Professional Documents

Culture Documents

Circ Basedf

Uploaded by

mdelacua2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circ Basedf

Uploaded by

mdelacua2Copyright:

Available Formats

"CIRCBASE" --- STEEL COLUMN CIRCULAR BASE PLATE ANALYSIS

Program Description:

"CIRCBASE" is a spreadsheet program written in MS-Excel for the purpose of analysis of steel column base

plates. Specifically, pipe columns base plates may be subjected to axial loads (compression only), with or

without column bending, plus shear. Base plate bearing pressure is checked as well as bolt tension, if

applicable. If shear is present, bolt shear as well as interaction of bolt tension and shear, if applicable, are

calculated. Finally, a propoesed base plate thickness is is checked.

This program is a workbook consisting of two (2) worksheets, described as follows:

Worksheet Name

Description

Doc

Complete method

This documentation sheet

Circular base plate analysis

Program Assumptions and Limitations:

1. This program follows the procedures and guidelines of "Design of Monopole Bases", by Daniel Horn, P.E.

2. This program follows the procedures and guidelines of the AISC 9th Edition Allowable Stress (ASD) Manual

(2nd Revision, 1995) for round hollow structural tube & column base plates subjected to flexure.

3. For steel interaction of anchor bolt tension and shear, this program follows:

Appendix D of ACI 318-02, "Building Code Requirements For Structural Concrete"

4. For concrete bearing, this program follows:

Section 10.17 of ACI 318-02, "Building Code Requirements For Structural Concrete"

5. User has option to take out some of the total shear though friction between column base and grout based

on column dead load and coefficient of friction, thus reducing amount of shear to be taken by anchor bolts.

6. Additional assumptions used in this program are as follows:

a. The column is centered on a circular base plate in both directions.

b. The column & base plate are centered on a round pedestal in both directions.

b. Axial column load, 'P' > 0 for the case with moment.

7. This program contains numerous comment boxes which contain a wide variety of information including

explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box

is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the

desired cell to view the contents of that particular "comment box".)

8. For the addition of gusset plates to the baseplate, this program derives the baseplate moments from

"Theory of Plates and Shells", by S. Tomonshenko. (1st Edition, 1940)

a. Table 26 - Deflection & Bending Moments for a Uniformly Loaded Plate with Two Opposite Edges

Simply Supported, the Third Edge Free and the Fourth is Built In (Page 218)

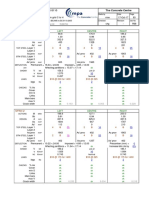

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

M=

Input Data:

OD(col) =

r(col) =

PL bearing

Column Loadings:

tcol =

area

Axial Load, P =

11.00

kips

Yes

Axial Load, P(DL) =

0.00

kips

No

Shear Load, V =

3.00

kips

e = 88.55 in

Moment @ Base, M =

974.00

in-kips

###

y = 9.95 in

###

Design Parameters:

###

Mod./High seismic risk region?

Yes

###

Is a grout pad present?

Yes

###

yo = 2.55 in

Column Outer Dia., OD(col) =

16.000

in

###

di = 16 in

Column wall thick, tcol =

0.500

in

###

Column Yield stress, Fy(col) =

35.000

ksi

###

Base Plate O.D., B =

25.000

in

###

Base Plate I.D., di =

16.000

in

###

Base Plate thick, t(PL) =

1.750

in

###

Plate Yield Stress, Fy =

36.00

ksi

###

Baseplate gussets present?

Yes

###

Gusset Plate thick, tg =

0.500

in

###

Gusset Plate height, hg =

12.000

in

###

No. of Gusset Plates, Ng =

8

###

BC = 20 in

Concrete Strength, f 'c =

4.000

ksi

###

B = 25 in

Coef. of Friction, =

0.55

###

Conc. Ped. diameter, OD(ped) =

30.00

in

###

ACI load factor, LF =

1.38

###

###

Anchor Bolt/Rod Data:

###

Total No. of Bolts, Nb =

6

bolts

###

Bolt Circle Dia, BC =

20.00

in

###

Bolt Diameter, db =

1 1/4

in

###

Anchor Bolt Material = F1554 (36)

###

###

Iteration:

###

q(start) =

86.0000

in

Start value should approx. equal eccentricity ###

q(calc) =

83.4276

in

A307

Change q(start) until Delta = 0.

