Professional Documents

Culture Documents

Key Words: Flow Rate Measurements, Discharge Measurements, Gibson Method

Uploaded by

userabcd9768Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Words: Flow Rate Measurements, Discharge Measurements, Gibson Method

Uploaded by

userabcd9768Copyright:

Available Formats

FLOW RATE (DISCHARGE) MEASUREMENTS IN HYDROPOWER PLANTS

BY MEANS OF GIBSON METHOD

FLOW RATE (DISCHARGE) MEASUREMENTS IN HYDROPOWER PLANTS

BY MEANS OF GIBSON METHOD

Key words: flow rate measurements, discharge measurements, Gibson method,

pressure-time method

Pressure-time or water hammer method, commonly called the Gibson method, is the one of

the basic methods for flow rate measurement applied in hydropower plants. It consists in flow

rate measurement basing on integration of pressure difference between two pipeline crosssections during fast flow stopping. Each unit of hydropower plant equipped with penstock of a

length exceeding 4D (four times of its internal diameter) is suitable for application of the

method Gibson. In the toughest conditions, with no access to the pipeline shell from the

outside, special manifolds for receiving the pressure in measuring cross-sections can be

prepared from the inside of the penstocks, after draining the pipeline.

Pressures or water levels are measured using high precision transducers, class 0.2% or better.

Values of flow rate are calculated from pressure signals by means of the GIB-ADAM code,

developed by Dr A. Adamkowski, several times validated in laboratory and in situ conditions

and repeatedly employed in many hydro-sets in Poland and Mexico.

Lately in the Institute of Fluid-Flow Machinery PASci in Gdansk the special method has been

developed which is dedicated for cases of more complex hydraulic geometries, e.g. curved

penstocks. The analysis of pipeline curvature on flow rate measurement is based on CFD

calculations. Grounding on one case it was already demonstrated that the correction

determined by this means changes the results of flow rate measurement through the turbine

for about 0.4% and the uncertainties of flow measurements are about 1-1.2% depending on

measuring conditions.

Furthermore, utilizing the Gibson method to flow rate measurement through water turbines

requires the knowledge of leakage rate through closed guide vanes, i.e. through the blade

interspace. Know-how about the leakage rates is also needed to estimate energy losses during

turbine shut-down, basically in cases when the cut-off valves and sluice valves are leaky. The

procedure for estimating their values was worked out.

In years 2003-2010 the Gibson method was successfully applied in energy efficiency research

on many hydropower units in Poland: hydropower plants Zarnowiec, Solina, Dychow,

Zydowo, Niedzica, Koronowo, Zur, Pilchowice, as well as in Mexico: hydropower plants

Angostura, Infiernillo, Chicoasen, Aquamilpa, Malpaso, Temascal, Villita, Villita, Cobano,

Novillo, Santa Rosa, Bacurato

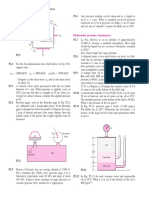

Example of water hammer method (Gibson method ) application

turbine no. 1

>3D

2D

2D

turbine no. 2

1-1

Pressure

surge tank

2-2

butterfly valve

Fig. 1: Schematic diagram of supply system of turbines under investigation with marked

hydrometric sections which were used in Gibson method

FLOW RATE (DISCHARGE) MEASUREMENTS IN HYDROPOWER PLANTS

BY MEANS OF GIBSON METHOD

10 m

Section 1-1 and 2-2

60

Pressure tap

Manifold

Fig. 2: Localization of pressure taps at each pipeline section 1-1 and 2-2.

venting valve

from manifold

in section 1-1

pipe with signal

cable inside

from manifold

in section 2-2

Fig. 3: Waterproof housing with pressure difference transducer installed inside.

Y [%]

FLOW RATE (DISCHARGE) MEASUREMENTS IN HYDROPOWER PLANTS

BY MEANS OF GIBSON METHOD

100

80

60

Y - recorded wicket gate

opening

40

20

0

Dp1-2, Dpf [kPa]

80

100

110

120

130

140

16

12

Dp f - calculated pressure

drop caused by friction in

penstock between sections

1-1 and 2-2

8

4

Dp 1-2 - pressure difference

measured between penstock

sections 1-1 and 2-2

0

-4

80

Q [m3/s]

90

210

180

150

120

90

60

30

0

90

100

110

120

130

140

110

120

130

140

Q - flow rate calculated

according Gibson method

80

90

100

time t [s]

Fig. 4: Recorded and calculated time changes of values related to discharge (flow rate)

measurement by means of Gibson method

References:

Adamkowski A., Janicki W., Steller J.: Comparison between results of flowrate measurement

by means of current-meter, pressure-time and ultrasonic methods, , Proc. of Conf.

