Professional Documents

Culture Documents

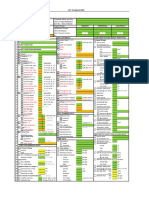

API 614-Chapter 3 DATA SHEET General Purpose Oil System Si Units

Uploaded by

tutuionutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 614-Chapter 3 DATA SHEET General Purpose Oil System Si Units

Uploaded by

tutuionutCopyright:

Available Formats

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 1 of 4

By:

Date:

Revision:

As built

For

Site

Oil System for

Supplier

Manufacturer

Purchase Order No.

NOTES:

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

NOTE: For definition of General Purpose basic system, see 1.1.1.

Overall system typical schematics:

Figure No.

Option Nos.

Comment

Basic oil supply module

Lube module at equipment

Drawing requirements

Component review

Oil Requirements: See Chapter 1 data sheet (1.2.5, 1.2.7, 1.2.8, 1.2.10, 1.2.11, and 1.2.13)

Baseplate/layout:

Combined with equipment base (1.4.11.2)

Grout hole/vent holes (1.3.5)

Point support (1.3.6)

Epoxy grout/primer pre-coat (1.3.5)

_______ m m min. clearance for components (1.2.12)

Basic system details:

Equipment coast-down time

______

Minimum start-up oil temperature

Sound level

_______

Components:

minutes

______

Shop test conditions

Field start-up/run-in conditions

Db max. (1.2.6)

Welding and special fabrication requirements

All steel external components (1.2.14)

Piping and Tubing:

Tubing fittingsMfg.

_______

Model _______

Carbon steel slip-on flanges not allowed (Table 1D)

Additional special requirements, see

Utilities manifolded to common connections

Through studs required

Heat tracing required by

Valve heads vented to reservoir

Air

Purch.

Vendor

Cooling water

Instrument test valves required

Radiographic examination (2.1.2.2)

Continuous flow transfer valves

Separate for coolers and filters

Tight shutoff required

with lifting jack

Rating: barg

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

319678935.xlsx

Page 1 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Oil conditioners: (if required)

Purchasers item no.

Driver for

Type

HP and enclosure

Portable or mounted on

Volts/PH/Hz

Rated m3/hr of oil

____

____

Manufacturer

Water removal rate

Model

Material of construction

Reservoir (1.4)

____

Pumps and drivers (1.5):

Figures no.

Purchaser item nos.

Include options no.

Full details on data sheet

Electric heater (1.4.7.1)

Pump type and material (1.5.1)

Special heater sizing (1.4.7.1.2)

Supplier standard

Oil level glass (1.4.5.1.4)

ANSI/ASME B73.1 horizontal

Low level alarm (1.4.6.2)

ANSI/ASME B73.2 vertical

50-mm fill opening (1.4.5.1.6)

Rotary positive displacement

Sloped bottom (1.4.4.3)

In-line

Free surfacem2

Submerged

Working capacity (min/liter)

Steel casing (1.2.14)

Retention capacity (min/liter)

API 610

Rundown capacity

Pump quantity and driver(s)

Normal operating range

Single-shaft driven

Charge capacity

Single-motor driven

Insulation clips (1.4.8)

Motor driven start-up w/shaft drive main (1.5.4.1)

Ladder with handrail (1.4.10.1)

Full-sized motor-driven start-up to double

Handrails on top (1.4.10.2)

Dual motor drive

as auxiliary pump (1.5.4)

Non-skid decking (1.4.10.3)

Dual steam turbine main/motor aux. (1.5.4)

Flanged vent

Pump installation

Flanged drain (1.4.4.4)

Removable strainer (1.5.14)

Extra connection (1.4.9)

Mounting pads (1.5.19.1)

Siphon breaker

Top mounted components permitted

Top mounted components are:

Submerged components and materials

Dimensions of tank L x W x H

319678935.xlsx, 3-24

_____

_____

_____

(m)

Page 2 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Filters:

Requisition No.

Lube oil rundown tanks

Purchaser item no.

Required, yes or no (1.9.1)

Duplex (1.7.3)

Per Figure 2A-13a or 2A-13b (1.9.1)

10 Micron filtration level (1.7.2)

Purchaser item no.

Manufacturer

Capacity (mins)

Model

Capacity (liters)

Design/test (psig)

Code construction/stamp

Material (1.9.1)

Design/test (barg)

Material: case and top

Code construction/stamp for

Cartridges: (1.7.6.3)

2A-13a (1.2.17, 1.9.4)

Thermal relief valves (1.7.3.8)

Nonhydroscopic elements (1.7.6.2)

Furnish _______ extra sets of cartridges.

