Professional Documents

Culture Documents

Cs01304den 0112

Uploaded by

Raj ChavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cs01304den 0112

Uploaded by

Raj ChavanCopyright:

Available Formats

Water for irrigation

Transforming 100 000 hectares of arid land into

fertileagricultural land with the potential to support

around 20 000 farmers

The Project

The Challenge

In 2002, a massive irrigation project was undertaken in the

southern part of Europe. The objective was to transform 100 000

hectares (1000 square kilometers) of arid land, typically capable of

supporting only olive or almond trees, into fertile and diverse agricultural land with the potential to support around 20 000 farmers,

thereby drastically improving the economy of the respective region

in this southern European country.

The investment needed would be around EUR 1.6 billion,

requiring an innovative collaboration between the regional

government, a group of private investors and an imaginative

future payment system for the farmers themselves.

Each of the seventeen pumping stations requires a commonheader discharge flowmeter, with line sizes up to DN 1200 (48").

While inline electromagnetic technology was the logical first

choice, the cost of such large flowmeters presented a problem,

and alternatives had to be considered. Endress+Hauser was

involved in an early stage of the project with the aim of providing

the best measurement solution.

The first phase of the project would be the construction of an

85 kilometer long canal, which would carry the 330 million cubic

meters per year of water required for the scheme.

Phase two would be the construction of the local distribution

infrastructures, comprising 17 pumping stations to collectively,

but selectively, feed 43 regulation basins. Together these would

hold the key to the balance and success of the whole scheme,

ensuring the fair supply of the valuable water to all stakeholder

farmers, and proper control of the upstream abstraction from the

river. Project completion is due by 2013.

The Solution

The question was whether to use an electromagnetic insertion

flowmeter or Prosonic Flow from Endress+Hauser based on the

ultrasonic transit time technology. The accuracy specifications

for the Prosonic Flow clamp-on version, and those for an

electromagnetic insertion meter from a competitor could be

considered comparable, at 2% of reading or better, but the

Prosonic Flow clamp-on version requires fewer straight inlet and

outlet runs.

Taking in account the easy installation and commissioning of the

Prosonic Flow clamp-on version, which offered further cost

benefits compared to electromagnetic insertion flowmeters, the

decision was made in favor of the Prosonic Flow.

After successful field trials, it was clear that Prosonic Flow is the

first choice for flow measurement for larger line sizes. The value

proposition was clearly understood.

Value proposition for

Prosonic Flow clamp-on

version

Easy installation and maintenance ...

The Prosonic flow clamp-on version is mounted on the

outside of the pipe and therefore has no physical contact

with the liquid in the pipe. This makes installation and

maintenance much easier and faster, as it can be done at

any time, without the need to shut down the operation.

No cutting or welding of the existing pipework is required for the installation.

Moreover, the Prosonic Flow clamp-on technology needs

shorter inlet and outlet pipe runs compared to electromagnetic insertion meters. This fact gives more freedom

in choosing the best place for the installation of the flow

meter.

... saves time and money

The river water used in the system will be totally raw,

with the possible of suspend solids. Inline flowmeters

would thus be highly prone to deposition and even

permanent damage of the meter. This would require

its removal andsubsequent maintenance. This can be

prevented with the Prosonic Flow clamp-on version,

mounted on the outside of the pipe.

All this helps to save time and money, for installation and

maintenance.

Advantages at a glance

Best value for money

Unbeatable for large line sizes

One meter fits it all

Clamp-on scales perfectly to any line size

from DN 15 (") to DN 4000 (160")

Flexible concept

Measure another location, line size,

liquid or pipe material with the same meter

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel. +41 61 715 81 00

Fax +41 61 715 25 00

http://www.endress.com

info@ii.endress.com

CS01304D/06/EN/01.12

71194342

INDD CS2

Straightforward installation

No cutting or welding of the existing pipework

Low maintenance

Done from the outside without shutting down

the operation

No degradation

No deposition on the sensor due to low quality

or aggressive liquids

You might also like

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Refrigeration and Air ConditioningDocument41 pagesRefrigeration and Air Conditioningrejeesh_rajendranNo ratings yet

- Storm Water Collection System Design PrinciplesDocument28 pagesStorm Water Collection System Design PrinciplesEngr Asad SufyanNo ratings yet

- The Complete Guide To Pipe Selection For Trenchless ProjectsDocument24 pagesThe Complete Guide To Pipe Selection For Trenchless ProjectsameygandhiNo ratings yet

- Area Classification: (IEC/EN 60529)Document1 pageArea Classification: (IEC/EN 60529)nestkwt1No ratings yet

- Hydrogen Gas Detectors FAQDocument4 pagesHydrogen Gas Detectors FAQAdrienne87aNo ratings yet

