Professional Documents

Culture Documents

15 Concreting

Uploaded by

Akhilesh KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15 Concreting

Uploaded by

Akhilesh KumarCopyright:

Available Formats

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

PROCEDURE

FOR

CONCRETING

PROJECT

: PAGUTHAN-NTPCJHANORE PIPELINE

PROJECT.

DOCUMENT NO

: JPL/GSPL/PNJPL/WP/C04

CLIENT

: GUJARAT STATE PETRONET LTD.

CONSULTANT

: DORSCH CONSULT (INDIA) PVT. LTD.

TPIA

: BAXCOUNSCEL INSPECTION

BUREAU PVT. LTD.

CONTRACTOR

: JAIHIND PROJECTS LIMITED

NAME

DESIGNATION

SIGNATURE

DATE

JPL

BIBPL

DCIL

PREPARED BY

REVIEWED BY

CHECKED &

APPROVED BY

GSPL

APPROVED

BY

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

TABLE OF CONTENTS

DESCRIPTION

PAGE NO.

1.0

PURPOSE...............................................................................................3

2.0

SCOPE....................................................................................................3

3.0

REFERENCES........................................................................................3

4.0

LIST OF EQUIPMENTS / INSTRUMENTS.. 3

5.0

METHODOLOGY....................................................................................3

5.5

QUALITY ASSURANCE & QUALITY CONTROL..................................13

6.0

HEALTH, SAFETY & ENVIRONMENT..................................................15

7.0

APPENDICES / FORMATS...................................................................16

1.0

PURPOSE:

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

This procedure describes the steps to be followed and required inspection &

tests for pre-concreting, during and post concreting of any structure for Kalol

Mehsana Gas Pipeline Project including all incidental items of work not shown on

specified but reasonably implied or necessary for the completion of the work

2.0

SCOPE:

This procedure covers the requirements for concreting activity for PNJPL Project

Only.

3.0

REFERENCES:

a. Technical Specification, Doc No: 1019-116-203.

b. Approved Drawing.

4.0

LIST OF EQUIPMENTS/INSTRUMENTS:

1.

Concrete Mixing Machine.(Diesel operated / Electrical operated)

2.

Weigh Batcher.(Calibrated)

3.

Concrete Vibrators along with needles of various diameter to suit

purpose(25mm & 40mm)

5.0

4.

Cube Moulds.(No of mould as per test specimen to be taken as per IS 456 /

2000 / Pg29).

5.

Temping rod as per IS 10286, 25mm SQ bar at bottom edge.

6.

Slump Cone. With 16 dia Temping rod with bore shape half round at bottom

edge.

7.

Thermometer. (i) Concrete Temperature (ii) Max. Min. Thermometer (scale

with rod) or (Digital).

8.

Laboratory Instruments

compressive strength.

METHODOLOGY :

for testing

of

ingredient

of

Concreate

and

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

5.1

Source Approval of Material for Concrete:

All sources of construction materials will be identified. Then properties of material

shall be tested / checked for acceptance criteria w.r.t Technical Spec. / relevant

Codes.

Cement:

Cement shall be procured from approved sources/manufacture. Initially MTC will be

submitted to Owner / Consultant for Source Approval. During execution process MTC

for each consignment shall be submitted to Owner/ Consultant for review Batch should

be with on 3 month.

Aggregates:

Coarse aggregates will be procured from approved sources. (Savalia)Sample of Coarse

aggregate from the quarry will be sent to external / internal Laboratory for testing and

approval Coarse aggregate shall meet the requirements of IS 383.

Fine aggregate will be procured only from approved sources. (BAHADURPUR)Sample of

fine aggregate will be sent to external / internal Laboratory for testing and approval Fine

aggregate shall meet the requirements of IS 383.

Water :

Water from bore well or nearby Terminal and/or NMC water will be used for mixing in

concrete and curing shall confirm to IS: 456:2000/Cl 5.4. Test report of water shall be

submitted to owner/consultant for source approval.

5.2 Transportation & Storage of Material:

Cement handling and storage:

Cement should be procured in bags and shall be stored in water tight, weather

tight, ground moisture tight to prevent absorption of moisture.

At all times, expose the cement as little as practicable to air because moisture in

the air causes hydration.

If cement becomes slightly lumpy during storage, its use may be permitted if

most lumps are sufficiently soft to be crushed between the thumb and fingers.

If an excessive number of lumps are encountered, the cement should be tested.

Storage facilities for bulk cement should include separate compartments for each

type of cement used.

Cement should be started in easily countable stacks with Id marks.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Sufficient space for storage, with one passage between stacks should be

arranged.

Bags of cement should be stacked on pallets or similar platforms to permit proper

circulation of air.

