Professional Documents

Culture Documents

7020 e

Uploaded by

cmfreire89Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7020 e

Uploaded by

cmfreire89Copyright:

Available Formats

Angle Seat Control Valve 7020

with integrated positioner

DN 8 up to DN 80

PN 40

Pneumatically operated control valves for neutral

through to highly aggressive media.

Integrated positioner

Compact design

All parts contacting the fluid made from stainless steel

Temperatures up to 200C

Working pressure up to 40 bar

Type 7020

with i/p-positioner

Type 8047

Control valve with integrated micropro-cessor-positioner for

the control of neutral through to aggressive media in process

engineering, chemical industry and for plant equipment.

Space saving design and low weight

No steady- state air consumption

Operation independent of mounting position and supply pressure variations

Not sensitive to vibration

Instrument grade air not essential

Software configurable flow characteristics

Protection Class IP65

Technical Information

Body material

Stainless steel 1.4408

Nominal sizes

DN 8 up to DN 80

Connections

Pipe thread acc. ISO 228-1 DN 8 up to DN 80

NPT thread

DN 8 up to DN 80

Welding ends

DN15 up to DN 65

Nominal pressure

PN40

Fluid temperature*

-30C up to +200C

Ambient temperature**

-15C up to +80C

*: Please consider further temperature versions

and limits in technical bulletin 32

**: Please consider the limitation of use of the

positioner

Type 7020

with digital positioner

Type 8049

Optionen

e.g.:

- Optical position indicator

- External I/P-converter Type 8045

- Ex-electropneumatic positioner

(

II 2 G EEx ib IIC T6)

Schubert & Salzer Control Systems GmbH, Bunsenstr. 38, 85051 Ingolstadt, Tel: +49 (0)841-9654 0, Fax: +49 (0)841 9654 590

info.cs@schubert-salzer.com, www.schubert-salzer.com

Angle Seat Control Valve 7020, standard design

with integrated positioner

external zero

adjustment

restriction screw

electropneumatical

positioner

Type 8047

W.

pneumatical positioner

Type 8047

y%

y%

100

75

50

25

100

75

50

25

rotatable

bonnet

internal stroke

feedback

Auenlippendichtung

exterior lip sealing

packing (self adjusting)

valve stem

body

digital positioner, Type

8049

internal stroke

feedback

rotatable bonnet

lip sealing

self-adjusting packing

valve stem (roller

burnished)

body

Materials

Body

Seating seal

Bonnet

Stainless steel 1.4408

PTFE

Brass chrome plated (actuator 50 mm, 80 mm )

Aluminium corrosion protected (actuator 125 mm )

Diaphragm actuator Stainless steel 1.4301/1.4305

Actuator springs

Stainless steel 1.4310 (actuator 50 mm, 80 mm, diaphr.act.)

Spring steel wire C, zinc coated (actuator 125 mm)

Packing

PTFE (carbon filled), spring 1.4310

Valve stem

Stainless steel 1.4571, roller burnished

Position indicator

PA Trogamid (clear)

Angle Seat Control Valve 7020, standard design

with integrated positioner

Positioner

For technical information of our positioners please refer to the corresponding data sheets.

Admissible Differential Pressures

digital positioner

DN

Diff.druck

8

15

20

25

25

32

32

32

40

40

40

bar

17

17

17

17

17

10

17

17

6

17

17

p/p- and i/p-positioner

Supply

pressure

range

bar

4-6

4-6

4-6

4-6

3-6

4-6

3-6

3-6

4-6

4-6

3-6

Piston

Springs

mm

80

80

80

80

250

80

125

250

80

125

250

Number

2*

2

2

1

4

1

2

4

1

3

6

* special springs

DN

Differential

pressure

8

15

20

25

25

32

32

32

40

40

40

bar

17

17

17

12

11

7

13

17

4

11

15

Supply

pressure

range

bar

4-6

4-6

4-6

4-6

2,8 - 6

4-6

3-6

2,8 - 6

4-6

4-6

3,4 - 6

* special springs

diaphragm actuator, direct pressure range

Differential pressure

Max. pressure (no)

Diaphragm

Supply air (bar)

(bar)

