Professional Documents

Culture Documents

Considerations For Choosing A Controller: Consideration Information To Record Why This Is Important

Uploaded by

Mohamed SaadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Considerations For Choosing A Controller: Consideration Information To Record Why This Is Important

Uploaded by

Mohamed SaadCopyright:

Available Formats

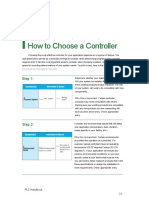

Considerations for Choosing a Controller

Use the worksheet on the following pages as a checklist of the things to consider when determining

programmable controller requirements. It lists the most important areas to consider when choosing

a system, and provides space for recording determinations of your system needs.

Consideration

Information to Record

1.

Proposed System ____ New system

2.

Environmental

Issues

3.

Discrete Devices

____

Codes/environmental

issues to consider

_____ Total inputs:

_____ AC

_____ DC

_____ Total inputs:

4.

Analog Devices

____ Voltage

____ Current

_____ Existing

system

____ No codes or

environmental

issues to consider

_____ Total outputs:

____ Thermo

_____ High speed counter

_____ Positioning

_____ Servo/stepper

_____ BASIC programming

_____ Real-time clock

_____ Others (list)

Determine whether your system is new or existing: Will your system

be installed from scratch or are there existing products already

installed? The rest of your system will need to be compatible with

new components.

Why this is im portant : Certain controller products may not be

compatible with others. Making sure your existing products are

compatible with any new products you are researching will save

you time and money. Check appropriate entry.

Consider any environmental issues that will affect your application

(temperature, dust, vibration, codes specific to your facility, etc.).

Why this is important: Certain environments may affect the operation of a controller. For example, typical controllers have an operating temperature of 0-55 degrees Celsius (32-130 degrees F). If

your application will include any extreme environmental conditions, or you have specific codes at your facility that must be met,

you will need to either research products that meet those specifications or design the installation to meet requirements. Check

appropriate entry.

Determine how many discrete devices your system will have. Which

types (AC, DC, etc.) are needed?

_____ Total outputs: Why this is important: The number and type of devices your system

will include is directly linked to the amount of I/O that will be

_____ AC

necessary for your system. You will need to choose a controller

_____ DC

that supports your I/O count requirements and has modules that

support your signal types.Enter quantities and type based on corresponding field devices.

____ RTD

5.

Specialty

Modules or

Features

(applicationspecific)

Why this is important

____ Voltage

____ Current

Determine how many analog devices your system will have.

Which types (voltage, current, temperature, etc.) are needed?

Why this is important: The number and type of devices your system

will include is directly linked to the amount of I/O that will be

necessary for your system. You will need to choose a controller that

supports your I/O count requirements and has modules that

support your signal types. Enter quantities and type based on corresponding field devices.

Determine whether your system will require any specialty features:

Will your application require high-speed counting or positioning?

What about a real-time clock or other specialty feature?

Why this is important: Specialty functions are not necessarily available in a controller CPU or in standard I/O modules.

Understanding the special functions your system may perform will

help you determine whether or not you will need to purchase additional specialty modules. Check all features required.

Table continued on the following page

Volume 13

eCS-4

Control Systems Overview

1 - 80 0 - 633 - 0405

Considerations for Choosing a Controller

Consideration

Information to Record

Hardware requirements:

________ K program memory required

(estimated)

________ K data memory required

(estimated)

______ Fast scan time required?

6.

CPU Required

______ Battery backup required?

Software/special function

requirements:

____ PID

7.

I/O Locations

____________________

_____ Ethernet

_____ PLC to PLC

8.

Commuications

_____ Modbus RTU

_____ ASCII (interface to serial devices)

_____ Other

_____

_____ PID loops

Floating

_____ number of loops needed

point math

9.

Programming

_____

Drum

sequencer

_____ Subroutines

_____ Direct interrupts

_____ Others (list)

w w w. a u to m a t i o n d i re c t . c o m

Determine the type of CPU you will need: How much memory will your

system require? How many devices will your system have (determines data

memory)? How large is your program, and what types of instructions will your

program include (determines program memory)? How fast a scan time do

you need?

Why this is important: Data memory refers to the amount of memory needed

for dynamic data manipulation and storage in the system. For example,

counter and timer instructions typically use data memory to store setpoints,

current values, and other internal flags. If the application requires historical

data retention, such as measured device values over a long period of time,

the size of the data tables required may determine the CPU model you

choose. Program memory is the amount of memory needed to store the

sequence of program instructions that have been selected to perform the

application. Each type of instruction requires a specific amount of program

memory, typically defined in a programming manual. Applications that are

basically sequential in nature can rely on the I/O device rule of thumb to estimate program memory (five words of memory for each I/O device); complex

applications will be more difficult to judge.

