Professional Documents

Culture Documents

Chapter 10 Quality Assurance

Uploaded by

Diana Ahmad ZaidanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 10 Quality Assurance

Uploaded by

Diana Ahmad ZaidanCopyright:

Available Formats

Elite Batch 2012

Quality assurance

I-Quality control tests: are specific tests that are used to maintain and monitor dental

x-

ray equipment ,supplies,and film processing .why to do such tests? To avoid excess exposure of

patients and personnel to x-radiation.

-equipment and supplies

Quality control tests are necessary to monitor dental x-ray machines

,films, screens and cassettes ,and viewing equipment to produce diagnostic quality radiographs.

-dental x-ray machines

i-All dental x-ray machines must be inspected and monitored periodically also they must be calibrated and

adjusted for accuracy by a qualified technician to ensure consistent x-ray machine performance and the

production of diagnostic radiographs .

ii-some states and local agencies provide dental x-ray equipment inspection services as part of their

registration and licensing procedures .

iii- the American academy of dental radiology recommends a number of annual tests for dental x-ray

machine .these tests are designed to identify minor malfunction including :machine output variations

,inadequate collimation ,tubehead drift ,timing errors, inaccurate kilovoltage and milliamperage.

those tests are:1- focal spot size test. 2-half-value layer test. 3- collimation beam alignment test .4kilovoltage test . 5- milliamperage test. 6- x-ray output test. 7-timer test . 8-tubehead stability test .

iv-those annual tests can be performed by the dentist, the dental hygienist ,dental assistant ,manufacturers

service representative.

v- those annual tests requires: basic testing material ,film, test logs to record the results.

-dental x-ray film

Films must be properly stored, protected and used before expiration date .

For quality control purpose ,when each box of film is opened it should be tested for freshness .how to do

this? 1-prepare the film .unwrap one unexposed film from a newly opened box .

2-process the film .use fresh chemicals to process the unexposed film .

The results of this test can be interrupted as follows :

1-if the processed film appears clear with a slight blue tint,the film is freash.

2-if the processed film appears fogged .the film should not be used.

-screens and cassettes

page |1

Elite Dental Team

Elite Batch 2012

They must be examined periodically for the presence of any scratches (if there are any scratches it

should be replaced) or dirt.

Screens should be cleaned on a monthly basis with cleaner recommended by the manufacturer

then antistatic solution should be applied to it.

Cassette holders must be examined every month for worn closures ,light leaks, warping ,all which

lead to fogged and blurred radiographs ;these cassettes should be repaired or replaced ,also

cassettes should be checked for adequate film to screen contact.

The following film to screen contact test is recommended:

1- insert one film between the screens in the cassette holder.

2-place a wire mesh test object on top of the loaded cassette.

3-position the position-indicating device using a 40-inch target film, while directing the

central ray perpendicular to the cassette.

4- expose the film using a 10 mA ,70 kVp ,and 15 impulses.

5-processe the exposed film.

6-chech it on a view box in a dimly lit room at a distance of 6 ft.

The results of this test can be interpreted as follows;

-adequate contact:if the wire mesh image seen on the film exhibits a uniform density ,so

proceed with the screen and the cassette.

-inadequate contact : if the wire mesh image seen on the film exhibits varying densities

(poor film to screen contact ,those areas appear darker than good contact areas) ,so replace

or repair the cassette.

- viewing equipment

-What is the viewbox or illuminator? It is a light source that is used to view dental

radiographs and it is important for interpreting dental radiographs, it contains a florescent

light bulbs that emit light throw plastic or plexiglass front .

-To say this viewbox function properly it should emit a uniform and subdued light.to check

for this (the proper viewing brightness) we use a photographic light meter.

-The viewbox should be periodically examined for the presence of dirt on the plexiglass

surface and ny discoloration.

-The surface of the viewbox should be wiped clean every week.

page |2

Elite Dental Team

Elite Batch 2012

-Any permanently discolored plexiglass surface or blackened fluorescent light bulbs must be

replaced.

-film processing

-It is one of the most critical areas in quality control ,so it is monitored daily .