(bar)

area

spring range

spring range

spring range

mm

DN

0,2 - 1 bar 0,4 - 2 bar 0,2 - 1 bar 0,4 - 2 bar 0,2 - 1 bar 0,4 - 2 bar

15

17

17

17

17

1,2

2,4

250

20

16

17

17

17

1,2

2,4

250

25

9

17

12

15

1,2

2,4

250

32

5

15

6

13

1,2

2,4

250

40

3

10

2

5

1,2

2,4

250

50

2

6

1

2

1,2

2,4

250

Kvs-Values

DN

8

100% 0,6

40% 0,24

25% 0,15

15%

10%

7,5%

15

3,8

1,5

0,93

0,4

-

linear

20

25

8,8

14

3,5

5,8

2,2

3,6

-

32

20

8

-

40

27

11

-

8

0,6

-

15

3

1,2

0,8

0,46

0,23

equal percentage

20

25

32

6

10

16

2,4

4

6

1,5

2,6

-

40

25

10

-

Piston

Federbestckung

mm

80

80

80

80

250

80

125

250

80

125

250

Number

2*

2

2

1

4

1

2

6

1

3

8

Angle Seat Control Valve 7020, reinforced design

with integrated positioner

DN50 up to DN80, PN40

digitaler

positioner, Type

8049

diaphragm

actuator

rolling diaphragm

piston actuator

head section,

reinforced

piston rod

reinforced

Admissible Differential Pressures

digital positioner

p/p- and i/p-positioner

DN

Differential

pressure (bar)

50

50

50

50

50

65

65

80

80

PTFE

3

9

12

17

17

5

13

3

9

PEEK

3

5

10

17

8

5

Supply

pressure

range

bar

4-6

4-6

3-6

4-6

4-6

4-6

4-6

4-6

4-6

Piston

Springs

mm

80

125

250

250

250

125

250

125

250

number

1

3

6

8*

12

3

12

3

12

Kvs-Values

DN

100%

63%

50

43

26

linear

65

52

32

80

69

-

equal percentage

50

65

80

34

44

59

23

29

-

DN

50

50

50

50

65

80

Differential

pressure (bar)

PTFE

2

6

12

16

9

6

Supply

pressure

range

bar

4-6

4-6

4-6

4-6

4-6

4-6

* standard spring configuration

Piston

Springs

mm

80

125

250

250

250

250

number

1

3

10

12 *

12

12

Angle Seat Control Valve 7020

with integrated positioner

Ordering Number System

1

7

Symbol:

Type

V

Size

9 10 11 12 13 14

1 - 6 : Please quote all 6 sections.

S

7 - 14: Quote only if required.

"V": Valve

"A": Actuator (valve without body)

"R": Repair kit (sealings)

1. Body type

2. Connection

3. Body materials

4. Seat material

5. Positioner

6. Actuator

7. Springs

1 angle body

control valve

Type 7020

0 pipe thread

ISO 228-1

5 NPT thread

6 without thread

D welding ends

acc. DIN11850

H welding ends

acc. ISO

2 stainless steel

1.4408

0 PTFE

6 p/p positioner, Type 8047

7 i/p positioner, Type 8047

8 i/p positioner with plug

connection M12x1, Type 8047

9 i/p positioner ex-proof

(II 2 G Eex ib IIC T6), plug

connection M12x1, Type 8047

C digital positioner, Type 8049

4 wire

R digital positioner Type 8049

2 wire

T digital positioner Type 8049

AS-i version

W digital positioner Type 8049

2 wire, ex-version

1 piston 80 mm

2 piston 125 mm

C diaphragm

D 250mm

- without

significance

1 spring to open

(only with digital

positioner)

P spring set

0,2-1bar

(D 250mm)

T 6 springs

(D 250mm)

W 8 springs

(D 250mm)

Y 12 springs

(D 250mm)

8. Characteristic

9. Packing

- linear

1 equal

percentage

- standard

2 packing

underneath

10. Kvs-value

1

2

3

4

5

6

Ordering Example:

full Kvs-value

red. to 40%

red. to 25%

red. to 15%

red. to 7,5%

red. to 22,5%

red.to 10%

11. Accessories

- without

6 pilot-valve DN2

230V AC

7 pilot-valve DN2

24V DC

12. Special versions

S To state if some

stations are

quoted!