If scan time is important in your application, consider the CPU processor

speed as well as instruction execution speed. Some CPUs are faster at

boolean logic but slower with data handling instructions.

Determine where your I/O will be located: Will your system require only

local I/O, or both local and remote I/O locations?

Why this is important: If subsystems will be needed at long distances from

the CPU, you will need a controller that supports remote I/O. You will also

have to determine if the remote distances and speeds supported will be

adequate for your application. Serial and Ethernet-based I/O hardware

are two typical choices available for most systems. This I/O may also be

referred to as distributed I/O, and may require a particular protocol, such

as Modbus.

Enter number of physical locations needed, and if/what specific protocol

may be required.

Determine your communication requirements: Will your system

be communicating to other networks, systems or field devices?

Why this is important: Communication ports (other than the programming

port) are not always included with a controller. Knowing your system

communication requirements will help you choose a CPU that supports

your communication requirements, or additional communication modules

if necessary. Check any/all communications functions required.

Determine your programming requirements: Does your application require

only traditional programming instructions, or are special instructions necessary?

Why this is important: Certain controllers may not support every type of instruction. You will need to choose a model that supports all instructions that you

may need for a specific application. For example, built-in PID functions are

much easier to use than writing your own code to perform closed-loop

process control. Typical instructions such as timers, counters, etc. are available

in most controllers; note any other special instructions required here. Check

any/all programming functions required.

Control Systems Overview

Systems

Overview

Programmable

Controllers

Why this is important

If special functions such as PID are required, the CPU you select may make

____ Floating Point Math

those functions easier to perform.

For program memory required, follow this rule of thumb: 5 words of proOthers (see Programming section below) gram memory for each discrete device and 25 words for each analog

device. Check or calculate all requirements that apply.

_______ _______ Remote Locations

Local . . .

only

Specific remote I/O protocol

required? Which one?

Company

Information

eCS-5

Field I/O

Software

C-more &

other HMI

Drives

Soft

Starters

Motors &

Gearbox

Steppers/

Servos

Motor

Controls

Proximity

Sensors

Photo

Sensors

Limit

Switches

Encoders

Current

Sensors

Pressure

Sensors

Temperature

Sensors

Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

Terminal

Blocks &

Wiring

Power

Circuit

Protection

Enclosures

Tools

Pneumatics

Appendix

Product

Index

Part #

Index

You might also like

- Solution - Manual The 8051 Microcontroller Based Embedded SystemsDocument14 pagesSolution - Manual The 8051 Microcontroller Based Embedded Systemsmanishpatel_79No ratings yet

- Head First SQLDocument586 pagesHead First SQLScribed Belize User100% (1)

- Considerations For Choosing A Controller: Consideration Information To Record Why This Is ImportantDocument2 pagesConsiderations For Choosing A Controller: Consideration Information To Record Why This Is ImportantRodrigo Iván Latorre AlmirallNo ratings yet

- PLC - Open ElectricalDocument4 pagesPLC - Open ElectricalHerman DamanikNo ratings yet

- Como Elegir Un PLCDocument8 pagesComo Elegir Un PLCmario serraNo ratings yet

- What Different Selection Citeria For PLC Selection Criteria: AdvantagesDocument2 pagesWhat Different Selection Citeria For PLC Selection Criteria: AdvantagesMahesh ShendeNo ratings yet

- Control Systems: Piu Ghosh Instrumentation and Control DepartmentDocument42 pagesControl Systems: Piu Ghosh Instrumentation and Control Departmentpiu_ghosh9966100% (1)

- Voice Controlled Wheel ChairDocument48 pagesVoice Controlled Wheel ChairAjith manjuNo ratings yet

- What Is A Programmable Controller?Document11 pagesWhat Is A Programmable Controller?Ernesto LeonNo ratings yet

- PLC - Selector PLCs - Programmable Logic Controllers - PLC Controller - Koyo PLC - PLC DirectDocument2 pagesPLC - Selector PLCs - Programmable Logic Controllers - PLC Controller - Koyo PLC - PLC DirectMd Mainul Hsoen ImonNo ratings yet

- PLC Selection CriteriaDocument2 pagesPLC Selection CriteriaGUNUPURI MANOHARNo ratings yet

- PLC Selection CriteriaDocument2 pagesPLC Selection Criteriamanuel rangelNo ratings yet

- Intro To EsDocument49 pagesIntro To EsGalal AtefNo ratings yet

- Lab 01 - Introduction To PLC Hardware and SoftwareDocument18 pagesLab 01 - Introduction To PLC Hardware and SoftwareSyed Abdullah Hasan Chishti100% (1)

- Microcontroller - LectureDocument29 pagesMicrocontroller - LectureChouaibou MouminiNo ratings yet

- PLC Selection Criteria For MicrocontrollerDocument2 pagesPLC Selection Criteria For MicrocontrollerAnkush PatilNo ratings yet

