Professional Documents

Culture Documents

Triz

Uploaded by

SaugatoDuttoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Triz

Uploaded by

SaugatoDuttoCopyright:

Available Formats

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No.

1, February 2013

Integrating TRIZ and AHP: A MPVs Utility

Compartment Improvement Design Concepts

M. U. Rosli, M. K. A. Ariffin, S. M. Sapuan, and S. Sulaiman

illustrated in Fig. 1. In TRIZ, there are a few tools including

the contradiction matrix, 40 inventive principles, laws of

evolution, scientific effects and Algorithm of inventive

solving (ARIZ) and substance-field analysis modeling. The

TRIZ approach has been employed to various design

problem-solving such as hydraulic cylinder improvement,

energy efficient notebook computer and energy-saving

products [2]-[4]. Several solutions in TRIZ method

highlighted on contradictions or trade-offs in identifying

innovative solutions which arose if an improvement in one

characteristic resulted in degradation of another

characteristic. Typically, designers attempted to compromise

or reach the balances which do not really solve the problem

instead. But in TRIZ, there was no compromising approach

but rather completely solve the contradiction arises. The

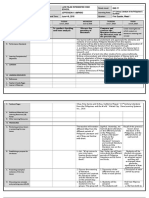

3939 contradiction matrix as shown partially in Fig. 2

provides designers 40 inventive principles to answer a

problem that involved a particular contradiction.

AbstractThis study sets up a systematic product design

model that assists decision makers or design engineers to

improved current design through idea generation method of

Theory of Inventive Problem Solving (TRIZ) and utilizing

analytical hierarchy process (AHP) performing the selection of

best generated idea. In addition, the proposed framework is

analyzed and evaluated by a case study of utility compartment

of MPV. There were 5 types of improved design triggered by

TRIZ principles approach and ranked based on selected

criteria by utilizing Expert Choice software. Employing the

proposed integrated methods on new product development or

product redesign may raise the concept design efficiency as well

as avoiding the cost waste during the product design and

development processes. In addition, this study also means to

investigate the strengths of TRIZ and AHP integration.

Index TermsAnalytical

conceptual design.

hierarchy

process,

TRIZ,

I. INTRODUCTION

The rivalry among the product manufacturers is becoming

more intensely, the transformation of customer product

preferences is speeding up, promoting enterprises

continuously introduce new product or improving current

product in term of innovation and high quality. At this

moment of transportation industry, a car has become more

than just a means of transportation and having car is not a

luxury but also a necessity of life. For many people,

especially with longer commutes will spend two hours or

more per day in their car doing boring routine driving tasks

on their way to work and back every day. To make this time

more valuable and safely driving, it is important to provide

good user experiences inside the automobile and the

manufacturer must fulfill the user needs.

Fig. 1. TRIZ problem solving process.

II. TRIZ

Theory of Inventive Problem Solving "TRIZ" acronym in

Russian was developed by Genrich Altshuller and his

colleagues, and currently being broadly developed and

practiced throughout any field. [1]. By utilizing the

knowledge base built from the analyses of just about millions

of patents which is mostly on technical design, this approach

solves technical problems and presents innovative product

design. It is believe that the creativity for innovation is a

structured systematic method, not just try and error as

Fig. 2. Partial of Contradiction matrix.

III. ANALYTICAL HIERARCHY PROCESS (AHP)

AHP is one of the most accepted methods commonly used

in industry to aid in multi-criteria alternatives selection

developed by Saaty [5]. One of the key strengths of AHP is

the use of pairwise comparisons to obtain precise ratio scale

priorities, instead of the long-established approaches of

assigning weights. This process judges against the relative

importance, performance or likelihood of two elements with

respect to another element in the upper level. A nine-point

scale is used to conduct the pair-wise comparisons for each

Manuscript received December 5, 2012; revised February 3, 2013.

The authors are with the Department of Mechanical and Manufacturing

Department, Faculty of Engineering, Universiti Putra Malaysia, 43400 UPM

Serdang, Selangor, Malaysia (e-mail: uzair_rosli@yahoo.com.my,

khairol@eng.upm.edu.my,

sapuan@eng.upm.edu.my,

suddin@eng.upm.edu.my).

DOI: 10.7763/IJMMM.2013.V1.7

32

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

level with respect to the goal of the best alternative selection

and represents as equally important, moderately more

preferred, strongly more preferred, very strongly more

preferred, and extremely more preferred to the others.

