Professional Documents

Culture Documents

Crosby® Turnbuckles

Uploaded by

Midfiild CosminCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby® Turnbuckles

Uploaded by

Midfiild CosminCopyright:

Available Formats

Turnbuckle_pg154.

fm Page 25 Saturday, November 8, 2008 12:07 PM

Crosby Turnbuckles

HG-223

Hook & Hook

Meets the performance

requirements of Federal

Specifications FF-T-79lb,

Type 1, Form 1 - Class 5,

and ASTM F-1145,

except for those

provisions required of

the contractor.

HG-225

Hook & Eye

Meets the performance

requirements of Federal

Specifications FF-T-79lb,

Type 1, Form 1 - Class 5,

and ASTM F-1145,

except for those

provisions required of

the contractor.

HG - 226

Eye & Eye

Meets the performance

requirements of Federal

Specifications FF-T-79lb,

Type 1, Form 1 - Class 5,

and ASTM F-1145,

except for those

provisions required of

the contractor.

HG - 227

Jaw & Eye

Meets the performance

requirements of Federal

Specifications FF-T-79lb,

Type 1, Form 1 - Class 5,

and ASTM F-1145,

except for those

provisions required of

the contractor.

Turnbuckle assembly combinations include: Eye and Eye, Hook and Hook,

Hook and Eye, Jaw and Jaw & Jaw and Eye.

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Crosbys Quenched and Tempered end fittings are normalized bodies have

enhanced impact properties for greater toughness at all temperatures.

Hot Dip galvanized.

Hooks are forged with a greater cross sectional area that results in a stronger

hook with better fatigue properties.

Modified UNJ thread on end fittings for improved fatigue properties. Body

has UNC threads.

Turnbuckle eyes are forged elongated, by design, to maximize easy

attachment in system and minimize stress in the eye. For turnbuckle sizes 1/4"

through 2-1/2", a shackle one size smaller can be reeved through

eye.

Forged jaw ends are fitted with bolts and nuts on sizes 1/4" - 5/8", and

pins and cotter on sizes 3/4" - 2-3/4".

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL

ONLY.

Lock Nuts available for all sizes.

Typical hardness levels, Tensile Strengths and Ductility Properties are

available for all sizes.

Turnbuckles can be furnished proof tested or magnaflux inspected with certificates if requested at time of order.

Crosby products meet or exceed all the requirements of ASME B30.26

including identification, ductility, design factor, proof load and temperature

requirements. Importantly, Crosby products meet other critical performance

requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

160

HG-228

Jaw & Jaw

Meets the performance

requirements of Federal

Specifications FF-T-79lb,

Type 1, Form 1 - Class 5,

and ASTM F-1145,

except for those

provisions required of

the contractor.

Modified thread:

Note stress relieving

radii in this unretouched

photo enlargement of the

supabuckle.

Standard thread:

Note stress building

sharp V in this

untouched photo

enlargement.

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

Rigging_eng.fm Page 161 Thursday, November 13, 2008 1:17 PM

Hook & Hook Turnbuckles

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Hooks are forged with a greater cross sectional area that results in a stronger hook with

better fatigue properties.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Lock Nuts available for all sizes (see page 170).

Comprehensive end fitting data provided on page 166.

Fatigue Rated.

HG-223

k o o H

&

k o o H

Rigging

Accessories

s e l k c u b n r u T

Meets the performance requirements of Federal

Specifications FF-T-791b, Type 1 Form 1 - CLASS 5,

and ASTM F-1145, except for those provisions

required of the contractor. For additional information, see page 391.

HG-223

Hook & Hook

Thread

Dia. &

Take Up

(in.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 12

5/8 x 6

5/8 x 12

3/4 x 6

3/4 x 12

3/4 x 18

7/8 x 12

1 x 12

HG2 3

HG-223

Stock No.

1030011

1030039

1030057

1030075

1030119

1030137

1030173

1030191

1030235

1030253

1030271

1030333

Working

Load

Limit

(lbs.)*

400

700

1000

1500

1500

2250

2250

3000

3000

3000

4000

5000

Weight

Each

(lbs.)

.33

.52

.83

1.88

2.77

3.21

4.58

4.20

6.92

8.65

9.85

14.8

A

.25

.31

.38

.50

.50

.63

.63

.75

.75

.75

.88

1.00

D

.44

.50

.56

.65

.65

.90

.90

.98

.98

.98

1.13

1.25

E

Closed

1.67

2.00

2.28

3.53

3.51

4.24

4.23

5.07

5.04

5.07

5.82

6.56

F

1.27

1.50

1.77

2.28

2.28

2.81

2.81

3.33

3.33

3.33

3.78

4.25

Dimensions

(in.)

J

K

Open

Closed

9.79

7.38

11.58

8.58

15.23

10.62

17.98

13.20

30.27

19.49

19.50

14.50

31.84

20.84

21.19

15.98

33.59

22.38

45.59

28.38

34.89

23.52

36.59

25.06

M

Open

12.20

14.08

17.84

20.76

33.05

22.50

34.84

24.40

36.80

48.80

38.26

40.12

N

Closed

8.20

9.58

11.84

14.76

21.05

16.50

22.84

18.40

24.80

30.80

26.26

28.12

BB

4.07

4.58

6.10

6.03

12.36

6.03

12.39

6.13

12.59

18.53

12.16

12.18

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

161

Rigging_eng.fm Page 162 Thursday, November 13, 2008 1:21 PM

Hook & Eye Turnbuckles

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckles sizes 1/4" through 1", a shackle one size

smaller can be reeved through eye.

Turnbuckle hooks are forged with a greater cross sectional area that results in a stronger

hook with better fatigue properties.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Lock Nuts available for all sizes (see page 170).

Comprehensive end fitting data provided on pages 166 & 167.

Fatigue Rated.

HG-225

s e l k c u b n r u T

e y E

&

k o o H

Meets the performance requirements of Federal

Specifications FF-T-791b, Type 1, Form 1 CLASS 6,

and ASTM F-1145, except for those provisions

required of the contractor. For additional information, see page 391.

HG-225

Hook & Eye

Thread

Dia. &

Take Up

(in.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 12

5/8 x 6

5/8 x 12

3/4 x 6

3/4 x 12

3/4 x 18

7/8 x 12

1 x 12

HG2 5

HG-225

Stock No.

1030636

1030654

1030672

1030690

1030734

1030752

1030798

1030814

1030850

1030878

1030896

1030958

Working

Load

Limit

(lbs.)*

400

700

1000

1500

1500

2250

2250

3000

3000

3000

4000

5000

Weight

Each

(lbs.)

