Professional Documents

Culture Documents

Estimation of Ultimate Recovery From Solution Gas-Drive Reservoirs

Uploaded by

Gilberto Garcia de la PazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimation of Ultimate Recovery From Solution Gas-Drive Reservoirs

Uploaded by

Gilberto Garcia de la PazCopyright:

Available Formats

T. P.

8018

Estimation of Ultimate Recovery from Solution

Gas-Drive Reservoirs

W. L. WAHL

L. D. MULLINS

E. B. ELFRINK

MAGNOLIA PETROLEUM CO.

DALLAS, TEX.

MEMBERS A/ME

INTRODUCTION

In the past few years several articles and papers presenting results

of solution gas-drive depletion calculations have appeared in the literature"'. Such calculations are of

interest to the oil industry, for investment decisions must often be

made before much is known about a

reservoir. At other times, an estimate

of the possible benefits to be realized

from alternate production methods

is desirable, and theoretical depletion

calculations can serve as a floor or

reference level from which to work.

In any case, an estimate of ultimate

oil recovery based upon engineering

data is commonly required.

An engineer confronted with the

problem of obtaining, for a specific

reservoir system, an estimate of ultimate oil recovery by solution gasdrive depletion usually will be forced

to perform the calculations himself.

This is despite the quantity of data

in the literature. Rarely will either

experience or the literature provide

results from a reservoir system similar in all important respects to the

one under consideration, and calculated results are not so plentiful that

satisfactory interpolation procedures

can be devised. Performing the calculations, however, is a tedious, timeconsuming task unless an electronic

computer is available, and, in practice, time and manpower are not always available for this purpose.

A quick, simple, consistent method

was needed for reducing the uncerOriginal manuscript received in Society of

Petroleum Engineers office Sept. 15. 1957.

Revised manuscript received April 16, 1958.

Paper presented at Southern California Petroleum Section Fall Meeting in Los Angeles.

Oct. 17-18, 1957.

lReferences given at end of paper.

~ETROLEUM

TRA~SACTIO~S,

AIME

tainty in estimated oil recovery from

solution gas-drive reservoirs when

only minimum information about the

reservoir system is available.

PROCEDURE

METHOD OF CALCULATION

The usual requisite assumptions

were made so that the material balance equation could be used to calculate data for the charts. The following assumptions were made: (1)

the reservoir is homogeneous and

isotropic; (2) oil recovery is due entirely to solution gas drive and

neither a gas cap nor a water drive

nor gravity drainage is present; (3)

the initial reservoir pressure is the

bubble-point pressure of the reservoir fluid; (4) initial total liquid

saturation is lOO per cent of pore

space; (5) interstitial water saturation remains at the initial value as

the reservoir pressure declines from

the bubble-point pressure to atmospheric pressure; (6) equilibrium gas

saturation is 5 per cent of pore

space; and (7) oil and gas saturations are uniformly distributed

throughout the reservoir at all times.

There are no saturation gradients

due to a wellbore, nor is the geometry of the reservoir system considered.

The material balance equation was

written in the form of a differential

equation' which was integrated to

determine the change in oil saturation for an assigned pressure drop.

Formal integration was not possible,

so recourse was made to the RungeKutta method' of numerical integration. All computations were performed on IBM equipment.

SPE 955-G

Numerical integration yielded the

change in oil saturation within the

reservoir as the pressure declined

from the bubble-point pressure to atmospheric pressure. The initial oil

saturation minus the change in oil

saturation yielded the oil saturation

at atmospheric pressure. The oil

originally in place was obtained by

dividing the initial oil saturation by

the initial formation volume factor

(differential liberation) while the oil

in place at atmospheric pressure was

obtained by dividing the final oil

saturation by the formation volume

factor at atmospheric pressure. Ultimate oil recovery, expressed as a

percentage of the initial oil in place,

was obtained by dividing the difference between the oil initially in place

and the oil in place at atmospheric

pressure by the oil initially in place

and multiplying by 100.

PVT DATA

As previously stated, charts were

based upon 135 solutions to the material balance equation. PVT properties of the reservoir fluids were variables in this equation and had to be

known as functions of pressure. The

required PVT data might have been

obtained from either actual reservoir

fluid systems or correlated data.

However, correlated PVT data were

developed and employed in the calculations for the following reasons:

(1) it is doubtful that 135 sets of

PVT data could have been obtained

for the values of variables investigated in this study, and (2) results

of recovery calculations from randomly obtained PVT data could not

be correlated as well as results from

selected PVT data.

The PVT data used to develop the

132

correlations consisted primarily of

Mid-Continent and Gulf Coast crude

oil systems although Canadian and

South American systems were represented. Data from approximately 75

fluid systems were u~ed, but only

part of the data were utilized for

anyone correlation. When only

mInImUm information about a fluid

system is available, the correlations

presented in Figs. 10 thru 14 may

prove useful.

The correlation of oil formation

volume factor (13 vs bubble-point

pressure is shown in Fig. 10. Suppose Eo and the bubble-point pressure for a reservoir fluid locate a

point somewhere on one of the

curves. Then Eo will decrease along

this curve with decreasing pressure.

Since Eo and the bubble-point pressure generally will not locate a point

exactly on one of the curves, it is

necessary to interpolate for values.

Solution gas-oil ratio (R,) vs

bubble-point pressure curves are prc0 )

IIHEItITITtAL WATfR IS ASSUMED TO BE

10 PER CENT 01'" JOORE SPACE AND DEAD OIL

VISCOSITY AT RESERV~R TMPERATURE TO

liE ONE HALF CENTIJOOISE.