For storage period of less than 60 days, stack the bags no higher than 14 layers,

and for longer periods, no higher than 7 layers.

FIFO (First-in First-out) system should be strictly followed.

Aggregates handling and storage:

Stockpiling of coarse aggregates should be kept to a minimum because fines

tend to settle and accumulate.

When stockpiling is necessary, use of correct methods minimize problems with

fines, segregation, aggregate breakage, excessive variation in grading and

contamination.

Stockpiling of coarse aggregates should be under shed only to prevent from

ambient temperature in order to maintain W/c ration.

Stockpiles should be built up in horizontal or gently sloping layers, not by end

dumping.

Trucks, loaders, and dozers, or other equipment should not be operated on the

stockpiles because, in addition to breaking the aggregates, they frequently dirt onto

the piles.

Provide a concrete base with good drainage to prevent contamination from

underlying material.

Prevent overlap of the different sizes of aggregates by suitable partition walls.

Protect dry, fine aggregates from being separated by the wind by using

windbreaks wherever required.

Reinforcement:

Ensure storage area is spacious.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Ensure reinforcement is stored sufficiently above the ground to avoid physical

damage and corrosion of reinforcement.

Keep reinforcement free from mud, oil, grease etc.

Provide a loose protective cover over the reinforcement to avoid direct exposure

to aggressive weathering conditions.

Avoid long-term storage of reinforcement on site.

Clean rust using sand paper/ Write brush before placing of form work if any

5.3 Prepour Inspection:

Prior to start of concrete pre-pour inspection shall be carried out as per checklist

attached with this procedure.

Survey, alignment checks:

The coordinates, levels and alignment of the area to be concreted shall be ensured by

checking them with temporary / permanent benchmarks and levels shall be marked as

per the drawings.

Excavation and foundation checks:

Excavate until sound strata is reached as per approved drawings because soil

under footings must have the bearing capacity required.

Such sound material may be original undisturbed soil or a properly compacted

soil. All soil surfaces upon which concrete is to be placed shall be well compacted

and free from standing water, mud or debris. Any expansive soil (like black cotton

soil) shall be removed.

For Plain Cement Concrete (PCC) works:

The major requirements for PCC is that the surface on which it has to be laid

should not be waterlogged as water in the soil may affect the water-cement ratio that

in turn affects the strength of concrete.

The surface of the soil shall be free from any loose debris.

The forms also shall be checked to ensure that their integrity remains intact

during concreting.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

The top level up to which concreting is be done shall be marked on the form at

various locations.

Approximately half an hour to starting of concrete, the surface to be concreted

must be made moist, so that the water in concrete is not absorbed into the soil and

shrinkages in concrete are prevented. This may be done by cleaning surface with

air-water jet, followed by an air jet to remove excess water.

Water proofing admixture of approved make should be added with the cement in

quantity not less than 2% by weight of cement.

Formwork and scaffolding checks:

Formwork is the total system of support for freshly placed concrete including the mould

which contacts the concrete as well as all supporting members, hardware and

necessary bracings.

Attention to safety is especially significant in formwork construction. The formwork must

support the concrete and construction live loads during its plastic state and until the

concrete becomes structurally self-sufficient.

The following checks shall be done.

Position of member with respect to the grids, axes and nearby structures and

shape of members.

The type of shuttering used shall satisfy the quality of concrete finish desired for

the finished structure, viz, F1, F2 or F3. Accordingly, the type of formwork used shall

vary.

The formwork and staging arrangements shall be checked with applicable

drawings.

Care shall be taken to provide adequate supporting arrangements at cantilevers

or construction joint locations (where temporary cantilevers are created).

Construction joints shall be well supported so that they remain intact during

handling and concreting.

Check whether the members are sufficiently braced to withstand vibration of

concrete, and to carry, without appreciable deflection, all dead and live loads to

which they may be subjected.

Alignment and level i.e.; verticality of the formwork. This shall be checked by first

transferring the point to the top of the form with respect to with that of the

neighbouring benchmarks on nearby benchmarks and then placing plumb bob at

various locations. Any deviations shall be made good within tolerance limits.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

The levels of form shall be checked with that of the neighboring benchmarks by

water level tube / Auto level

Finishing levels of concrete shall be marked on inside face of the forms.

Check for various dimensions should be of form along with check for

perpendicularity and diagonal distances.

Accuracy of dimensions within permitted tolerance as per the contract

specifications.

The formwork assembly shall be sufficiently tight to hold concrete pressure

without leakage.

The formwork joints should be tight enough to prevent leakage of cement slurry.

Where there are any Embedments to be provided; ensure their alignment, level

and intactness with the form.

Ensure that form release agents (if required) are uniformly applied.