13. Seal

- standard

14. Position

indicator

0 with position

indicator

(dig. positioner

standard)

7020/020V1620C1

Angle Seat Control Valve, nominal size DN 20, without thread, stainless steel, PTFE seat

material, N.C., digital positioner Typ 8049, 4-wire, with position indicator,

piston 80 mm, linear characteristic, Kvs-value = 8,8

reinforced design (from DN50):

Ordering Example:

7020/050V1620C1-----S-------K

Angle Seat Control Valve, nominal size DN 50, without thread, stainless steel, PTFE seat

material, N.C., digital positioner Typ 8049, 4-wire, with position indicator, piston 80 mm,

linear characteristic, Kvs-value = 43, reinforced design

K reinforced design

Angle Seat Control Valve 7020, piston actuator

with integrated positioner

Dimensions and Weights

I

D

I

D

G 1/8"

G 1/8"

G 1/8"

W.

y%

y%

100

100

75

75

50

50

25

25

50

SW2

50

SW2

SW 1

SW 1

1.4408

1.4408

E

B

p/p-positioner

Type 8047

i/p-positioner

Type 8047

F

Positioner

p/p

i/p

230

260

230

260

235

265

240

270

255

285

275

305

260

290

280

310

SW1

SW2

96

96

96

96

96

146

96

146

E

Positioner

p/p

i/p

220

250

220

250

225

255

235

265

250

280

265

295

255

285

270

300

80

80

80

80

80

105

80

105

20

25

31

39

48

48

55

55

30

30

30

30

30

30

30

30

p/p

3,7

3,7

3,8

4,0

4,3

6,9

4,6

7,2

i/p

4,0

4,0

4,1

4,3

4,6

7,2

4,9

7,5

96

146

275

285

270

285

80

105

68

68

32

32

5,3

7,8

5,5

8,1

DN

Actuator

A

G/NPT

8

15

20

25

32

32

40

40

80

80

80

80

80

125

80

125

1/4"

1/2"

3/4"

1"

1 1/4"

1 1/4"

1 1/2"

1 1/2"

60

65

75

90

110

110

120

120

12

15

16,3

19,1

21,4

21,4

21,4

21,4

150

150

21

25,7

reinforced design:

2"

50

80

2"

50

125

305

315

300

315

Weight (kg)

Dimensions in mm

Angle Seat Control Valve 7020, piston actuator

with integrated positioner

Dimensions and Weight

I

116

2x

M16x1,5

G1/8"

F1

y%

100

75

50

25

0

50

SW2

SW 1

E1

1.4408

B

C

digital positioner Type 8049

A

G/NPT

1/2"

3/4"

1"

1 1/4"

1 1/4"

1 1/2"

1 1/2"

Hub

SW1

SW2

65

75

90

110

110

120

120

12

13

15

17

17

19

19

96

96

96

96

146

96

146

309

314

324

339

369

344

374

301

306

311

326

356

331

361

9,5

14,5

19

21

21

24

24

80

80

80

80

105

80

105

25

31

39

48

48

55

55

30

30

30

30

30

30

30

Weight

(kg)

4,4

4,5

4,7

5,0

7,6

5,3

7,9

reinforced design:

50

80

2"

50

125

2"

65

125

2 1/2"

80

125

3"

150

150

180

214

25,7

26

30

34

96

146

146

146

350

365

385

435

350

365

380

380

24

24

24

24

80

105

105

105

68

68

85

100

32

32

36

41

5,9

8,5

8,9

11,4

DN

Actuator

15

20

25

32

32

40

40

80

80

80

80

125

80

125

Dimensions in mm

Angle Seat Control Valve 7020, diaphragm actuator

with integrated positioner

Dimensions and Weights

D

115

140

SW 2

SW 1

B

A

Text and pictures are not binding. We reserve the right, to alter the equipment.

diaphragm actuator D250 with digital positioner 8049

DN

15

20

25

32

40

50

65

80

A

G 1/2"

G 3/4"

G 1"

G 1 1/4"

G 1/2"

G 2"

G 2 1/2"

G 3"