It has the potential to result in a large number of nondiagnostic radiographs.

-We must routinely perform a quality control tests to determine whether the conditions for

film processing are acceptable.

-darkroom lighting

-it must be checked for light-tightness monthly and for proper safelighting every 6 months

.the following light leak test is recommended for the darkroom:

1- prepare the darkroom.close the darkroom door,and turn off all lights ,including the

safelight.

2-examine the darkroom once your eyes become accustomed to the darkness,observe the

areas around the door,the seams of the walls and ceiling,the vent areas and the keyhole for

light leaks.

-the results of this test can be interpreted as following:

1-no light leaks.if the darkroom is light - tight .no visible light is seen.so proceed with film

processing.

2-light leaks,if present are seen around the door through the seams of the walls or ceiling or

through a vent or a keyhole .so you can eliminate those leaks using a stripping or black tap

before proceeding the film processing .

Note: only after the light-tightness has been established can the safelighting be checked .we

use the following safelighting test (coin test):

1-prepare the darkroom,turn off all lights including the safelights.

2-prepare the film.unwarp one unexposed film.place it on a flate surface at least 4 ft from

the safelight,place coin on top of the film.

3- turn on the safelights,allowing the coin and the film to be exposed to the safelights.

4- remove the coin and process the film

The results of this test can be interpreted as the following:

page |3

Elite Dental Team

Elite Batch 2012

-proper safelighting.if no visible image is seen on the processed radiograph.this means that

safelight is correct so proceed with the film proessing.

-improper safelighting.if the image of the coin and the fogged background appear on the

processed radiograph,so the safelighting is not safe to use with this type of films.

* to avoid safelighting problems we must:

1-use the film manufacturer's recommended safelightfilters an bulb wattages 2- the film

must be unwrapped at least 4 ft away from the safelight.

*safelight problems must be corrected before proceeding the film processing.

7-processing equipment

-those equipment must be meticulously maintained and monitored daily.

-thermometer,developer,tempreture, level of water bath ,fixer solutions and timer must be

checked for accuracy with manual processing technique.

- the processing time and temperature recommendations of the film manufacturer must be

strictly followed.

-if you are using an automatic processing equipment ,we must check the water circulation

system and we must monitor the solution level ,the replenishment system and the

temperature .

-the manufacturer's procedure and maintenance directions must be followed carefully.

-each day 2 films must be tested in the automatic processor.the following automatic

processor test films is recommended:

1-prepare the films. Unwrap two unexposed films and expose one of them to light.

2- process both films in the automatic processor

The results can be interrupted as following:

-functioning processor. If the unexposed film appears clear and dry and the exposed to light film

appears dark and dry.so proceed with processing.

-nonfunctioning processor. If the unexposed film does not appear clear and dry and the exposed to

light film does not clearly appear dark and dry.so the processing solutions and dryer temperature

must be checked and corrections must be done before proceeding the processing.

8-processing solutions

Monitoring processing solutions is the most critical component of film processing quality control.

page |4

Elite Dental Team

Elite Batch 2012

-the processing solution must be replenished daily and changed every 3to 4 weeks as

recommended by the manufacturer.

-we can use quality control tests as an alternative to using the calendar to determine the freshness

of solutions.

-processing solutions must be evaluated each day before any patient films are processed.

-developer strength .when developer solutions loses strength ,the time temperature

recommendations of manufacturer can no longer be used as the standard of measurements . if you

want to check the strength of developer solutions is to compare film densities to a standard.and

one of the following tests can be used (for more details see table 10-1 in the book ,page 115):

I-reference radiograph: is one that is processed under ideal conditions and then used to compare

the film densities of radiographsthat are processed daily.the following teps can be taken to create a

refrane radiograph:

1-preparethe film.use fresh film to mke a refrance radiograph.

2-expose the film,using correct exposure factors.

3- process the film ,using fresh chemicals at the recommended time and temperature.

4- view the reference radiograph and the daily radiographs side on a viewbox.then compare

densities on reference radiograph with the densities on the daily radiograph.and this can be

interrupted as follows:

-matched densities: if the densities of reference and daily radiographs are matched ,the strength of

developer solution is adequate ,proceed the processing.

