Professional Documents

Culture Documents

Leakage Class of Control Valves

Uploaded by

g1232003gOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leakage Class of Control Valves

Uploaded by

g1232003gCopyright:

Available Formats

PERFORMANCE

ENGINEERED

SVF

Leakage Classifications of Control Valves

Classification of seat leakage through control valves

Control valves are designed to throttle and not necessary to close 100%.

A control valve's ability to shut off has to do with many factors as the type of valves

for instance. A double seated control valve have very poor shut off capability. The

guiding, seat material, actuator thrust, pressure drop, and the type of fluid can all

play a part in how well a particular control valve shuts off.

Seat Leakage Classifications

There are actually six different seat leakage classifications as defined by ANSI/FCI

70-2 1976(R1982) .

The most common used are

• CLASS IV

• CLASS VI

CLASS IV is also known as metal to metal. It is the kind of leakage rate you can

expect from a valve with a metal plug and metal seat.

CLASS VI is known as a soft seat classification. Soft Seat Valves are those where

either the plug or seat or both are made from some kind of composition material

such as Teflon or similar.

Valve Leakage Classifications

Class I - Valve Leakage Classifications

Identical to Class II, III, and IV in construction and design intent, but no actual shop

test is made. Class I is also known as dust tight and can refer to metal or resilient

seated valves.

Class II - Valve Leakage Classifications

Intended for double port or balanced singe port valves with a metal piston ring seal

and metal to metal seats.

• 0.5% leakage of full open valve capacity.

• Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125oF.

• Test medium air at 45 to 60 psig is the test fluid.

SVF Flow Controls, Inc.

13560 Larwin Circle

Santa Fe Springs, CA 90670

562-802-2255

PERFORMANCE

ENGINEERED

SVF

Typical constructions:

• Balanced, single port, single graphite piston ring, metal seat, low seat load

• Balanced, double port, metal seats, high seat load

Class III - Valve Leakage Classifications

Intended for the same types of valves as in Class II.

• 0.1% leakage of full open valve capacity.

• Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125oF.

• Test medium air at 45 to 60 psig is the test fluid.

Typical constructions:

• Balanced, double port, soft seats, low seat load

• Balanced, single port, single graphite piston ring, lapped metal seats, medium

seat load

Class IV - Valve Leakage Classifications

Intended for single port and balanced single port valves with extra tight piston seals

and metal to-metal seats.

• 0.01% leakage of full open valve capacity.

• Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125oF.

• Test medium air at 45 to 60 psig is the test fluid.

Typical constructions:

• Balanced, single port, Teflon piston ring, lapped metal seats, medium seat

load

• Balanced, single port, multiple graphite piston rings, lapped metal seats

• Unbalanced, single port, lapped metal seats, medium seat load

• Class IV is also known as metal to metal

SVF Flow Controls, Inc.

13560 Larwin Circle

Santa Fe Springs, CA 90670

562-802-2255

PERFORMANCE

ENGINEERED

SVF

Class V - Valve Leakage Classifications

Intended for the same types of valves as Class IV.

• The test fluid is water at 100 psig or operating pressure.

• Leakage allowed is limited to 5 x 10 ml per minute per inch of orifice diameter

per psi differential.

• Service dP at 50 to 125 oF.

Typical constructions:

• Unbalanced, single port, lapped metal seats, high seat load

• Balanced, single port, Teflon piston rings, soft seats, low seat load

• Unbalanced, single port, soft metal seats, high seat load

Class VI - Valve Leakage Classifications

Class VI is known as a soft seat classification. Soft Seat Valves are those where the

seat or shut-off disc or both

are made from some kind of resilient material such as Teflon. Intended for resilient

seating valves.

• The test fluid is air or nitrogen.

• Pressure is the lesser of 50 psig or operating pressure.

• The leakage limit depends on valve size and ranges from 0.15 to 6.75 ml per

minute for valve sizes 1 through 8 inches.

Port Diameter Bubbles per ml per

inches Millimeters minute minute

1 25 1 0.15

1 1/2 38 2 0.30

2 51 3 0.45

2 1/2 64 4 0.60

3 76 6 0.90

4 102 11 1.70

6 152 27 4.00

8 203 45 6.75

10 254 63 9

12 305 81 11.5

Typical constructions:

• Unbalanced, single port, soft seats, low load

SVF Flow Controls, Inc.