Generally, basic steps of AHP namely decomposition,

comparative judgment and synthesis. Sapuan et al. presented

eight steps of AHP in material selection case study [6]. The

advantages of AHP over other multi criteria methods are its

ability to check inconsistencies, intuitive appeal to the

decision makers and its flexibility. In the application of AHP,

the decision makers are assigning the judgements based on

their own experience and knowledge with respect to the

upper parent component in the hierarchy. The outcome is the

set of weight which represents their contributions or the

priorities. Decision situations which the AHP can be applied

include the evaluation, priority and ranking, benetcost

analysis, planning and development, allocations, and

decision-making. A. Kengpol et al. applied AHP as a

decision tool for the selection of advanced technology in

order to accomplish rapid product development [7] and M.I.

Al Khalil utilized AHP approach to pick the most appropriate

project delivery method [8]. The judgement of pairwise result

is incomplete if consistency analysis is not done. The

consistency ratio () is used to estimate the consistency of

the judgments of the participants. The is defined as [9]

Step 1: Product analysis

The elements of design that required to be improved and

criteria for evaluation were defined.

Step 2: Construct the Contradiction Matrix and propose the

related inventive principles

The engineering parameter was constructed and related

inventive principles will be proposed. The suggested

inventive principles were then may be adopted to stimulate

redesign ideas.

Step 3: Concept development

Several improvement ideas based on the input of suggested

principles from the previous step might be proposed and

illustrated by sketching approach.

Step 4: Construct the hierarchy of AHP and perform

judgments of pairwise comparison

Pairwise comparison construction and judgment were

performed by utilizing Expert Choice software. The

judgments were decided based on the authors experience

and knowledge by using the relative scale of pairwise

comparison. The priority vector of the judgment represented

the importance of each attributes.

Step 5: Develop all priority ranking

Additional calculation of the overall priority vector to pick

the best design concept must be performed after the

consistency calculation for all levels was concluded.

Step 6: Find the final evaluation and select the best design

Finally, weight vectors for the each levels of hierarchy

were evaluated using the methodology given in the ranking.

The final priority results were ranked based on their weights.

= /

where is called the consistency index which is defined as

=

V. THE CASE STUDY

A of 0.10 or less is considered acceptable, otherwise it

is considered inconsistent and the decision maker is allowed

to change the preferences. Judgments should be revised and

improved in order to obtain a consistent matrix.

In order to validate the applicability of the proposed

product design model, a case study of MPVs utility

compartment as portrayed in Fig. 4 was conducted.

IV. THE PROPOSED APPROACH

In this paper, a systematic product design approach of

TRIZ and AHP was applied as an integrated methodology for

design improvement. By converting up the complex design

problem into a contradiction matrix, TRIZ might provide

various design suggestions and AHP will be utilized as a

selection method for the ideas generated by TRIZ approach.

The integrated approach is displayed in Fig. 3 comprises of

the following steps.

Fig. 4. Current MPVs utility compartment.

Step 1: Product analysis and defining the problem

With the major aim to optimize the value in term of the

functionality, ergonomics and quality of the compartment

and at the same time, keeping the passenger in convenience

as well as the compartment is easy for operation and

manufacturability. The new compartment should have ability

to store big items and organize small items as well. From the

observation, theres no cup holder for front passenger. Hence,

instead of making another slot in the current dashboard for

cup holder, its an advantage if the compartment can serve the

function of cup holder.

Step 2: Idea generation of TRIZ contradiction principles

The specific objectives of multifunction for the utility

compartment was generalized into 39s TRIZ features as

Fig. 3. Proposed approach framework.

33

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

(#39- productivity, #36-device complexity) since that in

TRIZ definition, productivity and complexity means the

number of useful (value adding) functions or perform by a

system per unit time. Conversely, multiple functions might

caused the degrading of simplicity of application (#33-ease

of operation) and difficult to manufacture (#32-ease of

manufacturing) as shown in Table I. From the contradiction

matrix, several solution principles were suggested as shown

in Table I.

Concept

1

2

3

4

5

TABLE I: TRIZ CONTRADICTION AND GENERIC SOLUTION

Improving

Feature

#39

Productivity

Degraded

Feature

#33

Ease of

operation

#32

Ease of

manufacture

Solution

Principle

Segmentation

Nested Doll

Take out

Intermediary

#36

Complexity

Change

parameters

Other way

around

TABLE II: DESCRIPTION OF EACH CONCEPT

Brief description

The door of compartment serves the function as the cup

holder and table as well. Based on intermediary and other

way round principles

Mini pocket compartment to store small items such as coins

and pens. Based on take out and nested doll principles.