-unmatched densities: : if the densities of reference and daily radiographs are unmatched( daily

radiographs appears lighter ;the developer solution is even weak or cold but if the daily radiograph

appear darker; the developer solution is too concentrated or too warm).in the case of weak or

concentrated solution replace the developer solution ,but in the case of warm or cold solution the

temperature must be adjusted.

II-stepwedge radiograph: is a device constructed of layered Aluminum steps.when a stepwedge is

placed on top of a film and then exposed to x-ray ,the different steps absorb varying amounts of xray.when processed ,different film densities are seen .the following steps can be taken to create

stepwedge radiograph:

1-prepare the film.use a 20 fresh films to create a supply of films for daily testing.place an

aluminum stepwedge on top of one film.

2-expose the film. Repeate those two steps for the rest of the 20 films.

page |5

Elite Dental Team

Elite Batch 2012

3-using fresh chemicals ,process only one of the exposed films.this radiograph will exhibit a

different densities as result of using stepwedge(it is called standard stepwedge radiograph)

4-store the remaining 19 exposed films in a cool ,dry area protected from x-ray.

5-each day,after the chemicals have been replenished, process one of the exposed stepwedge

films.

6-- view the standard radiograph and the daily radiographs side by side on a viewbox .then

compare densities seen on standaredradiograph with the densities on the daily one.and results can

be interpreted as follows:

-matched densities:use the middle density seen on the standard stepwedge radiograph , if the

densities of standared and daily radiographs are matched ,the strength of developer solution is

adequate ,proceed the processing.

-unmatched densities: : if the density of daily radiograph is different from the standard by more

than 2 steps on the stepwedge .the developer solution must be changed.

III-normalizing device:it can be used to monitor developer strength and film densities,and it is

commercially available

Now,we will talk about fixer strength: fixer solution removes the unexposed silver halide crystals

on the film that results in clear areas on the processed film.if the fixer becomes weak the film takes

aa longer time to clear or to become transparent in the un exposed area ,but if it was strong the

film will be clear in 2 minuteswithout agitation.to monitor the fixer solution a clear test can be

done:

1-prepare the film.unwrap the film and immediately place it in the fixer solution.

2-check the film for clearing ,measure the time needed for clearing.

The results can be interpreted as follows:

-fast clearing .if the film clears in 2 min the fixer strength is adequate .proceed the processing.

-slow clearing.if the film is not completely clear within 2 min ,re-immerse in the fixer,if the film does

not completely clear within 3-4 min,the fixer is depleted and must be replaced

-

9- digital imaging

page |6

Elite Dental Team

Elite Batch 2012

-along with annual tests for the calibrations of the imaging equipment ,the receptors (whether for

direct or indirect imaging) also require periodic examination for bending ,scratching, and general

wear and tear.

-since digital sensors and imaging plates are used multiple times ,greater care in handling and

cleaning of the sensors.

-the damaged (by debris or bending) imaging sensors shows the same artifacts repeatedly.

-if there is any signs of separation from the sensor or deterioration ,the dental professionals who

use direct digital imaging must inspect the wired connection.

-commercial kits that are available include a set of test objects ,which can be used quickly and easily

on an ongoing basis to check the imaging performance, particularly those aspect that are subject to

deterioration.

-those kits allow for the following checks ;

Image retention ,sensitivity ,uniformity ,erasure cycle efficiency ,scaling errors ,blurring artifacts,

and resolution .

II-quality administration procedures

Definition: it is the management of the quality assurance plan in the dental office.

-the basic element of of a quality administration program include the following:

1-description of the plan: it should be on file and made available to all participating staff members(

staff members must plan must understand the standards of quality , the purpose and the

importance of maintaining quality control ) ,the standards of quality must be outlined by the

dentist.

2-assignment of duties: it should be on file and made available to all participating staff members

,each staff member assigned to perform a duty must understand the purpose and importance of

that specific duty.