Check whether all forms are perfectly clean and free from any objectionable matter. The

nails shall be driven in such manner that no nails shall protrude into the concrete.

Checks for Waterstops:

One half of the waterstop shall be embedded in the concrete upto the

center bulb leaving the other half to be embedded during concreting of the

successive layer of the construction joint.

Care should be exercised while pouring concrete without misaligning the

water stop. For this, the waterstops shall be supported either by shear key or Ushaped bars.

The quality of jointing shall be checked at site by bending the water stop at

joints. A good joint shall not open / puncture in bend. Dye penetrant test may also be

done to ensure the integrity of the joint.

It shall be ensured that extra length of water stop beyond the joint is left to

facilitate ease for further jointing / Over lapping

Ties and Fixings:

Check whether adequate numbers are provided as per the design.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Ensure that the length and spacing of ties and fixings is as per requirements.

The ties and fixtures shall be adequately tight.

Reinforcement Cement Concrete works:

RCC is often laid on a PCC base. If concrete is to be placed on previously cast

concrete, the surface of existing concrete shall be made clean before the

subsequent layer of concrete is laid on it.

Application of Bonding agent (approved make) than to be carried out on existing

concrete surface prior to concreting.

Check whether the cutting and bending of the reinforcement is as per the

approved Bar Bending Schedule (BBS). The parameters to be checked are

diameter, cutting length, shape of the bars bent against the approved BBS and

availability of lap length as per the drawings and specifications. Two successive laps

shall be suitably staggered.

Before reinforcement is placed, ensure that the surface is free from any

objectionable coatings such as oil, grease, dried mud, weak or dry mortar or

corrosion.

Check whether reinforcement is embedded at a distance equal to the cover to be

provided as per drawings.

Care shall be taken to tie the cover properly to the reinforcement so that it is not

displaced during concreting operations.

The binding wire shall be tied properly to ensure that the ends of the same are

encased in the concrete.

Staggering of reinforcement is to be ensured as per approved drawings.

Batching & Mixing of Concrete:

Batching of each size of aggregates and cement shall be carried out in turn.

The aggregates and cement will be batched by means of suitable weigh batching

machines and materials will be handled in steel boxes of specified size. Convenient

system of measuring water to the concrete mixture will be installed. Weigh batcher shall

be calibrated / verified periodically (once in 15 days). Calibration / Verification

Certificate/ report of weigh batcher shall be maintained. Also calibration / verification of

weight batcher is must when shifted from one to another location.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Suitable concrete mixers (10/7) of approved type will be used for mixing concrete

materials including water. Water shall be mixed with the help of proper measuring jars.

The mixer should comply with IS - 1791 meter concrite rate shall be 0.50 to 0.55

Accuracy of Batching:

Cement + 2% of the weight of the cement in the batch.

Aggregate + 2% of the weight of aggregate in the batch.

Water + 2% of the weight of water added to the batch.

Mixing of each batch time should not less then 2 minutes and at least 40 revolutions

after all the material & water are in drum.

Transportation, Placement of Concrete:

Placement of concrete will start only after section incharge ensures that the Pre -pour

inspections are carried out. Concrete will be transported from the mixer to the formwork

as rapidly as possible by a method, which will prevent the segregation or loss of any

ingredients and maintaining the workability of concrete.

in no case shall placing of concreting be done over 1.5m height (Dorping).

Compacting of Concrete

Slabs beams and similar members shall be poured in one operation.

All fixtures shall be embedded in concrete as shown on the drawings.

Concrete will be compacted with internal vibrators of size varying diameter.

Vibrators should not be used to move concrete laterally. They should be inserted

and withdrawn vertically, so that they quickly penetrate the layer and are

withdrawn slowly to remove entrapped air.

Vibrate at close intervals (usually 450 to 700 mm depending upon the mix), for

about 10 to 15 seconds, using a systematic pattern to ensure that all concrete is

adequately consolidated. The spacing shall provide some overlapping of the area

vibrated at each insertion. The proper vibration technique is, fast insertion and

slow withdrawal. Withdraw when concrete becomes fluid.

Vibrators needle shall be kept clear of forms at least by 100 mm.

The vibrators shall be withdrawn slowly, approximately at the rate of 75mm/sec.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

The vibrator shall penetrate full in the layer being placed and also penetrate the

layer below about 50 mm while the under-layer is still plastic, to ensure good

bond and homogeneity between the two layers and prevent the formation of cold

joints.

Care shall be taken to prevent contact of vibrators against the reinforcement

steel.As long as a running vibrator will sink into the concrete by means of its own

weight, it is not late for the concrete to benefit from vibration/re-vibration, which

improves compressive and bond strength.

Do not use the vibrator to cause concrete to flow from one location to another,

because such a practice usually causes segregation, with the larger coarse

aggregate remaining behind.