13560 Larwin Circle

Santa Fe Springs, CA 90670

562-802-2255

PERFORMANCE

ENGINEERED

SVF

Control Valve Leakage Classification - Overview

Testing

Leakage Maximum Procedures

Test Test

Class Leakage Required for

Medium Pressure

Designation Allowable Establishing

Rating

No test

I x x x

required

Air or 45 - 60 psig 45 - 60 psig or

water at or maximum maximum

0.5% of rated 50 - operating operating

II

capacity 125o F differential differential

(10 - whichever is whichever is

52oC) lower lower

0.1% of rated As

III As above As above

capacity above

0.01% of rated As

IV As above As above

capacity above

Maximum

Maximum

service

0.0005 ml per Water service

pressure

minute of water at 50 pressure drop

drop across

V per inch of port to125oF across valve

valve plug

diameter per psi (10 to plug not to

not to

differential 52oC) exceed ANSI

exceed ANSI

body rating

body rating

Actuator

50 psig or should be

Air or max rated adjusted to

nitrogen differential operating

Not to exceed

at 50 to pressure conditions

VI amounts shown in

125o F across valve specified with

the table above

(10 to plug full normal

52oC) whichever is closing thrust

lower applied to

valve plug seat

SVF Flow Controls, Inc.

13560 Larwin Circle

Santa Fe Springs, CA 90670

562-802-2255

You might also like

- Valve Leakage Classifications OverviewDocument4 pagesValve Leakage Classifications Overviewtonnyhawk24No ratings yet

- Seat Leakage ClassificationDocument10 pagesSeat Leakage ClassificationZulfequar R. Ali KhanNo ratings yet

- Leakage Classification of Control ValvesDocument4 pagesLeakage Classification of Control ValvesValerian PopescuNo ratings yet

- Leaked ValveDocument3 pagesLeaked ValveJosé Daniel ArenasNo ratings yet

- Seat Leakage Classifications: ANSI/FCI 70-2 1976 (R1982)Document4 pagesSeat Leakage Classifications: ANSI/FCI 70-2 1976 (R1982)Lou CestNo ratings yet

- Seccion 1 Curso Valvulas de Control Ver3 (Modo de Compatibilidad)Document101 pagesSeccion 1 Curso Valvulas de Control Ver3 (Modo de Compatibilidad)Petah LlopNo ratings yet

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- Control Valve 1706705612Document59 pagesControl Valve 1706705612changaiz899No ratings yet

- Seat Leakage ClassificationsDocument2 pagesSeat Leakage Classificationsgrig_cNo ratings yet

- Reliance Petroleum Control Valve OverviewDocument60 pagesReliance Petroleum Control Valve OverviewlavchemicalNo ratings yet

- Control Valve PresentationDocument61 pagesControl Valve PresentationmohamedNo ratings yet

- Control Valve PresentationDocument61 pagesControl Valve PresentationBorabta MstNo ratings yet

- Demystifying Leakage NomenclatureDocument3 pagesDemystifying Leakage Nomenclatureadresseapp100No ratings yet

- Seat Leakage GuideDocument16 pagesSeat Leakage GuideLv RamanNo ratings yet

- Deep Well Check Valves: Maximizing The FlowDocument4 pagesDeep Well Check Valves: Maximizing The FlowChris KNo ratings yet

- Best PPT On VALVESDocument155 pagesBest PPT On VALVESPanda BoyNo ratings yet

- Valves Seat LeakageDocument14 pagesValves Seat LeakageArunprasad MurugesanNo ratings yet

- Deepwell BrochureDocument4 pagesDeepwell BrochureАлексей КолесникNo ratings yet

- Basic Control Valve Sizing and SelectionDocument38 pagesBasic Control Valve Sizing and SelectionmohamedNo ratings yet

- Transformers Padmounted CompartmentalizedDocument2 pagesTransformers Padmounted CompartmentalizedRodel D DosanoNo ratings yet

- Basic Control Valve - Sizing & SelectionDocument38 pagesBasic Control Valve - Sizing & SelectionViệt Đặng XuânNo ratings yet

- Control ValveDocument37 pagesControl ValveSagar Bhardwaj100% (4)

- Digital Control Valve Model BV88: Technical DataDocument4 pagesDigital Control Valve Model BV88: Technical Datajoana ramirezNo ratings yet

- Female NPT Check Valves: Maximizing The FlowDocument4 pagesFemale NPT Check Valves: Maximizing The FlowChris KNo ratings yet