Sliding type of the door and flexible partition inside to store

big or small items. Based on segmentation and nested

doll principles.

File drawer type compartment with flexible partition inside.

Based on segmentation and other way round principles.

Drawer type compartment to store big items. Based on

nested doll and take out principles.

Project ideas

VI. RESULT AND DISCUSSION

-Adjustable partition

-Little compartment

in current

compartment

-Retractable type door

-Drawer concept

compartment

- Little compartment

in current

compartment

-Convertible door to

cup holder/laptop

table

-Retractable type door

-Upside-down door

Fig. 6. Pairwise comparison with respect to the sub-criteria.

Step 3: Concept generation

After scrutinizing the project ideas triggered by TRIZ

generic solution method, there were five new proposed

compartment designs as depicted in Fig. 5 with brief

description in Table II.

The results of AHP method utilizing Expert Choice

software were shown in Fig. 6 and Fig. 7. Based on the

alternatives of concept results, it was clear that Concept 1 of

converting the compartments door as a table and cup holder

ranked first with 0.245 (24.5%) and the last rank was Concept

4 (file drawer concept) with 0.171 (17.1%). The results of

Concept 2 (pocket drawer concept), Concept 3 (partition

compartment concept) and Concept 5 (box drawer concept)

are 0.210, 0.201 and 0.173 respectively.

Step 4: AHP

A four level hierarchy decision process was constructed

with a goal to select the best proposed design to improve

MPVs utility compartment design. A survey has been done

in order to determine the weight of main and sub-criteria

which is based on customers preference when buying a

MPV. Expert Choice software was utilized for AHP method.

The pairwise judgments were based on concepts illustration

and description as well as authors design experiences. The

rest of the steps were covered in AHP method.

Fig. 7. Relative weight for main factors, sub-factors and ranking of concept

alternatives.

In order to ensure the result achieved meets the objectives,

if the result of analysis were not satisfied with some reason

such as lack of information and inadequate model structure,

Fig. 5. Alternatives design of new compartment.

34

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

REFERENCES

the designer could perform the comparison again. When all

the concepts had been evaluated and received their scores

from AHP, based on compatibility of each concept, the

author was decided that the promising and innovative

concepts of Concept 1 and Concept 3 were chosen to take

further. The combination ended up with a totally new

improvised concept of compartment. This new concept of

improvement shown in Fig. 8 was considered to be more

innovative with convertible table/cup holder type door and

the compartment also could easily be cleaned as well.

Moreover, if larger storage volume is needed, the partition

inside could be moved with the invention of flexible

segmented partition.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Fig. 8. Sketch of final design.

[9]

VII. CONCLUSION

The problem solving and decision making process has

become essential in the industry. The conventional try and

error brainstorming processes of problem solving becomes

more structured and organized since the innovation of TRIZ

method. Meanwhile, AHP played an effective role as

decision making tool in order to select the most appropriate

decision. It was believed that the concept improvement

framework not only provided evidence that the integrated

AHP or TRIZ are better than the stand-alone method, but also

aided the researchers and decision makers in applying the

integrated AHP and TRIZ effectively. The study case

revealed that the concept combination generated from

TRIZs principles of intermediary, segmented, other way

around and take out can give the most ideal proposed design

for compartment improvement. This integration served an

ideal framework as a foundation step for product

improvement. It needed further steps to cover until final

implementation such as design specification, cost and

manufacturing processes. Further studies will focus on

integrating

the

developed

framework

into

a

computer-assisted design support system for product

improvement design.

G. Altshuller and L. Shulyak, 40 principles: TRIZ Key to Innovative,

Technical Innovation Center, Worcester, 2002.

F. Y. Zhang, Q. G. Zhang, P. Wang, and H. Liu, Product innovative

design based on AHP/ QFD/ TRIZ, International Technology and

Innovation Conference, pp.1-5, 2009.

C. H. Yeh, J. C. Y. Huang, and C. K. Yu, Integration of four-phase

QFD and TRIZ in product R&D: A notebook case study, Research in

Engineering Design, vol. 22, no. 3, pp. 125-141, 2011.