Delta =

2.5724

A36

A572

Results:

A588

F1554 (36)

Calculate the area of the outer circle:

F1554 (55)

F1554 (105)

r=

12.50

in = B/2

###

y = lo =

9.95

in = r-e+q

###

yo =

2.55

in = r-lo

###

in^2 = r^2*/2-yo*(r^2-yo^2)-r^2*asin(yo/r)

A1 =

182.24

###

###

###

No

Yes

ybc =

fbc =

Complete Method

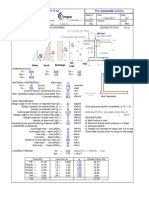

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

(continued)

=

APL =

Aconc =

(Aconc/APL) =

fc =

fc =

fc(allow) =

Results (continued):

Calculate the area of the inner circle

ri =

l=

yc =

Ac =

AT =

y1 =

Q1 =

y1c =

Qc =

QT =

8.00

5.45

2.55

-60.50

166.55

6.70

14,915

4.81

-5,066

13,833

in = di/2

in = ri-e+q

in = max(ri-l or -ri), or 0 if l<0

in^2 = -ri^2*/2+yc*(ri^2-yc^2)+ri^2*asin(yc/ri), or 0 if l<0

in^2 = A1+Ac+(n-1)*Ab+n*Ab

in = [2*(r^2-yo^2)^1.5]/3*A1

beff =

in^3 = A1*(e-y1)

y=

in = 0 if l<0, or [-2*(ri^2-yc^2)^1.5]/(3*Ac)

fpole =

in^3 =Ac*(e-y1c), or 0 if l<0

in^3 = Q1 + Qbolt + Qc

Calculate the moments of inertia

I1 =

Ic =

Ibolt =

IT =

q(calc) =

1,221,916

-424,371

356,488

1,154,032

83.43

in^4

in^4

in^4

in^4 = I1+Ic+Ibolt

in = IT/QT

Concrete Results:

Eccentricity, e =

Min. Eccentricity, e(min) =

ACI load factor, LF =

Conc bearing stress, fc(max) =

Factored bear stress, fc(max,f) =

ybc =

Conc bearing stress, fbc =

Factored bearing stress, fbc,f =

Strength reduction factor, =

PL to ped edge dist, d1a =

Min. bear length, d1 =

Conc bear area O.D., OD(bear) =

Conc bear area I.D., ID(bear) =

Baseplate bearing area, APL =

Concrete bearing area, Aconc =

(Aconc/APL) =

Allow. bear. stress, fc(allow) =

88.55

in = ABS(M/P)

4.41

in = (B^4-di^4)/(8*B*(B^2-di^2))

Method Valid

1.38

1.77

2.44

4.88

0.87

1.53

0.65

2.50

2.50

30.00

11.00

289.81

611.83

1.45

3.21

ksi = P*y/(q*AT-QT)

ksi = LF*fc(max)

in = BC/2-e+q(calc)

ksi @ bolt circle = P*ybc/(q*AT-QT)

ksi @ bolt circle = LF*fbc

in = [OD(ped)-di]/2

in = min[ d1a , r(col) ]

in = B+2*d1

in = di-2*d1

in^2 = /4*(B^2-di^2)

in^2 = /4*[OD(bear)^2-ID(bear)^2]

ksi = *0.85*(f 'c)*(Aconc/APL)

M(max) =

fmax =

fall =

Abt = 0.7854*(db-0.9743/n

M(max) =

fmax =

fall =

###

Baseplate W

###

Sweld =

Weld force, fwm =

Allowable weld stress, w =

Req'd weld size, h =

###

Steel Resu

###

Ng =

b=

L=

L/b =

fc(max) =

The following

L/b

x = b/2

###

fc(max,f) fc(allow), O.K.