- Check Valve SelectionDocument1 pageCheck Valve SelectionramkikkdNo ratings yet

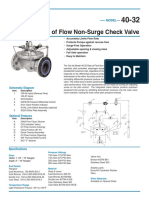

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Three-Phase Pad-Mounted TransformersDocument2 pagesThree-Phase Pad-Mounted TransformersmarkfoyNo ratings yet

- RV Series: High Pressure Anti-Cavitation Relief ValvesDocument6 pagesRV Series: High Pressure Anti-Cavitation Relief Valveselectrico65No ratings yet

- Basic Control Valve Sizing and SelectionDocument53 pagesBasic Control Valve Sizing and SelectionAtul TripathiNo ratings yet

- dsbv88 r15Document4 pagesdsbv88 r15Ricardo TurinNo ratings yet

- Series 600: Globe Style Sizes 3 Through 42 InchesDocument8 pagesSeries 600: Globe Style Sizes 3 Through 42 InchesSergio Veliz RNo ratings yet

- Bray - Valvulas Control RotativasDocument151 pagesBray - Valvulas Control RotativasAnnie De WildeNo ratings yet

- Catalogo SSV-Two-step-Product-leafletDocument6 pagesCatalogo SSV-Two-step-Product-leafletMicelliNo ratings yet

- VVI Control ValvesDocument13 pagesVVI Control ValvesPRONOJIT HUNTERNo ratings yet

- ISA Mentor Program WebEx Best Control Valve Rev0Document44 pagesISA Mentor Program WebEx Best Control Valve Rev0Harold David Gil MuñozNo ratings yet

- GA Industries Product Line BrochureDocument8 pagesGA Industries Product Line BrochureSathishkumar DhamodaranNo ratings yet

- VALVESDocument153 pagesVALVESHamood Ahmad100% (1)

- 008 DQDocument36 pages008 DQGabriela MotaNo ratings yet

- Solenoid Valve Handles Aggressive FluidsDocument6 pagesSolenoid Valve Handles Aggressive FluidsFrancisco Mones RuizNo ratings yet

- Pressure Testing Requirements For Valves CBD-P-07 Rev.00Document9 pagesPressure Testing Requirements For Valves CBD-P-07 Rev.00SDP02100% (1)

- Leakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208Document14 pagesLeakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208anon_9896895680% (1)

- Sizing & Selection: The Control ValveDocument7 pagesSizing & Selection: The Control ValveJamesTorresPalmaNo ratings yet

- Valtek Full Book PDFDocument529 pagesValtek Full Book PDFSamuel OnyewuenyiNo ratings yet

- 1.1 Daelim Pad Mounted TransformerDocument12 pages1.1 Daelim Pad Mounted Transformeralcibiades romeroNo ratings yet

- Ventil Brochure 2016 LRDocument44 pagesVentil Brochure 2016 LRbaaziz100% (1)

- The Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarDocument61 pagesThe Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarRaju NaiduNo ratings yet

- Control Valve TypesDocument46 pagesControl Valve TypesAnderson SiqueiraNo ratings yet

- PLUG VALVES SPVDocument16 pagesPLUG VALVES SPVJorge Hanna AkouriNo ratings yet

- Control-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFDocument10 pagesControl-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFPiush KumarNo ratings yet

- B16.104 Chinese PDFDocument1 pageB16.104 Chinese PDFalgerrlNo ratings yet

- FluidComponentsFullCatalog PDFDocument502 pagesFluidComponentsFullCatalog PDFPablo MNo ratings yet

- Dual Plate Check ValveDocument38 pagesDual Plate Check ValveVikas Kumar PathakNo ratings yet

- Valve Selection PDFDocument5 pagesValve Selection PDFKamil MarszałekNo ratings yet

- Check Valve - Type CK4ADocument4 pagesCheck Valve - Type CK4AHuong QuangNo ratings yet

- Butterfly Valves Purushotham: Pro R&D PVT LTDDocument7 pagesButterfly Valves Purushotham: Pro R&D PVT LTDPurushothamNo ratings yet

- ANSI VALVE LEAKAGE STANDARDS Gemco ValveDocument1 pageANSI VALVE LEAKAGE STANDARDS Gemco ValveelicaNo ratings yet

- UVPL-91-Top Guided Unbalanced Globe CAT-08 - 2017Document16 pagesUVPL-91-Top Guided Unbalanced Globe CAT-08 - 2017Subhash NarayananNo ratings yet