- Ece Embed Ed SystemDocument27 pagesEce Embed Ed SystemlakshmigajendranNo ratings yet

- MP Appli GendDocument6 pagesMP Appli GendAshfaq AhamedNo ratings yet

- Automated Logic CorporationDocument9 pagesAutomated Logic Corporationab_s5036No ratings yet

- Chapter-1: 1.1 Non Real Time Operating SystemsDocument58 pagesChapter-1: 1.1 Non Real Time Operating SystemsAnonymous XybLZfNo ratings yet

- Chapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsDocument16 pagesChapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsAmish VermaNo ratings yet

- ReportDocument10 pagesReportJay KevalramaniNo ratings yet

- CCCCCC CDocument60 pagesCCCCCC CSanthan ManneNo ratings yet

- Training ReportDocument44 pagesTraining Reportshaur20No ratings yet

- Embedded System DesignDocument22 pagesEmbedded System Designtrail meNo ratings yet

- Embedded Systems: Quiz 2Document19 pagesEmbedded Systems: Quiz 2171148 171148No ratings yet

- Chapter 14 - Processor Structure and FunctionDocument74 pagesChapter 14 - Processor Structure and FunctionDeadly ChillerNo ratings yet

- A PROJECT REPORT ON Electronic Voting MachineDocument97 pagesA PROJECT REPORT ON Electronic Voting Machinereddu143No ratings yet

- Embedded System DesignDocument98 pagesEmbedded System DesignMohammedNo ratings yet

- AN2596Document32 pagesAN2596Pasiutes VejasNo ratings yet

- 8 TemparatureDocument31 pages8 TemparatureDemonfox NarutoUzumakiNo ratings yet

- Unit 1Document20 pagesUnit 1prabhavathysund8763No ratings yet

- PLC Notes-3Document32 pagesPLC Notes-3PravinNo ratings yet

- Architecture of PLCDocument5 pagesArchitecture of PLCGAURAVNo ratings yet

- Notes BE&C 21ELN14-24 Module-3Document23 pagesNotes BE&C 21ELN14-24 Module-3Sharanabasaveshwara H BNo ratings yet

- I. 8051 Microcontroller: FeaturesDocument9 pagesI. 8051 Microcontroller: FeaturesSuresh IbkNo ratings yet

- 6 - DCS IapcDocument14 pages6 - DCS IapcNikita ChaudhariNo ratings yet

- Lab Sheet 4Document3 pagesLab Sheet 498140207No ratings yet

- Design of Programmable Logic Controller and I/O ExpansionsDocument5 pagesDesign of Programmable Logic Controller and I/O ExpansionsRanjan JlNo ratings yet

- 5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISDocument26 pages5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISIvomadnessNo ratings yet

- Microcontroller - Wikipedia..Document7 pagesMicrocontroller - Wikipedia..452bobNo ratings yet

- MC & ESY NotesDocument144 pagesMC & ESY NotesgodaserbNo ratings yet

- Group 6 Cpu Design PresentationDocument50 pagesGroup 6 Cpu Design PresentationFerry AriNo ratings yet

- CO&A 18EC35 Module-1 Notes Dileep Kumar K SDocument32 pagesCO&A 18EC35 Module-1 Notes Dileep Kumar K SThanushree RMNo ratings yet

- Tulsiramji Gaikwad-Patil College of Engineering and TechnologyDocument26 pagesTulsiramji Gaikwad-Patil College of Engineering and TechnologyShruti KambleNo ratings yet

- Introduction To Embbeded SystemsDocument42 pagesIntroduction To Embbeded SystemsSaikiran ReddyNo ratings yet

- Introduction To Programmable Logic Controllers (PLCS)Document20 pagesIntroduction To Programmable Logic Controllers (PLCS)eyob feshaNo ratings yet

- Voice Controlled Intelligent Security SystemDocument44 pagesVoice Controlled Intelligent Security SystemSarat ChandraNo ratings yet

- Lesson 1Document6 pagesLesson 1Kaizuke YoNo ratings yet

- GE Fanuc Series One PlusDocument300 pagesGE Fanuc Series One PlusRubén SánchezNo ratings yet

- Acknowledgement: DEVICE MANEGMENT SYSTEM" Has Given Us Immense PleasureDocument20 pagesAcknowledgement: DEVICE MANEGMENT SYSTEM" Has Given Us Immense PleasuresonalsrsNo ratings yet

- Esd 1Document40 pagesEsd 1154Soyal LonareNo ratings yet

- 5 2marksDocument22 pages5 2marksElakkiya N.SNo ratings yet

- Course FileDocument36 pagesCourse FileElakkiya N.SNo ratings yet

- Graphical System Design PDFDocument35 pagesGraphical System Design PDFLaasya ReddyNo ratings yet