Steel Results:

###

beff =

y=

fpole =

8.38

2.88

0.51

in = *B/Nb

in = B/2-e+q(calc)

ksi = P*y/[q(calc)*AT-QT]

###

###

###

###

###

Complete Method

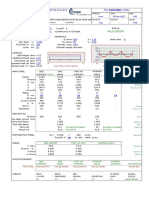

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

(continued)

Steel Results (continued):

Compression Side:

No. of Gusset Plates, Ng =

Gusset spacing, b =

Baseplate Length, L =

L/b =

L/b

8.00

10.73

4.50

0.42

plates

in = 2**([r+r(col)]/2)/Ng

in = 0.5[B-OD(col)]

Mx

x = b/2

My

y = L1

x = b/2

y=0

-0.500 fc*L^2

0.333

0.0078 fc*b^2

-0.428 fc*L^2

0.5

0.0293 fc*b^2

-0.319 fc*L^2

0.667

0.0558 fc*b^2

-0.227 fc*L^2

0.0972 fc*b^2

-0.119 fc*L^2

1.5

0.1230 fc*b^2

-0.124 fc*b^2

0.1310 fc*b^2

-0.125 fc*b^2

0.1330 fc*b^2

-0.125 fc*b^2

0.1330 fc*b^2

-0.125 fc*b^2

Conc bearing stress, fc(max) =

Cx =

Mx =

Cy =

My =

M(max) =

f(max) =

f(all) =

1.77

0.0189

3.845

-0.3718

-13.310

13.31

4.99

27.00

A

A1

Given A =

A2

Cx =

Mx =

This table is taken from

This table

is taken

Theory

Of Plates

Andfrom

Theory

Of Plates And

Shells

(Timoshenko)

Shells (Timoshenko)

ksi = P*y/(q*AT-QT)

in-kips/in = Cx*fc*b^2

in-kips/in = Cy*fc*L^2

in-kips

ksi = [6*M(max)]/t(PL)^2

ksi = 0.75*Fy

Tension Side:

A

A1

Given A =

A2

Cy =

My =

M(max) =

fs(max) =

Rcol =

tcol =

tg =

hg =

m = t(PL) =

a=

Z=

f(max) f(all), O.K.

Vg =

Mg =

fb(pole wall) =

fb(allow) =

f(max) f(all), O.K.

M(max) =

f(max) =

f(all) =

38.12

8.92

27.00

in-kips = Pten*[BC-OD(col)]/2

ksi = 6*M*(max)/[beff*t(PL)^2]

ksi = 0.75*Fy

Gusset spacing, b =

Rcol =

m=

a=

Z=

Vg =

Mg =

fb(pole wall) =

fb(allow) =

10.73

8.00

1.75

2.00

0.21

85.38

192.11

13.78

21.00

b1 =

in = 2**([r+r(col)]/2)/Ng

ybar =

I1 =

in = OD(col)/2

in = t(PL)

Nw =

in = 2*(tg+t)

w =

= 1/[ (0.177*a*m/sqrt(Rcol*t))(m/tcol)^2+1.0]

t =

kips = fc*b*L

b =

in-kips = *fc*b*L^2

fv =

ksi

fvw =

ksi = 0.6*Fy(col)

fb(pole wall) fb(allow), O.K.

201.06

4.84

fbw =

fsw =

frw =

v =

Column Wall:

Column to Baseplate Weld:

Sweld =

Weld force, fwm =

in^2 =(/4)*OD(col)^2

kips/in = M/Sweld

Weld design assumes 70

Weld

assumes 70

ksidesign

electrodes

ksi electrodes

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

Weld design assumes 70

Weld

design

assumes

70

ksi

electrodes

V

(bolts)

=

Subject:

Originator:

Checker:

ksi electrodes

Allowable weld stress, w =

14.85

ksi = 0.7071*0.3*(70 ksi)

Req'd weld size, h =

0.326

in = fwm/w

(continued)

Steel Results (continued):