Re-vibration of concrete is beneficial if the concrete will respond to the vibrator

and again become plastic.

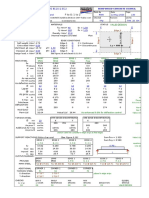

Refer figure 1 for illustration of a typical pour sequence with pre-determined

layers. In case of stoppage of concrete, due to breakdown of plant, pump etc. the

top layer of finished concrete need to be treated as a construction joint.

14

6

3

1

9

5

12

8

11

13

2

4

7

10

Fig. 1 A Typical pour sequence

5.4 Post Pour Inspection:

The following points shall be verified during post concrete survey.

The profile of the surface shall be verified with that of drawing.

The surface of concrete shall be free from any defects like air holes,

honeycombs, etc.

The concrete surface finish shall be smooth without any bulging, offsets due to

shuttering joints, exposed reinforcement etc.

The concrete structure shall be checked for evidence of any distress.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

The positions of inserts in concrete shall be verified to check whether they are in

line with the drawings.

If green cutting is required to be done, the finished surface of concrete shall be

checked for the presence of exposed aggregates.

The defects, if any, shall be made good at the earliest.

All the observations shall be recorded in Post Concrete Inspection Reports.

Post pour inspection is done in advance for any rectification. Also pour card

containing checklist such as grade of concrete, Reinforcement checks, availability of

equipment like mixer, Vibrator hoist etc.

Curing and protection:

Newly placed concrete shall be protected from rain, sun and wind by protective means.

Concrete will be cured by wet Hessian cloth. Hessian will be kept always wet.

Curing will be done for min 7 days.

5.5 Quality Control and Quality Assurance:

Routine Test of Cement:

The cement shall be tested as per Inspection and Test Plan (ITP).

The following properties are to be verified as a routine test.

Physical properties:

Normal consistency

Initial and final setting time

Compressive strength

Routine Test of Aggregates:

Gradation will be done once in a week or prior to start of major concreting and

whenever charge of source

Routine Test of Concrete:

Frequency of sampling of concrete will be as per IS 456. Steel cubes of size 150 mm x

150mm x 150 mm will be used. Calibration certificate of cube testing machine shall be

maintained. A Cube Register shall be maintained at the site for identification and

traceability of structure & cube test results.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Sampling frequency:

Quantity of concrete in work in cum

Number of Samples

1 to 5

1 (min.)

6 to 15

2

16 to 30

3

31 to 50

4

51 and above 4 plus one additional sample for each additional 50 cum or part thereof

One sample will consist of six numbers of standard cubes, out of which 3 cubes will be

tested at 7 days and 3 cubes for 28 days.

The individual in cube strength results shall standard not be more than + - 15 % of the

average.

Slump test will be done in order to check the workability of concrete

Slump valve shall be ------ mm for w/c racio 0.5 & 0.55 as per 15456.

5.6 Correction of Defect in Newly Hardened Concrete:

In spite of good workmanship & efforts to produce flawless concrete, some corrections

of defects may be required to be done. The treatment of newly hardened concrete will

include correction of consolidated related defects such as Honeycomb, Bug Holes and

repair of other defects such as plastic shrinkage cracks and spalls.

Pockets honey combing and other details, which may be formed due to

segregation, improper vibration etc. shall be repaired by cement mortar of

composition 1:2 immediately after removal of formwork. The voids if any shall be

properly keyed and reinforced, if necessary. Any fins or unsightly grout runs or

bulges shall be removed from surfaces exposed to view.

The rod holes shall be finished with cement or grouted to match. The existing

surface as closely as possible and shall be made leak proof.

Surface of the structural members exhibiting cracks, fissures in the concrete

cover/ plaster, cover, steel exposed uniformly, without disturbing the core of the

column.

Repair materials:

Various repair material may be used ( if required ) in general classified as follow.

Conventional concrete and Mortars

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Dry Pack Mortars

Cement Grouts

Chemical Grouts

Epoxy Resins

6.0 HEALTH, SAFETY & ENVIRONMENT

6.1 Risk Assessment & Control Measures:

Sr.

No.

Activity

1.

Material

handling like

cement,

aggregate

etc.

Form work &

Scaffolding

erection

Placement of

cave

6.2

Occupational Health Hazards and Control Measures

Hazard & Risk

Operational Control Measures

Health hazard due Personnel protective equipments such

to contact with

as Hand Gloves, Dust mask safety

excess cement &

shoes shall be provided to the workers

Dust

handling the cement. Provide safety

glass (goggles)

Sprinkle Water over aggregate to avoid

duct generation. Provide gum shoes

Inappropriate

staging, bracing etc.

Health Hazard.

Shall be erected, as per approved drawing

and safety checklist shall be strictly adhered.

