Professional Documents

Culture Documents

64 20 Fatigue

Uploaded by

AnantPawarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

64 20 Fatigue

Uploaded by

AnantPawarCopyright:

Available Formats

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Fatigue Evaluation of Reinforced Concrete

Highway Bridge

Habeeba A1, Sabeena M.V2, Anjusha R3

P.G. Student, Department of Civil Engineering, A.W.H Engineering College, Calicut, Kerala, India1

Professor, Department of Civil Engineering, A.W.H Engineering College, Calicut, Kerala, India2

Assistant Professor, Department of Civil Engineering, A.W.H Engineering College, Calicut, Kerala, India3

ABSTRACT: The increased traffic demand, material ageing, cracking of bridge components, physical damages

incurred by concrete, corrosion of reinforcement and inadequate maintenance of bridges necessitate the assessment of

bridges periodically for their performances. The accuracy of analytical assessment of bridges depends on the ability of

the tool to simulate the problem. The nonlinear analysis is one such tool to simulate the exact material behaviour, to

evaluate strength in inelastic range. An attempt has been made to perform nonlinear finite element analysis to analyse

the component of a selected road bridge. The aim of this dissertation is to study the fatigue life evaluation of reinforced

Concrete Highway Bridge. Nonlinear analysis of the structural element using ANSYS is carried out. RCC T-beam

Bridge has been chosen for detailed 3D nonlinear analysis. Fatigue evaluation of proposed bridge is also done using

SAP-2000. Fatigue life evaluation approaches using S-N curves are also presented.

KEYWORDS: Fatigue damage, Concrete bridge, Fatigue life, S-N curve, Non linear finite element analysis.

I.

INTRODUCTION

Bridges are not simply structures made out of materials, they are part of life. In many places life would be seriously

disrupted, traffic would be paralysed and business would be terribly affected if the bridges fail functioning. Hence the

assessment of bridges periodically for its performance turns out to be an important task. The bridge assessment can be

done by conducting laboratory experiments, field tests and also through analytical means. Fatigue is a progressive

deterioration of a structure by crack growth, due to a series of stress variations (cycles) resulting from the application of

repeated loads, such as induced in bridge components under traffic loads and heavy vehicle crossings. Bridge decks

must withstand one of the most damaging types of live load forces i.e., the concentrated and direct pounding of truck

wheels. A primary function of the deck is to distribute these forces in a favorable manner to the support elements

below. The current study restricts to analytical method of performance evaluation. In analytical method the accuracy of

the result depends upon the ability to simulate the problem. In reality, most of the problems are nonlinear in nature.

Hence nonlinear analysis is an effective tool to simulate the exact problem. Nonlinearity may be geometric or material

nonlinearity. A structure could encounter either one of the above or combination of both.

In this study, nonlinear finite element analysis is carried out using ANSYS which employs Newton Rapson technique

to solve the higher order differential equation. Elanthikadavu Bridge, a highway road bridge, situated at kodenjeri,

Calicut, Kerala, India is chosen for the present study. The loads are arrived as per IRC 6-2000 standards and the

responses are obtained by modelling the bridge superstructure in SAP 2000 v-14. The main objective of the study is to

evaluate the fatigue life of the reinforced concrete highway bridge under moving wheel loads.

II.

MATERIALS AND METHODS

The objective of the present study was to design the deck panel and supporting girders and to find out the fatigue life of

the specified reinforced concrete T-beam bridge under transient load due to moving vehicles. In this study, nonlinear

finite element analysis is carried out using ANSYS for Fatigue evaluation of reinforced concrete T beam Bridge, built

across river Iravinjipuya is chosen for the present study. Fatigue evaluation of bridge is also done using SAP-2000. The

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2561

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

loads are taken as per IRC 6-2000 standards. The work in this paper is divided in two stages. 1) Bridge super structure

modelling, 2) Analyse the deck panel and supporting girders and to find out the fatigue life of the specified reinforced

concrete T-beam bridge under transient load due to moving vehicles. The isotropic material property for modeling the

bridge is the elastic modulus (Ec) and Poissons ratio () of the concrete and steel. Modulus of Elasticity of concrete is

25000 N/mm2 and that of steel is 2x105 N/mm2. Poissons ratio of concrete is 0.2 and steel is 0.3

The paper is organized as follows. Section III is description of the bridge. Section IV and V presents computer

modelling of the proposed bridge. Fatigue Analysis and loading representation is given in Section VI and VII. Section

VIII and IX explains fatigue analysis using ANSYS and SAP software. Section X presents analysis result.