Gusset / Column / Baseplate Weld:

tg = 0.5 in

hg = 12 in

Weld design assumes 70

Weld

assumes 70

ksidesign

electrodes

ksi electrodes

t(PL) = 1.75 in

b1 = 6.28 in

Determine moment of inertia of gusset/baseplate section

Item

1

2

b

6.28

0.50

Totals

h

1.75

12.00

13.75

y

0.88

7.75

Baseplate effective width, b1 =

Location of gusset/basepl neutral axis, ybar =

Gusset/basepl moment of inertia, I1 =

# of welds, Nw =

Allowable weld stress, w =

Bending stress @ t.o. gusset, t =

Bending stress @ b.o. gusset, b =

Shear force @ face of baseplate, fv =

Horizontal weld force, fvw =

Horizontal req'd weld size, h =

Bending force on vert. weld, fbw =

Vertical shear on weld, fsw =

Resultant weld force, frw =

Req'd weld size, v =

A

11.00

6.00

17.00

6.28

3.30

258.28

2.00

14.85

7.77

2.46

8.82

4.41

0.30

1.94

3.56

4.05

0.27

A*y

9.62

46.50

56.12

A*y^2

8.42

360.38

368.79

=

=

LF =

s=

Pten = Tb = Nu =

Pten = Tb = Nu =

Vb = V u =

Ase =

Fy(bolt) =

Fut(bolt) =

Fut(bolt) =

Ns =

=

Vs =

=

=

=

Tension interaction =

=

Shear interaction =

=

=

=

Io

ion check =

2.81

=

72.00

=

74.81

=

in = *OD(col)/Ng

in = A*y/A

in^4 = Io+(A*y^2)-[(A*y)*ybar]

welds

ksi = 0.7071*0.3*(70 ksi)

ksi

ksi

kips/in = Vg*[(b1)*t(PL)]*[ybar-*t(PL)]/I1

kips/in = fv/Nw

in = fvw/w

k/in = t*tg/Nw

k/in = Vg/(hg*Nw)

k/in = SQRT(fbw^2+fsw^2)

in = frw/w

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

(continued)

Anchor Bolt/Rod Steel Tension and Shear (Per ACI 318-02):

Tensile strength reduction factor, =

Shear strength reduction factor, =

ACI load factor, LF =

A.B. Spacing, s =

Max. bolt tension, Pten = Tb = N =

Max. factored bolt tension, Nu =

Bolt Shear, V(bolts) =

Bolt Shear, Vb = Vu =

Ase =

Fy(bolt) =

Fut(bolt) =

Ns =

Vs =

Tension interaction =

Shear interaction =

Interaction check =

0.75

0.65

1.38

10.47

19.06

26.30

3.00

0.69

0.97

36.00

58.00

31.61

13.15

0.832

0.042

0.885

in = *BC/Nb

kips (See following page)

kips = LF*N

kips = V(total)-1/2**P(DL)

kips/bolt = V(bolts)/Nb

in^2

ksi

ksi

kips/bolt = 0.75**Ase*Fut(bolt)

kips/bolt = 0.75*0.8**0.6*Ase*Fut(bolt)

= Nu/(Ns)

S.R. 1.00, O.K.!

= Vu/(Vs)

S.R. 1.00, O.K.!

= Nu/(Ns) + Vu/(Vs)

S.R. 1.20, O.K.!

Steel anchor strength is OKAY!

* Shear strength of anchors with grout pads shall be multiplied by 0.8 ACI 318-02, Sect. D.6.1.3

* Anchor strength reduced by 75% due to seismic region ACI 318-02, Sect. D3.3.3

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

(continued)

Individual Anchor Bolt Forces:

Bolt #

1

2

3

4

5

6

ybolt

0.00

8.66

8.66

0.00

-8.66

-8.66

n

8.04

7.04

7.04

8.04

8.04

8.04

Max bolt tension, N =

Abt

0.969

0.969

0.969

0.969

0.969

0.969

n*Abolt

7.79

6.82

6.82

7.79

7.79

7.79

Qbolt

689.84

544.96

544.96

689.84

757.31

757.31

Ibolt

61086.71

43537.76

43537.76

61086.71

73619.33

73619.33

Totals

44.81

3984

356,488

19.06

Pbolt

7.08

-4.29

-4.29

7.08

19.06

19.06

kips

Note:

1. Tension (uplift) load = positive (+)

2. Compression (downward) load = negative (-)

3. Qbolt = n*Abolt*(e-ybolt)

4. n*Abolt = n*Abt (tension zone)

5. n*Abolt = (n-1)*Abt (compression zone)

