transmission system can be obtained in the

most cost eVective way.

The MS was received on 14 June 2001 and was accepted after revision

for publication on 13 December 2001.

*Correspondin g author: Department of Mechanical Engineering, Yuan

Ze University, 135 Yuan-Tung Road, Chung-Li, Taiwan 320.

B06701

IMechE 2002

In this research, it is found that a proper layout of

reduction ratios of a multistage gear train has a major

eVect on its total angular backlash. An optimization

model is constructed in order to nd the optimum reduction ratios that minimize the total angular backlash of a

gear train, under constraints on the total reduction ratio

and available space.

2

ANGULAR BACKLASH OF A GEAR TRAIN

Factors contributing to angular backlash mainly come

from two sources: (a) original manufacturing errors

and (b) assembly errors, such as centre distance tolerance, bearing tolerance and shaft and bearing tolerance.

In this study, the original manufacturing errors and the

centre distance tolerance are considered.

The original manufacturing errors of a gear are

specied by its quality grade. The quality grades of

spur gears and helical gears range from 0 to 9 in

JIS B 1703, and ranges from 0 to 12 in ISO 1328. These

two standards also have slightly diVerent denitions of

error estimation for each quality grade. According to

JIS B 1703 [5], the linear backlash at the pitch line is

estimated by

p

3

B 103 2r 0:65m

where r and m are the radius and module of the gear

respectively. The quality grade of the gear is reected

in the coe cient B in equation (1). For example, the

value B ranges from 10 to 25 for grade 0 gears (the

nest quality), from 10 to 28 for grade 1 gears and

from 10 to 90 for grade 8 gears.

Figure 1 shows the layout of a typical three-stage gear

train. The reduction ratios of the three gear pairs are

Proc Instn Mech Engrs Vol 216 Part B: J Engineering Manufacture

566

Y-L HSU AND S-G WANG

can be expressed as

1

1

1

6c 2C tan

r5 k3 r3 k2 k3 r1 k1 k2 k3

4

5

M

Motor

k1

k3

It will be cumbersome to consider all possible combinations of signs (plus or minus) of individual tolerances.

Therefore the total angular backlash at the output shaft

of a gear train out is expressed as the geometric sum of

individual tolerances 6m and 6c :

k2

JW

3

2

Fig. 1

out 26m 26c 1=2

6 5 4 3

2 1 2

r5 k 3

r3 k2 k3 r1 k 1 k2 k3

2 1=2

1

1

1

4C 2 tan 2

r5 k 3 r3 k2 k3 r1 k1 k2 k 3

A three-stage gear transmission system

k1 , k2 and k3 . The angular backlash of gear i can be

expressed as

i

i

ri

where i is the linear backlash and ri is the radius of gear

i. The total angular backlash can be expressed as a linear

sum of backlashes of individual gears, reected at the

output shaft of the gear train [6]. For the gear train in

Fig. 1, the total angular backlash due to original manufacturing errors reected at the shaft of gear 6 can be

expressed as

6m

6 5 =r5 4 =r4 3 =r3 2 =r2

=r

1 1

r6

k3

k3

k2 k3

k 2 k3 k1 k2 k3

6 5 4 3

1

2

r5 k3

r3 k2 k 3 r1 k1 k2 k3

Note that r6 r5 k3 , r4 r3 k2 and r2 r1 k1 .

Considering the centre distance tolerance, as shown

in Fig. 2, the eVect of a radial separation on the linear

backlash is

2C tan

where and C are the pressure angle and the centre

distance tolerance respectively. Similar to the derivation

of equation (3), the total angular backlash due to the

centre distance tolerance reected at the shaft of gear 6

THE OPTIMUM DESIGN MODEL

An optimum design model for a multistage gear train is

constructed in this section. The objective function is to

minimize the total angular backlash of the gear train

[equation (6)]. There are two constraints in this model:

the total available space and the total reduction ratio

of the gear train. Referring to Fig. 1, the allowable

space occupied by the gear train is limited within a

given value W:

2r2 r1

2r4 r3 r2

2r6 r5 r4

W

7

The total reduction ratio of the gear train has to be larger

than Kt ; therefore

k 1 k2 k3

Kt

Finally, the optimum design model can be written as

Minimize

out

6 5 4 3

1 2

2

r5 k 3

r3 k2 k3 r1 k 1 k2 k3

2 1=2

1

1

1

4C 2 tan 2

r5 k 3 r3 k2 k3 r1 k1 k2 k 3

subject to

g1 : 2r2 r1 W

Fig. 2

The inuence of centre distance tolerance on gear

backlash

Proc Instn Mech Engrs Vol 216 Part B: J Engineering Manufacture

g2 : 2r4 r3 r2 W

g3 : 2r6 r5 r4 W

0

B06701

IMechE 2002

MINIMIZING ANGULAR BACKLASH OF A MULTISTAGE GEAR TRAIN

the closest integers multiplied by M=2. Both continuous

and integer solutions are presented in the table. Note that

with the integer solution, some of the constraints in

equations (9) may be slightly violated.

Table 2 shows the reduction ratios that maximize the

total angular backlash of the gear train under the same

requirements of space and total reduction ratio. Comparing Tables 1 and 2, it can be seen that by simply

varying the reduction ratios, the maximum total angular

backlash is 2.52 times the minimum total angular backlash in this example. Note that both cases have the

same quality grade gears and the same centre distance

tolerances; therefore their manufacturing costs should

be about the same.

Also note that k1 k2 k3 for the reduction ratios

that minimize the total angular backlash. On the

contrary, k1 k2 k3 for the reduction ratios that

maximize the total angular backlash. This can easily be

explained by observing the objective function in equation

(10). The reduction ratio k3 appears in the denominators

of all six terms of the objective function, while k2 appears

in the denominators of four terms and k1 appears in the

denominators of only two terms. To minimize the total

angular backlash, obviously k3 has the top priority to

be as large as possible. The reduction ratio k2 has the

second priority, followed by k1 .

At the optimum solution shown in Table 1, space

constraints g1 and g3 are active. The total angular backlash can be further reduced if the space constraints are

relaxed. As shown in Fig. 3, for the same gear train

discussed above, the minimum total angular backlash

decreases as W increases.

Figures 4 and 5 show the change in minimum total

angular backlash with respect to the change in parameters B and C. Comparing Figs 4 and 5, it can be seen

that the total angular backlash is more sensitive to the

parameter B in this case. From this kind of parameter

analysis, designers can evaluate the cost of changing

into higher quality gears and the cost of tightening the

centre distance tolerance, to decide how to reduce the

total angular backlash in the most cost eVective way.

h1 : Kt k1 k2 k3 0

h2 : r2 =r1 k1 0

h3 : r4 =r3 k2 0

h4 : r6 =r5 k3 0

h5 : 1 B 103 3 2r1 0:65M 0

p

h6 : 2 B 103 3 2r2 0:65M 0

p

h7 : 3 B 103 3 2r3 0:65M 0

p

h8 : 4 B 103 3 2r4 0:65M 0

p

h9 : 5 B 103 3 2r5 0:65M 0

p

h10 : 6 B 103 3 2r6 0:65M 0

ri

Nmin M,

i 1, . . . , 6

ki

i 1, . . . , 3

Kmax ,

The last two constraints in equations (9) post upper and

lower bounds to the design variables ri and ki , where

Nmin is the minimum number of teeth of the gears and

Kmax is the maximum allowable reduction ratio. Note

that W, Kt , B, C, M, Nmin and Kmax are written in capital

letters to represent parameters that are given for a certain

case, but may vary from case to case.

SOLVING THE OPTIMUM DESIGN MODEL

To solve numerical values of this optimization model, a

set of parameters is rst assumed: W 100 mm,

Kt 120, B 30, C 0:020 mm, N min 18, Kmax 7

and M 0:5 mm. In this study, numerical optimization

software GAMS [7] was used to solve for the optimum

reduction ratios that minimize the total angular backlash

of the gear train (Table 1). Since the number of teeth has

to be an integer, the radii of the gears are rounded up to

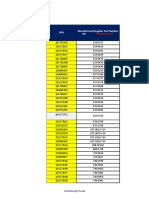

Table 1

Continuous solution

Integer solution

Optimum reduction ratios that minimize total angular backlash

out

k1

k2

k3

r1

r2

r3

r4

r5

r6

7:18 103

7:20 103

3.53

3.55

4.85

4.83

7.00

6.95

11.03

11.00

38.97

39.00

4.50

4.50

21.83

21.75

5.21

5.25

36.47

36.50

Table 2

Continuous solution

Integer solution

B06701

IMechE 2002

567

Reduction ratios that maximize total angular backlash

out

k1

k2

k3

r1

r2

r3

r4

r5

r6

18:08 10 3

18:12 10 3

7.00

7.00

7.00

7.00

2.45

2.44

4.50

4.50

31.50

31.50

4.50

4.50

31.50

31.50

4.50

4.50

11.02

11.00

Proc Instn Mech Engrs Vol 216 Part B: J Engineering Manufacture

568

Y-L HSU AND S-G WANG

Total angular backlash (10e-3)