Safety Harness to be used for work at height

Temporary railing to be fixed whenever

possibility of falling (Like dust etc.)

Gum shoes shall be used white purring

/leveling lxibraing the case

ENVIRONMENTAL MANAGEMENT :

Sr.No

Activity

1.

Material Handling

2.

Material

Transportation

3.

Batching and

mixing of concrete

4.

Placement of

concrete

Env. Aspect

Dust

generation

Vehicular

emission

Mixer wash

waste water

generation

Left out

concrete

Mitigation Measure

Dust mask shall be provided to

the workers handling the cement.

All the vehicles shall conforms to

PUC

Shall be treated and discharge

within specified permissible

Pollution control board limits.

Reuse/recycle option shall be

explored or otherwise shall be

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

generation

disposed in environment friendly

manner.

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/WPC-04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Project

: PAGUTHANE NTPC JHANORE PIPELINE PROJECT.

Report No:

7.0 APPENDIX / FORMATS:

Inspection Test Plan

Pre Pour Inspection Report

Post Pour Inspection Report

Gradation Analysis

Combined Gradation Analysis

Concrete Compressive strength

NOTE :

"In case any conflict between this procedure and contract specification, the later shall

govern"

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

INSPECTION TEST PLAN

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/WPC-04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Sr.

No

Report No:

Inspection Category

Inspection and Testing

Description

by TPIA

GSPL/Dorsch

a) Workability of Fresh

Concrete

R/W

R/W

b) Compressive Strength of

Concrete

R/W

R/W

a) Location of embedded parts /

water stoppers

R/W

R/W

b) Location of Construction,

Expansion Joints

R/W

R/W

c) Working of Fresh concrete

R/W

R/W

Page

Page

17 of

1823

of 20

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

d) Compressive Strength of

Concrete (Cubes

R/W

For JPL

R/W

For BIBPL

For DCIL/ GSPL

PRE POUR INSPECTION REPORT CONCRETE

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/WPC- 04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Report No:

Site Location

Concrete Grade :

Structure / Pour

Ref.Drg.No

Date & Time of Inspection :

Sl No

Description of Activity

01

Approval of Materials and Concrete Mix

02

Survey Checked as per Approved Drawings

03

Excavation/Trenching/Filling and surface preparation as per Drawing

04

Sprinkling water/PCC bending as per Drawing

05

Bar Bending Schedules prepared and approved

06

Reinforcement placing, tieing with binding wire, BBS as per Drawings and cleaning

of reinforcement, if any, as required etc.

07

Providing adequate no. of Cover Blocks of required thickness

08

Position of Spacers, chairs, Splices, Laps etc as per BBS/Drawings

09

Position of Construction Joints, Embedment plates, Pipe inserts, if any, etc. as per

Drawing

Yes

No

N/A

Remarks

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

10

Alignment/Location Post Tensioning Ducts, Accessories etc. as per Drawing

11

Check for Line, Level, alignment plump, supports and mould release Oil etc. of

Shuttering

12

Check for availability of Mixer, Weigh batcher, Vibrator, Slump Cone and Cube

Moulds etc. before start of Concreting

For JPL

For TPIA

For DCIL/ GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/WPC-04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Sl No

Description of Activity

01

Cured by covering with Wet Hessian bags / Sprinkling

water / application of Curing Compound

02

Checked for Stripping of Formwork / Supports etc. after

specified duration of Stripping time

03

Checked for Position of Embedment plates, Inserts,

Joints, pipes etc. if any

04

Post Concrete Survey, if necessary, carried out

05

Checked for presence of any Surface Defects i.e.,

minor/major cracks, voids, iregregation of aggregate

etc. if any

06

Repaired and Finished all Surface Defects by

specifications / approved methods

Report No:

Yes

No

N/A

Remarks

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

07

Structure or part of Structure is alright and allowed for

subsequent activity / backfilling around the structure

For JPL

For TPIA

For DCIL/ GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

GRADATION ANALYSIS

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/WPC-04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Report No:

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Location

Weight Taken :

Material

Sieve Size

(mm)

40

20

10.0

4.75

2.36

1.18

0.600

: 40mm / 20mm/ 10mm/ SAND

Wt

Retained

(gms)

% Retained

Cumulative

% Retained

ITEM:

% Passing

Remarks

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

0.300

0.150

For JPL

For TPIA

For DCIL/ GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

COMBINED GRADATION ANALYSIS

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/IRWPC-04

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision

:1

TPIA

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

Date

Contractor

: JAIHIND PROJECTS LIMITED.