III. DESCRIPTION OF THE BRIDGE

It is a roadway bridge 11.05m wide, and 97.28m long straight through three main longitudinal girders and sixteen cross

girders. 7.5m carriageway width and 22.3 m span RCC T-Beam bridge across river Iravinjipuza. The global method of

analysis for T-beam girder bridges involves the analysis of the deck slab and the longitudinal and crosses girders.

Materials used are of M25 concrete and Fe 415 steel. The bridge superstructure is 22.3m span simply supported, cross

sectional dimensions of the bridge is as shown in the Figure 1.

Fig.1 Cross-Sectional Dimensions of Bridge

IV. COMPUTER MODELING USING ANSYS

The whole bridge is first modeled in CATIA (Computer aided three dimensional interactive application) software and

then importing the model to ANSYS workbench and then importing the model to ANSYS Mechanical APDL. Finite

Element Analysis (FEA) represents a numerical method, which provides solution to problems that would otherwise be

difficult to obtain. The numerical analysis investigations were performed with commercial software ANSYS 14.5.

Modelling the complex behaviour of reinforced concrete, which is both non homogeneous and anisotropic, is a difficult

challenge in the finite element analysis of civil engineering structures. Where a special three-dimensional eight nodded

solid isoperimetric element, Solid 65 is developed. It models the nonlinear response of brittle materials and is based on

a constitutive model for the triaxial behaviour of concrete. Solid 65 allows the presence of four different materials

within each element; one matrix material (e.g., concrete) and a maximum of three independent reinforcing materials.

The concrete material is capable of directional integration point cracking and crushing besides incorporating plastic and

creep behaviour. The reinforcement (which also incorporates creep and plasticity) has uniaxial stiffness only. In the

current study, Solid 65 element available in ANSYS is employed for obtaining the ultimate load carrying capacity and

for determining the behaviour of concrete bridge under service load..

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2562

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

V. REINFORCEMENT MODELING

There are two techniques to model steel reinforcement in finite element models for reinforced concrete. The discrete

model and the smeared model. The reinforcement in the discrete model uses bar or beam elements that are connected to

concrete mesh nodes. The concrete and reinforcement share same nodes and concrete occupies the same regions as the

reinforcement. A drawback to this model is that the concrete mesh is restricted by the location of the reinforcement and

the volume of the mild-steel reinforcement is not deduced from the concrete volume. The smeared model overcomes

the concrete mesh restrictions. The smeared model assumes that reinforcement is uniformly spread throughout the

concrete elements in a defined region of the FE mesh. This approach is used for large-scale models. Here smeared

model of reinforcement is used.

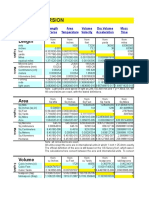

For smeared model, parameters to be considered are material number, volume ratio, and orientation angles ( and )

in X and Y directions respectively. Table 1 shows Real constants used for bridge slab. Rebar1, 2 and 3 mentioned in

Table 1 refer to vertical, horizontal and shear reinforcements. Volume ratio refers to the ratio of steel to concrete in

the element.

Table 1. Real constants for bridge slab

Real

Constants

Set

Element

type

Solid 65

Particulars

Constants

Real

Constant for

Rebar 1

Real

Constant for

Rebar 2

Real

Constant for

Rebar 3

Material Number

Volume Ratio

0.0009945

0.00453

0.0001211

Orientation Angle

90

Orientation Angle

90

90

VI. LOADING REPRESENTATION

Non linear analysis of bridge model was carried out under the simulated wheel load of IRC Class A wheeled vehicle as

per IRC 62000. Special technique is employed for representing a moving load or a vehicle. This method uses the

transient solution analysis of the ANSYS, placing the loads on one specified set of nodes at a time. The program

divides the axle weights in half and applies two wheel loads at a distance equal to half the vehicle width onto either side

of the centreline of vehicle travel. Figure 2 shows IRC Class A train of vehicle. Accumulating fatigue damage caused

by passing vehicles is needed for fatigue safety evaluation of existing concrete bridges. The fatigue life can also

expressed in terms of number of years. The design traffic is considered in terms of cumulative number of standard axle.