Coolers:

Type:

None required (1.6.1)

Per filter (extra over other spares).

Single

Connections only for off-base cooler (1.6.1.3)

Shell and tube

Fin fan

Refer to specification

Supplier std.

Plate frame (1.6.1.3)

Purchaser item no(s)

Duty: (Btu/hr) (KW)

Twin units (1.6.1)

Manufacturer

Details on data sheet

Model

Shell and tube:

Water side for steam heating

Design/test shell side (psig)

Water side corrosion allowance

Design/test tube side (psig)

TEMA class

Code construction/stamp (1.2.17)

Fouling factor water/oil side

Tube water velocity and capacity (mps/m3/liter)

Tube: L/OD/BWG

Material: shell

Removable bundle (1.6.3.4.1)

Channels and covers

Oil temperature control valve

Tube sheets and tubes

Thermal relief valve (1.6.1.7)

Removable tube bundle

Continuous flow transfer valves (1.8)

Separate for coolers and filters (1.8.1.1)

Rating: _______ psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Spectacle blinds (1.8.5)

319678935.xlsx, 3-25

Page 3 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Shop inspection

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist (4.1.1)

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Unit console test (4.3.1.3)

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Check pipe strain (4.3.1.4)

Use for complete unit shop test (4.3.1.2)

Pipe radiography (2.1.2.2)

Certified copies of all test logs and data

Witness

Sound level recorded during test

Comments:

319678935.xlsx, 3-26

Page 4 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 1 of 4

By:

Date:

Revision:

As built

For

Site

Oil System for

Supplier

Manufacturer

Purchase Order No.

NOTES:

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

NOTE: For definition of General Purpose basic system, see 1.1.1.

Overall system typical schematics:

Figure No.

Option Nos.

Comment

Basic oil supply module

Lube module at equipment

Drawing requirements

Component review

Oil Requirements: See Chapter 1 data sheet (1.2.5, 1.2.7, 1.2.8, 1.2.10, 1.2.11, and 1.2.13)

Baseplate/layout:

Combined with equipment base (1.4.11.2)

Grout hole/vent holes (1.3.5)

Point support (1.3.6)

Epoxy grout/primer pre-coat (1.3.5)

_______

ft min. clearance for components (1.2.12)

Basic system details:

Equipment coast-down time

minutes

Minimum start-up oil temperature

Sound level

_______

Components:

Shop test conditions

Field start-up/run-in conditions

Db max. (1.2.6)

Welding and special fabrication requirements

All steel external components (1.2.14)

Piping and Tubing:

Tubing fittingsMfg.

_______

Model

_______

Carbon steel slip-on flanges not allowed (Table 1D)

Additional special requirements, see

Utilities manifolded to common connections

Through studs required

Heat tracing required by

Valve heads vented to reservoir

Air

Purch.

Vendor

Cooling water

Instrument test valves required

Radiographic examination (2.1.2.2)

Continuous flow transfer valves

Separate for coolers and filters

Tight shutoff required

with lifting jack

Rating: psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

319678935.xlsx, 3-27

Page 5 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Oil conditioners: (if required)

Purchasers item no.

Driver for

Type

HP and enclosure

Portable or mounted on

Volts/PH/Hz

Rated GPM of oil

____

____

Manufacturer

Water removal rate

Model

Material of construction

Reservoir (1.4)

____

Pumps and drivers (1.5):

Figures no.

Purchaser item nos.

Include options no.

Full details on data sheet

Electric heater (1.4.7.1)

Pump type and material (1.5.1)

Special heater sizing (1.4.7.1.2)

Supplier standard

Oil level glass (1.4.5.1.4)

ANSI/ASME B73.1 horizontal

Low level alarm (1.4.6.2)

ANSI/ASME B73.2 vertical

2-inch fill opening (1.4.5.1.6)

Rotary positive displacement

Sloped bottom (1.4.4.3)

In-line

Free surfaceft2

Submerged

Working capacity (min/gal)

Steel casing (1.2.14)

Retention capacity (min/gal)

API 610

Rundown capacity

Pump quantity and driver(s)

Normal operating range

Single-shaft driven

Charge capacity

Single-motor driven

Insulation clips (1.4.8)

Motor driven start-up w/shaft drive main (1.5.4.1)

Ladder with handrail (1.4.10.1)

Full-sized motor-driven start-up to double

Handrails on top (1.4.10.2)

Dual motor drive

as auxiliary pump (1.5.4)

Non-skid decking (1.4.10.3)

Dual steam turbine main/motor aux. (1.5.4)

Flanged vent

Pump installation

Flanged drain (1.4.4.4)

Removable strainer (1.5.14)

Extra connection (1.4.9)

Mounting pads (1.5.19.1)

Siphon breaker

Top mounted components permitted

Top mounted components are:

Submerged components and materials

Dimensions of tank L x W x H

319678935.xlsx, 3-28

_____ / _____ / _____

(ft)

Page 6 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Filters:

Requisition No.