.31

.50

.79

1.80

2.70

2.98

4.35

4.21

6.52

8.24

9.34

13.9

A

.25

.31

.38

.50

.50

.63

.63

.75

.75

.75

.88

1.00

D

.44

.50

.56

.65

.65

.90

.90

.98

.98

.98

1.13

1.25

E

Closed

1.67

2.00

2.28

3.53

3.51

4.24

4.23

5.07

5.04

5.07

5.82

6.56

F

1.27

1.50

1.76

2.28

2.28

2.81

2.81

3.33

3.33

3.33

3.78

4.25

J

Open

11.66

13.50

17.09

19.57

31.86

21.11

33.45

22.61

35.01

47.01

36.11

37.65

Dimensions

(in.)

K

M

Closed Open

7.66 12.29

9.00 14.28

11.09 18.04

13.57 20.79

19.86 33.08

15.11 22.61

21.45 34.95

16.61 24.45

23.01 36.85

29.01 48.85

24.11 38.23

25.65 40.06

N

Closed

8.29

9.78

12.04

14.79

21.08

16.61

22.95

18.45

24.85

30.85

26.23

28.06

R

.81

.95

1.13

1.41

1.41

1.80

1.80

2.09

2.09

2.09

2.38

3.00

S

.34

.44

.53

.71

.71

.88

.88

1.00

1.00

1.00

1.25

1.43

X

Closed

1.76

2.20

2.48

3.56

3.54

4.35

4.34

5.12

5.09

5.12

5.79

6.50

BB

4.07

4.58

6.10

6.03

12.36

6.03

12.39

6.13

12.59

18.53

12.16

12.18

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

162

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

Rigging_eng.fm Page 163 Thursday, November 13, 2008 1:25 PM

Eye & Eye Turnbuckles

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckle sizes 1/4" through 2-1/2", a shackle one size

smaller can be reeved through eye.

Modified UNJ thread on end fittings for improved fatigue properties. Body has UNC

threads.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Lock Nuts available for all sizes (see page 170).

Comprehensive end fitting data provided on page 167.

Fatigue Rated.

HG-226

e y E

&

e y E

Rigging

Accessories

s e l k c u b n r u T

Meets the performance requirements of Federal

Specifications FF-T-791b, Type 1, Form 1 - CLASS 4,

and ASTM F-1145, except for those provisions

required of the contractor. For additional information, see page 391.

HG-226

Eye & Eye

Thread

Dia. &

Take Up

(in.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 12

5/8 x 6

5/8 x 12

3/4 x 6

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

HG2 6

HG-226

Stock No.

1031252

1031270

1031298

1031314

1031350

1031378

1031412

1031430

1031476

1031494

1031519

1031537

1031555

1031573

1031591

1031617

1031635

1031653

1031671

1031699

1031715

1031733

1031779

1031797

1031813

1031831

1031859

Working

Load

Limit

(lbs.)*

500

800

1200

2200

2200

3500

3500

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Weight

Each

(lbs.)

.29

.48

.75

1.72

2.63

2.75

4.12

4.22

6.12

7.83

8.83

11.5

9.62

13.0

16.3

20.2

19.9

23.8

27.8

28.7

34.1

39.6

50.7

58.2

83.5

149

174

A

.25

.31

.38

.50

.50

.63

.63

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

J

Open

11.94

13.92

17.56

19.94

32.23

21.72

34.06

23.24

35.64

47.64

36.70

49.17

26.24

38.24

50.24

62.84

42.14

54.14

66.70

44.24

56.24

68.86

57.38

69.38

75.68

79.18

81.34

K

Closed

7.94

9.42

11.56

13.94

20.23

15.72

22.06

17.24

23.64

29.64

24.70

31.17

20.24

26.24

32.24

38.84

30.14

36.14

42.70

32.24

38.24

44.86

39.38

45.38

51.68

55.18

57.34

M

Open

12.38

14.48

18.24

20.82

33.11

22.72

35.06

24.50

36.90

48.90

38.20

50.67

28.00

40.00

52.00

64.60

44.38

56.38

68.94

46.74

58.74

71.36

60.38

72.38

79.18

83.18

85.84

Dimensions

(in.)

N

Closed

8.38

9.98

12.24

14.82

21.11

16.72

23.06

18.50

24.90

30.90

26.20

32.67

22.00

28.00

34.00

40.60

32.38

38.38

44.94

34.74

40.74

47.36

42.38

48.38

55.18

59.18

61.84

R

.81

.95

1.13

1.41

1.41

1.80

1.80

2.09

2.09

2.09

2.38

2.38

3.00

3.00

3.00

3.00

3.59

3.59

3.59

4.09

4.09

4.09

4.65

4.65

5.81

6.49

7.00

S

.34

.44

.53

.71

.71

.88

.88

1.00

1.00

1.00

1.25

1.25

1.43

1.43

1.43

1.43

1.82

1.82

1.82

2.12

2.12

2.12

2.38

2.38

2.69

3.12

3.25

X

Closed

1.76

2.20

2.48

3.56

3.54

4.35

4.34

5.12

5.09

5.12

5.79

5.79

6.50

6.50

6.50

6.47

8.49

8.49

8.49

9.46

9.46

9.46

9.97

9.97

13.03

13.76

15.09

BB

4.07

4.58

6.10

6.03

12.36

6.03

12.39

6.13

12.59

18.53

12.16

18.63

6.18

12.18

18.18

24.84

12.06

18.06

24.62

12.32

18.32

24.94

18.37

24.37

24.48

24.60

24.65

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

163

Rigging_eng.fm Page 164 Thursday, November 13, 2008 1:27 PM

Jaw & Eye Turnbuckles

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckles eyes are forged and elongated, by design, to maximize easy attachment in

system and minimize stress in the eye. For turnbuckles size 1/4" through 2-1/2", a shackle

one size smaller can be reeved through eye.

Forged jaw ends are fitted with bolts and nuts for 1/4" through 5/8", and pins and cotters

on 3/4" through 2-3/4" sizes.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Lock Nuts available for all sizes (see page 170).

Comprehensive End fitting data on pages 167 & 168.

Fatigue Rated.

HG-227

s e l k c u b n r u T

e y E

&

w a J

Meets the performance requirements of Federal

Specifications FF-T-791b, Type 1, Form 1 - CLASS 8,

and ASTM F-1145, except for those provisions

required of the contractor. For additional information, see page 391.

