Professional Documents

Culture Documents

Armstrong

Uploaded by

Jorge HerreraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armstrong

Uploaded by

Jorge HerreraCopyright:

Available Formats

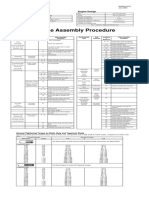

Series 4600F

HSC Fire Pumps & Packaged Systems

FILE NO:

DATE:

SUPERSEDES:

DATE:

F43.11

May 26, 2008

F43.11

Dec. 15, 2007

Series 4600F

Series 4600F - Truly Superior

The Series 4600F, drawing on

over 100 years of pump design

Recirculation

expertise and leadership, is the

f External Water Seal

Recirculation Lines

state of the art in Horizontal Split

Case pumps. It meets or exceeds

the requirements of NFPA and

testing laboratories involved in fire

Coupling

protection such as UL, ULC, & FM.

fUL Listed close-coupled coupling

The family of pumps capitalize on

the Tilted Parting concept to

minimize turbulence at the eye of

the impeller by its straight laminar

approach, thus maximizing

efficiency. The family was

designed with commonality of

parts, low installation cost, and

ease of maintenance objectives.

The pumps compact sizes are

ideally suited for space saving

packages and retrofit applications.

Stuffing Box Housing

fSelf contained Combination

Bearing & Seal Housing

f Permits packing change-out

without having to be removed

Drip Containment

fFitted with drain connection

Casing Wear Ring

f Replaceable Case Wear Rings

fLocked to prevent rotation or

axial displacement

f Impeller Wear Ring available

as an option

Pump Casing

f Designed to withstand the high

pressure requirement typical in

fire protection

Impeller

Shaft Sealing with Packing

fHydraulically balanced double suction

fDynamically balanced

fMinimum axial thrust

fHigh efficiency throughout operating range

fThree-piece Split Gland standard

fPacking replaceable without

disturbing wetted parts

fStuffing Box Extension

designed for easy access

Shaft Sleeves

fReplaceable bronze sleeves

fProtects shaft throughout

Stuffing Box

Bearings

f Easy removal with bearing nut

f Sealed, permanently greased

bearings

f Low Friction Lost Bearing

f Maintenance free

Tilted Parting Design Casing

fPermits laminar approach to eye of Impeller

fLower NPSH required

fLower pump profile

fMinimum pump footprint

fRemoveable rotating element without disturbing piping

fLow foot-mounted Casing to reduce vibrations

Bearing Housing

15 ANGLE CASING

f Removable without

removing top casing

Shaft

fMinimum deflection for long bearing life

fMinimum vibrations

f Identical shaft and parts for left and

right-hand drives

Suction and

Discharge on

same center line

HSC Fire Pumps & Packaged Systems

JOCKEY

CONTROLLER

FIRE PUMP

CONTROLLER

FUEL

TANK

12

3

M

AR

10

ST RONG

11

Horizontal

Fire

Systems

With years of experience in fire protection

industry, Armstrong can supply fire pump

systems with all necessary accessories ready

for site installation.

GUARANTEED ADVANTAGES

f Simplifies piping design

f Single source unit responsibility

f A complete package that will meet

NFPA-20 requirements

FIRE PUMP - ELECTRIC DRIVEN

1. Pump/motor

2. Fire pump controller

(with optional transfer switch)

3. Suction and discharge gauges

4. Air release valve

5. Casing relief valve (not shown)

6. Jockey pump

7. Common base

Features common to electric and diesel

Accessories - (electric or diesel)

Accessories - special for diesel or VFD

7

FIRE PUMP - DIESEL ENGINE DRIVEN

1. Pump/engine assembled with

fCooling system

fFuel system

fBattery system

fExhaust system

2. Fire pump controller

3. Suction and discharge gauges

4. Air release valve

6. Jockey pump

7. Common base

ACCESSORIES - ADDITIONAL (ELECTRIC OR DIESEL)

8.

9.

10.

11.