Cumulative number of standard axle is computed as per IRC 37 (2001). The following points are considered.

I.

Axle loading will be used for the calculation of stress ranges as per IRC Class A loading.

II.

For simplifying the number of cycles per vehicle will be assumed equal to one cycle per truck

III.

The value of average daily truck traffic (ADTT) was assumed less than 5228 truck/day.

IV.

The growth factor is assumed as 6-7.5% for road bridges in rural areas.

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2563

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Fig. 2 IRC-Class A Train of vehicle

VII.

REMAINING FATIGUE LIFE

Remaining fatigue life is find out by two ways

1. Fatigue evaluation based on S-N curve. Here S-N curves for RCC bridges, which were proposed by ASHTO, are

used in estimating the remaining fatigue life. The fatigue damage caused in the bridge is computed by using

Palm-gren Miners theory of linear damage accumulation. According to Miner linear fatigue accumulative

damage, fatigue damage can be calculated by:

The total damage to the structure is given by D= ni/Ni.

ni = Observed number of stress cycles for different stress ranges

Ni = Theoretical number of stress cycles corresponding to observed stress ranges from S-N curve.

i = 1,2,3 . Up to n stress ranges

For the current study the S-N curve was obtained using the ASTHO code.6.6.1.2

2. By checking the deflection values of deck slabs and supporting girders that failed the permissible deflection

limit. The deflection values are obtained from SAP-2000 software. The deflection for all the load cases met the

limit specified by IRC 24 (IRC 2001), which states that the total deflection caused by dead load, live load, and

impact should be less than 1/600 of the span.

VIII.

FATIGUE ANALYSIS USING ANSYS

Fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading..

Fatigue occurs when a material is subjected to repeated loading and unloading. Fatigue life is defined as the number of

stress cycles of a specified character that a specimen sustains before failure of a specified nature occurs. When the

cyclic stresses are below certain value (termed as fatigue limit /endurance limit), cracks do not initiate. But, if the cyclic

stresses are above the fatigue limit, cracks initiate after a certain number of cycles and then grow at a progressively

increasing rate until complete fracture occurs. S-N curve has been used for conducting a fatigue analysis.

A single span of the bridge is taken for detailed analysis. Then meshing is done using volume sweep meshing. Total

number of node is 363355. After meshing loading is applied as per IRC Class A and placing the loads on one specified

set of nodes at a time. Analysis done as the static non linear analysis of ANSYS. The first part of analysis calculates

the member deflection and stresses for the model configuration used. The second part, fatigue analysis of bridge is done,

by applying the number of cycles at each year. S-N curves for RCC bridges, which were proposed by AASHTO, are

used in estimating the remaining fatigue life. Stress and corresponding number of cycles values obtained from S-N

curve are applying to fatigue property table in ANSYS Mechanical APDL. After fatigue analysis we got a fatigue usage

factor or partial usage factor, whenever the partial usage factor > 1 the fatigue failure of the bridge occur. Maximum

stress coming node in deck slab, longitudinal girder and cross girder is taken fatigue analysis. Figure 3 shows Fatigue

analysis result of deck slab after 60 year. After 60 years number of cycles becomes 3.11x106 /day and partial usage

factor of deck slab is 1.03667. From the analysis fatigue life of deck slab is 60 year. Figure 4 shows bridge model in

ANSYS and Bridge displacement and maximum stress location.

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2564

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Fig. 3 Fatigue analysis result after 60 year

a)

b)

c)

Copyright to IJIRSET

d)

DOI: 10.15680/IJIRSET.2015.0404064

2565

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

e)

f)

Fig.4 a) Bridge full model in ANSYS workbench b) Bridge full model in ANSYS Mechanical APDL c) Meshed view

d) Bridge loading representation e) Bridge displacement f) Maximum stress location on the deck slab

IX.

FATIGUE ANALYSIS USING SAP

A 3D model of the entire bridge is created in SAP2000 software for getting fatigue life of the bridge. The material

properties are assigned to the components as concrete and the modulus of elasticity is calculated as per IS-456(2000).