- Horizontal Directional DrillingDocument7 pagesHorizontal Directional DrillingDebasis SahaNo ratings yet

- Design of Water Distribution SystemDocument6 pagesDesign of Water Distribution Systemcristina230% (1)

- Expansive Soils ThesisDocument116 pagesExpansive Soils Thesisiraqi-eng100% (1)

- Underground Piping Systems ExplainedDocument29 pagesUnderground Piping Systems ExplainedNabil Al-Khirdaji50% (2)

- SDS ConceptDocument4 pagesSDS ConceptssarangNo ratings yet

- Sewer DesignDocument41 pagesSewer DesignRaihan Amzad75% (4)

- Water Treatment Plant ProjectDocument16 pagesWater Treatment Plant ProjectAbhishek Chidambaram33% (3)

- SRDA-The Siphonic Guide-V1-1305 PDFDocument18 pagesSRDA-The Siphonic Guide-V1-1305 PDFYaseen MallickNo ratings yet

- TECHNICAL GUIDEDocument56 pagesTECHNICAL GUIDEsamozafaks100% (1)

- Water Distribution System PDFDocument12 pagesWater Distribution System PDFakhilchibberNo ratings yet

- DVR Vs NVRDocument3 pagesDVR Vs NVRGvds SastryNo ratings yet

- Surge Protec IIDocument14 pagesSurge Protec IIRaj ChavanNo ratings yet

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- 6 GTZ Datasheet On Vacuum Sewer Systems (2005)Document5 pages6 GTZ Datasheet On Vacuum Sewer Systems (2005)EddiemtongaNo ratings yet

- SEKISUI SPR CPIP & Sewer OnDocument8 pagesSEKISUI SPR CPIP & Sewer OnShaikh Muhammad AteeqNo ratings yet

- Mates Orals StuffDocument67 pagesMates Orals Stuffnishadyadav100% (7)

- In-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetDocument10 pagesIn-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetNikhil Mohan100% (1)

- CH 4 Sewers DesignDocument11 pagesCH 4 Sewers DesignmavessNo ratings yet

- Sewage Treatment PDFDocument17 pagesSewage Treatment PDFMaloSarkiNo ratings yet

- SRDA - A Guide To Siphonic Drainage - 2007Document18 pagesSRDA - A Guide To Siphonic Drainage - 2007Erin Lim100% (1)

- 海关数据Document125 pages海关数据李好No ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

- HDD BroschDocument24 pagesHDD BroschRomany AllamNo ratings yet

- SO 401B Concrete enDocument8 pagesSO 401B Concrete enknchnNo ratings yet

- Clamp-On Flow MeterDocument6 pagesClamp-On Flow MeterHanan Khan100% (1)

- Prosonic Flow 93PA1Document32 pagesProsonic Flow 93PA1andmar2011No ratings yet

- Innovations and Technological Developments in Long Distance Water Transmission SystemDocument7 pagesInnovations and Technological Developments in Long Distance Water Transmission SystemProphx BliziceNo ratings yet

- FPSO Flow Meter Fits Just RightDocument1 pageFPSO Flow Meter Fits Just RightJuan JaramilloNo ratings yet

- unrestricted mounted flow meterDocument4 pagesunrestricted mounted flow meterAfiqNo ratings yet

- MeasurIT Flexim ADM7207 Project NVV 0809Document1 pageMeasurIT Flexim ADM7207 Project NVV 0809cwiejkowskaNo ratings yet

- Hid - Design CriteriaDocument7 pagesHid - Design CriteriaNeima EndrisNo ratings yet

- MACE Case Study Sewer Lift Station MonitoringDocument2 pagesMACE Case Study Sewer Lift Station MonitoringAqua Technology GroupNo ratings yet

- Wastewater TreatmentDocument46 pagesWastewater TreatmentOsmanNo ratings yet

- IBP1064 - 19 Where Offshore Meets Onshore: Trenchless Solutions For Pipeline LandfallsDocument10 pagesIBP1064 - 19 Where Offshore Meets Onshore: Trenchless Solutions For Pipeline LandfallsMarcelo Varejão CasarinNo ratings yet

- Ultrasonic Flow MeasurementDocument18 pagesUltrasonic Flow MeasurementAdemuyiwa TalabiNo ratings yet

- West Pinchbeck, UKDocument2 pagesWest Pinchbeck, UKcanonscanmenaNo ratings yet

- Thames Crossness 2012 ABCDocument6 pagesThames Crossness 2012 ABCisaacnewtonasimovNo ratings yet

- Sewerage technology options and materialsDocument3 pagesSewerage technology options and materialsBabu BalajiNo ratings yet