25

20

15

10

5

0

60

70

80

90

100 110 120 130 140 150 160

W (mm)

Fig. 3

Minimum total angular backlash versus the change in available space

Total angular backlash (10e-3)

25

20

15

10

5

0

0

10

20

30

40

50

60

70

80

90

B

Fig. 4

Minimum total angular backlash versus the eVect of the change in parameter B on gear quality

Total angular backlash (10e-3)

7.3

7.25

7.2

7.15

0

0.01

0.02

0.03

0.04

0.05

0.06

C (mm)

Fig. 5

Minimum total angular backlash versus the change in centre distance tolerance

Proc Instn Mech Engrs Vol 216 Part B: J Engineering Manufacture

B06701

IMechE 2002

MINIMIZING ANGULAR BACKLASH OF A MULTISTAGE GEAR TRAIN

CONCLUSIONS

This paper presents an optimization model for nding

the optimum reduction ratios that minimize the total

angular backlash of a gear train. While the estimation

of total angular backlash in the optimization model

may not be quantitatively exact, several qualitative conclusions can be drawn:

1. Under the same design requirements on space and

total reduction ratio, simply varying the reduction

ratios can reduce the total angular backlash of a gear

train, while the manufacturin g cost stays the same.

2. To minimize the total angular backlash of a gear train,

the reduction ratio closest to the output shaft has the

highest priority to be made as large as possible.

3. The total angular backlash can be further reduced if

the constraints on available space are relaxed.

This optimization model and the parameter analysis

also provide a means to evaluate how to reduce the

total angular backlash of a gear train in the most cost

eVective way.

B06701

IMechE 2002

569

REFERENCES

1 Yoon, K. Y. and Rao, S. S. Dynamic load analysis of spur

gears using a new tooth prole. J. Mech. Des., 1996,

118(1), 16.

2 Iwase, Y. and Miyasaka, K. Proposal of modied tooth

surface with minimized transmission error of helical gears.

JSAE Rev., 1996, 17(2), 191 193.

3 Shibata, Y., Kondou, N. and Ito, T. Optimum tooth

prole design for hypoid gear. JSAE Rev., 1997, 18(3),

283287.

4 Yu, J.-C. and Ishii, K. Design optimization for robustness

using quadrature factorial models. Engng Optimization,

1998, 30(3/4), 203 225.

5 JIS B1703, Backlash for spur and helical gears. In JIS Handbook, Machine Elements, 1995, pp. 1689 1725 (Japanese

Standards Association).

6 Chironis, N. P. (Ed.) Gear Design and Application, 1971,

236 pp. (McGraw-Hill, New York).

7 Brooke, Kendrick, and Meeraus GAMS, A Users Guide, 1992

(The Scientic Press, South San Francisco, California).

Proc Instn Mech Engrs Vol 216 Part B: J Engineering Manufacture

You might also like

- Transmission Repair Manuals CVT JF011E (RE0F10A), RE0F06A - Rebuild InstructionsDocument13 pagesTransmission Repair Manuals CVT JF011E (RE0F10A), RE0F06A - Rebuild Instructionseduone6567% (3)

- Box Girder Design CraneDocument8 pagesBox Girder Design CraneSomi Khan100% (2)

- Optimum Design of Cyclone Separator: SeparationsDocument5 pagesOptimum Design of Cyclone Separator: SeparationsJeyakumar RajaNo ratings yet

- Hrones and Nelson AtlasDocument743 pagesHrones and Nelson AtlasJuan Pablo Pineda67% (3)

- Analysis of Axial Flux MotorDocument4 pagesAnalysis of Axial Flux MotorAvi GuptaNo ratings yet