The supports are considered as simple supports at both ends. Figure 5 shows the 3D model of the bridge created using

SAP2000. Moving loads are generated by defining standard vehicles in SAP environment. The live load considered for

our analysis is IRC Class A train of vehicles. It is found that the maximum deflection is obtained for the factored dead

load and live load fatigue load combination. Responses at the mid span are found and the whole model is chosen for a

detailed 3-D non linear analysis. By checking the deflection values that failed the permissible deflection limit. The

deflection for all the load cases met the limit specified by IRC 24 (IRC 2001), which states that the total deflection

caused by dead load, live load, and impact should be less than 1/600 of the span. Impact factor is applied as per IRC 62000. After applying dead load and live load fatigue load combination static non linear analysis is performed, then the

initial deflection obtained is 12.1mm. The deflection of the bridge is found out with the fatigue load. Figure 5 b) shows

the values of the deflection of the bridge model after 71 years, it was noticed that the maximum deflections is 38.5mm

which more than the IRC limits i.e. Span/600.

a)

Copyright to IJIRSET

b)

DOI: 10.15680/IJIRSET.2015.0404064

2566

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

c)

d)

Fig.5 a) Bridge model in SAP-2000 b) Bridge initial deflection c) Bridge deflection after 71 year d) Bending moment

diagram

X.

RESULT

Fatigue evaluation of the RCC bridge (Elanthikadavu bridge) done analytically based S-N curve using ANSYS

software. It was found that the remaining fatigue life for the deck slab of the bridge is to be 60 years and remaining life

of cross girders and longitudinal girders are to be 68 years and 72 years. Fatigue life of the bridge is also found out by

SAP-2000 software by checking the deflection values that failed the permissible deflection limit provided in IRC 24

(IRC-2001). From the SAP analysis the remaining life of the bridge is to be 71 years. As per IRC SP:60-2002 have

specified a service life of inforced concrete bride is 50-100 years, out of which the first 50 years must be totally free of

maintenance, while minor concrete repairs will be acceptable after the first 50 years. Figure 4,6 and 8 shows the

variation of Partial usage factor (PUF) with year graph for deck slab, longitudinal girder and cross girder. Figure 5,7

and 9 shows the variation of Partial usage factor (PUF) with No. of Cycles graph for deck slab, longitudinal girder and

cross girder.

Fig.4 Partial usage factor (PUF) year graph for deck slab

Copyright to IJIRSET

Fig.5 PUFNo. of cycles graph for deck slab

DOI: 10.15680/IJIRSET.2015.0404064

2567

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Fig.6 PUFyear graph for cross girder

Fig.7 PUFNo. of cycles graph for cross girder

Fig.8 PUFyear graph for longitudinal girder

Fig.9 PUFNo. of cycles graph for longitudinal girder

As per IRC SP:60-2002 have specified a service life of inforced concrete bride is 50-100 years, out of which the first

50 years must be totally free of maintenance, while minor concrete repairs will be acceptable after the first 50 years. As

per IRC 24 (IRC 2001), have specified that the total deflection caused by dead load, live load, and impact should bless

than 1/600 of the span. Fatigue analysis of the bridge is satisfied these IRC clauses, Hence the analysis result is justified

with IRC specification.

XI.

CONCLUSION

An evaluation of remaining fatigue life for reinforced concrete bridge was carried out under a given moving wheel

load. The remaining fatigue life for the deck slab of the bridge is to be 60 years and remaining life of cross girders and

longitudinal girders are to be 68 years and 72 years respectively.

REFERENCES

[1]

[2]

[3]

[4]

Fernando N. Leitao. Fatigue analysis and life prediction of composite highway bridge deck under traffic loading., Latin American Journal

of Solids and structures 2013.

A. Kanchanadevi and C. Umarani, Non-linear finite element analysis for assessment of bridges., International Journal of Earth Science and

Engineering, vol. 02, no.06, pp. 588595, 2009.

Salini Theres N Kurian,, Fatigue analysis of glass fiber Reinforced polymer (GFRP) Bridge deck panels, International Journal of Innovative

Research in Science, Engineering and Technology. Vol. 2, pp. 174-180, 2013.

Chun-Sheng Wang1, Mu-Sai Zhai,Fatigue Safety Monitoring and Fatigue Life Evaluation for Existing Concrete Bridge, 13th International

Conference on Fracture June 1621, 2013.

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2568

ISSN(Online) : 2319 - 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

Handy Michael Gilbert, Validation of a laboratory method for accelerated fatigue testing of bridge deck panels with a rolling wheel load, A

thesis submitted under Montana state university Bozeman, Montana.