EQUIlI8RIUM GAS SATUR ... nON 110 "'SSUMEO

TO liE FIVE PElt CENT OF JOORE SPACE.

fORMATION VOLUME FACTOII

.s HEII USE!) ULTIMATE

UNITS ARE It[SER"OIR a,,"ItELS

PElt IARREl OF RESIOUAL"Oll.

OIL

RECOVEIIY IS "ALIZO WHEN THE

SOLUTION GAS lOlL RATIO

RESERVOU' PRESSUIt[ HAS DECLINED

FROM THE eU8elE-P01NT ""[SSUflE

sented in Fig. 11. Procedure is similar to that for estimating oil formation volume factor. Corresponding values of solution gas-oil ratio

and bubble-point pressure locate a

point somewhere on one of the

curves, and solution gas-oil ratio

then decreases along the curve with

decreasing pressure. Interpolation between curves may be necessary.

A curve for reciprocal gas formation volume factor vs reservoir

pressure is shown in Fig. 12. Data

UNITS ARE $T"NO""O CUBIC FEET

PER 8AR"1.. OF RESIDUAL OIL

TO ArIltOSP'HE'UC .. RESSUItE.

~~

.'9 It,.

+">-(,,,

REDUIRED- UL.TIMATE RECOVERY FROM A SYSTEM

HiViiii"TaU'.L POINT ",RESSURE ~ 221)0 P$IA,

FOIUU,TiON VOLUME FACTOR' 1.6, AND ... SOLUTION

GAS lOlL RATiO. 1300 seF '8.1...

"

Co

"'~

~

e.

"c".j)

!!illii!!i!!lii

.~Ol

"c"1->-

"RDetOUR, STARTING AT THE LEFT $10 OF

THE CHAIIT, PROCEED HOFUZONT"LL'!' ALONG THE

22:50 PSt LINE TO A FORMATION VOLUME FACTOR

OF 1.6. HOW RISE VERTiCALLY TO THE 1300. SCF I

8at.. LIN. THEN GO HORIZONTALLY ",,.0 RE ... O ... ,.

UlTlM ...TE RECOVERY OF ):1.1 PER CENT.

..

RELAnONSHIP

0,

"-"V<,

0-<,

40

O"'C~

eo

,..,

10

$0

""

~~T~~"I.;O::O :::~"~T,~~(

..

"~

~ CONVERT TkE RECOVERY FIGURE OET

ERMINED IN EXAMPL.E I TO TANK Oil RECOVERED.

'<

'.c,

OATA REOUIREMENTS, OIFFERENTlAl ll8ERATiON DATA

GIVEN IN EXAMPL.E I. FLASH Ll8ERATlON DATA'

BU8SlE POINT PRESSURE' 22S0 PSIA, FOR .. ATlON

VOLU .. E FACTOR' 1.48S, FOR ..... nON VOLUME FACTOR

AT ... TMOSPHERIC PRESSURE 1.050 fOR 80TH FLASH

AND DIFFERENTIAL LIBERATION.

PROCEDURE: CAL.CULATE TkE OIL SATURATION AT

AT .. OSJOHERIC PR[SSURE BY SUBSTlTVTlNG OII'1R-

E(.':AoL)L~OE(';:'O).

(I)

OA']A

['~o:O]U:'O[.( ';: ')no]w~ UL" . "

Bo

80

."P

MOO

1.1i00

80

ATMOS

'0

._

- ] [ 100 ]

1.080

RECOVERY

BPP

0.000

_

1.&00

] ::358

.

OIL SATURATION ... T "'TMOSPHERIC PRESSURE. 0.390

NEXT, SU8STlTUTE THE CALCULATED VALUE OF Oil

SATURATION "'ND THE FL ... SH LIBERATION DATA INTO

EQUATION (l) AND C.... LCUlATE THE ULTIMATE OIL

RECOVERY AS A PERCENTAGE OF T... NI( OIL ORIGINALLY

IN JOLACE.

~

11'

~

]['OoJ~[

~

1.080

1.48S

J_UlTIMATE

- RECOVERY

ULTiMATE RECOVERY. 40.4 PElt CENT OF TANI( OIL

ORIGINAllY IN PLACE

FIG. I-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GASDRIVE RESERVOIRS.

REQUIRED' ULTIMATE RECOVERY FROM A SYSTEM

HiViNGT9U99LE POINT PRESSURE 22~0 PSIA,

fORMATION VOLUME FACTOR. 1.6, AND A SOLUTION

GAS lOlL RATIO' 1300 SCI' I BBL

INTERSTITlAt: WATER lS ASSUMED TO SE

10 PER CENT OF PORE SPACE AND DEAD OIL

VISCOStTy AT RESERVOIR TEMPERATURE TO

BE TWO CENTIPOISE.

EOUILIBRIUM GAS SATURATION IS ASSUMED

TO SE FIVE PER CENT OF PORE SPACE

PROCEDURE: STARTING AT THE LEfT SIDE: Of

THE CHART, PROCEED HORIZONTALLY ALONG THE

22~O PSI UNE TO A FORMATION VOLUME FACTOR

Of 1.6. NOW RISE VERTICALLY TO THE 1300 SCf I

B8L LINE THEN GO HORIZONTALLY AND READ AN

ULTIMATE RCOVE~Y OF 267 PER CENT.