- Skytron Elite 6500 Surgical Table - Maintenance ManualDocument78 pagesSkytron Elite 6500 Surgical Table - Maintenance ManualRaul Perez100% (1)

- Schematic Hyd Cat 349Document2 pagesSchematic Hyd Cat 349M. RozakNo ratings yet

- Cycloid Drive - Replaced by Planocentric Involute GearingDocument6 pagesCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Catalog 2009v1 Screen PDFDocument81 pagesCatalog 2009v1 Screen PDFDhany Siregar100% (1)

- Designing Well Paths To Reduce Drag and TorqueDocument7 pagesDesigning Well Paths To Reduce Drag and Torquedrilling moneytreeNo ratings yet

- 320c Plano HidraulicoDocument9 pages320c Plano HidraulicoJorge Calderon Rojas100% (1)

- Shaft Design ProjectDocument14 pagesShaft Design Projectjwm6085% (13)

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainFrom EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainNo ratings yet

- Column Steel DesignDocument37 pagesColumn Steel DesignIlya Joohari100% (1)

- Fresh Water GeneratorDocument1 pageFresh Water GeneratorJose OrtizNo ratings yet

- Design Project 2 Auto TrannyDocument9 pagesDesign Project 2 Auto TrannyUnmil PatelNo ratings yet

- Problem FormulationDocument5 pagesProblem FormulationSudeesh SudevanNo ratings yet

- Air-Operated Valve Evaluation Guide PDFDocument334 pagesAir-Operated Valve Evaluation Guide PDFMohamed Gawad ARaya100% (1)

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Determination of Optimum Gear Ratios of A Three STDocument9 pagesDetermination of Optimum Gear Ratios of A Three STzul isymaNo ratings yet

- Wee1964 N001Document9 pagesWee1964 N001Oliver RubioNo ratings yet

- Cone CVTDocument4 pagesCone CVTArun KumarNo ratings yet

- Choice of Blade Profile, Pitch and ChordDocument6 pagesChoice of Blade Profile, Pitch and Chordapi-27135468260% (5)

- 1 s2.0 S0957415899000082 MainDocument17 pages1 s2.0 S0957415899000082 MainEdgar GuerreroNo ratings yet

- Application and Improvement of Face Load Factor Determination Based On Agma 927Document19 pagesApplication and Improvement of Face Load Factor Determination Based On Agma 927Nursena SEVİNÇNo ratings yet

- CFEM4th Errata January 21 2013 UpdateDocument8 pagesCFEM4th Errata January 21 2013 UpdatejoshephwanciNo ratings yet

- Effect of Turning Angle On Flow Field Performance of Linear Bowed Stator in Compressor at Low Mach NumberDocument7 pagesEffect of Turning Angle On Flow Field Performance of Linear Bowed Stator in Compressor at Low Mach NumberMoses DevaprasannaNo ratings yet

- Section06B - Design ExamplesDocument68 pagesSection06B - Design Exampleslopez230No ratings yet

- Case Study 8C Design of Spur Gears For A Compressor Drive TrainDocument4 pagesCase Study 8C Design of Spur Gears For A Compressor Drive TrainZaqueu123No ratings yet

- Case Study and Stress Analysis of A 3Document12 pagesCase Study and Stress Analysis of A 3Talha MemonNo ratings yet

- 2018期末考考古題目Document4 pages2018期末考考古題目1 11No ratings yet

- DETC2007/XXX: The Multiobjective Optimization of A Prismatic DriveDocument9 pagesDETC2007/XXX: The Multiobjective Optimization of A Prismatic Drivemikesmith71poleNo ratings yet

- Determination of Optimum Gear Ratios of A Two-StagDocument8 pagesDetermination of Optimum Gear Ratios of A Two-StagmohammedNo ratings yet

- Modeling and Structural Analysis of Alloy Wheel Using COSMOSDocument6 pagesModeling and Structural Analysis of Alloy Wheel Using COSMOSRanjit RNo ratings yet

- Design Techniques For Reducing Cogging Torque in Permanent Magnet Flux Switching MachineDocument4 pagesDesign Techniques For Reducing Cogging Torque in Permanent Magnet Flux Switching MachinejalilemadiNo ratings yet

- Geometric Design For A Gerotor Pump With High Area EfficiencyDocument9 pagesGeometric Design For A Gerotor Pump With High Area Efficiencykanteron6443No ratings yet