HYDROFORUM2005, Kliczkw, December 7-9, 2005 (in Polish). pdf version

Sierra E.F., Adamkowski A., Urquiza B.G., Kubiak J., Lara H., Janicki W.: The Effect of

Boundary Layer Separation on Accuracy of Flow Measurement Using the Gibson Method,

Forum Paper FEDSM2007-37564, Proc. of 5th Joint ASME/JSME Fluids Engineering, July 30

August 2, 2007, San Diego, California, USA, pp. 1-8. pdf version

Adamkowski A., Janicki W.: Influence of some components of pressure-time method

instrumentation on flow rate measurement results, Proc. of Inter. Confer. HYDRO2007,

Granada, Spain, 15-17 Oct. 2007. pdf version

Adamkowski A., Janicki W., Urquiza G. Kubiak J., Basurto M., Discharge measurements

using the classic Gibson method with instrumentation nstalled inside a pipeline, Proc. of

FEDSM2008, ASME Fluid Engineering Conference, August 10-14, 2008, Jacksonville,

Florida USA, FEDSM2008-55309, pp. 1-7. pdf version

Adamkowski A., Janicki W.:A new approach to using the classic Gibson method to measure

discharge, 15th International Seminar on Hydropower Plants, Vienna, 26-28 November,

2008, pp. 511-522. pdf version

FLOW RATE (DISCHARGE) MEASUREMENTS IN HYDROPOWER PLANTS

BY MEANS OF GIBSON METHOD

Adamkowski A., Kubiak J., Sierra Fernando Z., Urquiza G.,Janicki W., Fernndez J. M., An

Innovative Approach to Applying the Pressure-Time Method to Measure Flow, HRW

(Hydraulic Review Worldwide), Volume 16, number 6 December 2008, pp. 40-49 pdf

version.

Adamkowski A., Krzemianowski Z., Janicki W. 2009, Improved Discharge Measurement

Using the Pressure-Time Method in a Hydropower Plant Curved Penstock, ASME Journal of

Gas Turbines and Power, SEPTEMBER 2009, Vol. 131, pp. 053003-1 - 053003-6. pdf

version

Adamkowski A. Janicki W., A method for measurement of leakage through closed turbine

wicket gates, Proceedings of the HYDRO2009, International Conference and Exhibition,

Lyon, France 26-28 October 2009, pp. 1-8. pdf version.

Adamkowski A.: Essential methods of SHP efficiency testing, Keynote address at the SHP

Research&Development Actors Network Meeting, The Szewalski Institute of Fluid-Flow

Machinery, Gdansk, September 10-11th, 2009 pdf version.

Adamkowski A., Janicki W., Selected problems in calculation procedures for the Gibson

discharge measurement method, 8th International Conference on Hydraulic Efficiency

Measurement - IGHEM 2010, Rookie, India, pp. 1-9. pdf version

For more details please contact:

Adam Adamkowski, DSc., Ph.D.

The Szewalski Institute of Fluid-Flow Machinery, PASci (IMP PAN)

Centre for Mechanics of Liquids, Department of Hydraulic Machinery

ul. Fiszera 14;

80-952 Gdask, Poland

Phone: +48 58 69 95 212

Fax: +48 58 341 61 44

Mobile: +48 606 571 642

E-mail: aadam@imp.gda.pl

You might also like

- Lab ManualDocument11 pagesLab ManualSujith SurapaneniNo ratings yet

- Calibration of Tipping Bucket Rain Gauge PDFDocument11 pagesCalibration of Tipping Bucket Rain Gauge PDFEdith Torres PalaciosNo ratings yet

- Pressure Transient PDFDocument11 pagesPressure Transient PDFenriqueg_53No ratings yet

- Venturi MetersDocument4 pagesVenturi Metershardik033No ratings yet

- Flow Regulation in PenstockDocument13 pagesFlow Regulation in PenstocksunilghajuNo ratings yet

- Calibration of VenturimeterDocument5 pagesCalibration of VenturimeteramarparimiNo ratings yet

- Calibration of Orifice MeterDocument5 pagesCalibration of Orifice Meteramarparimi67% (3)

- Broad Crested WeirDocument16 pagesBroad Crested WeirBenson Mwathi Mungai67% (3)

- Fluids Laboratory:) Venture Meter (Document8 pagesFluids Laboratory:) Venture Meter (aulaNo ratings yet