- Flow Conditioning Improves Accuracy 0719Document4 pagesFlow Conditioning Improves Accuracy 0719atorresh090675No ratings yet

- Guide On How To Develop A Small Hydropower Plant: Summary of The Basic ConceptDocument43 pagesGuide On How To Develop A Small Hydropower Plant: Summary of The Basic ConceptmalamlamaNo ratings yet

- Hydraulic Machinery For Improvement of The Global Enviromental SystemDocument6 pagesHydraulic Machinery For Improvement of The Global Enviromental SystemFolpoNo ratings yet

- Custody As Cash RegisterDocument5 pagesCustody As Cash RegisterNasrul AdliNo ratings yet

- ACO S Range BrochureDocument20 pagesACO S Range BrochureBasil OguakaNo ratings yet

- Raw Materials | Pipelines: Siemens Helps Transport 590K Barrels DailyDocument2 pagesRaw Materials | Pipelines: Siemens Helps Transport 590K Barrels DailyzirimiaNo ratings yet

- AttachmentDocument31 pagesAttachmenttedy yidegNo ratings yet

- Case Study ViennaDocument3 pagesCase Study ViennamahaprakashNo ratings yet

- Data Sheet: Multical® 21 & Flowiq® 2101Document20 pagesData Sheet: Multical® 21 & Flowiq® 2101Lavanya ReddyNo ratings yet

- Design of SewersDocument7 pagesDesign of SewersXyrene Ashley MagatNo ratings yet

- Ijciet 09 07 116Document8 pagesIjciet 09 07 116Yusuf JaveedNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Sewer Cleaning and InspectionDocument11 pagesSewer Cleaning and InspectionKwang Je Lee100% (1)

- Hasang Hydro Power Plant Generates 275 GWh AnnuallyDocument62 pagesHasang Hydro Power Plant Generates 275 GWh AnnuallyMark Jayson Baes NamucoNo ratings yet

- Hapter Astewater Ollection Ystems D W C SDocument17 pagesHapter Astewater Ollection Ystems D W C Sjoescribd55No ratings yet

- V-Cone DP PDFDocument6 pagesV-Cone DP PDFhotnatkapoorNo ratings yet

- Submitted To: Dr. Saimer Parveez: Abdul Wahab Environmental EngineeringDocument23 pagesSubmitted To: Dr. Saimer Parveez: Abdul Wahab Environmental Engineeringshahmeerhasnain786No ratings yet

- pt878 Panametrics PDFDocument4 pagespt878 Panametrics PDFJ00pNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Wastewater Collection Systems Comparison: William T. Hensley, International Territory Manager, Orenco Systems, IncDocument5 pagesWastewater Collection Systems Comparison: William T. Hensley, International Territory Manager, Orenco Systems, IncmeskbNo ratings yet

- Ultrasonic Gas Measurement in A Production Environment - SickDocument11 pagesUltrasonic Gas Measurement in A Production Environment - SickShakeel AhmedNo ratings yet

- Design Report (Public Health)Document10 pagesDesign Report (Public Health)subramanyam kumarNo ratings yet

- Cement Plant Saves Energy with Online Air Flow MeasurementDocument3 pagesCement Plant Saves Energy with Online Air Flow MeasurementKenny RuizNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- Annexure For Pressure GaugeDocument2 pagesAnnexure For Pressure GaugeRaj ChavanNo ratings yet

- XFDocument1 pageXFRaj ChavanNo ratings yet

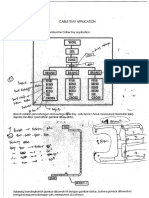

- Pdms Cable TrayDocument10 pagesPdms Cable TrayRaj ChavanNo ratings yet

- His AtlDocument7 pagesHis AtlRaj ChavanNo ratings yet

- Drak A Mog CatalogDocument376 pagesDrak A Mog Catalogdadok999No ratings yet

- PL-2303 Windows XP Driver UpdateDocument1 pagePL-2303 Windows XP Driver UpdatePolo AlvarezNo ratings yet

- Marine Electrical KnowledgeDocument53 pagesMarine Electrical KnowledgeRhn RhnNo ratings yet

- Proline Prosonic Flow 93W: Technical InformationDocument32 pagesProline Prosonic Flow 93W: Technical InformationRaj ChavanNo ratings yet

- Instrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Document88 pagesInstrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Raj ChavanNo ratings yet

- SU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Document30 pagesSU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Ahmed MohamedNo ratings yet

- Unitronics IdntolvurDocument24 pagesUnitronics IdntolvurRaj ChavanNo ratings yet

- NEMA Motor Manual Section on AccessoriesDocument16 pagesNEMA Motor Manual Section on AccessoriesDelfinshNo ratings yet