- PLC SelectionDocument10 pagesPLC Selectionphani22No ratings yet

- Een 11 Finals Lec3Document16 pagesEen 11 Finals Lec3lavadiajhonNo ratings yet

- NetApp FAS System Diagnostic-Level PDFDocument30 pagesNetApp FAS System Diagnostic-Level PDFdbo61No ratings yet

- Slide 1 (Introduction)Document33 pagesSlide 1 (Introduction)Amit VishwakarmaNo ratings yet

- Es Unit-1Document20 pagesEs Unit-1supraja tirumalasettiNo ratings yet

- Describe Three Common and Mark Recognition DevicesDocument2 pagesDescribe Three Common and Mark Recognition Devicesdark angelNo ratings yet

- AYR190 - Review For CAT Only - 02 14 2008 - Rev 24Document140 pagesAYR190 - Review For CAT Only - 02 14 2008 - Rev 24Ruth Viotti SaldanhaNo ratings yet

- A Preliminary Inventory of The Arabic HermeticaDocument2 pagesA Preliminary Inventory of The Arabic HermeticaRick RockNo ratings yet

- Unattended Install Help PDFDocument4 pagesUnattended Install Help PDFSeptian Wahyu PriyonoNo ratings yet

- Synchronous Data Flow AlgorithmsDocument12 pagesSynchronous Data Flow Algorithmscpayne10409No ratings yet

- TCS Topics PatternDocument4 pagesTCS Topics PatternAkshay KayapakNo ratings yet

- Approaches To Curriculum DesignDocument2 pagesApproaches To Curriculum DesignRuth Amelia Munthe100% (3)

- PWP Chapter 2Document56 pagesPWP Chapter 2Sanket BadaveNo ratings yet

- 1st Periodical Test in EnglishDocument2 pages1st Periodical Test in Englishleizle uretaNo ratings yet

- 3 Things Jesus Is Calling Us To, and It's Not More WorkDocument8 pages3 Things Jesus Is Calling Us To, and It's Not More WorkJohn Christopher RomeroNo ratings yet

- Modul Latih Tubi PT3Document81 pagesModul Latih Tubi PT3liniNo ratings yet

- 206-Manasi Bonde-EXPERIMENT NO 1Document10 pages206-Manasi Bonde-EXPERIMENT NO 1Manasi BondeNo ratings yet

- Ricoeur - Approaching The Human PersonDocument10 pagesRicoeur - Approaching The Human Personlucas StamfordNo ratings yet

- ANIMELYRICSDocument35 pagesANIMELYRICSLeah ArnaezNo ratings yet

- PENDALAMAN MATERI BAHASA INGGRIS KELAS 8 Present ContDocument3 pagesPENDALAMAN MATERI BAHASA INGGRIS KELAS 8 Present ContGendis LinuwihNo ratings yet

- The Seasons Fun Activities Games 11997Document1 pageThe Seasons Fun Activities Games 11997Marinela AnghelNo ratings yet

- Debussy 0407Document117 pagesDebussy 0407ravikumar@sssNo ratings yet

- Adverbs: How, When and WhereDocument11 pagesAdverbs: How, When and WhereDeepa Ramiah Deepa RamiahNo ratings yet

- Distributed Database DesignDocument73 pagesDistributed Database Designsheenam_bhatiaNo ratings yet

- English Internet Slang - 30 Essential Slang Terms For Surviving OnlineDocument19 pagesEnglish Internet Slang - 30 Essential Slang Terms For Surviving OnlinegreeshmaNo ratings yet

- Charlie and The Chocolate Factory: Golden Ticket WinnerDocument3 pagesCharlie and The Chocolate Factory: Golden Ticket WinnerIleana Monica BarbulescuNo ratings yet

- 50 Puzzles Seating Arrangement Questions Download PDF - CompressedDocument41 pages50 Puzzles Seating Arrangement Questions Download PDF - Compressedshaik hafeezNo ratings yet

- RPH Bi Year 6-Unit 1 (w1-2)Document10 pagesRPH Bi Year 6-Unit 1 (w1-2)Shavani VaniNo ratings yet

- Jesus Christ: The RedeemerDocument11 pagesJesus Christ: The RedeemerTassos KioulachoglouNo ratings yet

- Lattice PLLDocument21 pagesLattice PLLHoracio DorantesNo ratings yet

- CARA Tool User ManualDocument11 pagesCARA Tool User ManualRambir KaushikNo ratings yet

- Parti Di Ricambio - 22186472DDocument132 pagesParti Di Ricambio - 22186472DpippoNo ratings yet

- General Physics 1 Quarter 1 Week 5 SSLMDocument6 pagesGeneral Physics 1 Quarter 1 Week 5 SSLMMaki ATNo ratings yet

- Every Man Shall Give As He Is AbleDocument9 pagesEvery Man Shall Give As He Is AblemakybuNo ratings yet