Report No:

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Location

Weight Taken :

Material

Sieve Size

(mm)

40

20

10.0

4.75

2.36

1.18

: 40mm / 20mm/ 10mm/ SAND

ITEM:

% Passing

40mm

20mm

10mm

40mm

%

Proportions

20mm

%

10mm

%

Total

Remarks

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

0.600

0.300

0.150

For JPL

For TPIA

For DCIL/ GSPL

Name:

Sign:

Name:

Sign:

Name:

Sign:

Date:

Date:

Date:

CONCRETE COMPRESSION STRENGTH

Owner

Consultant

TPIA

Contractor

Project

: GUJARAT STATE PETRONET LTD.

: DORSCH CONSULT (INDIA) PVT.LTD.

:BAXCUNSEL INSPECTION BUREAU PVT.LTD..,

: JAIHIND PROJECTS LIMITED.

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Format: JPL/GSPL/PNJPL/WPC-04

Revision : 1

Date

:

Report No:

Grade of Concrete :

Structure

:

Location

:

Size

: 150x150x150

Date of Casting

:

Sl No

Date of casting Testing

Load

Strength (N/mm2)

Average (N/mm2)

Days 7/28

Rem.

JAIHIND PROJECTS LIMITED.

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

For JPL

For BIBPL

For DCIL/ GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

You might also like

- 10 Process Piping Welding Pipe To Flange, Weldolet, Fitting, If, Valve, Higher Thickness Pipe (Document11 pages10 Process Piping Welding Pipe To Flange, Weldolet, Fitting, If, Valve, Higher Thickness Pipe (Akhilesh KumarNo ratings yet

- Filletweld 1Document4 pagesFilletweld 1Prakash RajNo ratings yet

- Single V WeldDocument4 pagesSingle V WeldkoyahassanNo ratings yet

- Anti TermiteDocument30 pagesAnti TermiteAkhilesh KumarNo ratings yet

- Design of Base Plate and Anchor BoltsDocument7 pagesDesign of Base Plate and Anchor BoltsShaikh Muhammad AteeqNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument16 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- Boundary WallDocument1 pageBoundary WallnaseerNo ratings yet

- Turbo Ventilator CapacityDocument1 pageTurbo Ventilator CapacityRajendra Kumar GuptaNo ratings yet

- BbsDocument24 pagesBbsGanesh EshwarNo ratings yet

- Larsen & Toubro Limited - Ecc DivisionDocument1 pageLarsen & Toubro Limited - Ecc DivisionOuseppachan AmbookenNo ratings yet

- Design and Performance of A 15m Deep Excavation For A Wagon TipplerDocument5 pagesDesign and Performance of A 15m Deep Excavation For A Wagon TipplerlingamkumarNo ratings yet

- False Form WKDocument12 pagesFalse Form WKRonald Cario SeguinNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- ZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkDocument1 pageZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkASAALE GLORIANo ratings yet

- Concrete Flatwork Calculator: DateDocument3 pagesConcrete Flatwork Calculator: DateSebastian GusetuNo ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- BS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BDocument1 pageBS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BmodarthNo ratings yet

- Larsen & Toubro Limited - Ecc DivisionDocument1 pageLarsen & Toubro Limited - Ecc DivisionOuseppachan AmbookenNo ratings yet

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeDocument5 pagesSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANANo ratings yet

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakNo ratings yet

- Metod Statement of Well Point De-Watering For Cement SiloDocument5 pagesMetod Statement of Well Point De-Watering For Cement SiloSmart ShivaNo ratings yet

- PaintingDocument6 pagesPaintingAkhilesh KumarNo ratings yet

- Hidden BeamDocument1 pageHidden BeamKulal SwapnilNo ratings yet

- SWIODocument1 pageSWIOpreeti kumariNo ratings yet

- Sight Glass CalculationDocument1 pageSight Glass CalculationHafizh DaruNo ratings yet

- Civil SpecificationsDocument86 pagesCivil Specificationstiruyam@gmail.comNo ratings yet

- Now This Rent Agreement Witnesseth As Under:-FIXED-TERM AGREEMENT: Tenants Agree To Rent This Dwelling For A Fixed Term of 11 MonthsDocument3 pagesNow This Rent Agreement Witnesseth As Under:-FIXED-TERM AGREEMENT: Tenants Agree To Rent This Dwelling For A Fixed Term of 11 Monthssalman khanNo ratings yet

- Wall Sandwich PanelsDocument4 pagesWall Sandwich PanelsSiniora AkoumNo ratings yet

- Itp Structural Steel Work Erection BlogDocument6 pagesItp Structural Steel Work Erection BlogIndwell RaigarhNo ratings yet

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- FQP For Chimney 3 MechanicalDocument4 pagesFQP For Chimney 3 MechanicalKuldeep ChakerwartiNo ratings yet