Manjeetkumar M Nagarmunnoli, Effect of deck thickness in rcc t-beam bridge, international journal of structural and civil engineering.

Research, vol. 03, no.01, pp. 36-43, 2014.

Umarani Gunasekaran Load rating of bridgescurrent practices and issues. ATI - Applied Technologies & Innovations Vol. 2 , No. 9-18,

2010

El-Hussieny, Field test and numerical modeling of a steel bridge for fatigue evaluation, American society of civil engineers 6th

International Engineering and Construction Conference. June 28-30, 2010.

Hazim Al Khusaibi, Truss bridge analysis Truck weights. Finite element analysis engineering mechanics 461

R. Michael Bigges, Furman w, Finite element modeling and analysis of reinforced concrete bridge decks, Report submitted under Virginia

Transportation Research Council

AASHTO. American Association of State Highway and Transportation Officials, Washington, DC. AASHTO LRFD bridge design

Specifications 4 th edition 2007.

Indian Road Congress (IRC). (2000a). IRC 6: Standard specifications and code of practice for road bridges, section II, loads & stresses,

Indian Road Congress, New Delhi, India.

Indian Roads Congress (IRC). (SP 2002). IRC 60: an approach document for assessment of remaining life of concrete bridgesda1, Indian

Road Congress, New Delhi, India.

Indian Road Congress (IRC). (2001). IRC 24: Standard specifications an code of practice for road bridges, Indian Road Congress, New Delhi,

India

Indian Road Congress (IRC). (2001 ). IRC 37: Guidelines for design of flexible pavements, Indian Road Congress, New Delhi, India

Copyright to IJIRSET

DOI: 10.15680/IJIRSET.2015.0404064

2569

You might also like

- New Rich Text DocumentDocument1 pageNew Rich Text DocumentAnantPawarNo ratings yet

- New Rich Text DocumentDocument1 pageNew Rich Text DocumentAnantPawarNo ratings yet

- SJ Iw MTMZ MZGDocument6 pagesSJ Iw MTMZ MZGAnantPawarNo ratings yet

- MDOT Bridge Ratings: Statewide, MA Bridge RatingDocument1 pageMDOT Bridge Ratings: Statewide, MA Bridge RatingAnantPawarNo ratings yet

- BridgeDocument9 pagesBridgeAnantPawarNo ratings yet

- Appendix A. Modeling ToolDocument89 pagesAppendix A. Modeling ToolTahir BajwaNo ratings yet

- IRC Guide Design Monitoring EvaluationDocument74 pagesIRC Guide Design Monitoring EvaluationAnantPawarNo ratings yet

- Bridge RuleDocument105 pagesBridge Ruleamawauce78% (9)

- RFP DocumentDocument154 pagesRFP DocumentAnantPawarNo ratings yet

- IJREATV1I2029Document5 pagesIJREATV1I2029amit_saxena_10No ratings yet

- IJREATV1I2029Document5 pagesIJREATV1I2029amit_saxena_10No ratings yet

- Strengthening Runway Bridge Mumbai Airport Using FRPDocument15 pagesStrengthening Runway Bridge Mumbai Airport Using FRPAnantPawarNo ratings yet

- Beam CantileverDocument16 pagesBeam CantileverAdam SlametNo ratings yet

- Ok Nityesh BhattDocument8 pagesOk Nityesh BhattAnantPawarNo ratings yet

- Wall DesignDocument13 pagesWall DesignAnantPawarNo ratings yet

- TAXABLE VALUES AND MARKET VALUES BY PROPERTY CLASSDocument1 pageTAXABLE VALUES AND MARKET VALUES BY PROPERTY CLASSAnantPawarNo ratings yet

- Shear WallDocument6 pagesShear WallAnantPawar100% (1)

- Calculation of Live Load Reaction For AbutmentsDocument4 pagesCalculation of Live Load Reaction For Abutmentsvasu7900No ratings yet

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLNo ratings yet

- Saisc Structural Steel Section PropertiesDocument12 pagesSaisc Structural Steel Section PropertiesAnantPawarNo ratings yet

- Influence LinesDocument6 pagesInfluence LinesduckeNo ratings yet

- Construction Estimate for Flexible Electronics CenterDocument68 pagesConstruction Estimate for Flexible Electronics CenterAnantPawarNo ratings yet