HG-227

Jaw & Eye

Thread

Dia. &

Take Up

(in.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

HG2 7

HG-227

Stock No.

1031877

1031895

1031911

1031939

1031957

1031975

1031993

1032019

1032037

1032055

1032073

1032091

1032117

1032135

1032153

1032171

1032199

1032215

1032233

1032251

1032279

1032297

1032313

1032331

1032359

1032395

1032411

1032439

1032457

1032475

Working

Load

Limit

(lbs.)*

500

800

1200

2200

2200

2200

3500

3500

3500

5200

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Weight

Each

(lbs.)

.33

.52

.80

1.77

2.25

2.67

2.98

3.72

4.35

4.51

5.56

6.42

8.14

9.10

11.6

10.0

13.4

16.7

20.6

20.9

24.8

28.8

30.6

36.0

41.5

52.1

59.7

89.9

158

187

A

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

B

.45

.50

.53

.64

.64

.64

.79

.79

.79

.97

.97

.97

.97

1.16

1.16

1.34

1.34

1.34

1.34

1.84

1.84

1.84

2.06

2.06

2.06

2.60

2.60

2.62

3.06

3.69

E

Closed

1.66

2.02

2.11

3.22

3.20

3.20

3.90

3.89

3.89

4.71

4.68

4.68

4.71

5.50

5.50

6.09

6.09

6.09

6.06

8.09

8.09

8.09

8.93

8.93

8.93

9.36

9.36

11.80

13.26

14.92

G

.64

.87

.85

1.07

1.07

1.07

1.32

1.32

1.32

1.52

1.52

1.52

1.52

1.77

1.77

2.05

2.05

2.05

2.05

2.82

2.82

2.82

2.81

2.81

2.81

3.35

3.35

3.74

4.44

4.19

J

Open

11.57

13.50

16.91

19.30

25.59

31.59

20.73

27.07

33.07

22.17

28.57

34.57

46.57

35.68

48.15

25.03

37.03

49.03

61.63

40.76

52.76

65.32

42.50

54.50

67.12

55.37

67.37

72.66

76.08

78.05

Dimensions

(in.)

K

M

Closed Open

7.57 12.28

9.00 14.30

10.91 17.87

13.30 20.48

16.59 26.77

19.59 32.77

14.73 22.27

18.07 28.61

21.07 34.61

16.17 24.09

19.57 30.49

22.57 36.49

28.57 48.49

23.68 37.91

30.15 50.38

19.03 27.59

25.03 39.59

31.03 51.59

37.63 64.19

28.76 43.98

34.76 55.98

41.32 68.54

30.50 46.21

36.50 58.21

43.12 70.83

37.37 59.77

43.37 71.77

48.66 77.95

52.08 82.68

54.05 85.67

N

Closed

8.28

9.80

11.87

14.48

17.77

20.77

16.27

19.61

22.61

18.09

21.49

24.49

30.49

25.91

32.38

21.59

27.59

33.59

40.19

31.98

37.98

44.54

34.21

40.21

46.83

41.77

47.77

53.95

58.68

61.67

R

.81

.95

1.13

1.41

1.41

1.41

1.80

1.80

1.80

2.09

2.09

2.09

2.09

2.38

2.38

3.00

3.00

3.00

3.00

3.59

3.59

3.59

4.09

4.09

4.09

4.65

4.65

5.81

6.49

7.00

S

.34

.44

.53

.71

.71

.71

.88

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.43

1.43

1.43

1.43

1.82

1.82

1.82

2.12

2.12

2.12

2.38

2.38

2.69

3.12

3.25

X

Closed

1.76

2.20

2.48

3.56

3.54

3.54

4.35

4.34

4.34

5.12

5.09

5.09

5.12

5.79

5.79

6.50

6.50

6.50

6.47

8.49

8.49

8.49

9.46

9.46

9.46

9.97

9.97

13.03

13.76

15.09

BB

4.07

4.58

6.10

6.03

9.36

12.36

6.03

9.39

12.39

6.13

9.59

12.59

18.53

12.16

18.63

6.18

12.18

18.18

24.84

12.06

18.06

24.62

12.32

18.32

24.94

18.37

24.37

24.48

24.60

24.65

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

164

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

Rigging_eng.fm Page 165 Thursday, November 13, 2008 1:33 PM

Jaw & Jaw Turnbuckles

s e l k c u b n r u T

w a J

&

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Forged jaw ends are fitted with bolts and nuts for 1/4" through 5/8", and pins and cotters

on 3/4" through 2-3/4" sizes.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

Lock Nuts available for all sizes (see page 170).

Comprehensive end fitting data provided on page 168.

Fatigue Rated.

w a J

Rigging

Accessories

HG-228

Meets the performance requirements of Federal

Specifications FF-T-791b,Type 1, Form 1 - CLASS 7,

and ASTM F-1145, except for those provisions

required of the contractor. For additional information, see page 391.

HG-228

Jaw & Jaw

Thread

Dia. &

Take Up

(in.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

HG2 8

HG-228

Stock No.

1032493

1032518

1032536

1032554

1032572

1032590

1032616

1032634

1032652

1032670

1032698

1032714

1032732

1032750

1032778

1032796

1032812

1032830

1032858

1032876

1032894

1032910

1032938

1032956

1032974

1033018

1033036

1033054

1033072

1033090

Working

Load

Limit

(lbs.)*

500

800

1200

2200

2200

2200

3500

3500

3500

5200

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Weight

Each

(lbs.)

.37

.56

.85

1.82

2.29

2.71

3.21

3.95

4.58

4.80

5.85

6.72

8.45

9.37

11.8

10.4

13.8

17.1

21.0

21.9

25.9

29.8

32.6

38.0

43.5

53.5

61.1

96.3

167

199

A

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

B

.45

.50

.53

.64

.64

.64

.79

.79

.79

.97

.97

.97

.97

1.16

1.16

1.34

1.34

1.34

1.34

1.84

1.84

1.84

2.06

2.06

2.06

2.60

2.60

2.62

3.06

3.69

E

Closed

1.66

2.02

2.11

3.22

3.20

3.20

3.90

3.89

3.89

4.71

4.68

4.68

4.71

5.50

5.50

6.09

6.09

6.09

6.06

8.09

8.09

8.09

8.93

8.93

8.93

9.36

9.36

11.80

13.26

14.92

G

.64

.87

.85

1.07

1.07

1.07

1.32

1.32

1.32

1.52

1.52

1.52

1.52

1.77

1.77

2.05

2.05

2.05

2.05

2.82

2.82

2.82

2.81

2.81

2.81

3.35

3.35

3.74

4.44

4.19

Dimensions

(in.)