H. Zheng, H. C. Zhang, and F. Y. Zhang, An innovative design of

energy-saving products based on QFD/TRIZ/DEA integration, in

Proc. IEEE 17Th International Conference on Industrial Engineering

and Engineering Management, pp. 831-834, 2010.

L. T. Saaty and L. G. Vargas, Models, methods, concepts and

applications of the analytical hierarchy process, Kluwer Academic

Publishers, Boston, 2001.

Sapuan, S. M. Kho, J. Y. Zainudin, E. S. Leman, Z. Ali, and B. A. A.

Hambali, A materials selection for natural fiber reinforced polymer

composites using analytical hierarchy process, Indian Journal of

Engineering and Materials Sciences. Indian J. Eng. Mater. Sci, vol. 18,

no. 4, pp. 255-267, 2011.

A. Kengpol and C. O. Brien, The development of a decision support

tool for the selection of an advanced technology to achieve rapid

product development, International Journal of Production

Economics, vol. 69, no. 2, pp. 177191, 2011.

M. I. A. Khalil, Selecting the appropriate project delivery method

using AHP, International Journal of Project Management, vol. 20,

pp. 469474.

T. L. Saaty, The analytic hierarchy process, McGraw-Hill, New York,

1980.

Mohd Uzair Rosli is currently a Ph.D. student in

Department of Mechanical and Manufacturing, Universiti

Putra Malaysia. He earned his B.Eng. degree in

Manufacturing Engineering from Universiti Malaysia

Perlis and M.Eng. in Manufacturing System from

Universiti Putra Malaysia. His research interests are

manufacturing system and design.

Mohd Khairol Anuar Ariffin is currently an associate

professor and head of Department of Mechanical and

Manufacturing, Universiti Putra Malaysia. He earned his

B. Eng degree in Manufacturing System Engineering,

Northumbria University, UK, M.Sc. of Manufacturing

Engineering, Universiti Putra Malaysia and Ph.D. from

University of Sheffield, UK. His research interests include

Optimisation, Advanced Manufacturing Technology,

Automation and Robotics, CAD/CAM.

Sapuan Salit is currently a professor in Department of

Mechanical and Manufacturing, Universiti Putra

Malaysia. He earned his B.Eng. degree in Mechanical

Engineering from University Newcastle, Australia, M.Sc.

in Engineering Design from Louborough University, UK

and Ph.D. from De Montfort University, UK. His

research interests include Biocomposite materials and

concurrent engineering.

Shamsuddin Sulaiman is currently a professor in

Department of Mechanical and Manufacturing, Universiti

Putra Malaysia. He earned his B.Eng. degree in

Mechanical Engineering from University Putra Malaysia,

Malaysia, M.Sc. and Ph.D. in Engineering Design from

Mech. Eng University of Wales Swansea, UK. His

research interests include Manufacturing Engineering;

CAD/CAM, Mould and Die, Casting Technology.

ACKNOWLEDGMENT

The authors thank to Mr. Zaraq Shaifuddin Zamrah,

Section Manager of Vendor Improvement and Education in

Proton Automobile Company for providing the information

and guidance in this research work. The research was

conducted under Fundamental Research Grant Scheme

number 03-01-12-1108FR

35

You might also like

- Development of Theoretical Framework of Ultimate Fashion and Textile Design Process ModelDocument24 pagesDevelopment of Theoretical Framework of Ultimate Fashion and Textile Design Process ModelSaugatoDutto0% (1)

- LS-DYNA Theory ManualDocument811 pagesLS-DYNA Theory ManualSaugatoDuttoNo ratings yet

- Case Tesla Motors Part IDocument16 pagesCase Tesla Motors Part ISaugatoDutto100% (2)

- The Frame Analysis and Testing For Student FormulaDocument5 pagesThe Frame Analysis and Testing For Student FormulaSaugatoDuttoNo ratings yet

- Design and Drawing of Water TankDocument38 pagesDesign and Drawing of Water TankSaugatoDutto67% (3)

- Notes of F.MDocument159 pagesNotes of F.Mnidhalsaada100% (1)

- Nasa Aprop1Document22 pagesNasa Aprop1SaugatoDuttoNo ratings yet

- A Case Study On Arav in D Eye Care SystemsDocument4 pagesA Case Study On Arav in D Eye Care SystemsSaugatoDuttoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Theresa Reyes Special Program in Arts (SPA)Document29 pagesTheresa Reyes Special Program in Arts (SPA)Genevieve RufinoNo ratings yet

