Professional Documents

Culture Documents

Apollo A108 Series Automatic Control Valve

Uploaded by

DGWCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apollo A108 Series Automatic Control Valve

Uploaded by

DGWCopyright:

Available Formats

Job Name:

Job Location:

Engineer:

Contractor:

Tag:

PO Number:

Representative:

Wholesale Distributor:

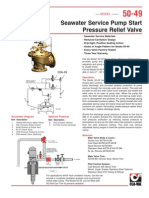

A108 Series

Pressure Relief/Pressure Sustaining

Automatic Control Valve

DESCRIPTION

The A108 has a wide range of applications: anywhere a system must be protected from pressures

that are too high (relief ) or too low (sustaining).

The normally closed, spring-loaded pilot, sensing upstream pressure, responds to changes in pressure

and causes the main valve to do the same. The net result is a constant modulating action of the pilot and

main valve to hold the upstream pressure constant. The pilot system is equipped with a closing speed

control that fine tunes the valve response to the system variables. Proudly made in the USA.

FEATURES

Relief Valve: Limits inlet pressure by

relieving excess pressure

Pressure Sustaining: Prevents inlet

pressure from dropping below a

predetermined minimum

Operates over a wide flow range

Inlet pressure is adjustable with single

screw

Quick opening and adjustable closing

speed

Can be maintained without removal

from the line

Factory tested and can be pre-set to

your requirements

SIZES

GLOBE/ANGLE

Screwed Ends: 1-1/4 - 3

Grooved Ends: 1-1/2 - 4

Flanged Ends: 1-1/4 - 24 (globe)

1-1/4 - 16 (angle)

MAXIMUM PRESSURE

End

Connections

Threaded

Grooved

150# Flanged

300# Flanged

Ductile

Iron

640 psi

300 psi

250 psi

640 psi

Steel/

SS

640 psi

300 psi

285 psi

740 psi

Bronze

500 psi

300 psi

225 psi

500 psi

STANDARD MATERIALS LIST

Part Name

Body/Bonnet

Seat Ring

Stem

Spring

Diaphragm

Seat Disc

Pilot

Tubing & Fittings

SCHEMATIC

Material

Ductile Iron (epoxy coated),

Carbon Steel (epoxy coated),

Stainless Steel,

B61 Bronze

-Others available (consult factory)

Bronze, Stainless Steel

Stainless Steel, Monel

Stainless Steel

Nylon Reinforced Buna-N,

Viton, EPDM

Buna-N, Viton, EPDM

Bronze, Stainless Steel

Other pilot system components:

Bronze/Brass -All Stainless Steel

Copper/Brass, Stainless Steel

COMPONENTS (as shown on the schematic diagram)

No.

1

2

3

4

5

6

7

Component

Model 65 Basic Control Valve

Model 1330 Pressure Relief/Back Pressure Pilot

Model 126 Ejector (Fixed orifice pilot system supply restrictor)

Model 141-3 Flow Control Valve (Adjustable closing speed control)

Model 159 Y-Strainer (Protects pilot system from dirt/debris)

Model 141-4 Isolation Ball Valves

Model 155 Visual Indicator (Optional)

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

www.apollovalves.com | (704) 841-6000

This specification is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specification without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1373 04/14 Page 1 of 2

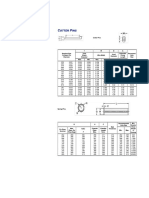

A108 Series

Pressure Relief/Pressure Sustaining

Automatic Control Valve

Dimensions - Inches

Dim

A

C

Angle

D

Angle

H

End Conn.

Screwed

Grooved

150# FLGD

300# FLGD

Screwed

Grooved

150# FLGD

300# FLGD

Screwed

Grooved

150# FLGD

300# FLGD

ALL

1-1/4 1-1/2

8-3/4

8-3/4

8-1/2

8-3/4

4-3/8

4-3/8 *

4-1/4

4-3/8

3-1/8

3-1/8 *

3

3-1/8

10

2

9-7/8

9-7/8

9-3/8

9-7/8

4-3/4

4-3/4

4-3/4

5

3-7/8

3-7/8

3-7/8

4-1/8

11

* Grooved end not available in 1-1/4.