J

K

Open

Closed

11.19

7.19

13.07

8.57

16.25

10.25

18.65

12.65

24.94

15.94

30.94

18.94

19.74

13.74

26.08

17.08

32.08

20.08

21.09

15.09

27.49

18.49

33.49

21.49

45.49

27.49

34.65

22.65

47.12

29.12

23.82

17.82

35.82

23.82

47.82

29.82

60.42

36.42

39.37

27.37

51.37

33.37

63.93

39.93

40.76

28.76

52.76

34.76

65.38

41.38

53.35

35.35

65.35

41.35

69.64

45.64

72.97

48.97

74.75

50.75

M

Open

12.18

14.12

17.50

20.14

26.43

32.43

21.82

28.16

34.16

23.68

30.08

36.08

48.08

37.62

50.09

27.18

39.18

51.18

63.78

43.58

55.58

68.14

45.68

57.68

70.30

59.16

71.16

76.72

82.18

85.50

N

Closed

8.18

9.62

11.50

14.14

17.43

20.43

15.82

19.16

22.16

17.68

21.08

24.08

30.08

25.62

32.09

21.18

27.18

33.18

39.78

31.58

37.58

44.14

33.68

39.68

46.30

41.16

47.16

52.72

58.18

61.50

BB

4.07

4.58

6.10

6.03

9.36

12.36

6.03

9.39

12.39

6.13

9.59

12.59

18.53

12.16

18.63

6.18

12.18

18.18

24.84

12.06

18.06

24.62

12.32

18.32

24.94

18.37

24.37

24.48

24.60

24.65

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

165

Rigging_eng.fm Page 166 Thursday, November 13, 2008 1:43 PM

Turnbuckle - Hook End Fittings

Quenched and Tempered.

Hot Dip galvanized steel.

Hooks are forged with a greater cross sectional area that results in a stronger hook with

better fatigue properties.

Modified UNJ thread for improved fatigue properties.

Fatigue Rated.

HOOK

END FITTINGS

s g n i t t i F

d n E

k o o H

e l k c u b n r u T

HG-4037

Hook End Fittings

Shank

Dia. &

Take Up

(in.)

* 1/4 x 4

* 5/16 x 4-1/2

* 3/8 x 6

1/2 x 6

1/2 x 12

5/8 x 6

5/8 x 12

3/4 x 6

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

RHHo k

RH Hook

Stock No.

1070012

1070030

1070058

1070076

1070110

1070138

1070174

1070192

1070236

1070254

1070272

1070290

1070316

1070334

LH Hook

Stock No.

1070539

1070557

1070575

1070593

1070637

1070655

1070691

1070717

1070753

1070771

1070799

1070815

1070833

1070851

Working

Load

Limit

(lbs.)

400

700

1000

1500

1500

2250

2250

3000

3000

3000

4000

4000

5000

5000

Weight

Each

(lbs.)

.09

.15

.27

.59

.75

1.05

1.31

1.35

2.13

2.51

3.12

3.62

3.96

4.72

Dimensions

(in.)

A

.25

.31

.38

.50

.50

.63

.63

.75

.75

.75

.88

.88

1.00

1.00

B

.25

.31

.38

.50

.50

.63

.63

.75

.75

.75

.88

.88

1.00

1.00

C

.41

.50

.61

.78

.78

1.00

1.00

1.21

1.21

1.21

1.37

1.37

1.53

1.53

D

.44

.50

.56

.65

.65

.90

.84

.98

.98

.98

1.13

1.13

1.25

1.25

F

1.27

1.50

1.76

2.28

2.28

2.81

2.81

3.33

3.33

3.33

3.78

3.78

4.25

4.25

G

.50

.56

.62

.82

.82

1.00

1.00

1.13

1.13

1.13

1.26

1.26

1.38

1.38

H

2.59

3.00

3.88

4.19

7.19

4.44

7.44

4.56

7.56

10.56

7.81

10.81

5.06

8.06

I

3.44

4.01

5.00

6.19

9.19

6.75

9.75

7.43

10.43

13.43

11.13

14.13

8.84

11.84

L

4.10

4.79

5.92

7.38

10.38

8.25

11.25

9.20

12.20

15.20

13.13

16.13

11.06

14.06

* Mechanical Galvanized

166

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

Turnbuckle - Eye End Fittings

Quenched and Tempered.

Hot Dip galvanized steel.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckle sizes 1/4" through 2-1/2", a shackle one

size smaller can be reeved through eye.

Modified UNJ thread for improved fatigue properties.

Fatigue Rated.

EYE

END FITTINGS

s g n i t t i F

d n E

e y E

e l k c u b n r u T

HG-4037

Eye End Fittings

RHEye

RH Eye

Stock No.

1071057

1071075

1071093

1071119

1071137

1071155

1071173

1071191

1071217

1071235

1071253

1071271

1071299

1071315

1071333

1071351

1071379

1071397

1071413

1071431

1071459

1071477

1071495

1071510

1071538

1071574

1071592

1071618

1071636

1071654

LH Eye

Stock No.

1071672

1071690

1071716

1071734

1071752

1071770

1071798

1071814

1071832

1071850

1071878

1071896

1071912

1071930

1071958

1071976

1071994

1072010

1072038

1072056

1072074

1072092

1072118

1072136

1072154

1072190

1072216

1072234

1072252

1072270

Working

Load

Limit

(lbs.)

500

800

1200

2200

2200

2200

3500

3500

3500

5200

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Weight

Each

(lbs.)

.07

.13

.23

.51

.59

.68

.82

.95

1.08

1.36

1.55

1.73

2.10

2.61

3.12

3.15

3.81

4.48

5.15

7.07

8.12

9.16

10.3

11.8

13.3

17.5

19.5

28.9

46.4

60.2

Dimensions

(in.)