- Mass Flow Rate Measurement of Gas/Liquid Two-Phase Flow in Horizontal Pipe Based On V-Cone Flow Meter and Adaptive Wavelet NetworkDocument6 pagesMass Flow Rate Measurement of Gas/Liquid Two-Phase Flow in Horizontal Pipe Based On V-Cone Flow Meter and Adaptive Wavelet NetworkFernando GuerreroNo ratings yet

- Hydrostatic Testing Procedure 02250-1Document2 pagesHydrostatic Testing Procedure 02250-1RanielNo ratings yet

- Applied Sciences: Uncertainty Assessment For Determining The Discharge CoeDocument10 pagesApplied Sciences: Uncertainty Assessment For Determining The Discharge CoeSakil MollahNo ratings yet

- Paper - Pressure PulseDocument16 pagesPaper - Pressure PulsePaul TiclaNo ratings yet

- 120 Icpmg 2002 89 94Document6 pages120 Icpmg 2002 89 94Nu NguyenNo ratings yet

- Flow Rate Measurement Using The Pressure-Time MethDocument14 pagesFlow Rate Measurement Using The Pressure-Time MethFAISALNo ratings yet

- Optimal Volume Selection of Air Vessels in Long-Distance Water Supply SystemsDocument13 pagesOptimal Volume Selection of Air Vessels in Long-Distance Water Supply SystemsKenn WahhNo ratings yet

- Effect of Ejector Con Guration On Hydrodynamic Characteristics of Gas-Liquid Ejectors PDFDocument11 pagesEffect of Ejector Con Guration On Hydrodynamic Characteristics of Gas-Liquid Ejectors PDFPan MachinneNo ratings yet

- Performance Testing Procedure For Centrifugal PumpsDocument5 pagesPerformance Testing Procedure For Centrifugal PumpsNitin S Jog100% (11)

- AFMS Conference Louisiana 1999Document6 pagesAFMS Conference Louisiana 1999Philip A Lawrence C.Eng. F. Inst M.C.No ratings yet

- CFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientDocument9 pagesCFD Analysis of Flow Through Venturi Tube and Its Discharge CoefficientCharan RavulaNo ratings yet

- Turbine Owmeter Response To Transitional Ow Regimes: Flow Measurement and Instrumentation November 2017Document15 pagesTurbine Owmeter Response To Transitional Ow Regimes: Flow Measurement and Instrumentation November 2017Lam Trinh NguyenNo ratings yet

- Flow Meter MeasurementDocument12 pagesFlow Meter Measurementrahman75% (8)

- A Compilation of Laboratory ReportsDocument57 pagesA Compilation of Laboratory ReportsEli Leopoldo Geneston100% (3)

- Flow Measurement Methods Applied To Hydro Power Plants: March 2012Document19 pagesFlow Measurement Methods Applied To Hydro Power Plants: March 2012João Marcos Monteiro BernardesNo ratings yet

- A Novel Method For Transient Leakage Flow Rate Calculation of Gas Transmission PipelinesDocument43 pagesA Novel Method For Transient Leakage Flow Rate Calculation of Gas Transmission PipelinesMasoud NasiriNo ratings yet

- B.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionDocument3 pagesB.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionJohnSmithNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document19 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Oil and Gas Production Surveillance TechniquesDocument44 pagesOil and Gas Production Surveillance TechniquesTrini_thugNo ratings yet

- Y Branch Head LossDocument6 pagesY Branch Head Lossvcock6109No ratings yet

- Pump Performance: Study of The Different Factors That Influence JetDocument1 pagePump Performance: Study of The Different Factors That Influence Jetsdsw02No ratings yet

- Measurement of Flow Meter LaboratoryDocument16 pagesMeasurement of Flow Meter LaboratoryTemitayo SolankeNo ratings yet

- ARCHIVE Proceedings of the Institution of Mechanical Engineers Conference Proceedings 1964-1970 (Vols 178-184) Various Titles Labelled Volumes a to S Volume 180 Issue 310 1965 [Doi 10.1243_PIME_CONFDocument13 pagesARCHIVE Proceedings of the Institution of Mechanical Engineers Conference Proceedings 1964-1970 (Vols 178-184) Various Titles Labelled Volumes a to S Volume 180 Issue 310 1965 [Doi 10.1243_PIME_CONFSree288No ratings yet

- Aysu Zamanova Lab1Document38 pagesAysu Zamanova Lab1leman quliyevaNo ratings yet