2-1/2

10-1/2

10-1/2

10-1/2

11-1/8

6

6

6

6-3/8

4

4

4

4-3/8

11

3

13

13

12

12-3/4

6-1/2

6-1/2

6

6-3/8

4-1/2

4-1/2

4

4-3/8

11

4

-15-1/4

15

15-5/8

-7-5/8

7-1/2

7-13/16

-5-5/8

5-1/2

5-13/16

12

6

-20

17-3/4

18-5/8

--10

10-1/2

--6

6-1/2

13

8

--25-3/8

26-3/8

--12-11/16

13-3/16

--8

8-1/2

14

10

--29-3/4

31-1/8

--14-7/8

15-9/16

--11-3/8

12-1/16

17

12

--34

35-1/2

--17

17-3/4

--11

11-3/4

18

14

--39

40-1/2

--------20

16

--40-3/8

42

--20-13/16

21-5/8

--15-11/16

16-1/2

20

24

--62

63-3/4

--------28-1/2

For maximum efficiency, the OCV control valve should be mounted in a piping system so that the valve bonnet (cover) is in the top

position. Other positions are acceptable but may not allow the valve to function to its fullest and safest potential. In particular,

please consult the factory before installing 8 and larger valves, or any valves with a limit switch, in positions other than described.

Space should be taken into consideration when mounting valves and their pilot systems.

A routine inspection & maintenance program should be established and conducted yearly by a qualified technician.

factory code

A108

valve type/

model number

connection full port

A108 = Standard A = Angle/Flanged

ANSI CLS 150

B = Angle/Flanged

ANSI CLS 300

C = Angle/Threaded

(1-1/4 3)

E = Angle/Grooved Ends

(1-1/2 4)

F = Angle/Flanged

CLS 300 x CLS 150

G = Globe/Flanged

ANSI CLS 150

(Full & Reduced Port)

H = Globe/Flanged

ANSI CLS 300

(Full & Reduced Port)

J = Globe/Threaded Ends

(1-1/4 3)

V = Globe/Grooved Ends

(1-1/2 4)

002

series extension

002 = Pressure Relief/

Pressure Sustaining

003 = Pressure Relief/

Pressure Sustaining

and Check Valve

004 = Pressure Relief/

Pressure Sustaining

and Solenoid Shutoff

Valve

020

Valve Size body & bonnet

Full Port

material

012 = 1-1/4 1 = Ductile Iron

015 = 1-1/2 NSF 61-Epoxy Coated

020 = 2

2 = Cast Steel

025 = 2-1/2 5 = B61 Bronze

030 = 3

7 = Stainless Steel

040 = 4

060 = 6

080 = 8

010 = 10

120 = 12

140 = 14

160 = 16

240 = 24

seat ring

pilot,

Elastomers

material

fittings, tube

1 = Bronze B61

3 = EPDM

Code Pilot Ftgs Tube

2 = Stainless Steel

(Standard NSF-61)

1

BZ

BRS

CU

SS

SS

SS

BZ

SS

SS

How to order your A108 valve

When Ordering please provide:

Fluid to be controlled -Model Number -Size

Globe or Angle -End Connection -Body Material

Trim Material -Pilot Options -Pressure Setting or

Spring Range -Special Requirements / Installation requirements.

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

www.apollovalves.com | (704) 841-6000

This specification is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specification without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1373 04/14 Page 2 of 2

You might also like

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Three Way ValvesDocument8 pagesThree Way ValvesWalter JosephNo ratings yet

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocument7 pagesMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetDocument7 pagesMustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M115 (Globe), M1115 (Angle) Specification SheetDocument7 pagesMustang Series M115 (Globe), M1115 (Angle) Specification SheetWattsNo ratings yet

- F110-14, F1110-14 Specification SheetDocument6 pagesF110-14, F1110-14 Specification SheetWattsNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- RedvalvE 90 01Document4 pagesRedvalvE 90 01Rizal FalevyNo ratings yet

- 90-01 Reductora de Presion Cla-ValDocument4 pages90-01 Reductora de Presion Cla-ValPablo SolisNo ratings yet

- Valves BarendsenDocument63 pagesValves BarendsenidontlikeebooksNo ratings yet

- M110-14, M1110-14 Specification SheetDocument6 pagesM110-14, M1110-14 Specification SheetWattsNo ratings yet

- Classic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetDocument7 pagesClassic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetWattsNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- FM-200 Alpha Series SystemsDocument6 pagesFM-200 Alpha Series SystemsGurusumiNo ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- 3105 B 26Document3 pages3105 B 26ParIs MoRanNo ratings yet

- CLAVAL Pressure Reducing ValveDocument4 pagesCLAVAL Pressure Reducing ValvermgatocNo ratings yet

- PRV SizingDocument4 pagesPRV SizingTiffany CombsNo ratings yet

- Single Seat Valve Description Code PagesDocument6 pagesSingle Seat Valve Description Code PagesCarlos Omar Jave BobadillaNo ratings yet

- 417 Model E Alarm Check ValvesDocument4 pages417 Model E Alarm Check ValvesM Kumar MarimuthuNo ratings yet

- Es Acv 1116FMDocument4 pagesEs Acv 1116FMWattsNo ratings yet

- 50B4KGDocument2 pages50B4KGonin007No ratings yet

- Triple Duty Valve BrochureDocument8 pagesTriple Duty Valve Brochuresas999333No ratings yet