3-monitoring schedule :this schedule must be posted in the office and it must contain all quality

control tests and the frequency of testing for all dental x-ray equipment ,supplies ,and film

processing.

4-maintainence schedule :this schedule must be posted in the office ,and it must contain the

routine service and inspection of dental x-ray machines and processing equipment.

5-record-keeping log : it should carefully maintained and kept o file in dental office and it should

contain all quality control tests including; the test performed, the date performed ,and the test

page |7

Elite Dental Team

Elite Batch 2012

results also it should contain processing solutions which lists the dates of solution replacement

,replenishment , and processor or tank cleaning.

6-plan for evaluation and revision: it should be a part of the quality administration plan.

7-In-service training :it is recommended periodically for staff members to upgrade and improve xray exposure techniques and film processing procedure.

III-operator competence

-the dentist is ultimately the responsible for the overall quality assurance plan ,also the dentist is

responsible for the diagnostic quality for all radiographs regardless of who expose and process the

films.

- to ensure the production of diagnostic radiographs ,the dentist depends on the skills of competent

dental radiographer ,who is competent in both exposure and processing techniques.

- if a nondiagnostic image was produced,the operator must retake the image ,and the number of

retakes must be kept to an absolute minimum .

That's all

Thank you

Done by :hadeel aljarrah

page |8

Elite Dental Team

You might also like

- Final MIT Logbook JamilDocument15 pagesFinal MIT Logbook Jamilammar-nasir3314No ratings yet

- Assignment Intensifying ScreenDocument7 pagesAssignment Intensifying ScreenYõüñg SyrüxNo ratings yet

- Oral RadiologyDocument15 pagesOral RadiologymirfanulhaqNo ratings yet

- X-Ray Film Processing InformationDocument2 pagesX-Ray Film Processing InformationSatish PaswanNo ratings yet

- Utz Relevant Terminologiespdf PDFDocument47 pagesUtz Relevant Terminologiespdf PDFAmanda LoveNo ratings yet

- X-Ray Intensifying Screens: Prof. J.K Tonui, PHDDocument42 pagesX-Ray Intensifying Screens: Prof. J.K Tonui, PHDLajja Parikh PatelNo ratings yet

- The X-Ray Film and Other Image ReceptorsDocument29 pagesThe X-Ray Film and Other Image ReceptorsbontleNo ratings yet

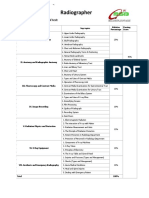

- Radiographer Exam Content and ReferencesDocument2 pagesRadiographer Exam Content and ReferencesJashim Jumli IINo ratings yet

- General Radio Graphic Image QualityDocument9 pagesGeneral Radio Graphic Image QualityRouben ParmanumNo ratings yet

- 2012 ASTRO Radiation and Cancer Biology Practice Examination and Study Guide PDFDocument193 pages2012 ASTRO Radiation and Cancer Biology Practice Examination and Study Guide PDFKoustav Majumder100% (2)

- The Safe Use of Fluoroscopy: Radiation Protection Ala' ThawabtehDocument41 pagesThe Safe Use of Fluoroscopy: Radiation Protection Ala' ThawabtehDiaa AyobNo ratings yet

- Review of Radiographic Techniques For The Paediatric PatientDocument50 pagesReview of Radiographic Techniques For The Paediatric Patientapi-3775747100% (3)

- Physical Characteristics of X Ray FilmDocument29 pagesPhysical Characteristics of X Ray Filmbalak1127No ratings yet

- X-Ray Film, Intensifying Screens and Grids PDocument37 pagesX-Ray Film, Intensifying Screens and Grids PprasadNo ratings yet

- 7368693Document56 pages7368693Mylena Ch100% (1)

- SkeletaxrayDocument144 pagesSkeletaxrayradiologgNo ratings yet

- US OB Review (#1 - 61)Document205 pagesUS OB Review (#1 - 61)Júlio Muniz100% (1)

- I. RadiologyDocument13 pagesI. RadiologyBobohNo ratings yet

- 2 Fundamental Principles of RadiobiologyDocument28 pages2 Fundamental Principles of RadiobiologyAngelo RamosNo ratings yet