- Drainase PasteurDocument10 pagesDrainase PasteurAndhika SasongkoNo ratings yet

- Metrology and Measurement Systems: Index 330930, ISSN 0860-8229 WWW - Metrology.pg - Gda.plDocument14 pagesMetrology and Measurement Systems: Index 330930, ISSN 0860-8229 WWW - Metrology.pg - Gda.pleduryuNo ratings yet

- 003Document13 pages003NSBMRNo ratings yet

- CE142P-2 Experiment 9Document10 pagesCE142P-2 Experiment 9Faye AnneNo ratings yet

- Advanced Techniques For Acoustic Liquid Level DeterminationDocument14 pagesAdvanced Techniques For Acoustic Liquid Level Determinationmáté_galambosiNo ratings yet

- GFM Lab ReportDocument102 pagesGFM Lab ReportÁlvaroDeLaGarza100% (1)

- Objective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionDocument11 pagesObjective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionAmmar Al-AghbariNo ratings yet

- 028 Flare Gas Metering (English)Document12 pages028 Flare Gas Metering (English)Sergio A. Rdz. F.No ratings yet

- Geseran BendalirDocument9 pagesGeseran BendalirYaakub MYNo ratings yet

- Fluid Friction Measurement Experiment Jan20Document5 pagesFluid Friction Measurement Experiment Jan20Ammar AzfarNo ratings yet

- Performance Test of A Hydraulic Turbine Mid Term 2Document8 pagesPerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNo ratings yet

- Sp250-78 Nist Calibration Services For HydrometersDocument36 pagesSp250-78 Nist Calibration Services For HydrometersJeyson Ocampo100% (1)

- Pressure Wave Downhole Communication Technique For Smart Zonal Water InjectionDocument9 pagesPressure Wave Downhole Communication Technique For Smart Zonal Water Injectionlibra mingNo ratings yet

- Sample Problem - NPSHA Calculation For PumpsDocument6 pagesSample Problem - NPSHA Calculation For Pumpsanayo100% (1)

- SPE Swab Surge Field Validations PDFDocument5 pagesSPE Swab Surge Field Validations PDFAbhayNo ratings yet

- Venturimeter, Orificemeter & Rotameter Calibration Set-Up: Experiment No. 4Document9 pagesVenturimeter, Orificemeter & Rotameter Calibration Set-Up: Experiment No. 4Somya MaheshwariNo ratings yet

- Revista Brasileira de Engenharia Agrícola e AmbientalDocument7 pagesRevista Brasileira de Engenharia Agrícola e AmbientalEzra PakarNo ratings yet

- Student Code of Ethic (SCE)Document10 pagesStudent Code of Ethic (SCE)Rahim GenesisNo ratings yet

- FM230-Hydraulics Lab 2 2010 Small Rig ADLDocument12 pagesFM230-Hydraulics Lab 2 2010 Small Rig ADLAlex RepseviciusNo ratings yet

- Characteristics of Flow Meters With Sediment Laden PDFDocument4 pagesCharacteristics of Flow Meters With Sediment Laden PDFDigvijay SinghNo ratings yet

- Injectivity and Well Deliv Test and AnalysisDocument18 pagesInjectivity and Well Deliv Test and AnalysisKyosuke HilmiNo ratings yet

- 7.9 Vertical Flow PerformanceDocument33 pages7.9 Vertical Flow PerformanceAgung Daoe0% (1)

- A New Improved Formula For Calculating Trashrack LossesDocument8 pagesA New Improved Formula For Calculating Trashrack LossesNikom KraitudNo ratings yet

- 6-Energy Loss in BendsDocument12 pages6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Valveless Pressure Regulation With A Submerged Micro-Hole: Ping-Hei Chen, Jin-Cherng Shyu, and Wen-Feng ChengDocument9 pagesValveless Pressure Regulation With A Submerged Micro-Hole: Ping-Hei Chen, Jin-Cherng Shyu, and Wen-Feng ChengMayur PatelNo ratings yet

- NIST Calibration Services For HydrometersDocument36 pagesNIST Calibration Services For HydrometersAdda L MonteroNo ratings yet

- Call It A New DocumentDocument1 pageCall It A New Documentuserabcd9768No ratings yet

- Disclosure To Promote The Right To InformationDocument25 pagesDisclosure To Promote The Right To Informationuserabcd9768100% (2)

- Call It A New DocumentDocument1 pageCall It A New Documentuserabcd9768No ratings yet