- Steel Standard Sections From Is 800Document11 pagesSteel Standard Sections From Is 800Rassal KarimNo ratings yet

- Interconnecting Pipe Rack - TF1-PRK-510Document68 pagesInterconnecting Pipe Rack - TF1-PRK-510Khac Hoang PhamNo ratings yet

- Final Soil Test ReportDocument7 pagesFinal Soil Test ReportPrateek JhanjiNo ratings yet

- Welding Design For Rebar To Cast in PlateDocument1 pageWelding Design For Rebar To Cast in PlateMyat Thu Zar KhineNo ratings yet

- DOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Document38 pagesDOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Gautam AcharyyaNo ratings yet

- Column Alignment ProtocolDocument71 pagesColumn Alignment Protocolstboilers .utclkotputliNo ratings yet

- Procedure For Flooring WorksDocument4 pagesProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Hume PipesDocument3 pagesHume PipesSathish100% (1)

- EqualAngle PDFDocument2 pagesEqualAngle PDFGalih PutraNo ratings yet

- ResumeDocument5 pagesResumeRohit GuptaNo ratings yet

- Concrete Cube Test Report: Cast Laboratories Pte LTDDocument1 pageConcrete Cube Test Report: Cast Laboratories Pte LTDsawwahwahNo ratings yet

- Architectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationDocument36 pagesArchitectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationTokio87No ratings yet

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pages7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresNo ratings yet

- Disclosure To Promote The Right To InformationDocument289 pagesDisclosure To Promote The Right To InformationAshish Pattanaik100% (1)

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- BrickworkDocument4 pagesBrickworkAntony GodwinNo ratings yet

- RFI Chipping & PaddingDocument80 pagesRFI Chipping & Paddingcrys suryo prayogoNo ratings yet

- 4) Method Statement For Steel WorkDocument5 pages4) Method Statement For Steel WorkMukesh PrajapatNo ratings yet

- UC 305x305x118 Hksc:2011 Approach: StrutDocument2 pagesUC 305x305x118 Hksc:2011 Approach: StrutChan Kin CheungNo ratings yet

- Road CrossingDocument5 pagesRoad CrossingMahata PriyabrataNo ratings yet

- M4 501 01 (R0)Document214 pagesM4 501 01 (R0)ksshashidharNo ratings yet

- List of Materials ConstructionDocument1 pageList of Materials ConstructionMaan GalangNo ratings yet

- Rigging Calc. Kato NK550Document9 pagesRigging Calc. Kato NK550ashadiamirNo ratings yet

- QES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & DrawingDocument2 pagesQES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & Drawingrupesh417No ratings yet

- Concrete Works SpecificationDocument16 pagesConcrete Works SpecificationLem1985100% (2)

- Method Statement Water ProofingDocument16 pagesMethod Statement Water ProofingVinod MasaniNo ratings yet

- Methodstament For RCC and PCCDocument6 pagesMethodstament For RCC and PCCDeepak Patil100% (1)

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument14 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument16 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- PaintingDocument6 pagesPaintingAkhilesh KumarNo ratings yet

- WaterproofingDocument5 pagesWaterproofingAkhilesh KumarNo ratings yet

- 12 Form WorkDocument7 pages12 Form WorkAkhilesh KumarNo ratings yet

- 11-Backfiling at Station NoDocument7 pages11-Backfiling at Station NoAkhilesh KumarNo ratings yet

- Procedure For Flooring WorksDocument4 pagesProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Procedure For Horticulture WorksDocument4 pagesProcedure For Horticulture WorksAkhilesh KumarNo ratings yet

- Procedure For Plumbing Sanitary WorkDocument5 pagesProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- Reinforcement Work Proc.Document5 pagesReinforcement Work Proc.Akhilesh Kumar0% (1)

- 06-Earthwork in ExcavationDocument7 pages06-Earthwork in ExcavationAkhilesh KumarNo ratings yet

- Procedure For Fencing WorksDocument3 pagesProcedure For Fencing WorksAkhilesh KumarNo ratings yet

- Procedure For Roof Water ProofingDocument4 pagesProcedure For Roof Water ProofingAkhilesh KumarNo ratings yet

- Procedure For Area Grading and Development WorksDocument3 pagesProcedure For Area Grading and Development WorksAkhilesh KumarNo ratings yet

- Proedure For PlasteringDocument4 pagesProedure For PlasteringAkhilesh KumarNo ratings yet

- Procedure For Surveying and Levels FixingDocument3 pagesProcedure For Surveying and Levels FixingAkhilesh KumarNo ratings yet

- Procedure For ScafoldingDocument4 pagesProcedure For ScafoldingAkhilesh KumarNo ratings yet

- Procedure For Steel Door Windows and VentilatorsDocument3 pagesProcedure For Steel Door Windows and VentilatorsAkhilesh KumarNo ratings yet