SEE

FlGURE

",

.00

700

'0

1000

t2~O

.0

$0

eo

70

ao

toO

'TOTA\. I,,!QUID UTUII.t.TK*

1'11

con

Of POII SPAC

AS HERE USED ~ULTIMATE OIL

RECOVERY IS REALIZED WHEN TJoIE

RESERVOIR PRESSURE HAS OECLtNED

FROM THE 8U89LEPOINT PRESSURE

TO ATMOSPHERIC PRESSURE.

FORMATION VOLUME FACTOR

UNITS ARE RESERVOIR iARRELS

PER 9ARREL OF RESIDUAL OIL.

SOLUTION GAS I OtL RATIO

UNITS ARE STANDARD CUIIIC FlET

PER BARREL OF RESiDUAL. OIL.

22GO

:000

3:100

4000

FORMATION

VOLUME FACTOR

FIG. 2-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GASDRIVE RESERVOIRS.

133

YOLo

21:-1,

1l).3H

for the curve were obtained in the

following manner.

Gas gravities as functions of pressure were obtained from PVT analyses of reservoir fluids. Gas gravities

were used to determine pseudo-critical temperatures and pressures from

published correlations.' Pseudo-critical temperatures and pressures in

turn permitted the pseudo-reduced

temperatures and pressures to be

calculated because pressure histories

and temperatures of the fluid systems

were known. Published correlations'

were employed to determine compressibility factors which, in turn,

permitted the reciprocal formation

volume factors to be calculated as

fUnctions of pressure.

The reservoir fluids used as the

basis for Fig. 12 had bubble-point

pressures ranging from 1,485 to

4,000 psia and represented reservoirs

having temperatures ranging from

132 to 284 F.

Fig. 13 shows gas-saturated oil

viscosity vs solution gas-oil ratio.

Gas viscosity vs reservoir pressure

is presented in Fig. 14. Gas gravity

and pressure data were obtained

from analyses of reservoir fluids, and

the method of Carr, Kobayashi and

Burrows" was used to compute the

gas viscosity at reservoir conditions

as a function of pressure. PVT data

from which the correlation was developed had bubble-point pressures

ranging from 1,146 to 4,200 psia

30

REQUiRED. ULTI .....TE RECOIIERY FROM A SYSTEM

I-lAVING A BUBBLE POINT PRESSURE ~ 2250 PSI.,

FORMATION VOLUME FACTOR: 1.6, AND A SOLUTION

GAS lOlL RATIO. 1300 SCf fBBl

PROCEOURE

STARTING AT THE

LEfT

SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PSI LINE TO A FORMATION VOLUME fACTOR

OF 1.6. NOW RISE VERTICALLY TO THE 1300 SCFI

BBl LINE. THEN GO HORIZONTALLY AND READ AN

ULTIMATE RECOVERY OF 178

EXAMPLE

PER CENT.

-4'

.-'--

SOLUTION

GAS lOlL RATIO

750

.... ~

_0

60

ro

~

~

TOTAL LIQUltl SATURATION

~ER

CErH OF PORE SI"ACE

NOTE:

AS HERE USED "ULTIMATE OIL

RECOVERyM IS REALIZED WHEN THE

RESERVOIR PRESSURE HAS DECLINED

FROM THE BUBBLE-POINT II'RESSURE

TO ATMOSPHERIC PRESSURE.

3500

FORMATION VOLUME fACTOR

UNITS ARE RESERVOIR 8ARREL.S

PER 8ARREL. OF RESIDUAL. OIL..

SOLUTION GAS lOlL RATIO

UNITS ARE STANDARD CUBIC FEET

PER BARREL. OF RESIDOAL OIL..

4000

FORMATION

FIG. 3-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS.

REOUIRED

4Z

ULTIMATE RECOVERY' FROM A SY'STEM

~BUBBLE POINT PRESSURE ~ 2250 PSIA,

FORMATION VOLUME FACTOR = 1.6, AND A SOLUTION

GAS lOlL RATIO' 1300 SCF I BBL.

40

3.

PROCEDuRE STARTING AT THE LEFT SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PSI LINE TO A FORMATION VOLUME FACTOR

or 1.6. NOW RIU VERTICALLY TO THE 1300 SC'f"1

BBL LINE. THEN GO HORIZONTAL.LY AND READ AN

ULTIMATE RECOVERY' OF 30.8 PER CENT.

EXAMPLE

SEE

INTERSTITIAL WATER 'IS ASSUMED TO BE

30 PER CENT OF PORE SPACE AND DEAD OIL

VISCOSITY AT RESERVOIR TEMPERATURE TO

BE ONE HALF CENTIPOISE.

EQUILIBRIUM GAS SATURATION IS ASSUMED

TO 8E FIVE PER CENT OF PORE SPACE.

FIGURE I

300

750~

'0

60

10

eo

~o

100

TOT.t.LLIQUIDSATUItATION

P'EItCENTOF P'ORE SPACE

1000'

,.00

AS HERE USED "ULTIMATE OIL

RECOVERY~ IS REALIZED WHEN THE

RESERVOIR PRESSURE HAS DECLINED

FROM THE BUBBLE-POINT PRESSURE

TO ATMOSPHERIC "RESSURE.

FORMATION VOLUME FACTOR

UNITS ARE RESERVOIR BARRELS

PER BARREL OF RESIDUAL OIL..

SOLUTION GAS I OIL RATIO

UNITS ARE STANDARD CUBIC FEfT

PfR BARREL OF RESIDUAL. OIL..

3300

4000

FIG. 4--CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GASDRIVE RESERVOIRS.