Suction OS&Y gate valve

Discharge butterfly valve

Check valve

Test tee

ACCESSORIES - SPECIAL FOR DIESEL OR VFD

12. Main relief valve

13. Enclosed cone (not shown)

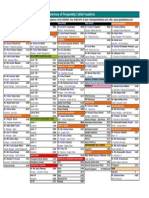

fFire Pump Coverage Chart

Electrical 60 hz

Rated Capacity (L/min)

1890

2850

3800

4750

5700

7600

9500

11400

250

3600 RPM

1750

6 X 5 X 12

6 X 5 X 12

6 X 5 X 12

8 X 6 X 12.5

1500

200

1250

150

8 X 6 X 10

5 X 4 X 10

5 X 4 X 10

6 X 5 X 10

8 X 6 X 15

100

6 X 5 X 15

8 X 6 X 15

10 X 8 X 14

6 X 5 X 15

50

5 X 4 X 12

6 X 5 X 12

8 X 6 X 12.5

1000

12 X 8 X 18

8 X 6 X 10

12 X 8 X 18

750

12 X 8 X 18

10 X 8 X 14

500

8 X 6 X 12.5

275

500

750

1000

1250

1500

2000

2500

4750

5700

7600

9500

3000

Rated Capacity (USGPM)

Electrical 50 Hz

Rated Capacity (L/min)

1890

2850

3800

3000 RPM

250

1750

6 X 5 X 15

200

1500

6 X 5 X 15

6 X 5 X 15

10 X 8 X 14

10 X 8 X 14

6 X 5 X 12

150

1250

6 X 5 X 12

1000

8 X 6 X 12.5

8 X 6 X 12.5

5 X 4 X 10

100

10 X 8 X 11

6 X 5 X 10

8 X 6 X 10

5 X 4 X 10

50

6 X 5 X 9.5

8 X 6 X 10

8 X 6 X 16

8 X 6 X 16

8 X 6 X 16

750

8 X 6 X 10

8 X 6 X 15

10 X 8 X 14

12x8x18

500

275

500

750

1000

1250

1500

2000

Rated Capacity (USGPM)

Note: Higher ranges may be available for diesel driven applications.

2500

Rated Head (kPa)

Rated Head (psi)

1500 RPM

Rated Head (kPa)

Rated Head (psi)

1800 RPM

fTypical Specifications

Horizontal Fire Pump - Electric Motor Driven*

Supply and install as indicated on plans one (1) fire pump system consisting of:

1. FIRE PUMP

One Armstrong, SERIES 4600F, Size _____________ double suction

horizontal split case fire pump listed by [Underwriters Laboratories of

Canada (ULC)], [Underwriters Laboratories Inc. (UL)] and/or [approved by

Factory Mutual (FM)] having a capacity of _______________ USGPM for a

pressure boost of _______________ PSIG. Suction pressure

______________ PSIG.

Pump casing shall be of cast iron, axially split with a 15 angle that will

minimize NPSH requirements and dimensions. Lower half shall contain

suction and discharge nozzles. Suction and discharge connections shall be

on the same elevation. Top half and rotating element shall be removable

without disturbing the piping. Casing shall be fitted with replaceable bronze

wearing rings. Impeller shall be bronze, double suction, enclosed type fully

balanced and keyed to an alloy steel shaft. Shaft shall to be fitted with

replaceable bronze sleeves. Shaft shall be mounted in two dust tight deep

grooves, sealed, and permanently greased ball bearings.

5. FIRE PUMP CONTROLLER

The fire pump controller shall be specifically approved for fire pump service

by [ULC], [UL] and/or [FM]. The controller shall be of the combined manual

and automatic stop, _______________starting method, Model ____________

as manufactured by___________. All equipment shall be enclosed in an

approved drip proof enclosure. The control equipment shall be completely

assembled, wired and tested at point of manufacture prior to shipment.

Circuit breaker shall have an interrupting capacity of _________kAmps or a

withstand rating of ____________ kAmps RMS.

Water pressure switch shall be suitable for _________ PSI working pressure.

5A. FIRE PUMP CONTROLLER AND AUTOMATIC TRANSFER

SWITCH COMBINATION

The automatic transfer switch controller combination shall be approved by

[UL], [ULC] and/or [FM], Model ________________ as manufactured

by________________. The automatic transfer switch and the pump controller

shall each be mounted in separate enclosures, mechanically attached to

form one unit and provide for protected interlock wiring.

Bearings shall be mounted in cartridge type housing so that they shall be

replaceable without opening pump casing. Bearings shall be easily

removable by rotating bearing removal nut. No special tools or bearing puller

are to be necessary.

The automatic transfer switch shall be capable of automatic power transfer

from normal to alternate_______________ [generator] / [second utility]

emergency power source in case of normal supply failure and automatically

re-transfer after restoration of normal power conditions.

Each stuffing box shall be fitted with a three piece bronze gland. Stuffing box

shall be fitted with a stuffing box extension to facilitate the packing rings

removal. Packing rings shall be removable without disturbing wetted parts or

the pump bearings. Water seal recirculation lines made from non-corroding

material shall be piped to pump volute.