- What Does NAMUR NE 43 Do ForDocument1 pageWhat Does NAMUR NE 43 Do ForRaj ChavanNo ratings yet

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Document2 pagesWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanNo ratings yet

- One NoteDocument11 pagesOne NoteRaj ChavanNo ratings yet

- and 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFDocument8 pagesand 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFdialixhNo ratings yet

- Chem Earth PointsDocument65 pagesChem Earth PointsRaj ChavanNo ratings yet

- His AtlDocument7 pagesHis AtlRaj ChavanNo ratings yet

- EINTH012Document32 pagesEINTH012Raj ChavanNo ratings yet

- Schneider Electric - Overload Relay Trip CurvesDocument84 pagesSchneider Electric - Overload Relay Trip CurvesMichael Parohinog GregasNo ratings yet

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Document2 pagesWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanNo ratings yet

- Cost Estimation Techniques for Uncertain ProjectsDocument7 pagesCost Estimation Techniques for Uncertain ProjectsRaj ChavanNo ratings yet

- Unit 6: Project EvaluationDocument12 pagesUnit 6: Project EvaluationRaj ChavanNo ratings yet

- BN330500dt PDFDocument19 pagesBN330500dt PDFvvNo ratings yet

- Masterbrace Adh 2200: Description AdvantagesDocument2 pagesMasterbrace Adh 2200: Description AdvantagesHaseeb AhmedNo ratings yet

- Feati-Civil Engineering Department 1994-2007 - Feati University-Civil Engineering Department Thesis 1997-2007Document11 pagesFeati-Civil Engineering Department 1994-2007 - Feati University-Civil Engineering Department Thesis 1997-2007Paulo ParenasNo ratings yet

- PhotosynthesisDocument17 pagesPhotosynthesisMichelleAquinoSuzukiNo ratings yet

- PSCI Module 1Document4 pagesPSCI Module 1Sha IraNo ratings yet

- MPC of Complex SystemsDocument232 pagesMPC of Complex SystemsDimitris TzNo ratings yet

- GLAP1550 ManualDocument6 pagesGLAP1550 ManualYapNo ratings yet

- Freshwater Ecosystems.Document16 pagesFreshwater Ecosystems.Khylle Rey FanugaNo ratings yet

- Codex Standard For Boiled Dried Salted Anchovies CODEX STAN 236-2003Document6 pagesCodex Standard For Boiled Dried Salted Anchovies CODEX STAN 236-2003henryNo ratings yet

- Reaction Paper Water Treatment Group 1Document3 pagesReaction Paper Water Treatment Group 1Hrv AquinoNo ratings yet

- WAPCOS Annual Report 2017-18 English PDFDocument312 pagesWAPCOS Annual Report 2017-18 English PDFAkash GroverNo ratings yet

- Cyanide SpillDocument3 pagesCyanide SpillMita MandalNo ratings yet

- Site Condition ReportDocument12 pagesSite Condition ReportDigital ArmyNo ratings yet

- Sylvania KatalogDocument2 pagesSylvania KatalogCk_psihNo ratings yet

- Ramsar Sites and Historic Conservation of BiodiversityDocument8 pagesRamsar Sites and Historic Conservation of BiodiversityAryan ChopraNo ratings yet

- Steam Water Cycle Chemistry - DoDocument11 pagesSteam Water Cycle Chemistry - DoIcygolden PalaceNo ratings yet

- P02 SDG XXX XXX Lan Agm 4583a PDFDocument1 pageP02 SDG XXX XXX Lan Agm 4583a PDFSweetdessert BonapetitNo ratings yet

- Instructors Manual 6th EditionDocument504 pagesInstructors Manual 6th EditionhugogallagherNo ratings yet

- .Design & Fabrication of Automatic Drainage Cleaning System Using Solar Panel PDFDocument2 pages.Design & Fabrication of Automatic Drainage Cleaning System Using Solar Panel PDFJonesNo ratings yet

- 10 Advantages of Precast Structures - Steel Construction DetailingDocument12 pages10 Advantages of Precast Structures - Steel Construction Detailingsarre mamoudouNo ratings yet

- Reading III: Main Idea & Supporting DetailsDocument16 pagesReading III: Main Idea & Supporting DetailsMaria RomeroNo ratings yet

- Mrunal How To Prepare Geography Optional For UPSC MainsDocument9 pagesMrunal How To Prepare Geography Optional For UPSC MainsGauravPriyank TyagiNo ratings yet

- DiccionaDocument495 pagesDiccionaEnescon SacNo ratings yet

- Earthen Dams: Ancient Structures Built With Natural MaterialsDocument66 pagesEarthen Dams: Ancient Structures Built With Natural MaterialsFarhan KaziNo ratings yet