PETROLEUM TRANSACTIONS, AIME

134

and reservoir temperatures ranging

from 95 to 284 0 F.

k,gjk,o ratio as a function of oil saturation alone. The equation is

tive permeability data from field

measurements on sandstone reservoirs

were examined with the objective of

developing a k,jk,o ratio-saturation

correlation which could be used in

this study. It was found that when

interstitial water saturation was

treated as a parameter in the correlating procedure, an equation could

be written which expressed the

krojk"o RATIO

All variables except one in the

material balance equation are functions of reservoir pressure, the exception being the relative permeability ratio, krojkro> which must be

known as a function of saturation

in order to solve the equation. Rela-

= ~ (0.0435 + 0.4556~)

k"ojk"o

and

where So, is equilibrium gas saturation, a constant = 0.05 in these calculations; Sw is interstitial water saturation, fraction of pore space; So is

EXAMPLE

RECUIRED ULTIMATE RECOVERY FROM A SYSTEM

HAVING A BUBBLE POINT PRESSURE: 2250 PSIA.

FORMATION VOLUME FACTOR: 1.6, AND A SOLUTION

GA5/0lL RATIO = 1300 SCF I BBl

~

STARTING AT THE 'oEFT SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PS I liNE TO A FORMATION VOLUME FACTOR

OF 1.6. NOW RISE VERTICALLY TO THE 1300 5CF I

BBl

UNE

ULTIMATE

THEN GO HORIZONTALLY AND READ AN

RECOVERY OF 238 PER CENT.

EXAMPLE

SEE

FIGURE

kr'il/kro

I.

RELATIONSHIP

500~

'\!

SOLUTION

GAS / OIL. RATIO

"'\L

1000

SO

10

80

'0

H++-f-++-Nf-.+'4C.J..'1-++.h-1~

H- ++-+++-++

750

100

",.

TOTAL LlQUIO SATURATION

PER CENT Of PORE SPACE

1\

, I

AS HERE USED "ULTIMATE OIL

RECOVERY" IS REALIZED WHEN THE

RESERVOIR PRESSURE HAS DECL.INED

FROM THE BUBBL.E-POINT PRESSURE

TO ATMOSPHERIC PRESSURE.

FORMATION VOL.UME FACTOR

UNITS ARE RESERVOIR' BARRELS

PER BARREL OF RESIDUAL OIL..

SOLUTION GAS / OIL RATIO

UNITS ARE STANDARD CUBIC FEE':

PER BARREL OF RESIDUAL OIl.

FIG. 5-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS.

EXAMPLE I

REQUIRED ULTIMATE RECOVERY FROM A SYSTEM

HAVING A BUBBLE POINT PRESSURE: 2250 PSIA,

FORMATION VOLUME FACTOR: 1.6, AND A SOLUTION

GAS/OIL RATIO ~ 1300 SCF/BBL.

PROCEDURE: STARTING AT THE LEFT SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PSI LINE TO A FORMATION VOL.t,lME FACTOR

OF 1.6. NOW RISE VERTICALLY TO THE 1300 SCF /

BBL LINE. THEN GO HORIZONTALLY ANt) READ AN

ULTIMATE RECOVERY OF 15.0 PER CENT.

EXAMPLE

k nl1 /k ro

j'lj",~C\Ll"~"1'~'I"'~~"~~~II~i~~~i~~!2j8~~h:

-:~

.. :"'l],\1""'1 :'"

po

26

>.

30 PER CENT OF PORE SPACE AND DEAD OIL

~~S\O:~T~E~\I~~~~r'OIR

U(>/.

24

-1,'9',.

('

22

~

H-+++-l-++N-'h,.pW~-1>..PI.~~o;,<H-.J--l'o<f-+"'-+-,M++-f-.+:>"

TEMPERATURE TO

INTERSTITIALGAS

WATER

IS ASSUMED

TO BE

EOUllIBRIUM

SATURATION

IS ASSUMED

TO BE FIVE PER CENT OF PORE SPACE.

~""0

~"

20

H-+++-l-+~

..

~!; ~

,,~

18

I.

"('1-,.

14

RELATIONSHIP

SOLUTION

GAS / OIL RATIO

60

70

eo

90

TOTAL LlOUID SATURATION

PER CEHT OF PORE SPACE

NOTE:

AS HERE USED "ULTIMATE OIL

RECOVERY" IS REALIZED WHEN THE

RESERVOIR PRESSURE HAS DECLINED

FROM THE BUBBLE-POINT PRESSURE

TO ATMOSPHERIC PRESSURE.

FORMATION VOLUME FACTOR

UNITS ARE RE~ERVOIR BARRELS

PER BARREL OF RESIDUAL OIL

SOLUTION GAS lOlL RAT 10

UNITS ARE STANDARD CUBIC FEE T

PER BARREL OF RESIDUAL OIl.

FORMATION

VOLUME

FACTOR

FIG. 6-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS,

YOLo :l13, 1958

oil saturation, fractIOn of pore space;

and C is a constant = 0.25 in these

calculations.

The krg/k ro ratio vs saturation

curves calculated with the equation

are shown in Fig. 15. Since every

value of interstitial water saturation

yields a different krg/k ro ratio curve,

Fig. 15 shows the k"g/k,o ratio vs

total liquid saturation with interstitial

water as a parameter. These curves

are the result of a data correlation.

As such, they exhibit trends observed

in data, but, obviously, they do not

duplicate nor are they characteristic

of all k,jk,o ratio curves.