6. JOCKEY PUMP

2. ELECTRIC MOTOR

The fire pump shall be directly coupled through flexible coupling to a

horizontal electric motor with a maximum HP of_____________ at

__________RPM, _________ VOLT , _______ PHASE _________ CYCLE.

Motor shall be UL Listed for fire pump service, open drip proof, standard

efficiency with 1.15 service factor.

The pump shall be supplied with the following accessories:

f

f

f

One (1) combination suction gauge 3 dial type with cock and lever

handle.

One (1) discharge gauge, 3 dial type, with cock and lever handle.

One (1) air release valve.

One (1) casing pressure relief valve.

4. OTHER ACCESSORIES

Pump shall be fitted with one (1) eccentric suction reducer and one (1)

concentric discharge increaser, as required (by mechanical contractor) to fit

NFPA20 recommended piping sizes.

One (1) outside test header shall be supplied with one (1) set of ____ x

2 hose valves with caps and chains.

S. A. Armstrong Limited

23 Bertrand Avenue

Toronto, Ontario

Canada, M1L 2P3

T: (416) 755-2291

F (Main): (416) 759-9101

7. JOCKEY PUMP CONTROLLER

The jockey pump shall be controlled by an automatic jockey pump

controller model___________ as manufactured by ___________with

full voltage starter.

8. MOUNTING AND TESTING

3. MINIMUM FITTINGS

The jockey pump shall be manufactured by _____________

Model______________ for a capacity of __________ USGPM and a pressure

boost of ____________ PSIG. The jockey pump shall be driven by an [open

drip proof] [totally enclosed fan cooled] electric motor of _______HP

________ RPM __________ VOLT ______ PHASE________ CYCLE.

Armstrong Pumps Inc.

93 East Avenue

North Tonawanda, New York

U.S.A., 14120-6594

T: (716) 693-8813

F: (716) 693-8970

The fire pump shall be suitable for a maximum working pressure of

__________. The fire pump shall be hydrostatically tested at twice the

maximum working pressure for at least 5 minutes. The fire pump shall be

performance tested at rated speed. The fire pump shall furnish not less than

150% of rated capacity at a pressure not less than 65% of rated head. The

shut-off total head of the fire pump should not exceed 140% of total rated

head. A certified test curve, indicating the flow, head, power and efficiency

shall be supplied for the field acceptance test. The fire pump and electric

motor shall be base mounted and aligned at the pump manufacturers

factory. Final alignment shall be made after installation on site

* Please refer to Armstrong Fire Pump Catalogue for Diesel Driven Typical

Specifications.

Armstrong Holden Brooke Pullen

Wenlock Way

Manchester

United Kingdom, M12 5JL

T: +44 (0) 161 223 2223

F: +44 (0) 161 220 9660

S.A. Armstrong Limited 2008

For Armstrong locations worldwide, please visit www.armstrongpumps.com

You might also like

- Thermal Oil Centrifugal Pump Technical ManualDocument25 pagesThermal Oil Centrifugal Pump Technical ManualbeqsNo ratings yet

- Hypro D50 Service ManualDocument32 pagesHypro D50 Service Manualjimi9488No ratings yet

- B HidraulicaDocument28 pagesB HidraulicaTin100% (1)

- Compact End Suction PumpsDocument8 pagesCompact End Suction PumpsRohith RavindranathNo ratings yet

- Model OCS15RA AND SSR-15Document2 pagesModel OCS15RA AND SSR-15ahnafNo ratings yet

- FMC Core Drilling Pumps CatalogDocument26 pagesFMC Core Drilling Pumps Catalogemuno008100% (1)

- George E. Failing Company's SPEED STAR 185K Drilling RigDocument2 pagesGeorge E. Failing Company's SPEED STAR 185K Drilling RigCarlos Galvez100% (1)

- Pump Spec SheetDocument1 pagePump Spec SheetTiffany DacinoNo ratings yet

- The Horizontal HD Pump Parts ListDocument17 pagesThe Horizontal HD Pump Parts ListVictor AlcantaraNo ratings yet

- 200h-917121-Chapter Eight-Engine Timing Part 1 PDFDocument3 pages200h-917121-Chapter Eight-Engine Timing Part 1 PDFFauan SNo ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- Houttuin 216 10Document6 pagesHouttuin 216 10royert80No ratings yet

- Sykes Pump BookletDocument105 pagesSykes Pump BooklethipsterzNo ratings yet

- Pressure Sequence ValvesDocument3 pagesPressure Sequence ValvesJegan SJ100% (1)

- Basic Pump SizingDocument50 pagesBasic Pump SizingRizaldiSaputraNo ratings yet

- 1-Axial Piston Pumps and Motors-HydromobilDocument8 pages1-Axial Piston Pumps and Motors-HydromobilSocaciu VioricaNo ratings yet