- Orthopantomography (: Orthopantograph or OPG)Document4 pagesOrthopantomography (: Orthopantograph or OPG)Arslan Aslam100% (1)

- Basic QA RadiologyDocument55 pagesBasic QA RadiologyWahyu Widhianto100% (10)

- Physical Characteristics of An X Ray FilmDocument29 pagesPhysical Characteristics of An X Ray Filmbalak112760% (5)

- Saudi Radiography TechnologistDocument1 pageSaudi Radiography TechnologistJashim Jumli IINo ratings yet

- Oral MedicineDocument174 pagesOral Medicineindah100% (1)

- Star Primer 2014 InvitationDocument4 pagesStar Primer 2014 InvitationBhavik ChopdaNo ratings yet

- ISUOG - Fetal Nervous System ExaminationDocument8 pagesISUOG - Fetal Nervous System ExaminationAzucenaNo ratings yet

- Film Faults and Factors Affecting The Radiographic ImageDocument28 pagesFilm Faults and Factors Affecting The Radiographic Imagebathinsreenivas100% (1)

- Fluoroscopy Equipment DiagramDocument3 pagesFluoroscopy Equipment Diagramapi-338781568No ratings yet

- 103manual QAP Radiologi Pindaan Januari 2019Document115 pages103manual QAP Radiologi Pindaan Januari 2019UMGC Sri RampaiNo ratings yet

- 10a-Intro To Radiographic - Critique - Problem - SolvingDocument39 pages10a-Intro To Radiographic - Critique - Problem - SolvingIstianahNo ratings yet

- Radiology Request Forms ResearchDocument8 pagesRadiology Request Forms Researchtruevine_ministryNo ratings yet

- Radiology MCQDocument2 pagesRadiology MCQginnidhillonNo ratings yet

- PathologyDocument53 pagesPathologyEdwin Mccain100% (1)

- 1-Introduction To RadiologyDocument15 pages1-Introduction To RadiologyMuhammed Maryam ometereNo ratings yet

- MRI Lecture NotesDocument33 pagesMRI Lecture NotesBrandon44No ratings yet

- PanoramikDocument38 pagesPanoramikStephanie Victoria100% (1)

- Radiation Safety GuidelinesDocument6 pagesRadiation Safety GuidelinesFourthMolar.comNo ratings yet

- Managing Patient Dose in Computed Tomography (CT)Document28 pagesManaging Patient Dose in Computed Tomography (CT)ALE X RAY100% (1)

- Eukaryotic Cell Parts and Functions (Flores)Document4 pagesEukaryotic Cell Parts and Functions (Flores)Dharyl FloresNo ratings yet

- Chapter 3 - Introduction To Nuclear MedicineDocument4 pagesChapter 3 - Introduction To Nuclear MedicineunknownxemNo ratings yet

- Test Bank For Merrills Atlas of Radiographic Positioning and Procedures 13th Edition by LongDocument6 pagesTest Bank For Merrills Atlas of Radiographic Positioning and Procedures 13th Edition by Longdominicmaximus44uNo ratings yet

- UltrasoundDocument20 pagesUltrasoundyechale tafereNo ratings yet

- Intensifying Screens ReviewDocument21 pagesIntensifying Screens ReviewLorraine ChanNo ratings yet

- Cardiac Review (#1 - 67)Document380 pagesCardiac Review (#1 - 67)juliana cataniNo ratings yet

- Production and Properties of X - Rays: MODULE-20Document105 pagesProduction and Properties of X - Rays: MODULE-20Santosh BhandariNo ratings yet

- 1stprize CR Auditpostercomp C Reid 2015Document1 page1stprize CR Auditpostercomp C Reid 2015webber_denzNo ratings yet

- FGDP X-Ray Book Web v2 PDFDocument190 pagesFGDP X-Ray Book Web v2 PDFMariana IdorașiNo ratings yet

- Digestive System (Anatomy)Document11 pagesDigestive System (Anatomy)GynewNo ratings yet