A

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

H

2.59

3.00

3.88

4.19

5.69

7.19

4.44

5.94

7.44

4.56

6.06

7.56

10.56

7.81

10.81

5.06

8.06

11.06

14.06

8.38

11.38

14.38

8.75

11.75

14.75

12.16

15.16

15.59

17.56

17.69

R

.81

.95

1.13

1.41

1.41

1.41

1.80

1.80

1.80

2.09

2.09

2.09

2.09

2.38

2.38

3.00

3.00

3.00

3.00

3.59

3.59

3.59

4.09

4.09

4.09

4.65

4.65

5.81

6.50

7.00

S

.34

.44

.53

.71

.71

.71

.88

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.43

1.43

1.43

1.43

1.82

1.82

1.82

2.12

2.12

2.12

2.38

2.38

2.69

3.12

3.25

U

.22

.28

.34

.44

.44

.44

.50

.50

.50

.63

.63

.63

.63

.75

.75

.88

.88

.88

.88

1.12

1.12

1.12

1.25

1.25

1.25

1.50

1.50

1.75

2.00

2.25

V

.78

1.00

1.21

1.59

1.59

1.59

1.88

1.88

1.88

2.26

2.26

2.26

2.26

2.75

2.75

3.19

3.19

3.19

3.19

4.06

4.06

4.06

4.62

4.62

4.62

5.38

5.38

6.19

7.12

7.75

W

4.19

4.99

6.12

7.41

8.91

10.41

8.36

9.86

11.36

9.25

10.75

12.25

15.25

13.10

16.10

11.00

14.00

17.00

20.00

16.19

19.19

22.19.

17.37

20.37

23.37

21.19

24.19

27.59

29.59

30.92

* Mechanical Galvanized

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

167

Rigging

Accessories

Shank

Dia. &

Take Up

(in.)

* 1/4 x 4

* 5/16 x 4 1/2

* 3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

Turnbuckle - Jaw End Fittings

Quenched and Tempered.

Hot dip galvanized steel.

Forged jaw ends are fitted with bolts and nuts on sizes 1/4" through 5/8", and pins and

cotters on sizes 3/4" through 2-3/4".

Modified UNJ thread for improved fatigue properties.

Fatigue Rated.

JAW

END FITTINGS

s g n i t t i F

d n E

w a J

e l k c u b n r u T

HG-4037

Jaw End Fittings

Shank

Dia. &

Take Up

(in.)

* 1/4 x 4

* 5/16 x 4 1/2

* 3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

RH Jaw

RH Jaw

Stock No.

1072298

1072314

1072332

1072350

1072378

1072396

1072412

1072430

1072458

1072476

1072494

1072519

1072537

1072555

1072573

1072591

1072617

1072635

1072653

1072671

1072699

1072715

1072733

1072751

1072779

1072813

1072831

1072859

1072877

1072895

LH Jaw

Stock No.

1072911

1072939

1072957

1072975

1072993

1073019

1073037

1073055

1073073

1073091

1073117

1073135

1073153

1073171

1073199

1073215

1073233

1073251

1073279

1073297

1073313

1073331

1073359

1073377

1073395

1073439

1073457

1073475

1073493

1073518

Working

Load

Limit

(lbs.)

500

800

1200

2200

2200

2200

3500

3500

3500

5200

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Dimensions

(in.)

Weight

Each

(lbs.)

.11

.17

.28

.56

.63

.72

1.05

1.18

1.31

1.65

1.84

2.03

2.41

2.88

3.25

3.56

4.22

4.89

5.56

8.10

9.14

10.2

12.3

13.8

15.3

18.9

21.0

35.3

55.8

72.4

A

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

B

.45

.50

.53

.64

.64

.64

.79

.79

.79

.97

.97

.97

.97

1.16

1.16

1.34

1.34

1.34

1.34

1.84

1.84

1.84

2.06

2.06

2.06

2.60

2.60

2.62

3.06

3.69

C

.91

1.02

1.15

1.36

1.36

1.36

1.75

1.75

1.75

2.09

2.09

2.09

2.09

2.56

2.56

2.76

2.76

2.76

2.76

3.72

3.72

3.72

4.16

4.16

4.16

4.66

4.66

5.61

5.84

6.57

D

.30

.30

.36

.42

.42

.42

.55

.55

.55

.69

.69

.69

.69

.81

.81

.94

.94

.94

.94

1.19

1.19

1.19

1.47

1.47

1.47

1.72

1.72

2.09

2.38

2.88

F

.63

.69

.81

1.00

1.00

1.00

1.31

1.31

1.31

1.63

1.63

1.63

1.63

1.88

1.88

2.12

2.12

2.12

2.12

2.63

2.63

2.63

3.12

3.12

3.12

3.50

3.50

4.19

5.62

6.12

H

2.59

3.00

3.88

4.19

5.69

7.19

4.31

5.81

7.31

4.56

6.06

7.56

10.56

7.81

10.81

5.06

8.06

11.06

14.06

8.38

11.38

14.38

8.75

11.75

14.75

12.16

15.16

15.59

17.20

17.35

I

Nom.

Min.

3.72

4.41

5.28

6.51

8.01

9.51

7.12

8.62

10.12

7.86

9.36

10.86

13.86

11.70

14.70

9.35

12.35

15.35

18.35

14.25

17.25

20.25

15.07

18.07

21.07

18.49

21.49

23.82

25.61

26.75

L

Nom.

Min.

4.09

4.81

5.75

7.07

8.57

10.07

7.91

9.41

10.91

8.84

10.34

11.84

14.84

12.81

15.81

10.59

13.59

16.59

19.59

15.79

18.79

21.79

16.84

19.84

22.84

20.58

23.58

26.36

29.09

30.75

Y

1.13

1.39

1.47

1.81

1.81

1.81

2.36

2.36

2.36

2.81

2.81

2.81

2.81

3.25

3.25

3.73

3.73

3.73

3.73

4.92

4.92

4.92

5.27

5.27

5.27

6.25

6.25

7.28

9.04

9.56

MM

1.41

1.41

1.58

1.87

1.87

1.87

2.44

2.44

2.44

2.56

2.56

2.56

2.56

3.09

3.09

3.44

3.44

3.44

3.44

4.53

4.53

4.53

5.13

5.13

5.13

6.00

6.00

6.88

7.50

8.38

OO

Bolt

Pin

.25

.25

.31

.37

.37

.37

.50

.50

.50

.63

.63

.63

.63

.75

.75

.88

.88

.88

.88

1.13

1.13

1.13

1.38

1.38

1.38

1.63

1.63

2.00

2.25

2.75

* Mechanical Galvanized

168

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

Turnbuckles - Body Only

HG-2510 BODY

y l n O

y d o B

Heat treat by normalizing.

Hot Dip galvanized.

UNC threads

Fatigue Rated.

Meets the performance requirements of Federal Specifications FF-T-791b,

Type 1, Form 1 - Class 2, except for those provisions required by the contractor.

s e l k c u b n r u T

Contain Center Rib

HG-2510

HG-2510

Stock No.