6. Ibolt = [ n*Abt^2/(4) + n*Abt*(e-ybolt)^2]

7. Pbolt = P*[e-ybolt-q(calc)]/(q(calc)*AT-QT)*[n*Abt]

Comments:

1. Controlling strength design load case was 1.2*[Ds+Do+AF]+1.0*E(+Z) where Mx = 1340 in-kips.

2. Controlling service load case was Ds+Do+AF+0.7*E(+Z) where Mx = 974 in-kips.

3. ACI concrete load factor used for design = (1340 in-k)/(974 in-k) = 1.376, say 1.38.

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name:

Job No.:

V=

V

(bolts)

=

Subject:

Originator:

Checker:

Complete Method

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Curved Beams 2Document5 pagesCurved Beams 2Robel MetikuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lifting PadeyeDocument16 pagesLifting PadeyeLưu XuânNo ratings yet

- Circular SlabsDocument19 pagesCircular SlabsVarshith Reddy100% (1)

- Weld Design - Inplace and Accidental Conditions: InputDocument2 pagesWeld Design - Inplace and Accidental Conditions: InputinnovativekarthiNo ratings yet

- Introduction To Vibration and Pulsation in Reciprocating Compressors 1 PDFDocument28 pagesIntroduction To Vibration and Pulsation in Reciprocating Compressors 1 PDFSandeep BhatiaNo ratings yet

- Pilecap DesignDocument1 pagePilecap Designmdelacua2No ratings yet

- M1 MechanicsDocument208 pagesM1 MechanicsMohammed Abdallah100% (2)

- Marcet Boiler Lab ReportDocument4 pagesMarcet Boiler Lab ReportJohnConor98% (40)

- Vibration Analysis of Circular CylindricDocument243 pagesVibration Analysis of Circular CylindricAlfonso BautistaNo ratings yet

- Aspect-96-155 Lateral Buckling PalmerDocument20 pagesAspect-96-155 Lateral Buckling PalmerJuan Roberto López Betanzos100% (2)

- Spreadsheets To BS 8110: B E B EDocument1 pageSpreadsheets To BS 8110: B E B Emdelacua2No ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- Continuous BeamsDocument1 pageContinuous Beamsmdelacua2No ratings yet

- DFFDFF PDFDocument1 pageDFFDFF PDFmdelacua2No ratings yet

- Analysis: Spreadsheets To BS 8110 D&D: Main Beam Grids C To H, From Grid 1 To 3Document5 pagesAnalysis: Spreadsheets To BS 8110 D&D: Main Beam Grids C To H, From Grid 1 To 3mdelacua2No ratings yet

- Spreadsheets To BS 8110: From GridsDocument1 pageSpreadsheets To BS 8110: From Gridsmdelacua2No ratings yet

- StabilityDocument1 pageStabilitymdelacua2100% (1)

- Basement WallDocument1 pageBasement Wallmdelacua2No ratings yet

- Spreadsheets To BS 8110 Etc: The Concrete CentreDocument1 pageSpreadsheets To BS 8110 Etc: The Concrete Centremdelacua2No ratings yet

- ScheduleDocument1 pageSchedulemdelacua2No ratings yet

- Spreadsheets To BS 8110: Span 3Document1 pageSpreadsheets To BS 8110: Span 3mdelacua2No ratings yet

- Foundation Design: Exhaust StackDocument8 pagesFoundation Design: Exhaust Stackmdelacua2No ratings yet

- RCC33 Flat Slabs (A & D)Document1 pageRCC33 Flat Slabs (A & D)mdelacua2No ratings yet

- Rigorous Continuous BeamsDocument1 pageRigorous Continuous Beamsmdelacua2No ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 17-Oct-2017 160Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 17-Oct-2017 160mdelacua2No ratings yet

- Ribbed Slabs (A & D)Document1 pageRibbed Slabs (A & D)mdelacua2No ratings yet

- Spreadsheets To BS 8110: Approximate Weight of ReinforcementDocument1 pageSpreadsheets To BS 8110: Approximate Weight of Reinforcementmdelacua2No ratings yet

- Spreadsheets To BS 8110: Span 3Document1 pageSpreadsheets To BS 8110: Span 3mdelacua2No ratings yet