DISCUSSION

The nine charts for estimating

ultimate oil recovery from solution

gas-drive reservoirs are presented in

Figs. 1 through 9. Each chart incorporates a sample calculation to demonstrate the method of operation. For

these charts, the interstitial water

saturation determines the relative permeability ratio-total liquid saturation

relationship. Values of bubble-point

pressure, oil formation volume factor, and solution gas-oil ratio shown

34

EXAMPLE I

REOUIRED

ULTIMATE RECOVERY FROM A SYSTEM

HAVING A BUBBLE POINT PRESSURE; 2250 PSI.,

FORMATION VOLUME fACTOR; 1.6. AND A SOLUTION

GAS/OIL RATIO -'300 SCF/BBL.

PROCEDURE:

STARTING AT THE LEFT SlOE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PSI LINE TO A FORMATION VOLUME FACTOR

OF 1.6. NOW RISE VERTICALLY TO THE 1300 SCF I

BBl LINE. THEN GO HORIZONTALLY AND REAO AN

ULTIMATE RECOVERY OF 21.8 PER CENT.

EXAMPLE

SEE FIGURE I

k'Q Ik ro

RELATIONSHIP

..~ 0 I

60

eo

10

90

TOTAL LlOUID SATURATION

PER CENT

or

PORE SPACE

FIG. 7-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS.

EXAMPLE I

REQUIRED ULTIMATE RECOvERY FROM A SYSTEM

HAVING A BUBBLE POINT PRESSURE" 2250 PSIA,

FORMATION VOLUME FACTOR" 1.6, ANO A SOLUTION

GAS/OIL RATIO ~ 1300 SCF/BBL.

PROCEDURE: STARTING AT THE LEFT SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

2250 PSI LINE TO A FORMATION VOLUME FACTOR

OF 1.6. NOW RISE VERTICALLY TO THE 1300 SCFI

BBL LINE. THE~ GO HORIZONTALLY AND READ AN

ULTIMATE RECOVERY OF 17.6 PER CENT.

EXAMPLE

SEE

FIGURE

krQ Ik ro

,.....--..R'.,~":.,...,~~,"'1'...-0....-f\,...,....L""~,---,-..,~~_~I'..~~-:;. . . . ~

..

30

H-+--/"'.t-'P....>j,,-1'o..l'.:f'.N-l'~d'I,d-'!o.-t~+i- ~

I

',I, "l-l

AS HERE USED "ULTIMATE OIL

RECOVEllty" IS REALIZED WHEN THE

RESERVOIR PRESSURE HAS DECLINED

FROM THE BUBBLE-POINT PRESSURE

TO ATMOSPHERIC PRESSURE.

FORMATION VOLUME FACTOR

UNITS ARE RESERVOIR BARIitElS

PER BARREL OF RESIDUAL OIL

SOLUTION GAS lOlL RAT 10

UNITS ARE STANDARD CUBIC FEET

PER BARREL OF RESIDUAL OIl.