Lube oil rundown tanks

Purchaser item no.

Required, yes or no (1.9.1)

Duplex (1.7.3)

Per Figure 2A-13a or 2A-13b (1.9.1)

10 Micron filtration level (1.7.2)

Purchaser item no.

Manufacturer

Capacity (mins)

Model

Capacity (gal.)

Design/test (psig)

Code construction/stamp

Material (1.9.1)

Design/test (psig)

Material: case and top

Code construction/stamp for

Cartridges: (1.7.6.3)

2A-13a (1.2.17, 1.9.4)

Thermal relief valves (1.7.3.8)

Nonhydroscopic elements (1.7.6.2)

Furnish

_______

extra sets of cartridges.

Coolers:

Type:

None required (1.6.1)

Per filter (extra over other spares).

Single

Connections only for off-base cooler (1.6.1.3)

Shell and tube

Fin fan

Refer to specification

Supplier std.

Plate frame (1.6.1.3)

Purchaser item no(s)

Duty: (Btu/hr) (KW)

Twin units (1.6.1)

Manufacturer

Details on data sheet

Model

Shell and tube:

Water side for steam heating

Design/test shell side (psig)

Water side corrosion allowance

Design/test tube side (psig)

TEMA class

Code construction/stamp (1.2.17)

Fouling factor water/oil side

Tube water velocity and capacity (fps/gpm)

Tube: L/OD/BWG

Material: shell

Removable bundle (1.6.3.4.1)

Channels and covers

Oil temperature control valve

Tube sheets and tubes

Thermal relief valve (1.6.1.7)

Removable tube bundle

Continuous flow transfer valves (1.8)

Separate for coolers and filters (1.8.1.1)

Rating: _______ psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Spectacle blinds (1.8.5)

319678935.xlsx, 3-29

Page 3 of 8, Date Printed: 05/30/2016

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Shop inspection

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist (4.1.1)

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Unit console test (4.3.1.3)

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Check pipe strain (4.3.1.4)

Use for complete unit shop test (4.3.1.2)

Pipe radiography (2.1.2.2)

Certified copies of all test logs and data

Witness

Sound level recorded during test

Comments:

319678935.xlsx, 3-30

Page 4 of 8, Date Printed: 05/30/2016

You might also like

- t000005801 PDFDocument7 pagest000005801 PDFMohammed Hassan B KorainaNo ratings yet

- Difference Between API 611 and API 612 - Mechanical Engineering SiteDocument8 pagesDifference Between API 611 and API 612 - Mechanical Engineering SiteAlfredo VelasquezNo ratings yet

- Unit 8 Reciprocatng Compressors: StructureDocument26 pagesUnit 8 Reciprocatng Compressors: StructureRakeshKrNo ratings yet

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 pageC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNo ratings yet

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- Api 673 SiDocument11 pagesApi 673 Situtuionut100% (1)

- LOS Sizing Calcs - API 614 Chapter2 Upload VersionDocument1 pageLOS Sizing Calcs - API 614 Chapter2 Upload VersionZoebair100% (2)

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Turboprop Engine TP100Document2 pagesTurboprop Engine TP100Maurizio BernasconiNo ratings yet

- Api 613Document10 pagesApi 613ecsuperalNo ratings yet

- Combustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable ToDocument10 pagesCombustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable Totutuionut100% (1)

- DHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageDocument61 pagesDHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageThanh Tin NguyenNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- Centrifugal Compressor Performance CalculationsDocument4 pagesCentrifugal Compressor Performance CalculationsFreddy RoaNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Compressor Power PointDocument28 pagesCompressor Power PointDiden Dz100% (1)

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- Control Valve SizingDocument4 pagesControl Valve SizingAmolNo ratings yet

- Hot Oil Flushing Procedure For Mechanical PackageDocument20 pagesHot Oil Flushing Procedure For Mechanical PackageRicky Hendra Silalahi67% (6)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document9 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNo ratings yet