- WBM For Road Work Proc.Document3 pagesWBM For Road Work Proc.Akhilesh KumarNo ratings yet

- Roof Treatment Proc.Document4 pagesRoof Treatment Proc.Akhilesh KumarNo ratings yet

- Dark Room ProcessingDocument153 pagesDark Room Processingsneha ravichandranNo ratings yet

- Ag Ss Kx6 Fdc400kxe6Document3 pagesAg Ss Kx6 Fdc400kxe6Shafik AtwiNo ratings yet

- Flora Kidd The Married LoversDocument183 pagesFlora Kidd The Married Loversanahita_agarwal76% (21)

- Avaya RADVISION SCOPIA - Product PDFDocument109 pagesAvaya RADVISION SCOPIA - Product PDFcaveman2001No ratings yet

- Conplast Ae300Document3 pagesConplast Ae300talatzahoorNo ratings yet

- Proposed New Cebu City Medical Center A-02: Lower Ground - Masonry ActivitiesDocument1 pageProposed New Cebu City Medical Center A-02: Lower Ground - Masonry ActivitiesJing AytonaNo ratings yet

- TT8850AT001 SkyPatrol - AT Command Set - Rev 1 - 4 PDFDocument68 pagesTT8850AT001 SkyPatrol - AT Command Set - Rev 1 - 4 PDFJAVIER Prada100% (1)

- Archicad Template Checklist v2 0Document7 pagesArchicad Template Checklist v2 0nedblaNo ratings yet

- Troubleshooting Routers CiscoDocument100 pagesTroubleshooting Routers CiscokarderisNo ratings yet

- R. Baker - Summer Beyond WishDocument1 pageR. Baker - Summer Beyond WishroseclearingNo ratings yet

- Construction Sequence LNG Storage TankDocument31 pagesConstruction Sequence LNG Storage TankArt G. Enzi100% (12)

- Recycled Asphalt PavementDocument36 pagesRecycled Asphalt PavementAbhishek MaddheshiyaNo ratings yet

- Kerio Connect Adminguide en 7.1.3 2461Document412 pagesKerio Connect Adminguide en 7.1.3 2461James OmaraNo ratings yet

- Informatica IDQ Dashboard Reports 961Document14 pagesInformatica IDQ Dashboard Reports 961Josh TownsendNo ratings yet

- Crackwise ArticleDocument8 pagesCrackwise ArticleYarko YurechkoNo ratings yet

- Chery A1 PartesDocument54 pagesChery A1 PartesAlexferminNo ratings yet

- 121102170404SS 578-2012 - Preview PDFDocument9 pages121102170404SS 578-2012 - Preview PDFAnonymous RrwCr7a0% (1)

- Mengatasi Masalah Eror Saat Kita Memanggil LocalhostDocument3 pagesMengatasi Masalah Eror Saat Kita Memanggil LocalhostdarwinNo ratings yet

- Sandblast Concrete Surfaces PDFDocument4 pagesSandblast Concrete Surfaces PDFSuneesh PNo ratings yet

- Steel Arch Bridge Construction 12Document18 pagesSteel Arch Bridge Construction 12Tfk BajaNo ratings yet

- Lapto WalterDocument15 pagesLapto WalterWalter Unais CordovaNo ratings yet

- Flo Fab Under Base Bid. Equivalent Units May Be Submitted As DeductDocument6 pagesFlo Fab Under Base Bid. Equivalent Units May Be Submitted As DeducttexmoNo ratings yet

- IDQ LearningDocument33 pagesIDQ LearningPradeep Kothakota0% (1)

- Public Class: Singleton, Prototype, Request, Session and Global SessionDocument6 pagesPublic Class: Singleton, Prototype, Request, Session and Global SessionAshihsNo ratings yet

- U-Bild: Lawyer's BookcaseDocument8 pagesU-Bild: Lawyer's BookcaseEmilian Baluta100% (1)

- Electrical Regulations: 7 Earth ConnectionsDocument3 pagesElectrical Regulations: 7 Earth ConnectionsVijay PatelNo ratings yet

- E02 Installation of Cable HV LV With IndexDocument5 pagesE02 Installation of Cable HV LV With Indexsyed_sadiq62100% (2)

- TECU Product Range 2019 enDocument36 pagesTECU Product Range 2019 enSimonaManolacheNo ratings yet

- Configuring Hadoop Security With Cloudera ManagerDocument52 pagesConfiguring Hadoop Security With Cloudera ManagerBoo CoriNo ratings yet

- ATV LXM IS Option Modules S1A45591 11Document10 pagesATV LXM IS Option Modules S1A45591 11arnaucuentatrabajoNo ratings yet