2.

~~~t~~+.::tt~t~~~~~~~:~;JI'..;:t~~t~-il\"i:I:ll'..';.t1.::.t~~,

I'.

26

I.

I.

16

RELATIONSHIP

14

12

10

':-0'._

&0

10

60

90

TOTAL LIQUID SATURATION

PER CENT Of PORE SPACE

INTERSTITIAL WATER IS ASSUMED 10 BE

50 PER CENT OF PORE SPACE AND DEAD OIL

VISCOSITY AT RESERVOIR

TEMPERATURE TO

BE TWO CENTIPOISE.

EQUILIBRIUM GAS S~TURATION IS ASSUMED

10 BE FIVE PER CENT OF PORE SPACE.

FORMATION

VOLUME

FACTOR

FIG. 8-CHART FOR ESTIMATING ULTIMATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS.

PETROLEUM TRANSACTIONS, AIME

136

!!2..!L

EXAMPLE I

~

AS HERE .uSED "ULTIMATE OIL

RECOVERY" IS REALIZED WHEN THE

RESERVOIR PRESSUftE HAS DECLINED

FROM THE BU88LE~POINT PRESSURE

TO ATMOSPHERIC PRESSUftE.

FORMATION VOLUME FACTQR

UNITS ARE RESERVO'R IARRELS

.,.~..,

ULTIMATE RECOVERY FROM A SYSTEM

HAVING A BUBBLE POINT PRESSURE: 2250 PSIA

FORMATION VOLUME FACTOR = 1.6, AND A SOLUTION

GAS lOlL RATIO ~ 1300 SCF 18aL.

l'~

-9.....

'1'''0

~~

-9,,;

PROCEOURE: STARTING AT THE LEFT SIDE OF

THE CHART, PROCEED HORIZONTALLY ALONG THE

~250 PSI LINE TO A FORMATION VOLUME FACTOR

OF 1.6. NOW RISE ..... VERTICALLY TO THE 1300 SCF 1

BeL LINE. THEN GO HORIZONTALLY AND READ AN

ULTIMATE RECOVERY OF 12.7 PER CENT.

PE:O~~;~;~ g~S"/E~:~U:;T~~L.

C'~

"".,.

UNITS ARE STANDARD CUI,e FEET

PER BARREL OF RESIDUAL OIL

0",

'1'~

EXAMPLE

SEE FIGURE

.o~-9

oS"'0"

"(

I.

krQ Ill ro RE.LATIONSHIP

0'1'

/G'1J..

<fr

0

<i-

'"<

"l'~

...~ o.

Pi

II

60

10

80

ltO

100

TOTAL LlQUIO SATURATION

PER CENT OF PORE SPACE

INTERSTITIAL WATER IS ASSUMED TO BE

50 PER CENT OF PORE SPACE AND DEAD OIL

VISCOSITY AT RESERVOIR TEMPERATURE TO

BE TEN CENTIPOISE.

EQUIL1BRIUM GAS SATURATION IS ASSUMED

TO BE FiVE PER CENT OF PORE SPACE.

FIG. 9-CHART FOR ESTIMATING liLTl~'lATE RECOVERY FROM SOLUTION GAS-DRIVE RESERVOIRS.

on the charts, but not used in the

calculations, were obtained by interpolation. Formation volume factors

of 1.1 and 1.2 bbl/bbl and solution

gas-oil ratios of 300 and 400 scf/bbl

were obtained by extrapolation; these

values are shown as dashed lines on

the charts. Locations of the 4,000-psi

point on the pressure axes were obtained by extrapolation.

Values of formation volume factor

and solution gas-oil ratio necessary

for use of the charts should be obtained from a differential analysis. If

only flash (equilibrium) data are

available, differential data must be

estimated from the flash data. At

present, there are no correlations

available for this purpose, but an

empirical relationship between flash

and differential formation volume

factors is presented in Fig. 16. A

similar relationship between flash

and differential solution gas-oil ratio

is presented in Fig. 17.

Maximum solution gas-oil ratio

shown on the charts is 2,000 scf/bbl.

-_.- -acro----~o6--~-~-3200

eu8BLEPOINT

This limit was imposed because the

straight material balance approach

to primary depletion calculations is

not adequate for high gas-oil ratio

fluid systems. The free reservoir gas

contains components which separate

as liquids in the stock tank, and a

different approach to estimating recovery is desirable.

The meaning of ultimate oil recovery has been restricted here to

that oil recovered as the reservoir

pressure declined from the bubblepoint pressure to atmospheric pressure. If the reservoir fluid is undersaturated at the initial reservoir pressure, the total recovery would be

the sum of (1) the recovery due to

fluid expansion as the reservoir pressure decreased from the initial value

to the bubble-point pressure, and (2)

the ultimate oil recovery estimated

by means of one of the charts.

Charts may be used to estimate

only the ultimate oil recovery-the

final answer. They cannot be used to

estimate recovery as a function of

pressure decline, for the assumption

of an initial total liquid saturation

equal to 100 per cent of pore spa .. "

prohibits it.

Ultimate oil recovery figures are

expressed in terms of residual oil.

The reason for this is that differential liberation was presumed to occur

within the reservoir, and the end

product of a differential liberation is

residual oil. However, ultimate oil

recovery may be obtained as a percentage of the stock-tank oil initially

in place by performing the necessary

calculations. All data necessary to

compute the reservoir oil saturation

at atmospheric pressure are available

in this paper. When both differential

and flash liberation data are available

or can be estimated, the tank oil

recovered can be determined. A calculation of this type is shown in

Fig. 1.

Ultimate oil recovery on the charts

is expressed as a percentage of the

initial oil in place, which depends

upon the oil formation volume factor and the reservoir oil saturation.

Since the fractional reservoir oil saturation is the quantity one minus

the water saturation minus the gas

Tooo

P.~SSURE,PSI.

FI(;. lO-TYPICAL OIL FORMATION VOL

U~IE FACTOR CURVES VS BUBBLE-POINT

PRESSURE.

BUBBLE-POI NT PRESSURE, PS I A

FIG. ll-TYPICAL SOLUTION GAS-OIL RA

TIO CURVES VS RUBBLEPOINT PRESSURE.

RESERVOIR PRESSURE,PSIA

FIG. 12 - RECIPROCAL GAS FORMATIO.'

VOLUME FACTOR VS RESERVOIR PRESSURE.