- Finals Rad ProtectDocument7 pagesFinals Rad ProtectNicko PerezNo ratings yet

- PresentationDocument37 pagesPresentationZubair MohammedNo ratings yet

- FRCR US Lecture 1Document76 pagesFRCR US Lecture 1TunnelssNo ratings yet

- Barium Swallow (Cine Oesophagram) : Hyelhirra P. MsheliaDocument25 pagesBarium Swallow (Cine Oesophagram) : Hyelhirra P. MsheliaJameeluh TijjanyNo ratings yet

- Ultrasound of Eye and OrbitDocument90 pagesUltrasound of Eye and OrbitManish Kumar100% (1)

- Grids and Scatter ReductionDocument79 pagesGrids and Scatter ReductionMondiaal Financial ServicesNo ratings yet

- Quality Assurance and Infection Control: Dr. Louie HammadDocument14 pagesQuality Assurance and Infection Control: Dr. Louie HammadPrince AhmedNo ratings yet

- Radiology Final 3Document3 pagesRadiology Final 3qmalNo ratings yet

- Lecture 4 The DarkroomDocument9 pagesLecture 4 The Darkroomflavio_jacNo ratings yet

- IV B.Tech II Semester: Non Destructive EvaluationDocument40 pagesIV B.Tech II Semester: Non Destructive EvaluationJEERU BHAGAVANULUNo ratings yet

- Darkroom and Film Processing Handout RAD TECH ADocument2 pagesDarkroom and Film Processing Handout RAD TECH ADomingo McKenzie May P.No ratings yet

- Radiographic ArtifactsDocument40 pagesRadiographic ArtifactsJanine Claire BucoNo ratings yet

- Chapter 10 Quality AssuranceDocument8 pagesChapter 10 Quality AssuranceDiana Ahmad ZaidanNo ratings yet

- Oral Histology Questions Part 1Document8 pagesOral Histology Questions Part 1Khalid Mortaja50% (4)

- Oral Histology MCQ Quiz PDFDocument77 pagesOral Histology MCQ Quiz PDFaaaa86% (7)

- Handbook PDFDocument21 pagesHandbook PDFDiana Ahmad ZaidanNo ratings yet

- AS Biology Paper 1Document16 pagesAS Biology Paper 1wegdan100% (2)

- Enquiry Into Life - Sylvia MaderDocument16 pagesEnquiry Into Life - Sylvia MaderDiana Ahmad ZaidanNo ratings yet

- List of Text Books 2011-2012 For A/AS Level (EDEXCEL)Document2 pagesList of Text Books 2011-2012 For A/AS Level (EDEXCEL)Diana Ahmad ZaidanNo ratings yet

- EC1sh ADocument4 pagesEC1sh Ashah143No ratings yet

- As A TeacherDocument1 pageAs A TeacherDiana Ahmad ZaidanNo ratings yet

- Quick and Clever Beading EbookDocument120 pagesQuick and Clever Beading Ebook1770518322263100% (2)

- Guide To Beading ToolsDocument18 pagesGuide To Beading ToolsMoshira Abo ElȜella50% (2)

- Biology ............................................................................................................................ 2Document16 pagesBiology ............................................................................................................................ 2Diana Ahmad ZaidanNo ratings yet

- How To Draw Sheets - Many ThingsDocument72 pagesHow To Draw Sheets - Many ThingsDiana Ahmad ZaidanNo ratings yet

- EdexcelA2BiologyRG 9781846905995 pg44 58 WebDocument15 pagesEdexcelA2BiologyRG 9781846905995 pg44 58 WebRishi PatelNo ratings yet

- Revision TipsDocument7 pagesRevision TipsDiana Ahmad ZaidanNo ratings yet

- Agfa Karat 36Document38 pagesAgfa Karat 36Pati GualterosNo ratings yet

- University University: PON Passive Optical NetworkingDocument59 pagesUniversity University: PON Passive Optical NetworkingNguyễnĐìnhDầnNo ratings yet

- Chemistry SM XI 2021-22Document154 pagesChemistry SM XI 2021-22SHRUTI AGARWALANo ratings yet