- RCC81 Foundation Pads: SingleDocument1 pageRCC81 Foundation Pads: Singlemdelacua2No ratings yet

- SummaryDocument1 pageSummarymdelacua2No ratings yet

- Spreadsheets To BS 8110: Column InternalDocument1 pageSpreadsheets To BS 8110: Column Internalmdelacua2No ratings yet

- Spreadsheets To BS 8110 8th Floor Slab, From A To G: Weight of ReinforcemenDocument1 pageSpreadsheets To BS 8110 8th Floor Slab, From A To G: Weight of Reinforcemenmdelacua2No ratings yet

- Post Tensioned AnalysisDocument1 pagePost Tensioned Analysismdelacua2No ratings yet

- Spreadsheets To BS 8110: Span 3Document1 pageSpreadsheets To BS 8110: Span 3mdelacua2No ratings yet

- RCC91 One-Way SolidDocument6 pagesRCC91 One-Way Solidmdelacua2No ratings yet

- Spreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)Document1 pageSpreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)mdelacua2No ratings yet

- Crack Width Notes PDFDocument1 pageCrack Width Notes PDFmdelacua2No ratings yet

- Spreadsheets To BS 8110: Columns A1, D1, A5 & D5 RMW 20-Apr-2017 31Document1 pageSpreadsheets To BS 8110: Columns A1, D1, A5 & D5 RMW 20-Apr-2017 31mdelacua2No ratings yet

- Pump Capacity FinalDocument1 pagePump Capacity FinalBrin EntongNo ratings yet

- Seismic Raves: Tremor Observations From An Electronic Dance Music FestivalDocument8 pagesSeismic Raves: Tremor Observations From An Electronic Dance Music FestivalMaría MarchianoNo ratings yet

- Power Law CoefficientDocument2 pagesPower Law CoefficientMervyn JohnNo ratings yet

- Must Read ONGC Fluid Mechanics Questions With AnswersDocument5 pagesMust Read ONGC Fluid Mechanics Questions With AnswersIgbereyivwe TejiriNo ratings yet

- Abhyudaya - Theme WriteupsDocument6 pagesAbhyudaya - Theme WriteupsJuhi SinghNo ratings yet

- Mechanical Properties of SolidsDocument15 pagesMechanical Properties of Solidsprabs20069178No ratings yet

- Phases of Matter - Video QuestionsDocument1 pagePhases of Matter - Video Questionsapi-329058682No ratings yet

- Case 1 REPORTDocument13 pagesCase 1 REPORTnorman1968No ratings yet

- Fundamentals of Statics Power Point PresentationDocument68 pagesFundamentals of Statics Power Point Presentationviveksp99No ratings yet

- Solution Manual For Fundamentals of Hydraulic Engineering Systems 4th Edition by Houghtalen - Compress PDFDocument6 pagesSolution Manual For Fundamentals of Hydraulic Engineering Systems 4th Edition by Houghtalen - Compress PDFpotineNo ratings yet

- SE Prod FM CH 3 Flow in Pipes NumericalsDocument23 pagesSE Prod FM CH 3 Flow in Pipes NumericalsASHOK SUTHARNo ratings yet

- Extra Exercise Partial Differential EquationDocument3 pagesExtra Exercise Partial Differential EquationabefardyyahoocomNo ratings yet

- Chapter 3 (MEC681) - MHI PDFDocument71 pagesChapter 3 (MEC681) - MHI PDFمحمد فائزNo ratings yet

- States of Matter PDFDocument18 pagesStates of Matter PDFArnav AmbreNo ratings yet

- Engineering Mechanics MCQDocument6 pagesEngineering Mechanics MCQeafz111No ratings yet

- PHY101Document336 pagesPHY101TIAMIYU DAMILARE SAMUELNo ratings yet

- 2nd Year Breakdown + ReviewDocument7 pages2nd Year Breakdown + ReviewSuperman6424No ratings yet

- Factors Affecting Acoustics in BuildingsDocument2 pagesFactors Affecting Acoustics in BuildingsReign JandaNo ratings yet

- Fluid Dynamics AssignmentDocument6 pagesFluid Dynamics AssignmentUzair ArslanNo ratings yet

- Unit IDocument5 pagesUnit IJackson ..No ratings yet