- Air CompressorDocument48 pagesAir CompressorMarius Condurache0% (1)

- 299HDocument20 pages299HJulian Esteban Arnaiz VargasNo ratings yet

- HytrolDocument44 pagesHytrolMark Mach AllenNo ratings yet

- PRS 09i EX PDFDocument5 pagesPRS 09i EX PDFengp3077No ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Modulating Float ValvesDocument4 pagesModulating Float ValvesJayakrishnan RadhakrishnanNo ratings yet

- Suction Guide & Flo-Trex Valve Series: Pump TrimDocument8 pagesSuction Guide & Flo-Trex Valve Series: Pump Trimsiva_nagesh_2No ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- Aw50 40.aw50 42Document8 pagesAw50 40.aw50 42eedee392% (13)

- Oil Pump Type E 1001 Gear Sizes 4-6-7Document2 pagesOil Pump Type E 1001 Gear Sizes 4-6-7Titu NicuNo ratings yet

- Equilibar Hygienic FD Series Back Pressure RegulatorDocument4 pagesEquilibar Hygienic FD Series Back Pressure RegulatorEquilibarNo ratings yet

- E 50 49 - FireDocument2 pagesE 50 49 - FireJulio C. Sivira CallejaNo ratings yet

- Anderson Greenwood - Pentair Series 400 Modulating Datasheet PDFDocument4 pagesAnderson Greenwood - Pentair Series 400 Modulating Datasheet PDFSARATH KRISHNAKUMARNo ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Mustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetDocument8 pagesMustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetWattsNo ratings yet

- Quick Exh Valves 13QS1 Rev 0110Document2 pagesQuick Exh Valves 13QS1 Rev 0110136339No ratings yet

- HPCO2Document23 pagesHPCO2Abdul RahmanNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- RUELCO - Diff Pressure SwitchDocument2 pagesRUELCO - Diff Pressure SwitchAiman Hilmi Aiman HilmiNo ratings yet

- TFP910 09 2014Document20 pagesTFP910 09 2014goskleNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- CO2 AnsulDocument17 pagesCO2 AnsulJorge RVNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- WW 770-UDocument4 pagesWW 770-UAhmad NasserNo ratings yet

- Actuated ValvesDocument4 pagesActuated ValvestjendraNo ratings yet

- SRC Alpha Version1 PDFDocument26 pagesSRC Alpha Version1 PDFRajat JainNo ratings yet

- F113-6RFP, F1113-6RFP Specification SheetDocument16 pagesF113-6RFP, F1113-6RFP Specification SheetWattsNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Lee Spring CatalogDocument391 pagesLee Spring CatalogDGWNo ratings yet

- Nord-Lock Washers: The Original Wedge-Locking SolutionDocument16 pagesNord-Lock Washers: The Original Wedge-Locking SolutionDGWNo ratings yet

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDocument2 pagesWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWNo ratings yet

- He130 - Driveway Asphalt Coating: Physical PropertiesDocument2 pagesHe130 - Driveway Asphalt Coating: Physical PropertiesDGWNo ratings yet

- Overkote Asphalt Pavement Coating: DescriptionDocument1 pageOverkote Asphalt Pavement Coating: DescriptionDGWNo ratings yet

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Document2 pagesMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWNo ratings yet

- 01 04tocDocument428 pages01 04tocFaltooNo ratings yet

- Flat Washer and FastenersDocument49 pagesFlat Washer and FastenersDGWNo ratings yet

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- Wood Finishing Basics: Application Techniques & Product SelectionDocument13 pagesWood Finishing Basics: Application Techniques & Product SelectionDGWNo ratings yet

- D-01 7041 Flange-ANSI 125,150-RevlDocument4 pagesD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasNo ratings yet

- Threaded RodDocument1 pageThreaded RodDGWNo ratings yet

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDocument2 pagesTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWNo ratings yet

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- E Pipe Restraint ROMAC 612 CDocument1 pageE Pipe Restraint ROMAC 612 CDGWNo ratings yet

- Schedule 80 Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 Pipe Dimensions & Pressure RatingsDGWNo ratings yet

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- Rubber Expansion JointsDocument9 pagesRubber Expansion JointsDGWNo ratings yet

- PVC Gravity Sewer PipeDocument1 pagePVC Gravity Sewer PipeDGWNo ratings yet

- Countersinking Drill Bit ReamerDocument1 pageCountersinking Drill Bit ReamerDGWNo ratings yet

- Thrust Restraint For Expansion JointDocument2 pagesThrust Restraint For Expansion JointDGWNo ratings yet

- The First Hillside Washer That Eliminated Back-Up Plates!Document1 pageThe First Hillside Washer That Eliminated Back-Up Plates!DGWNo ratings yet