VOL. 213,

1958

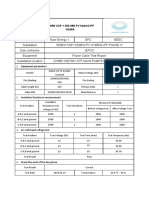

Table l-Reservoir Systems Used to Develop

Ultimate Oil Recovery Charts

2000

..J

01

01

;;:..J

1600

~o

~~

'" :> 1200

..J~

cO)

-'"

1-11:

is

IL

800

11:0

'"

o

750

750

1,500

1,500

1,500

2,250

2,250

2,250

2,250

2,250

3,000

3,000

3,000

3,000

3,000

IL

IL

400

FIG. 13-GAS-SATURATED OIL VISCOSITY

VS SOLUTION GAS-OIL RATIO.

--I

~.022

~~ ~ ,020

;n

00

400

800

1200

1600

FLASH GOR, SCF PER BBL OF TANK OIL

FIG. 17 - EMPIRICAL RELATIONSHIP Br:TWEEN FLASH AND DIFFEIlENTlAL LIIlER\TTON SOIXTION GAS-OIl, RATIOS.

0.0 1 Ii

100

500

500

1,000

1,000

1,000

1,000

1,500

1.500

2,000

1,500

1.500

2,000

2,000

2,000

1.10

1.30

1.30

1.30

1.50

,1.50

1.80

1.50

1.80

1.80

1.80

2.10

1.80

2.10

2.50

1.06

1.08

1.07

1.07

1.09

1.08

1.11

1.08

1.11

1.11

1.09

1.11

1.09

1.11

1.13

g~

;

~.OI6

~ ~.Ol

:; .012

.01 00

500

1000

1500

2000

2500 3000

3500

RESERVOI R PRESSURE, PSIA

FIG. 14-GAS VISCOSITY YS RESERVOIH

PRESSURE.

2

~

<t

a:

0

~

'"

.....

0.1

'"

100

TOTAL liQUID SATURATIO~

PER CENT OF PORE S PAC E

FIG.

15-krQ /k ro

VS TOTAL LIQvlD

SATURATION.

0:

~g

<t ...J

IL <t

2.4

w::;)

~ ~

2.2

...Jw

o a:

> IL

Zo

o

2.0

;: a: I .8

saturation, it is apparent that water

saturation is directly involved in calculating the ultimate oil recovery

figures on the charts .

Maximum deviation from the calculated value of ultimate oil recovery

is one-half recovery per cent for all

charts. However, recovery figures obtained by means of the charts should

be regarded as estimates since properties of reservoir systems, as well as

hydrocarbon systems, depart in varying degree from the assumed properties listed earlier. Additional data for

constructing the charts would have

been desirable in order to more thoroughly check them, but results obtained compare very well with results

of similar depletion calculations prec

sented by Muskat.' However, in describing the systems he investigated,

Muskat did not provide sufficient information in all cases so that recovery

from identical systems can be estimated from the charts. Even so,

those systems for which a comparison

could be checked within two recovery

per cent. The reservoir systems used

for the charts are listed in Table 1.

Interstitial water saturation and

dead-oil viscosity of an actual reservoir system may not correspond

exactly to anyone of the charts. l!1

this case, interpolation will be necessary. Consider the following system.

Interstitial water saturation

<tal

20

Dead-oil viscosity

I ep

Oil formation vol ume factor 1.6 bbl/bbl

...J al

Bubble-point pressure

!!a:I.4

The above values of B" R, and

bubble-point pressure are found on

all charts, but there is no chart for

20 per cent interstitial water saturationor dead-oil viscosity of 1 cpo

The method to be described is suggested as a suitable interpolation

procedure.

Use each of the nine charts to

determine ultimate oil recovery for

~

zo

~ ~

WW

ILUI

ILW

1.2

;; a: I .01.0

1.2

1.4

1.6

1.8

2.0

FLASH FORMATION

VOLUME FACTOR, RESERVOIR

8BlS I BBl OF TANK 01 l

FIG. 16 - EMPIRICAL RELATIONSHIP BE

TWEEN FLASH AND DIFFEIlENTIAL LIBEIlA

TlON FOIlMATION VOLUME FACTOIlS.

PETROI,EllM TRANSACTIONS. AIME

Dead-oil

viscosity.

(ep)

10

2

'/'

Ultimate oil recovery

for interstitial water saturation

10 per cent

30 per cent

50 per cen'

17.8

16.0

12.7

26.7

23.8

17.6

35.8

30.8

21.8

Now plot ultimate oil recovery vs

interstitial water saturation with

dead-oil viscosity as the parameter.

From the curves read values of ultimate oil recovery at 20 per cent interstitial water saturation for deadoil viscosities of 10, 2, and 112 cpo

These values' are as follows.

Dead-oil

viscosity,

(ep)

Ultimate oil recovery

(per cent)

10

17.0

25.5

33.6

'/'

Next, plot dead-oil viscosity vs

ultimate oil recovery and read an

ultimate oil recovery of 29.4 per cent

for a dead-oil viscosity of 1 cpo

ACKNOWLEDGMENT

The authors wish to thank P. R.

McGee, O. D. Ferris, A. S. Lee, and

J. T. Nipper for programming calculations for the Datatron computer.

REFERENCES

per cent pore space

::;: .....

a:UI

~ all .6

Solution gas-oil ratio

the given values of Bo,R. and bubblepoint pressure. Values so obtained

are given in the following table.

1. Muskat. Morris: Physical Principal.s

0/ Oil Production, McGraw-Hill Book

1,300 sef/bbl

2,250 psia

Co., Inc., N. Y. (1949) .

2. Scarborough, James B.: Numerical

Mathematical Analysis, 2nd Ed., The

Johns Hopkins Press, Baltiniore

(1950) .

:~.

Carr. N. L.. Kcbayashi, R., and Burrows, D. B.: Trans. AIME (1954)

204, 264.

.t. Natural Gasoline Supply Men's Asso-

ciation Data Book (1951).

5. Arps, J. J., and Roberts, T. G.: Trans.

AIME (1955) 204, 120.

***

You might also like

- Federal Pipeline Safety StandardsDocument154 pagesFederal Pipeline Safety StandardsGilberto Garcia de la PazNo ratings yet

- Spwla 2009 64051Document7 pagesSpwla 2009 64051Gilberto Garcia de la PazNo ratings yet

- 028 Ds Retrievable WhipstockDocument2 pages028 Ds Retrievable WhipstockGilberto Garcia de la PazNo ratings yet