- MR1608 AppdDocument15 pagesMR1608 AppdSteve AbonyiNo ratings yet

- MSA Guide To Flame DetectionDocument9 pagesMSA Guide To Flame DetectionGianfranco GirardiNo ratings yet

- Applications of Uv VisibleDocument3 pagesApplications of Uv VisibleLaiba ZulfiqarNo ratings yet

- CoreLine LED Brochure 2013Document20 pagesCoreLine LED Brochure 2013Dragan VuckovicNo ratings yet

- S Parameter LTspiceDocument6 pagesS Parameter LTspice29377No ratings yet

- Antenna Design For The Laptop Radar Project : 2011 MIT Independent Activities Period (IAP)Document28 pagesAntenna Design For The Laptop Radar Project : 2011 MIT Independent Activities Period (IAP)DrArchek PraveenNo ratings yet

- White Paper - IsO 13655 Measurement ConditionsDocument5 pagesWhite Paper - IsO 13655 Measurement ConditionsSebastian GutiérrezNo ratings yet

- 1996494754question Bank em Waves, Ray Optics & Wave OpticsDocument36 pages1996494754question Bank em Waves, Ray Optics & Wave OpticsAnkitNo ratings yet

- Analysing A Photographer - Man RayDocument1 pageAnalysing A Photographer - Man Rayapi-563918643No ratings yet

- Toric Soft Contact Lenses For AstigmatismDocument20 pagesToric Soft Contact Lenses For AstigmatismVelcea Irina100% (2)

- Newton's RingsDocument6 pagesNewton's RingsKashish GulatiNo ratings yet

- CBSE Class-12 Physics Quick Revision Notes Chapter-09: Ray Optics and Optical InstrumentsDocument5 pagesCBSE Class-12 Physics Quick Revision Notes Chapter-09: Ray Optics and Optical InstrumentsMayank MishraNo ratings yet

- Extended Spectral Analysis of Internal Quantum Efficiency (BASORE)Document6 pagesExtended Spectral Analysis of Internal Quantum Efficiency (BASORE)Joseph FurgiaruNo ratings yet

- Free To Air Antenna: OptimaxDocument8 pagesFree To Air Antenna: OptimaxMASOUDNo ratings yet

- COLORSDocument21 pagesCOLORSAna Cristina Castro-CayabyabNo ratings yet

- Lecture Notes ANT3: Basic Radiation TheoryDocument7 pagesLecture Notes ANT3: Basic Radiation TheoryTamer Saleh El SayedNo ratings yet

- LED Flood Light: 【GNOFL Series】Document10 pagesLED Flood Light: 【GNOFL Series】Girlie Iglesia San BuenaventuraNo ratings yet

- PHA313 (22 - 23) - MOT - Optical Methods of The Analysis Presentataion - OMA - FINAL - 24 10 22 IDocument71 pagesPHA313 (22 - 23) - MOT - Optical Methods of The Analysis Presentataion - OMA - FINAL - 24 10 22 Ipako ramaphaneNo ratings yet

- Chapter 11 Human Eye and Colourful World NoteDocument13 pagesChapter 11 Human Eye and Colourful World NoteJay MakiNo ratings yet

- Application Note: Leds For Strobe LightsDocument7 pagesApplication Note: Leds For Strobe LightsMartinNo ratings yet

- Exepermint 1Document4 pagesExepermint 1Jhone SaaimonNo ratings yet

- Ecuaciones ClorofilaDocument8 pagesEcuaciones ClorofilaSilvia MartinezNo ratings yet

- Antennas and Wave Propagation-II MarksDocument33 pagesAntennas and Wave Propagation-II MarksBRINDHASHINEY100% (2)

- CHAPTER 6 LatihanDocument35 pagesCHAPTER 6 LatihanYusfalina Mohd YusoffNo ratings yet

- The Fresnel Diffraction IntegralDocument4 pagesThe Fresnel Diffraction IntegralVincent Luigil AlceraNo ratings yet

- Brosur Lampu Jalan PLC-GSM 200WDocument2 pagesBrosur Lampu Jalan PLC-GSM 200Wbudi utomoNo ratings yet