- Ascended Masters and ChannelingDocument13 pagesAscended Masters and ChannelingAshique Chandan100% (1)

- Detecting Deep-Fake Videos From Phoneme-Viseme MismatchesDocument9 pagesDetecting Deep-Fake Videos From Phoneme-Viseme MismatchesEloisa PotrichNo ratings yet

- Psychological Testing - Intelligence and The Binet ScaleDocument14 pagesPsychological Testing - Intelligence and The Binet ScaleSomanya KaurNo ratings yet

- Docu FictionDocument106 pagesDocu FictionMaria José Barros100% (2)

- Elpt Sample Booklet Revised PDFDocument47 pagesElpt Sample Booklet Revised PDFlakadiaNo ratings yet

- EIM DLL GRADE 11 WEEk 5Document3 pagesEIM DLL GRADE 11 WEEk 5Jeremiah HaliqueNo ratings yet

- Hortatory Exposition Text: A. Listening Activity I. Lead in ActivityDocument18 pagesHortatory Exposition Text: A. Listening Activity I. Lead in ActivityKade Wie UndergrownNo ratings yet

- Course Information LPPP 1123 201920202 PDFDocument6 pagesCourse Information LPPP 1123 201920202 PDFfatin marliaNo ratings yet

- The French Fluency Formula - Master The LanguageDocument211 pagesThe French Fluency Formula - Master The LanguageMinh Tân LêNo ratings yet

- Cultural Intelligence: By: Iman ShafiqueDocument6 pagesCultural Intelligence: By: Iman ShafiqueimanNo ratings yet

- Semantics PDFDocument13 pagesSemantics PDFsutraNo ratings yet

- TEXTO ORIGINAL - What Is ADHD - 4 PagesDocument4 pagesTEXTO ORIGINAL - What Is ADHD - 4 PagesGrace ValenciaNo ratings yet

- Cus 3701 Ass 2Document8 pagesCus 3701 Ass 2Henko HeslingaNo ratings yet

- American Scholar AnalysisDocument3 pagesAmerican Scholar AnalysisBrince MathewsNo ratings yet

- Tugas 1 - Selpia Yunita Ibrahim - 1847041012 - M7.1Document7 pagesTugas 1 - Selpia Yunita Ibrahim - 1847041012 - M7.1Selpia Yunita IbrahimNo ratings yet

- Fdocuments - in - Myp Unit Planner Wikispaces Li Unitplansolveequationwhich Specific MypDocument5 pagesFdocuments - in - Myp Unit Planner Wikispaces Li Unitplansolveequationwhich Specific MypKelly OroszNo ratings yet

- Oral Communication Quarter 1 Summative TestDocument2 pagesOral Communication Quarter 1 Summative TestJoyce NuenaNo ratings yet

- Session Guide On Informal Classroom AssessmentDocument8 pagesSession Guide On Informal Classroom AssessmentChesee Ann Sopera DrisNo ratings yet

- Wordwise 1Document2 pagesWordwise 1Carmen BugnarNo ratings yet

- Bcu g87 Magc 205 Finals Lesson GDocument6 pagesBcu g87 Magc 205 Finals Lesson GJoan BayanganNo ratings yet

- Goal Setting MayurDocument10 pagesGoal Setting MayurMayur SainiNo ratings yet

- Individual Contribution (Imtiaz Dan Syafiq)Document2 pagesIndividual Contribution (Imtiaz Dan Syafiq)dimniousNo ratings yet

- TEACHER WENDY BOHORQUEZ UltimoooDocument9 pagesTEACHER WENDY BOHORQUEZ UltimoooGABRIEL URBANONo ratings yet

- DLL 21ST Week 1Document4 pagesDLL 21ST Week 1Charlene Aguilar Javin100% (1)

- Trick QuestionDocument69 pagesTrick Questionphamlinh_cnn7625No ratings yet

- Text Summarization and Conversion of Speech To TextDocument5 pagesText Summarization and Conversion of Speech To TextIJRASETPublicationsNo ratings yet

- Write Preposition of Place or TimeDocument10 pagesWrite Preposition of Place or TimeRamonaNo ratings yet

- THE SYMBOL: The Origin and Basis of Human Behavior by Leslie A. WhiteDocument12 pagesTHE SYMBOL: The Origin and Basis of Human Behavior by Leslie A. WhiteMike McDNo ratings yet

- The Kindergarten Program 2016Document331 pagesThe Kindergarten Program 2016api-262302386No ratings yet