- Test DocumentDocument1 pageTest Documentuserabcd9768No ratings yet

- Mesa TanksDocument2 pagesMesa Tanksuserabcd9768No ratings yet

- Test DocumentDocument1 pageTest Documentuserabcd9768No ratings yet

- ThisDocument1 pageThisuserabcd9768No ratings yet

- Good WorkDocument1 pageGood Workuserabcd9768No ratings yet

- Good WorkDocument1 pageGood Workuserabcd9768No ratings yet

- Nrrform PDFDocument1 pageNrrform PDFRonald KahoraNo ratings yet

- ThisDocument1 pageThisuserabcd9768No ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 161-Gmaw-Zug-Asme (Beni Kantona-3g) - WPQDocument4 pages161-Gmaw-Zug-Asme (Beni Kantona-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 11 Centrifugal Pumps Trouble-Shooting ElevenDocument44 pages11 Centrifugal Pumps Trouble-Shooting ElevenAbdallah MansourNo ratings yet

- GassesDocument18 pagesGassesah_16036566No ratings yet

- Fluid Power Graphic SymbolsDocument21 pagesFluid Power Graphic SymbolsMahaman kabirouNo ratings yet

- Mozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011Document12 pagesMozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011tsar mitchelNo ratings yet

- Hydraulic Oil HLP 68Document2 pagesHydraulic Oil HLP 68javierNo ratings yet

- LPG Fuel System Engine Mazda M4-2.0GDocument23 pagesLPG Fuel System Engine Mazda M4-2.0GArmando OrtaNo ratings yet

- Capsu Logo Word Docs 1Document4 pagesCapsu Logo Word Docs 1Ashley ZuniegaNo ratings yet

- Iodine Removal PDFDocument8 pagesIodine Removal PDFAnonymous 6tg80e6BqANo ratings yet

- Impulse Tubing InstrumentsDocument2 pagesImpulse Tubing InstrumentssuhailfarhaanNo ratings yet

- Throttling Characteristics of Multi-Hole Orifice in Multi Stage AssemblyDocument13 pagesThrottling Characteristics of Multi-Hole Orifice in Multi Stage AssemblyGuglielmoNo ratings yet

- EN Pressure sdr17Document1 pageEN Pressure sdr17Alan FloresNo ratings yet

- As 3840.1-1998 Pressure Regulators For Use With Medical Gases Pressure Regulators and Pressure Regulators WitDocument7 pagesAs 3840.1-1998 Pressure Regulators For Use With Medical Gases Pressure Regulators and Pressure Regulators WitSAI Global - APACNo ratings yet

- Calibration Test CertificateDocument7 pagesCalibration Test CertificateMohamed RaafatNo ratings yet

- Unit 2 PumpsDocument11 pagesUnit 2 PumpsThuy TranNo ratings yet

- HRY Microproject GP 1Document22 pagesHRY Microproject GP 1SHUBHAM PANHALKARNo ratings yet

- A ProcessDocument41 pagesA ProcessjulioNo ratings yet

- 8.3.6.2 Barrier Buffer Fluid Reservoirs - API 682 4th EdDocument10 pages8.3.6.2 Barrier Buffer Fluid Reservoirs - API 682 4th EdAlberto OrtegaNo ratings yet

- MIT2 06S13 Pracprbquiz1Document5 pagesMIT2 06S13 Pracprbquiz1dbNo ratings yet

- High Pressure Rotary Oil Seals SizesDocument2 pagesHigh Pressure Rotary Oil Seals SizesbavinrajNo ratings yet

- Pumps StudentsDocument62 pagesPumps StudentsAKHIL JOSEPH100% (1)

- Control Valves Detail SheetDocument163 pagesControl Valves Detail SheetodivalentineNo ratings yet

- Safety ValvesDocument11 pagesSafety ValvesMohamed AliNo ratings yet

- Refrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APDocument2 pagesRefrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APAljoša HribarNo ratings yet

- Line Identification Line P&Id Size Pipe No. Line No. (In.) Spec Service (PD-) FromDocument56 pagesLine Identification Line P&Id Size Pipe No. Line No. (In.) Spec Service (PD-) Fromsamer8saifNo ratings yet

- Hydrocracker Complex Presentation For BPST 23Document50 pagesHydrocracker Complex Presentation For BPST 23fbriandityaNo ratings yet

- 750-263 5 2015Document456 pages750-263 5 2015weweqweqwNo ratings yet

- VALVESDocument153 pagesVALVESHamood Ahmad100% (1)

- Victor Welding and Heating NozzleDocument6 pagesVictor Welding and Heating Nozzleagniva datta100% (1)

- Print FrankDocument17 pagesPrint FrankAnagha NandaNo ratings yet