- Tap Drill DataDocument1 pageTap Drill DataDGWNo ratings yet

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDocument2 pagesJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWNo ratings yet

- Bolt - Astm A449Document2 pagesBolt - Astm A449DGWNo ratings yet

- Tap Drill ChartDocument2 pagesTap Drill ChartDGWNo ratings yet

- Screw Threads DesignDocument1 pageScrew Threads DesignDGWNo ratings yet

- Cotter Pins and Spring PinsDocument1 pageCotter Pins and Spring PinsDGWNo ratings yet

- Standard Pipe Schedules and Sizes ChartDocument1 pageStandard Pipe Schedules and Sizes ChartDGWNo ratings yet

- Steel Rebar SizesDocument1 pageSteel Rebar SizesDGWNo ratings yet

- Refrigeration Practical 1Document6 pagesRefrigeration Practical 1SamNo ratings yet

- Wire DrawingDocument4 pagesWire DrawingSolomon NgussieNo ratings yet

- Steel8 PDFDocument18 pagesSteel8 PDFJon LawheadNo ratings yet

- Tripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Document16 pagesTripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Abhijit RoyNo ratings yet

- Low Pressure Steam Curing of Precast UnitsDocument4 pagesLow Pressure Steam Curing of Precast Unitsdash1991No ratings yet

- Chapter - 7 Materials HandlingDocument14 pagesChapter - 7 Materials HandlingTanaya KambliNo ratings yet

- Essa® Fire Assay Multiload and Multipour SystemsDocument4 pagesEssa® Fire Assay Multiload and Multipour SystemsLuz ContrerasNo ratings yet

- Caleb Catalogue DiscspringDocument5 pagesCaleb Catalogue DiscspringsantoshNo ratings yet

- Towards 4.0: The Smelter of The FutureDocument4 pagesTowards 4.0: The Smelter of The FutureShyamal VermaNo ratings yet

- Cooling Tower Lab ReportDocument9 pagesCooling Tower Lab ReportDinesh Kumar Vijeyan100% (6)

- Muller Tapping MachineDocument8 pagesMuller Tapping MachineKUMAARRRNo ratings yet

- Various Advantages and Disadvantages of Waste Incineration - Conserve Energy FutureDocument1 pageVarious Advantages and Disadvantages of Waste Incineration - Conserve Energy FutureKumar SeerattanNo ratings yet

- Wasco Brochure 2012Document31 pagesWasco Brochure 2012Amir Asyraf SuhailiNo ratings yet

- Reverse Osmosis DETAILSDocument38 pagesReverse Osmosis DETAILSgkdora574100% (1)

- Reinforcing Steel Bars and TendonsDocument31 pagesReinforcing Steel Bars and TendonsJebone Stein Web JuarbalNo ratings yet

- F1079Document2 pagesF1079Gustavo Suarez100% (1)

- The Tubular Film Blowing ProcessDocument9 pagesThe Tubular Film Blowing ProcessAlmir MachadoNo ratings yet

- Chapter 8 - Part A - Fully Developed Laminar Flow PDFDocument12 pagesChapter 8 - Part A - Fully Developed Laminar Flow PDFShubham ChoudharyNo ratings yet

- THK Paint Defects GB PDFDocument24 pagesTHK Paint Defects GB PDFmaddyNo ratings yet

- (Rev) Electrowinning of Zing From Sulphate Solutions - M Mufti AbdillahDocument27 pages(Rev) Electrowinning of Zing From Sulphate Solutions - M Mufti AbdillahDafi GhifariNo ratings yet

- History of Iron and Steel BridgesDocument2 pagesHistory of Iron and Steel BridgesKAii Magno Guia0% (1)

- ETD 2004 CircularDocument2 pagesETD 2004 Circularagarwalabhay3_991072No ratings yet

- Bosch Catalog - Edition 2014Document456 pagesBosch Catalog - Edition 2014longtrandang5867No ratings yet

- h40d PDFDocument310 pagesh40d PDFnghia phanNo ratings yet

- PSM 2Document23 pagesPSM 2luisNo ratings yet

- FDA Updates On Hand Sanitizers Consumers Should Not Use FDADocument7 pagesFDA Updates On Hand Sanitizers Consumers Should Not Use FDAMary Claire PattonNo ratings yet

- Soil Nail Thesis PresentationDocument36 pagesSoil Nail Thesis Presentationjoshua humirangNo ratings yet

- Specifications: PartsDocument1 pageSpecifications: PartsJohn reinaNo ratings yet

- Kisweld CatalogDocument76 pagesKisweld Cataloglara_rajkumar667No ratings yet

- Chapter Four Stabilized Pavement MaterialsDocument46 pagesChapter Four Stabilized Pavement Materialsyeshi janexoNo ratings yet