1033893

1033919

1033937

1033955

1033973

1033991

1034017

1034035

1034053

1034071

1034099

1034115

1034133

1034179

1034197

1034213

1034231

1034259

1034277

1034339

1034357

1034375

1034437

1034455

1034473

1034552

1034570

1034632

1034678

1034696

Working

Load

Limit

(lbs.)

500

800

1200

2200

2200

2200

3500

3500

3500

5200

5200

5200

5200

7200

7200

10000

10000

10000

10000

15200

15200

15200

21400

21400

21400

28000

28000

37000

60000

75000

Weight

Each

(lbs.)

.15

.22

.29

.70

1.03

1.27

1.11

1.59

1.96

1.50

2.17

2.66

3.63

3.61

5.27

3.32

5.34

7.35

9.85

5.72

7.58

9.45

8.01

10.4

12.9

15.7

19.2

25.8

55.9

54.0

Dimensions

(in.)

AA

4.87

5.59

7.29

7.70

11.03

14.03

8.02

11.38

14.38

8.26

11.72

14.72

20.66

14.62

21.09

9.00

15.00

21.00

27.66

15.40

21.40

27.96

15.82

21.82

28.45

22.44

28.44

29.13

31.66

31.66

BB

4.07

4.58

6.10

6.03

9.36

12.36

6.03

9.39

12.39

6.13

9.59

12.59

18.53

12.16

18.63

6.18

12.18

18.18

24.84

12.06

18.06

24.62

12.32

18.32

24.94

18.37

24.37

24.48

24.60

24.65

CC

.40

.51

.60

.84

.84

.84

1.00

1.00

1.00

1.07

1.07

1.07

1.07

1.23

1.23

1.41

1.41

1.41

1.41

1.67

1.67

1.67

1.75

1.75

1.75

2.04

2.04

2.33

3.53

3.51

DD

.72

.82

.88

1.19

1.19

1.19

1.43

1.43

1.43

1.74

1.74

1.74

1.74

2.00

2.00

2.45

2.45

2.45

2.45

2.62

2.62

2.62

2.99

2.99

2.99

3.62

3.62

4.14

5.62

5.62

EE

.34

.38

.38

.68

.68

.68

.83

.83

.83

.94

.94

.94

.94

1.13

1.13

1.25

1.25

1.25

1.25

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.75

2.75

GG

.50

.56

.63

.81

.81

.81

1.00

1.00

1.00

1.13

1.13

1.13

1.13

1.31

1.31

1.50

1.50

1.50

1.50

1.88

1.88

1.88

2.25

2.25

2.25

2.62

2.62

3.00

3.88

3.88

HH

.38

.44

.50

.63

.63

.63

.75

.75

.75

.94

.94

.94

.94

1.06

1.06

1.25

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

1.75

2.12

2.12

2.38

3.12

4.48

JJ

.17

.19

.19

.28

.28

.28

.34

.34

.34

.40

.40

.40

.40

.47

.47

.60

.60

.60

.60

.56

.56

.56

.62

.62

.62

.75

.75

.88

1.25

1.25

* Mechanical Galvanized

Contains Center Rib for additional body support.

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

169

Rigging

Accessories

Shank

Dia. &

Take Up

(in.)

* 1/4 x 4

* 5/16 x 4-1/2

* 3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

Rigging_eng.fm Page 170 Thursday, November 13, 2008 1:54 PM

Stub End Turnbuckles

HS-251

s e l k c u b n r u T

d n E

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Complete assembly is self - colored.

Reference American Welding Society Specifications for proper welding procedures.

Meets the performance requirements of Federal Specifications FF-T-791b, Type 1

Form 1 - CLASS 3, and ASTM F-1145, except for those provisions required of the contractor.

b u t S

HS-251

Stub End Turnbuckles

Shank

Dia. &

Take up

(in.)

3/8 x 6

1/2 x 6

5/8 x 6

3/4 x 6

7/8 x 6

1x6

1 x 12

1-1/8 x 6

1-1/4 x 6

1-1/4 x 12

1-1/2 x 12

s t u N

HS-251

HS-251

Stock No.

1033143

1033161

1033223

1033287

1033367

1033429

1033447

1033508

1033526

1033544

1033642

Working

Load

Limit

(lbs.)

1200

2200

3500

5200

7200

10000

10000

12400

15200

15200

21400

Weight

Each

(lbs.)

.75

1.25

2.11

3.27

4.78

6.36

8.80

8.88

10.18

13.60

20.44

Dimensions

(in.)

A

.38

.50

.63

.75

.88

1.00

1.00

1.13

1.25

1.25

1.50

6.00

6.00

6.00

6.00

6.00

6.00

12.00

6.00

6.00

12.00

12.00

7.13

7.50

7.88

8.25

8.63

9.00

15.00

9.13

9.13

15.12

15.75

.56

.75

.94

1.13

1.31

1.50

1.50

1.56

1.56

1.56

1.88

U

4.44

4.25

4.06

4.38

4.69

5.00

5.00

4.94

5.44

5.44

5.38

W

16.00

16.00

16.00

17.00

18.00

19.00

25.00

19.00

20.00

26.00

26.50

k c o L

LOCK NUTS

HG-4060 / HG-4061

Lock Nuts

Dimensions

(in.)

HG-406

Thread

Diameter

(in.)

1/4

5/16

3/8

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-1/2

1-3/4

2

2-1/2

2-3/4

170

Right

Hand

HG-4060

Stock No.

1075115

1075133

1075151

1075197

1075213

1075231

1075259

1075277

1075295

1075311

1075357

1075393

1075419

1075455

1075473

Left

Hand

HG-4061

Stock No.

1075491

1075516

1075534

1075570

1075598

1075614

1075632

1075650

1075678

1075696

1075730

1075776

1075794

1075838

1075856

Weight

Per 100

(lbs.)

.80

1.30

2.00

4.00

7.00

11.00

16.30

23.80

32.00

62.50

72.00

112.00

150.00

330.00

425.00

P

.44

.50

.56

.75

.94

1.13

1.31

1.50

1.50

1.88

2.25

2.75

3.12

3.88

4.25

Q

.50

.56

.64

.86

1.06

1.26

1.50

1.69

1.69

2.13

2.53

3.18

3.61

4.47

4.91

.16

.19

.22

.31

.38

.42

.48

.55

.55

.72

.84

1.00

1.12

1.50

1.62

Copyright 2008 The Crosby Group, Inc.