- Amfg L0918BCDDocument5 pagesAmfg L0918BCDLuis AparcanaNo ratings yet

- AOSS AccumulatorsDocument7 pagesAOSS AccumulatorsPiero Fabrizzio Mendoza FuenteNo ratings yet

- HHF-1600 Direct-Drive Utilized Pump User ManualDocument18 pagesHHF-1600 Direct-Drive Utilized Pump User ManualAhmed100% (1)

- Berkeley Ownwes ManualDocument28 pagesBerkeley Ownwes ManualMoses Alvarado100% (1)

- SJ Petro LGF-500 Mud Pump Operation ManualDocument52 pagesSJ Petro LGF-500 Mud Pump Operation ManualSEAZONE EXIM100% (1)

- Margin Press Test AdjustDocument8 pagesMargin Press Test AdjustDidi PrawiraNo ratings yet

- Xq114-6yx Manual PDFDocument55 pagesXq114-6yx Manual PDFFredy NavasNo ratings yet

- W-440 Manual - CN-EN (2ND V)Document39 pagesW-440 Manual - CN-EN (2ND V)ADM MTCNo ratings yet

- 420 Mobile Piston Pump Design Code CDocument41 pages420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- SpareParts F11Document23 pagesSpareParts F11Eduardo CramerNo ratings yet

- FranksDocument3 pagesFranksNawab Muhammad Ibrahim100% (1)

- W, SW, V, SV Series External Bearing Twin Screw PumpDocument33 pagesW, SW, V, SV Series External Bearing Twin Screw PumpfrancisNo ratings yet

- PZH (PZ-8) Pump Parts List AF 19002011Document25 pagesPZH (PZ-8) Pump Parts List AF 19002011mantilla7No ratings yet

- P086ti 1Document2 pagesP086ti 1Serhan AysanNo ratings yet

- Leading Oil & Gas CTU Support Equipment ManufacturerDocument2 pagesLeading Oil & Gas CTU Support Equipment ManufacturerRudi Cressa100% (1)

- HHF-1600 Drilling Pump Parts ListDocument33 pagesHHF-1600 Drilling Pump Parts ListAhmedNo ratings yet

- DETROIT 12V71TA Data PDFDocument2 pagesDETROIT 12V71TA Data PDFO mecanicoNo ratings yet

- Enerpac High Pressure Hand PumpsDocument2 pagesEnerpac High Pressure Hand PumpsMachineryengNo ratings yet

- CP CatalogDocument20 pagesCP CatalogCentral Hydraulics100% (1)

- CAT 3412 DM9128 Spec SheetDocument6 pagesCAT 3412 DM9128 Spec SheetDicky RiskyNo ratings yet

- Fristam FP ManualDocument20 pagesFristam FP ManualatlimacoNo ratings yet

- Duplo MaticDocument8 pagesDuplo MaticHENRYGALLEGOSNo ratings yet

- Swisspump Nds 50hzDocument96 pagesSwisspump Nds 50hzNour Nour El IslamNo ratings yet

- GE Industrial Push Buttons CatalogDocument134 pagesGE Industrial Push Buttons CatalogMilton SantoNo ratings yet

- 3406 Engine Assem ProcedureDocument2 pages3406 Engine Assem ProcedureOli MijanaNo ratings yet

- Honghua Hydraulic Power Unit Parts ListDocument29 pagesHonghua Hydraulic Power Unit Parts Listcmrig74No ratings yet

- Split Case Pumps Technical Brochure - XylemDocument12 pagesSplit Case Pumps Technical Brochure - Xylemneurolepsia3790No ratings yet

- Mccoy Clincher Casing TongDocument81 pagesMccoy Clincher Casing TongShag ShaggyNo ratings yet

- Sehs8984 01Document11 pagesSehs8984 01NimNo ratings yet

- Hydraulic Starting Systems For Diesel EnginesDocument6 pagesHydraulic Starting Systems For Diesel Enginesasas07No ratings yet

- Charles Rig Supplies, Inc.: Instruction ManualDocument9 pagesCharles Rig Supplies, Inc.: Instruction Manualashad100% (1)

- Instructions for Maximizing Performance of JDN BOP Handling SystemsDocument10 pagesInstructions for Maximizing Performance of JDN BOP Handling SystemsReda El-AwadyNo ratings yet

- Engine specifications and maintenance proceduresDocument7 pagesEngine specifications and maintenance proceduresAbel Alejandro Vera TriviñosNo ratings yet

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- 3516 - 1825kVA PrimeDocument6 pages3516 - 1825kVA PrimeAdul Rahmat100% (1)