- Oil Lubrication Systems and APIDocument35 pagesOil Lubrication Systems and APIMuhammad ImranNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocument3 pagesTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasNo ratings yet

- Thomasssen Comp SelectionDocument2 pagesThomasssen Comp Selectionmahesh_eilNo ratings yet

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocument6 pagesTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutNo ratings yet

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocument4 pagesToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- KT Components E 01Document8 pagesKT Components E 01Mvk RajuNo ratings yet

- ReciprocatingCompressorPower-US Field UnitsDocument2 pagesReciprocatingCompressorPower-US Field UnitshihihiNo ratings yet

- API 617 Centrifugal Compressors 6th Ed - Nozzle LoadingDocument5 pagesAPI 617 Centrifugal Compressors 6th Ed - Nozzle Loadingreach_arindomNo ratings yet

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocument3 pagesAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutNo ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- Section 10 - CompressorsDocument69 pagesSection 10 - CompressorsChakerZagroubaNo ratings yet

- Superior - Cylinder Databook - ValvesDocument8 pagesSuperior - Cylinder Databook - ValvesJake NavarreteNo ratings yet

- Power Monitoring in Hybrid Power System With Fault DetectionDocument6 pagesPower Monitoring in Hybrid Power System With Fault DetectionIJRASETPublicationsNo ratings yet

- ORC Waste Heat-HoldmannDocument27 pagesORC Waste Heat-Holdmannbart.amaral3771100% (2)

- Api 670Document10 pagesApi 670ecsuperalNo ratings yet

- Flame ArresterDocument16 pagesFlame Arresteriran1362No ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Site Performance Review - Gas TurbineDocument10 pagesSite Performance Review - Gas TurbinemishraenggNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurearvind pillaiNo ratings yet

- Reciprocating Compressor Capacity Control Simple Reliable 1670707033Document13 pagesReciprocating Compressor Capacity Control Simple Reliable 1670707033mohammad1412No ratings yet

- Safety Relief Valve DatasheetDocument1 pageSafety Relief Valve Datasheetalmandhari330% (1)

- Specification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessDocument30 pagesSpecification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessFrancisco Gonzalez100% (1)

- API 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitsDocument7 pagesAPI 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitstutuionutNo ratings yet

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- TGT M WPP DS 0012 - C - Datasheet For Caisson Sump PumpDocument7 pagesTGT M WPP DS 0012 - C - Datasheet For Caisson Sump Pumpvovancuong8No ratings yet

- 521 TiDocument4 pages521 Tisa.somaNo ratings yet

- 8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)Document22 pages8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)LongTuanNo ratings yet

- Compressor Packager Guide WEB NewDocument4 pagesCompressor Packager Guide WEB NewJaroslav KurucNo ratings yet

- Accelertion Head PDFDocument5 pagesAccelertion Head PDFEng AlfNo ratings yet

- C18H0 UFAA78 ProposalDocument9 pagesC18H0 UFAA78 Proposaledward baskaraNo ratings yet

- API 682 4th Ed DatasheetDocument2 pagesAPI 682 4th Ed DatasheetMuhammad Ghufran KhanNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- Codes & Standards - ROTARYDocument2 pagesCodes & Standards - ROTARYUmair PervaizNo ratings yet

- Crosby SizingDocument89 pagesCrosby SizingNattapong Pongboot100% (1)

- Understanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsDocument3 pagesUnderstanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsLam TranNo ratings yet

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity Controlswapneel_kulkarniNo ratings yet

- Bog CompressorDocument7 pagesBog CompressorsswahyudiNo ratings yet

- Blackmer Autogas HandbookDocument32 pagesBlackmer Autogas HandbookMuhammad ImranNo ratings yet

- Estudos de Casos - Revamps & Upgrades HOERBIGERDocument11 pagesEstudos de Casos - Revamps & Upgrades HOERBIGERJoseNo ratings yet

- Case 52 Problems With A Blocked-In Centrifugal PumpDocument2 pagesCase 52 Problems With A Blocked-In Centrifugal Pumphwang2No ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- PC PumpDocument5 pagesPC Pumpphantanthanh100% (1)

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocument1 pagePages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNo ratings yet

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 pagesAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutNo ratings yet

- Duty Specification FOR Hot Oil System Package Unit: GeneraDocument5 pagesDuty Specification FOR Hot Oil System Package Unit: GeneraSuchart TarasapNo ratings yet