- Spe 84246 MSDocument16 pagesSpe 84246 MSGilberto Garcia de la PazNo ratings yet

- WV Pid 002 Inline Downhole FilterDocument1 pageWV Pid 002 Inline Downhole FilterGilberto Garcia de la PazNo ratings yet

- Spe 178049 MSDocument11 pagesSpe 178049 MSGilberto Garcia de la PazNo ratings yet

- Otc 25927 MSDocument23 pagesOtc 25927 MSGilberto Garcia de la PazNo ratings yet

- Spe 84246 MSDocument16 pagesSpe 84246 MSGilberto Garcia de la PazNo ratings yet

- H03706Document2 pagesH03706Gilberto Garcia de la PazNo ratings yet

- Waterweb® Service: A Relative Permeability Modifier (RPM)Document11 pagesWaterweb® Service: A Relative Permeability Modifier (RPM)bhargav103No ratings yet

- WPC 30134Document3 pagesWPC 30134Gilberto Garcia de la PazNo ratings yet

- SPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaDocument12 pagesSPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaGilberto Garcia de la PazNo ratings yet

- Spe 96818 MSDocument9 pagesSpe 96818 MSGilberto Garcia de la PazNo ratings yet

- SPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaDocument12 pagesSPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaGilberto Garcia de la PazNo ratings yet

- 1616Document5 pages1616Gilberto Garcia de la PazNo ratings yet

- A Practical Approach To The Interpretation of Cement Bond Logs @Document10 pagesA Practical Approach To The Interpretation of Cement Bond Logs @Gilberto Garcia de la PazNo ratings yet

- SPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaDocument12 pagesSPE 163913 Application of Sand Jet Perforations For Multizone Fracturing in CBM Wells, IndiaGilberto Garcia de la PazNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kutai - Ec 05 Manual enDocument4 pagesKutai - Ec 05 Manual enHorea PopNo ratings yet

- EE-101 (Unit 4)Document46 pagesEE-101 (Unit 4)Chauhan AyushmaanNo ratings yet

- Lec 6-13 Plane Curvilinear MotionDocument76 pagesLec 6-13 Plane Curvilinear MotionSaqib SherNo ratings yet

- Review Propagating ErrorDocument8 pagesReview Propagating ErrorNg Swee Loong Steven100% (1)

- HTF Buildigng Cable Hippot Test From VFD To MotorDocument20 pagesHTF Buildigng Cable Hippot Test From VFD To Motorمحمد ابن علیNo ratings yet

- SH - No. Description: Power Control Equipments, B'LoreDocument31 pagesSH - No. Description: Power Control Equipments, B'LoreBalamurugan ArumugamNo ratings yet

- Relative Lowering of Vapour Pressure - 1524262518Document4 pagesRelative Lowering of Vapour Pressure - 1524262518PavitraNo ratings yet

- Flicker Analysis and Methods For Electric Arc Furnace Flicker (EAF) MitigationDocument6 pagesFlicker Analysis and Methods For Electric Arc Furnace Flicker (EAF) MitigationIndah PermataNo ratings yet

- 기초회로이론 챕터6 과제Document118 pages기초회로이론 챕터6 과제lostdream0515No ratings yet

- Harmonics MCPQG Ieee 2005Document54 pagesHarmonics MCPQG Ieee 200523OtterNo ratings yet

- Convection Tutorial Sheet 3Document4 pagesConvection Tutorial Sheet 3Charlotte BNo ratings yet

- ICEpower50ASX2 Datasheet 1 8Document34 pagesICEpower50ASX2 Datasheet 1 8Lucas MaldonadoNo ratings yet

- TERM 2 Important Questions of Class 11thDocument9 pagesTERM 2 Important Questions of Class 11thAdityaNo ratings yet

- LT Capacitor Intervention at MEPCO Saves MillionsDocument3 pagesLT Capacitor Intervention at MEPCO Saves MillionsElectrical-EngineerNo ratings yet

- Anly Controller: Multi Function Digital Voltage RelayDocument3 pagesAnly Controller: Multi Function Digital Voltage RelayHannan RizqiNo ratings yet

- 1SBL397001R1300 Af80 30 00 13 PDFDocument5 pages1SBL397001R1300 Af80 30 00 13 PDFFilip KrižanNo ratings yet

- Vacuum Circuit-Breaker - 36/40.5 KV: Instruction ManualDocument40 pagesVacuum Circuit-Breaker - 36/40.5 KV: Instruction Manualzhang1988No ratings yet

- A Level Physics 13 June2015Document20 pagesA Level Physics 13 June2015Anthony0% (1)

- Basic HvacDocument31 pagesBasic HvacRahul Jatrothu NaikNo ratings yet

- Forces at RestDocument67 pagesForces at RestOdaneNo ratings yet

- Line Sizing ProcedureDocument123 pagesLine Sizing ProcedureEkundayo John100% (3)

- Power DesignDocument19 pagesPower DesignSushant PetareNo ratings yet

- SPM Physics Wave Oscillation Damping ResonanceDocument4 pagesSPM Physics Wave Oscillation Damping ResonanceIVAN TIONG WEI JUN MoeNo ratings yet

- Pallivasal Internship ReportDocument19 pagesPallivasal Internship ReportGO KUNo ratings yet

- Review Problems: Dimensions, Dimensional Homogeneity, and UnitsDocument29 pagesReview Problems: Dimensions, Dimensional Homogeneity, and UnitsBassem SayedNo ratings yet

- ELIVAC SMART VACUUM SYSTEM SAVES 80% ENERGYDocument8 pagesELIVAC SMART VACUUM SYSTEM SAVES 80% ENERGYseimarfelipeNo ratings yet

- Flow Measurement FundamentalsDocument77 pagesFlow Measurement FundamentalsGaming UserNo ratings yet

- 2009-03, High Voltage Cables (Nexans, Olex)Document56 pages2009-03, High Voltage Cables (Nexans, Olex)Ling_Li_WeiNo ratings yet

- Hydro Electricity and Hydro Power Plant: By-Rajkumar Parihar (B11074)Document34 pagesHydro Electricity and Hydro Power Plant: By-Rajkumar Parihar (B11074)AninVincelyNo ratings yet

- Power Systems Analysis - Bee 21 & Bew 21Document3 pagesPower Systems Analysis - Bee 21 & Bew 21zy44cwfjjgNo ratings yet