- NullDocument6 pagesNullGERARDO DELGADONo ratings yet

- W1100 1200 1310broDocument4 pagesW1100 1200 1310brokdpmansiNo ratings yet

- Drilling Mud Pump Pump Fluid End PartsDocument2 pagesDrilling Mud Pump Pump Fluid End PartsleoNo ratings yet

- Vermeer D220x300Document4 pagesVermeer D220x300Suryantoro Wono NarodoNo ratings yet

- TX-450SB Pressures to 10k PSI Flows to 105 GPM Power to 450HPDocument2 pagesTX-450SB Pressures to 10k PSI Flows to 105 GPM Power to 450HPmawannnNo ratings yet

- PU158TI Fire Pump Driver: Power RatingDocument3 pagesPU158TI Fire Pump Driver: Power RatinghectorNo ratings yet

- Bro ShureDocument6 pagesBro ShureoskarzNo ratings yet

- Armstrong Elec-Hsc-F43.11 HSC BrochureDocument4 pagesArmstrong Elec-Hsc-F43.11 HSC BrochureRoger AklNo ratings yet

- Soal Upk B Inggris PKBM WinaDocument11 pagesSoal Upk B Inggris PKBM WinaCuman MitosNo ratings yet

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 pageDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNo ratings yet

- EcR - 1 Leading and Lagging IndicatorsDocument10 pagesEcR - 1 Leading and Lagging IndicatorsMiloš ĐukićNo ratings yet

- SM RSJ 420 800Document77 pagesSM RSJ 420 800elshan_asgarovNo ratings yet

- EO On Ban of Fireworks (Integrated)Document2 pagesEO On Ban of Fireworks (Integrated)Mario Roldan Jr.No ratings yet

- AYUSHMAN BHARAT Operationalizing Health and Wellness CentresDocument34 pagesAYUSHMAN BHARAT Operationalizing Health and Wellness CentresDr. Sachendra Raj100% (1)

- Slaked Lime MSDS Safety SummaryDocument7 pagesSlaked Lime MSDS Safety SummaryFurqan SiddiquiNo ratings yet

- Cap 716 PDFDocument150 pagesCap 716 PDFjanhaviNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- Grab Go Porter S 5 ForcesDocument2 pagesGrab Go Porter S 5 ForcesUtkarsh SharmaNo ratings yet

- Auditor General Insurance Regulation Dec 2011Document23 pagesAuditor General Insurance Regulation Dec 2011Omar Ha-RedeyeNo ratings yet

- 7 Surprising Cyberbullying StatisticsDocument4 pages7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Acc101Q7CE 5 3pp187 188 1Document3 pagesAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNo ratings yet

- Đề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiDocument17 pagesĐề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiHanh YenNo ratings yet

- Lesson Plan 7 Tabata TrainingDocument4 pagesLesson Plan 7 Tabata Trainingapi-392909015100% (1)

- A. Kumar Aswamy Job Offer LetterDocument1 pageA. Kumar Aswamy Job Offer LetterHimanshu PatelNo ratings yet

- Hypertension Protocol Mukta VatiDocument18 pagesHypertension Protocol Mukta VatiDr. Avnish UpadhyayNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetRaheel Neo AhmadNo ratings yet

- Analysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Document2 pagesAnalysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Eustache NIJEJENo ratings yet

- English III Module 2 Simple Present Job and Job VerbsDocument4 pagesEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesNo ratings yet

- Gate Installation ReportDocument3 pagesGate Installation ReportKumar AbhishekNo ratings yet

- Study On Marketing Strategies of Fast Food Joints in IndiaDocument35 pagesStudy On Marketing Strategies of Fast Food Joints in IndiaNiveditaParaashar100% (1)

- C. Drug Action 1Document28 pagesC. Drug Action 1Jay Eamon Reyes MendrosNo ratings yet

- Annex 8 Qualification of BalancesDocument11 pagesAnnex 8 Qualification of BalancesMassimiliano PorcelliNo ratings yet

- Operating Instructions: Katflow 100Document52 pagesOperating Instructions: Katflow 100Nithin KannanNo ratings yet

- Esaote MyLabX7Document12 pagesEsaote MyLabX7Neo BiosNo ratings yet

- Nitric OxideDocument20 pagesNitric OxideGanesh V GaonkarNo ratings yet

- Medpet Pigeon ProductsDocument54 pagesMedpet Pigeon ProductsJay Casem67% (3)

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiDocument10 pagesAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099No ratings yet

- Request Baha Alert PPMPDocument3 pagesRequest Baha Alert PPMPLö Räine AñascoNo ratings yet