All Rights Reserved

You might also like

- TurnbucklesDocument6 pagesTurnbucklesRonny Andalas100% (1)

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- Astm A 521Document10 pagesAstm A 521Mohammad SahmoudNo ratings yet

- Crosby ShacklesDocument18 pagesCrosby ShacklesAnjar DarundriyaNo ratings yet

- Tecnoplast SRL - Product ListDocument44 pagesTecnoplast SRL - Product Listbarino1966No ratings yet

- Bridon Offshore ExplorationDocument44 pagesBridon Offshore ExplorationAthox QhurienNo ratings yet

- Titan CG RelfDocument1 pageTitan CG RelfRuano Andreola StumpfNo ratings yet

- NOV Elevator Link CompatibilityDocument2 pagesNOV Elevator Link CompatibilityisamelgqNo ratings yet

- MANNUL of Double Ram BOP Cameron Type UDocument44 pagesMANNUL of Double Ram BOP Cameron Type URaouf Rasmy ShalabyNo ratings yet

- International Standard: Cranes - Inspections - GeneralDocument6 pagesInternational Standard: Cranes - Inspections - GeneralNational MarineNo ratings yet

- Galvanized Steel CableDocument3 pagesGalvanized Steel CableEdward van MartinoNo ratings yet

- Master Bushing-Insert Bowls - API 7KDocument2 pagesMaster Bushing-Insert Bowls - API 7KcristinelbNo ratings yet

- Rebuild KitDocument3 pagesRebuild KitMehdi SoltaniNo ratings yet

- Elevador Blohm & VossDocument55 pagesElevador Blohm & Vosspedro Luis100% (1)

- 1.8.1.1.11.2.3 Titan C Service Manual (NEW)Document70 pages1.8.1.1.11.2.3 Titan C Service Manual (NEW)WayneNo ratings yet

- API 4G - E5 Addendum 2Document4 pagesAPI 4G - E5 Addendum 2KATHERINE RIVERANo ratings yet

- Catalogo 511Document4 pagesCatalogo 511Luis Oswaldo R PNo ratings yet

- API Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)Document6 pagesAPI Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)hesam abbaszadehNo ratings yet

- Travelling Block YC-450 NOVDocument1 pageTravelling Block YC-450 NOVMohamed Medany100% (1)

- EN 13889 - 2008 - ShacklesDocument4 pagesEN 13889 - 2008 - ShacklesRoby MastreNo ratings yet

- Standards Update Notice (Sun) ISSUED: July 8, 2020Document3 pagesStandards Update Notice (Sun) ISSUED: July 8, 2020jklelvis100% (1)

- Pipe Handler Machine - 10909071-PIBDocument2 pagesPipe Handler Machine - 10909071-PIBPopovici AlexandruNo ratings yet

- Ansi A92 2Document19 pagesAnsi A92 2Bruno CoronelNo ratings yet

- NOV Anson - M95 Plug ValvesDocument23 pagesNOV Anson - M95 Plug ValvesRafael Perez100% (1)

- HH-Travling BlockDocument3 pagesHH-Travling Blockabdi rachman100% (2)

- BS 3701 1964Document12 pagesBS 3701 1964Mohamed FaroukNo ratings yet

- West TucanaDocument3 pagesWest TucanaSarfaraz PatelNo ratings yet

- 06d AppendixB4 (550HP) 1582536012902Document94 pages06d AppendixB4 (550HP) 1582536012902Harsh TiwariNo ratings yet

- Asme A90 1 2003Document38 pagesAsme A90 1 2003Fernando AguilarNo ratings yet

- DNV, TIFF TIN For Case-Hardened GearsDocument6 pagesDNV, TIFF TIN For Case-Hardened GearsPeter Carden100% (1)

- Aot GG (350 Ton) Bottleneck ElevatorDocument1 pageAot GG (350 Ton) Bottleneck ElevatorCarlig Radu MihaiNo ratings yet

- Wellhead Equipment CatalogDocument29 pagesWellhead Equipment CatalogDewy PambayunNo ratings yet

- Chapter06 TurnbucklesDocument14 pagesChapter06 TurnbucklesDylan RamasamyNo ratings yet

- RR C 271D PDFDocument58 pagesRR C 271D PDFRami GhorbelNo ratings yet

- Asme b30.9-2006 SlingsDocument4 pagesAsme b30.9-2006 Slingslagartoitla0% (1)

- MD Totco Electric Torque SystemDocument22 pagesMD Totco Electric Torque SystemFernando TovarNo ratings yet

- Figure Union Identification Instructions-NEWDocument4 pagesFigure Union Identification Instructions-NEWArgonauta_navegadorNo ratings yet

- Termination For Steel Wire Ropes-Safety - Ferrules and Ferrule-Securing BS-EN 13411-3 PDFDocument34 pagesTermination For Steel Wire Ropes-Safety - Ferrules and Ferrule-Securing BS-EN 13411-3 PDFMaazARazaNo ratings yet

- Ingersoll Rand Air Motors PDFDocument98 pagesIngersoll Rand Air Motors PDFVicctor PiñaNo ratings yet

- Titan Class Type "B" Reset Relief Valve Operations & Maintenance ManualDocument20 pagesTitan Class Type "B" Reset Relief Valve Operations & Maintenance ManualJuan LorenzoNo ratings yet

- M8 McKissick SheavesDocument18 pagesM8 McKissick Sheavesmahmoud heikal100% (1)

- GJ-204-016 Mud Pump 2 & 3 UpgradeDocument6 pagesGJ-204-016 Mud Pump 2 & 3 UpgradeKuna Stanbekov100% (1)

- Shaffer NOV Type 72 ShearsDocument2 pagesShaffer NOV Type 72 ShearsTitanBOP100% (1)

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Fa2.5i Fa5i Fa5ti PartsDocument52 pagesFa2.5i Fa5i Fa5ti Partsmohammad salleh100% (1)

- Usha Martin Wirerope HandbookDocument72 pagesUsha Martin Wirerope Handbookhaydarburedah100% (2)

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 pagesManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNo ratings yet

- DNV RP E101 (Jan2012) Re Certification of Well Equipment On Norwegian CSDocument18 pagesDNV RP E101 (Jan2012) Re Certification of Well Equipment On Norwegian CSNils Antoine FreundNo ratings yet

- NSL Loler MatrixDocument1 pageNSL Loler MatrixAndrew Grimes100% (1)

- Wire Rope Specification PDFDocument133 pagesWire Rope Specification PDFjgtkd74100% (1)

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesBoby ThomasNo ratings yet

- Turnbuckle Hook To EyeDocument1 pageTurnbuckle Hook To EyeeraswastaNo ratings yet

- Crosby G2140 ShackleDocument1 pageCrosby G2140 Shacklepgarrett775814233No ratings yet