- FP12148-00 Model 1Document8 pagesFP12148-00 Model 1gkek87No ratings yet

- FLW (EU - EXP - DOM) (Ver.1.1)Document540 pagesFLW (EU - EXP - DOM) (Ver.1.1)dollareNo ratings yet

- Technical Specification Tables For Construction Equipment VehicleDocument75 pagesTechnical Specification Tables For Construction Equipment VehicleHarley HariNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocument2 pagesSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNo ratings yet

- New Steel Plate LNGDocument7 pagesNew Steel Plate LNGtutuionutNo ratings yet

- AZOBEDocument4 pagesAZOBEtutuionutNo ratings yet

- Technical Insulation - Cryolene PDFDocument8 pagesTechnical Insulation - Cryolene PDFtutuionutNo ratings yet

- Required System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitsDocument20 pagesRequired System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitstutuionutNo ratings yet

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 pagesAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNo ratings yet

- Storage Tank Normal Venting Capacity CalculationsDocument1 pageStorage Tank Normal Venting Capacity CalculationstutuionutNo ratings yet

- Tank 305Document74 pagesTank 305tutuionutNo ratings yet

- DC MOTOR - EnerconDocument19 pagesDC MOTOR - EnerconJoanna Fabricante100% (1)

- BP Statistical-Reviewofworldenergy 2011Document28 pagesBP Statistical-Reviewofworldenergy 2011Ridhanda Putra KotoNo ratings yet

- Power System Operation Corporation LTD.: Northern Regional Load Despatch CentreDocument10 pagesPower System Operation Corporation LTD.: Northern Regional Load Despatch CentrerohitctppNo ratings yet

- VANUATUDocument2 pagesVANUATUAlejandra MendietaNo ratings yet

- Solar RefrigerationDocument26 pagesSolar Refrigerationfiroz aryaNo ratings yet

- Ehvs PDFDocument24 pagesEhvs PDFantoniomecptNo ratings yet

- 175 GW Parliamentary Standing Committee March 2021Document118 pages175 GW Parliamentary Standing Committee March 2021Niraj KumarNo ratings yet

- Module Solare AlgatecDocument2 pagesModule Solare Algatecradu_dobreNo ratings yet

- Zeolite Water Adsorption Refrigeration SystemDocument4 pagesZeolite Water Adsorption Refrigeration Systemvaibhav100% (1)

- Eleweout-IMT ENG PODocument2 pagesEleweout-IMT ENG POCharles RoumiNo ratings yet

- Circuit BreakerDocument10 pagesCircuit BreakermeraatNo ratings yet

- Governing System of Stage-1 200 MW TurbineDocument13 pagesGoverning System of Stage-1 200 MW TurbineSamNo ratings yet

- HG 12 SeriesDocument2 pagesHG 12 SeriesJoséNo ratings yet

- HiQ Catalogue Manufacturing Linde899 88337Document307 pagesHiQ Catalogue Manufacturing Linde899 88337Pierre FermatNo ratings yet

- Project Proposal On Design and Fabrication of Low Head TurbineDocument15 pagesProject Proposal On Design and Fabrication of Low Head TurbinePawan SharmaNo ratings yet

- Safety Clearance Recommendations For TransformerDocument6 pagesSafety Clearance Recommendations For Transformerjannumits100% (1)

- Disjuntor Andeli AW45Document7 pagesDisjuntor Andeli AW45hudsonNo ratings yet

- 1994 - Bernhardt - Dry Cleaning of SugarcaneDocument6 pages1994 - Bernhardt - Dry Cleaning of SugarcaneAlejandro AguirreNo ratings yet

- MicrogridDocument2 pagesMicrogridNitin KakadNo ratings yet

- No Power Plant Capacity Location Year CODDocument3 pagesNo Power Plant Capacity Location Year CODSudi ArtoNo ratings yet

- Sustainable Village ModelDocument34 pagesSustainable Village ModelBapatla SasikanthNo ratings yet

- Potato ThesisDocument3 pagesPotato ThesisDa VeNo ratings yet

- CREW: Environmental Protection Agency: Responsive Documents: 3-2-15: Batch 5Document48 pagesCREW: Environmental Protection Agency: Responsive Documents: 3-2-15: Batch 5CREW100% (1)

- Danida Fellowship Course 2013Document4 pagesDanida Fellowship Course 201398_kingsukNo ratings yet

- Reaction Turbines - Francis and Kaplan PDFDocument16 pagesReaction Turbines - Francis and Kaplan PDFDeva Raj100% (3)

- FACTS CatalogDocument28 pagesFACTS CatalogAchint KumarNo ratings yet