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- No. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- Hydraulics - Written ReportDocument7 pagesHydraulics - Written ReportChristian ConsignaNo ratings yet

- GILMAN Guide To Designing and Sizing Hydraulic Ram Pump SystemDocument6 pagesGILMAN Guide To Designing and Sizing Hydraulic Ram Pump SystemGil Salas CagalawanNo ratings yet

- Piping Material ClassesDocument42 pagesPiping Material Classest_i_f_anoNo ratings yet

- 307C Excavators Hydraulic System: Baj1-Up Bcm1-UpDocument2 pages307C Excavators Hydraulic System: Baj1-Up Bcm1-Upqwureyquwery67% (3)

- Corrected Valve Sizes 21.10.'23Document2 pagesCorrected Valve Sizes 21.10.'23Padmakumar T CNo ratings yet

- 2021 09 20 Gravity Sewerage Drawings v1.1Document123 pages2021 09 20 Gravity Sewerage Drawings v1.1jjslfNo ratings yet

- All Auxilary PumpsDocument10 pagesAll Auxilary PumpsRana Yasir AyubNo ratings yet

- Reasons For High TemperatureDocument4 pagesReasons For High TemperatureKachena JamesNo ratings yet

- PumpsDocument46 pagesPumpsDr. Rachid djoudjouNo ratings yet

- Variable Displacement Axial Piston Pumps PVPC Single PumpsDocument6 pagesVariable Displacement Axial Piston Pumps PVPC Single PumpsLary SchezilNo ratings yet

- Bomba de Diafragma Samoa DF50 PDFDocument54 pagesBomba de Diafragma Samoa DF50 PDFArnulfo Diaz CuellarNo ratings yet

- 9500 Series Snap Pilot IOM ManualDocument84 pages9500 Series Snap Pilot IOM ManualPSNo ratings yet

- Water Resource EnggDocument9 pagesWater Resource EnggShaik Jhoir100% (1)

- Flow and Pressure Control ValvesDocument9 pagesFlow and Pressure Control ValvesMaryland SalcedoNo ratings yet

- Pump and Compressor Design & Heuristics:: Dr. Chandra Mouli M.RDocument38 pagesPump and Compressor Design & Heuristics:: Dr. Chandra Mouli M.RRayan HassanNo ratings yet

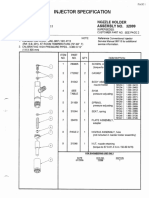

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Miguel RojasNo ratings yet

- Fire Fighting Equipment Couplings and Fittings GuideDocument58 pagesFire Fighting Equipment Couplings and Fittings GuideMANUELGRACIANINo ratings yet

- Diagramatic Plumbing Layout PDFDocument1 pageDiagramatic Plumbing Layout PDFdkdesign consultantNo ratings yet

- Design Sanjeev 1Document18 pagesDesign Sanjeev 1riteshreplyNo ratings yet

- Pressure relief valve cartridge specificationsDocument4 pagesPressure relief valve cartridge specificationsCARLOS RAMIREZNo ratings yet

- A1A2Document6 pagesA1A2Tommy ArjanggiNo ratings yet

- Hydraulics and Electrics Guide for Agricultural EquipmentDocument208 pagesHydraulics and Electrics Guide for Agricultural EquipmentVlad Ptashnichenko100% (1)

- 20Document14 pages20Sileshi BekeleeNo ratings yet

- Approved Hydraulic Fluids For Putzmeister Concrete PumpsDocument1 pageApproved Hydraulic Fluids For Putzmeister Concrete PumpsNazeeh Abdulrhman AlbokaryNo ratings yet

- Series 20 Axial Piston Pumps: Technical InformationDocument20 pagesSeries 20 Axial Piston Pumps: Technical InformationTan JaiNo ratings yet

- Order MaterialsDocument4 pagesOrder MaterialsAndri AjaNo ratings yet

- Technical Data: EVMSG45 2-2F5BQ1EG E/5.5Document6 pagesTechnical Data: EVMSG45 2-2F5BQ1EG E/5.5MujtabaNo ratings yet

- TF Bosch VP44 Fuel Pump (Ver1)Document43 pagesTF Bosch VP44 Fuel Pump (Ver1)Carlos A Romero92% (37)

- Brake HidraulicsDocument40 pagesBrake HidraulicsSERGIO CARDENAS CASTILLONo ratings yet