- Jagtap-2015-Simulation of Quarter Car Model Using MatlabDocument8 pagesJagtap-2015-Simulation of Quarter Car Model Using MatlabKyle N SamarooNo ratings yet

- Vežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDocument15 pagesVežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDJordje JovanovicNo ratings yet

- Dynamic Behaviour of A Soil Compaction Tamping MachineDocument42 pagesDynamic Behaviour of A Soil Compaction Tamping MachineБорис ПетковNo ratings yet

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- Topology and Preliminary Design Slotless Brushless Motor: of DCDocument3 pagesTopology and Preliminary Design Slotless Brushless Motor: of DCflorin91No ratings yet

- Design and Development of Passive Magnetic BearingDocument6 pagesDesign and Development of Passive Magnetic BearingIJMERNo ratings yet

- A Design Method For Cage Induction Motors With Non-Skewed Rotor BarsDocument2 pagesA Design Method For Cage Induction Motors With Non-Skewed Rotor BarsLava KumarNo ratings yet

- 387 BaruDocument17 pages387 BaruPhillip MillerNo ratings yet

- Pavement Design 18Cv825Document4 pagesPavement Design 18Cv825Yashodhar SrbNo ratings yet

- Machine-Design - Gear Shaft ProblemDocument51 pagesMachine-Design - Gear Shaft ProblemkidseismicNo ratings yet

- NTN TR75 en P140Document9 pagesNTN TR75 en P140Vijay KumarNo ratings yet

- Three Point Load Application in Single Tooth Bending Fatigue Test For Evaluation of Gear Blank Manufacturing MethodsDocument5 pagesThree Point Load Application in Single Tooth Bending Fatigue Test For Evaluation of Gear Blank Manufacturing MethodsSwapvaibNo ratings yet

- Test Transient TiresDocument12 pagesTest Transient TiressiritapeNo ratings yet

- Sustainability 10 02067 PDFDocument19 pagesSustainability 10 02067 PDFDeenanathNo ratings yet

- Optimal Design of Quarter Car Vehicle Suspension System: December 2010Document5 pagesOptimal Design of Quarter Car Vehicle Suspension System: December 2010Ankit JakharNo ratings yet

- Improved Performance Model of Turbocharger Centrifugal CompressorDocument7 pagesImproved Performance Model of Turbocharger Centrifugal CompressorjswxieNo ratings yet

- Timing Belt PDFDocument4 pagesTiming Belt PDFAndiSubhanSyahPutraNo ratings yet

- Chen 2005Document11 pagesChen 2005Muhammad UsamaNo ratings yet

- Structural Analysis and Optimisation of Press BrakesDocument10 pagesStructural Analysis and Optimisation of Press BrakesGogyNo ratings yet

- Calibration and Validation of The Shell Fatigue Model Using AC10 and AC14 Dense Graded Hot Mix Asphalt Fatigue Laboratory DataDocument10 pagesCalibration and Validation of The Shell Fatigue Model Using AC10 and AC14 Dense Graded Hot Mix Asphalt Fatigue Laboratory DataRUMMNo ratings yet

- 26 181 GigerDocument6 pages26 181 GigerYouMineNo ratings yet

- Surface Durability of Spur and Helical Gears - KHK GearsDocument12 pagesSurface Durability of Spur and Helical Gears - KHK GearsKalipse FerreiraNo ratings yet

- Optimum Design of A Subsonic Axial - Ow Compressor Stage: Applied EnergyDocument9 pagesOptimum Design of A Subsonic Axial - Ow Compressor Stage: Applied EnergyOnnuri WonNo ratings yet

- Gear ShavingDocument6 pagesGear ShavingRuchira Chanda InduNo ratings yet

- Theory of Machines & Machine DesignDocument3 pagesTheory of Machines & Machine DesignAvilash JainNo ratings yet

- Crankshaft VibrationDocument8 pagesCrankshaft VibrationjohansolNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Network and Asset Benefits of Real Time DataDocument83 pagesNetwork and Asset Benefits of Real Time DataJose Ancasi EspinalNo ratings yet

- Exercise On Weibull AnalysisDocument2 pagesExercise On Weibull AnalysisJose Ancasi EspinalNo ratings yet