- Rent Vs Buy Analysis Rental Information: Expected Sale Price Upon Sale (Do Not Enter) $0.00 (Do Not Enter)Document18 pagesRent Vs Buy Analysis Rental Information: Expected Sale Price Upon Sale (Do Not Enter) $0.00 (Do Not Enter)AnantPawarNo ratings yet

- RATE ANALYSIS FOR CONSTRUCTION MATERIALS AND LABOURDocument81 pagesRATE ANALYSIS FOR CONSTRUCTION MATERIALS AND LABOURAnantPawarNo ratings yet

- Buy RentDocument73 pagesBuy Rentskidmore7No ratings yet

- Shear WallDocument9 pagesShear WallAnantPawarNo ratings yet

- Reservoir 11Document54 pagesReservoir 11Satya kaliprasad vangaraNo ratings yet

- Concrete Continuous Footing Quantity Take-Off WorksheetDocument17 pagesConcrete Continuous Footing Quantity Take-Off WorksheetAnantPawarNo ratings yet

- Beam Cracked Moment of InertiaDocument1 pageBeam Cracked Moment of InertiaAnantPawarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor Jones: What's Inside in ContextDocument27 pagesThe Emperor Jones: What's Inside in ContextHarshvardhan RaiNo ratings yet

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- Rakpoxy 150 HB PrimerDocument1 pageRakpoxy 150 HB Primernate anantathatNo ratings yet

- Research Paper On Organ DonationDocument8 pagesResearch Paper On Organ Donationsheeliya whiteNo ratings yet

- Published Filer List 06072019 Sorted by CodeDocument198 pagesPublished Filer List 06072019 Sorted by Codeherveduprince1No ratings yet

- Chemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechDocument14 pagesChemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechKrispin FongNo ratings yet

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet

- Manju Philip CVDocument2 pagesManju Philip CVManju PhilipNo ratings yet

- Linguistics: Chapter 1 - 10Document41 pagesLinguistics: Chapter 1 - 10Ahmad A. JawadNo ratings yet

- Done by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikDocument12 pagesDone by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikRamya BalanNo ratings yet

- Practical LPM-122Document31 pagesPractical LPM-122anon_251667476No ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocument6 pages99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaNo ratings yet

- Reaction rate determination and simulation of hydrogenation processDocument3 pagesReaction rate determination and simulation of hydrogenation processToMemNo ratings yet

- The Invisible Hero Final TNDocument8 pagesThe Invisible Hero Final TNKatherine ShenNo ratings yet

- Fiery Training 1Document346 pagesFiery Training 1shamilbasayevNo ratings yet

- Khaton Prayer BookDocument47 pagesKhaton Prayer BookKarma TsheringNo ratings yet

- Marksmanship: Subject: III. Definition of TermsDocument16 pagesMarksmanship: Subject: III. Definition of TermsAmber EbayaNo ratings yet

- 256267a1Document5,083 pages256267a1Елизавета ШепелеваNo ratings yet

- Daughters of The Storm by Kim Wilkins - Chapter SamplerDocument32 pagesDaughters of The Storm by Kim Wilkins - Chapter SamplerHarlequinAustraliaNo ratings yet

- Mba Project GuidelinesDocument8 pagesMba Project GuidelinesKrishnamohan VaddadiNo ratings yet

- 40 Multiple Choice Questions in Basic StatisticsDocument8 pages40 Multiple Choice Questions in Basic StatisticsLevi CorralNo ratings yet

- Revised Man As A Biological BeingDocument8 pagesRevised Man As A Biological Beingapi-3832208No ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- Where On Earth Can Go Next?: AppleDocument100 pagesWhere On Earth Can Go Next?: Applepetrushevski_designeNo ratings yet

- Brooks Instrument FlowmeterDocument8 pagesBrooks Instrument FlowmeterRicardo VillalongaNo ratings yet

- The Life and Works of Jose RizalDocument20 pagesThe Life and Works of Jose RizalBemtot Blanquig100% (1)

- Turbine 1st Stage Nozzle - DPTDocument15 pagesTurbine 1st Stage Nozzle - DPTAnonymous gWKgdUBNo ratings yet

- The Rich Hues of Purple Murex DyeDocument44 pagesThe Rich Hues of Purple Murex DyeYiğit KılıçNo ratings yet