B

65

75

90

110

120

150

180

214

Data sheet 7020e /Version: 27.08.2012

C

15

16,3

19,1

21,4

21,4

25,7

30,2

33,5

D

238

238

238

238

238

238

238

238

E

340

350

360

370

380

410

425

475

F

350

360

370

385

395

410

420

410

G

285

295

305

315

325

350

370

410

H

280

290

300

310

320

335

350

355

SW1

25

31

39

48

55

68

85

100

SW2

30

30

30

30

30

36

36

41

Angle

50

50

50

50

50

50

50

45

Weight kg

15,6

15,7

15,9

16

16,2

16,5

16,9

19,4

Dimensions in mm

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

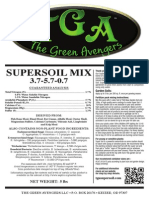

- TGA Supersoil 5lbDocument1 pageTGA Supersoil 5lbKatherine CampbellNo ratings yet

- Pharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.Document3 pagesPharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.anto_pharma7784No ratings yet

- 10 Things You Need To Know About Premixes: by DSM Nutritional ProductsDocument2 pages10 Things You Need To Know About Premixes: by DSM Nutritional ProductsanaNo ratings yet

- RingMethod Zuidema WatersDocument2 pagesRingMethod Zuidema WatersJack Yoseph Martinez OrtegaNo ratings yet

- Bet MethodDocument16 pagesBet MethodG Nivetha100% (1)

- MK1977 CongressDocument173 pagesMK1977 CongressGodshalllaughNo ratings yet

- Hofmeister Series: Ions Franz Hofmeister ProteinsDocument11 pagesHofmeister Series: Ions Franz Hofmeister ProteinsRajeshwari SridharanNo ratings yet

- G10 - Handout - Organic - Makeup Handout - First WeekDocument4 pagesG10 - Handout - Organic - Makeup Handout - First WeekSheela BatterywalaNo ratings yet

- 242 Chemistry Resources CH 5 8Document137 pages242 Chemistry Resources CH 5 8Tina Sima88% (8)

- Datasheet Z-PrimercoatDocument1 pageDatasheet Z-PrimercoatСтанислав ПодольскийNo ratings yet

- 5 Minute Guide Electricity StorageDocument17 pages5 Minute Guide Electricity StorageCarlos HolguinNo ratings yet

- Different Manicure Equipment, Materials and CosmeticsDocument36 pagesDifferent Manicure Equipment, Materials and CosmeticsRenlen EstevesNo ratings yet

- Bag Tanning IndiaDocument8 pagesBag Tanning IndiaBurhoneySonNo ratings yet

- tmpA3C2 TMPDocument11 pagestmpA3C2 TMPFrontiersNo ratings yet

- Cleaning Validation MACO v2.1Document3 pagesCleaning Validation MACO v2.1Syifa FatasyaaNo ratings yet

- Use of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si EngineDocument6 pagesUse of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si Enginepetchiappan pNo ratings yet

- Everyday Science PDFDocument101 pagesEveryday Science PDFMahmood SyedNo ratings yet

- Plug Design Case StudyDocument24 pagesPlug Design Case StudyAnonymous EsZwKlnBNo ratings yet

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreDocument8 pagesFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZNo ratings yet

- Work Instructions (W.I.)Document18 pagesWork Instructions (W.I.)Shamsul Azhar MohdNo ratings yet

- Principles of Crop Growth Simulation ModellingDocument57 pagesPrinciples of Crop Growth Simulation ModellingManuel P. Marcaida IIINo ratings yet

- Asme Sec V Art 6 2007 (Ingles)Document8 pagesAsme Sec V Art 6 2007 (Ingles)fdvrevtrfvrtfNo ratings yet

- Ceramic Tile Fixing StatementDocument5 pagesCeramic Tile Fixing StatementAmit KhazanchiNo ratings yet

- Unit 5.12 PrecipitationDocument16 pagesUnit 5.12 PrecipitationMutale InongeNo ratings yet

- Density MethodDocument5 pagesDensity MethodMajed DawaNo ratings yet

- LBR 2014 - ReDocument62 pagesLBR 2014 - ReEugen XhaferajNo ratings yet

- Dissolution TestDocument5 pagesDissolution TestAlecza Mae SavellaNo ratings yet

- 3 PRE BOARD GENERAL EDUCATION Some College StudentsDocument14 pages3 PRE BOARD GENERAL EDUCATION Some College StudentsMary-Rose CasuyonNo ratings yet

- CADD Unit 4 TPDocument7 pagesCADD Unit 4 TPmohitNo ratings yet

- Oleic Acid TechnologiesDocument11 pagesOleic Acid Technologiessoham kawaleNo ratings yet