- A Method To Derive Friction and Rolling Power Loss Formulae For Mixed EHLDocument12 pagesA Method To Derive Friction and Rolling Power Loss Formulae For Mixed EHLJose Ancasi EspinalNo ratings yet

- Tools For Failure Data AnalysisDocument9 pagesTools For Failure Data AnalysisWillinton Pacori CaceresNo ratings yet

- Fe 2 DPoissonDocument3 pagesFe 2 DPoissonJose Ancasi EspinalNo ratings yet

- Backlash Fault DiagnosisDocument11 pagesBacklash Fault DiagnosisJose Ancasi EspinalNo ratings yet

- Fluid Mechanics - Problem Solver - WILLIAMSDocument58 pagesFluid Mechanics - Problem Solver - WILLIAMScarvalhaisgomes5462No ratings yet

- Automatic Transmission SystemDocument24 pagesAutomatic Transmission SystemKamaldeep SinghNo ratings yet

- Fabco TC-180 Parts List With BPNDocument4 pagesFabco TC-180 Parts List With BPNRami DalNo ratings yet

- United States Patent (19) : (73) Assignee: Pringle Electrical ManufacturingDocument16 pagesUnited States Patent (19) : (73) Assignee: Pringle Electrical ManufacturingKIRUBEL MENBERUNo ratings yet

- Be301 02 PDFDocument56 pagesBe301 02 PDFNikita SharmaNo ratings yet

- December 16, 2008 S-B-27.00/102b P-B-27.00/102a and T-B-27.00/103a Dated January 9, 2008 27Document5 pagesDecember 16, 2008 S-B-27.00/102b P-B-27.00/102a and T-B-27.00/103a Dated January 9, 2008 27psuguyNo ratings yet

- Direct and Indirect ControlDocument31 pagesDirect and Indirect Controladaptive4u45270% (1)

- 520L0813 S40 M25 Variable Pump SPM PDFDocument20 pages520L0813 S40 M25 Variable Pump SPM PDFjose manuel barroso pantojaNo ratings yet

- 5MM Bore DMF Monoflange Flange X ScrewDocument1 page5MM Bore DMF Monoflange Flange X ScrewgeevenNo ratings yet

- 14 Oil PumpDocument14 pages14 Oil PumpTayfun SezişNo ratings yet

- BVA Remote Valves CatalogDocument1 pageBVA Remote Valves CatalogTitanplyNo ratings yet

- Caliper PRICEDocument7 pagesCaliper PRICEUmar Md ZanNo ratings yet

- Kinematics-of-Machine LAB ManualDocument82 pagesKinematics-of-Machine LAB ManualPrathmesh JamodeNo ratings yet

- UNIT-II Oil Hydraulic System and Its Components Marks-14Document32 pagesUNIT-II Oil Hydraulic System and Its Components Marks-14Chaitanya Yenge100% (2)

- Work SheetDocument2 pagesWork SheetKuma DabaNo ratings yet

- Ecodan FTC5 - EHPT20XDocument52 pagesEcodan FTC5 - EHPT20Xclan_partijeNo ratings yet

- Gear Box: by Yashvir Singh Asst. Prof. Mech. EnggDocument14 pagesGear Box: by Yashvir Singh Asst. Prof. Mech. EnggYashvir SinghNo ratings yet

- Biffi-Model-GIG-GIGS-Direct Gas-AktuatorDocument12 pagesBiffi-Model-GIG-GIGS-Direct Gas-AktuatorGuillermo Damian0% (1)

- Transmission Hydraulic Control 966Document3 pagesTransmission Hydraulic Control 966Walid Houran100% (1)

- SELAHPADS PUMP EQUIPMENT SCHEDULE 2-ModelDocument1 pageSELAHPADS PUMP EQUIPMENT SCHEDULE 2-ModelMark Anthony ValbuenaNo ratings yet

- SP 20 SP 25 ManualDocument18 pagesSP 20 SP 25 ManualdiegoNo ratings yet

- Pump PtoDocument1 pagePump PtolilikNo ratings yet

- SSP 320 6 Speed Manual Gearbox 0A5Document36 pagesSSP 320 6 Speed Manual Gearbox 0A5Trương HàoNo ratings yet

- Genuine Metaris MHP/M Series Gear PumpsDocument4 pagesGenuine Metaris MHP/M Series Gear PumpsTravisReign Dicang02No ratings yet