- CrosbyDocument1 pageCrosbybdispoNo ratings yet

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Document1 pageCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupNo ratings yet

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1No ratings yet

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13No ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- R. Stahl Schaltgeräte GMBH Page 1 / 2 Data Sheet 27.08.2012Document2 pagesR. Stahl Schaltgeräte GMBH Page 1 / 2 Data Sheet 27.08.2012Midfiild CosminNo ratings yet

- LS 05S Spare Parts CatalogDocument9 pagesLS 05S Spare Parts CatalogMidfiild CosminNo ratings yet

- Foot ValvesDocument4 pagesFoot Valveskingathur26681No ratings yet

- Prosonic M FMU 40/41/42/43: Ultrasonic Level MeasurementDocument40 pagesProsonic M FMU 40/41/42/43: Ultrasonic Level MeasurementNova Ade KusumaNo ratings yet

- PS Portable GFCI Brochure 2012 PDFDocument4 pagesPS Portable GFCI Brochure 2012 PDFMidfiild CosminNo ratings yet

- R. Stahl Schaltgeräte GMBH Page 1 / 2 Data Sheet 27.08.2012Document2 pagesR. Stahl Schaltgeräte GMBH Page 1 / 2 Data Sheet 27.08.2012Midfiild CosminNo ratings yet

- Graco Hydra Clean Pump 312585E PDFDocument24 pagesGraco Hydra Clean Pump 312585E PDFMidfiild CosminNo ratings yet

- Stahl PDFDocument10 pagesStahl PDFMidfiild CosminNo ratings yet

- Oteco Rig Hardware Product BrochureDocument12 pagesOteco Rig Hardware Product BrochureMidfiild CosminNo ratings yet

- Spir Star Valves & Fittings PDFDocument26 pagesSpir Star Valves & Fittings PDFMidfiild CosminNo ratings yet

- Arc FlashDocument16 pagesArc FlashMidfiild Cosmin100% (1)

- Rigex - Hands Free Tools and Price ListDocument6 pagesRigex - Hands Free Tools and Price ListMidfiild CosminNo ratings yet

- Compact Range of Operators and Pilot Lights: SwitchesDocument1 pageCompact Range of Operators and Pilot Lights: SwitchesMidfiild CosminNo ratings yet

- Mahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportDocument5 pagesMahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportRavi LoveNo ratings yet

- Report On Monitoring and Evaluation-Ilagan CityDocument5 pagesReport On Monitoring and Evaluation-Ilagan CityRonnie Francisco TejanoNo ratings yet

- Transformational LeadershipDocument75 pagesTransformational LeadershipvincentpalaniNo ratings yet

- SQLDocument13 pagesSQLRadhakrishnan__7263No ratings yet

- 3 AcmeCorporation Fullstrategicplan 06052015 PDFDocument11 pages3 AcmeCorporation Fullstrategicplan 06052015 PDFDina DawoodNo ratings yet

- Investing in Granada's Property Market - Gaspar LinoDocument1 pageInvesting in Granada's Property Market - Gaspar LinoGaspar LinoNo ratings yet

- Synchronous Machines-1Document41 pagesSynchronous Machines-1Rouxcel abutoNo ratings yet

- Routine Maintenance For External Water Tank Pump and Circulation Pump On FID Tower and Rack 2017-014Document5 pagesRoutine Maintenance For External Water Tank Pump and Circulation Pump On FID Tower and Rack 2017-014CONVIERTE PDF JPG WORDNo ratings yet

- Category (7) - Installation and Maintenance of Instrumentation and Control SystemsDocument3 pagesCategory (7) - Installation and Maintenance of Instrumentation and Control Systemstafseerahmed86No ratings yet

- Schermer 1984Document25 pagesSchermer 1984Pedro VeraNo ratings yet

- Philpost RRDocument6 pagesPhilpost RRGene AbotNo ratings yet

- Ducati WiringDocument7 pagesDucati WiringRyan LeisNo ratings yet

- King Saud UniversityDocument10 pagesKing Saud UniversitypganoelNo ratings yet

- NATO Obsolescence Management PDFDocument5 pagesNATO Obsolescence Management PDFluisNo ratings yet

- Chapter 10 OutlineDocument3 pagesChapter 10 OutlineFerrari75% (4)

- Assignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementDocument3 pagesAssignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementGenithon PanisalesNo ratings yet

- Dash8 200 300 Electrical PDFDocument35 pagesDash8 200 300 Electrical PDFCarina Ramo LakaNo ratings yet

- Editor Attach 1327138073 1832Document59 pagesEditor Attach 1327138073 1832Monther Al DebesNo ratings yet

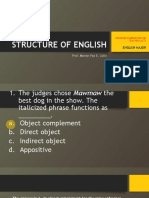

- LET-English-Structure of English-ExamDocument57 pagesLET-English-Structure of English-ExamMarian Paz E Callo80% (5)

- Bobcat E34 - E35Z Brochure - Adare MachineryDocument8 pagesBobcat E34 - E35Z Brochure - Adare MachineryNERDZONE TVNo ratings yet

- Hatayoga 1Document11 pagesHatayoga 1SACHIDANANDA SNo ratings yet

- Engine Stalls at Low RPM: Diagnostic CodesDocument3 pagesEngine Stalls at Low RPM: Diagnostic CodesAmir Bambang YudhoyonoNo ratings yet

- U2 KeyDocument2 pagesU2 KeyHằng ĐặngNo ratings yet

- History of Old English GrammarDocument9 pagesHistory of Old English GrammarAla CzerwinskaNo ratings yet

- Lesson 23 Career PathwaysDocument34 pagesLesson 23 Career PathwaysAlfredo ModestoNo ratings yet

- Merging Shapes - 10 Minutes To Better Painting - Episode 1Document12 pagesMerging Shapes - 10 Minutes To Better Painting - Episode 1Nguyên HàNo ratings yet

- Lugam Annex Elementary School Second Quarter Second Periodical Test in EPP 6 H.EDocument4 pagesLugam Annex Elementary School Second Quarter Second Periodical Test in EPP 6 H.Ejess amielNo ratings yet

- NCP - DMDocument4 pagesNCP - DMMonica Garcia88% (8)

- Sheet (8) Synchronous Machine Problem (1) :: SolutionDocument5 pagesSheet (8) Synchronous Machine Problem (1) :: Solutionمكاريوس عيادNo ratings yet

- Wood ReportDocument36 pagesWood Reportメルヴリッ クズルエタNo ratings yet