Professional Documents

Culture Documents

Exair - Air Knives Presentation

Uploaded by

api-322850372Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exair - Air Knives Presentation

Uploaded by

api-322850372Copyright:

Available Formats

Air Knives

Super Air Knife

Super Air Knife

Quiet, hard-hitting curtain of

air for blowoff, cleaning, drying

and cooling

Surprisingly quiet! - only

69 dBA!

Reduced air consumption!

Uniform airflow!

40:1 Air Amplification

Super Air Knife

What is the Super Air Knife?

A more efficient way to clean, dry or cool parts, webs or

conveyors

Delivers a uniform sheet of laminar airflow across the entire

length with hard-hitting force

Dramatically reduces compressed air usage and noise when

compared to other blow offs

Sound level at 80 PSIG (5.5 BAR) is surprisingly quiet at

69 dBA for most applications

Air amplification ratios (entrained air to compressed air) of 40:1

are produced

Meets OSHA maximum dead-ended pressure and noise

requirements

Super Air Knife

Applications

Part drying after wash

Sheet cleaning in strip mills

Conveyor cleaning

Part or component cooling

Web drying or cleaning

Environmental separation

Pre-paint blowoff

Bag opening/fill operations

Scrap removal on converting

operations

Super Air Knife - Applications

Drying Applications

Fast moving bottles are blown

dry by (2) Model 110012 12"

(305mm) Super Air Knives prior

to labeling

A Model 110024SS 24" (610mm)

Stainless Steel Super Air Knife

dries bolt covers exiting an

electro-polishing tank

Super Air Knife - Applications

Drying Applications

(continued)

Axle hubs are dried using (3)

Super Air Knives (one vertically

on each side of the hub and one

across the top)

A Model 110048 48" (1219mm)

Super Air Knife provides wide

surface coverage to clean, dry or

cool several parts at once

Super Air Knife - Applications

Blowoff Applications

(5) Model 110003 3" (76mm)

Super Air Knives blow chips off

the fixture, tools and ways on

this boring operation

(1) Model 11000 6" (152mm)

Super Air Knife blows solvent

from a circuit board following a

flux removal operation

Super Air Knife - Applications

Cooling Applications

A Model 110018 18" (457mm)

Super Air Knife cools molten

plastic following dip molding

High volume airflow from a

Model 110006 6" (152mm) Super

Air Knife keeps linear induction

motors on an indoor roller

coaster from overheating

Super Air Knife - Applications

Cleaning Applications

A series of Super Air Knives

blows contaminants from car

bodies prior to paint

Super Air Knife

How The Super Air Knife Works

Compressed air flows through an

inlet (1) into the plenum chamber of

the Super Air Knife. The flow is

directed to a precise, slotted orifice

As the primary airflow exits

the thin slotted nozzle (2),

it follows a flat surface that

directs the airflow in a

perfectly straight line. This

creates a uniform sheet of

air across the entire length

of the Super Air Knife

Velocity loss is minimized and force is maximized as the

room air (3) is entrained into the primary air stream at a

ratio of 40:1. The result is a well defined sheet of laminar

airflow with hard hitting force and minimal wind shear

Super Air Knife

Features:

Quiet - 69 dBA for most applications

Minimal air consumption

40:1 air amplification

Uniform airflow across entire length

Variable force and flow

No moving parts - maintenance free

Easy mounting - compressed air inlets on each end and bottom

Compact, rugged, easy to install

Stainless steel screws in all models

Recessed hardware for easy mounting

Stock lengths to 48" (1219mm) in aluminum and stainless steel (ss - for temperatures up to 800F

(427C), food processing or corrosive environments)

316 stainless steel available on special order

Special lengths available

Unlimited system lengths of uninterrupted airflow available

Super Air Knife Accessories

The Universal Air Knife

Plumbing Kit provides the

hose and fittings to couple

the inlets for best

performance

The Coupling Bracket Kit is

used to join two Super Air

Knives

Available for aluminum,

stainless and 316 stainless

Super Air Knives

Universal Air Knife Mounting System

Provides a secure, precise positioning for any Air Knife

Super Air Knife

Standard Air Knife

Full-Flow Air Knife

Super Ion Air Knife

Standard Ion Air Knife

Durable, stainless steel construction

Provides a maximum extension of 30 (762mm)

For Air Knives 24 (610mm) or longer, use (2) Universal

Air Knife Mounting Systems

Super Air Knife

Replacement For Expensive, Noisy Blowers

Blower manufacturers like to talk about low energy cost but

conveniently ignore:

High purchase price

Blower noise

Bulky size

You might not get the part dried or cleaned on the first pass

AND - none of them like to talk about the downtime you'll

experience when you have to send the blower head back to them to

replace the bearings every year or so

Super Air Knife

Important Facts About Blowers

Filters must be replaced every one to three months

Belts must be replaced every three to six months

Blower bearings wear out quickly due to the motor that must turn

at 17-20,000 RPM in order to generate effective airflows

Poorly designed seals that allow dirt and moisture infiltration along

with environments above 125F (52C) decrease the one year

bearing life

Typical bearing replacement is at least once a year at a cost near

$1000 (most are not field replaceable)

Sound levels often exceed OSHA noise level exposure requirements

Air volume and velocity are often difficult to control since

mechanical adjustments are required

Super Air Knife - Specials

A special curved stainless steel

Super Air Knife holds test tubes

in place on a rotating index

table.

A PVC Super Air Air Knife

designed to withstand a

phosphorus enviroment

Super Air Knife - Specials

A PVDF Super Air Knife resists

a highly acidic environment.

A flat Super Air Knife, only

11/16 thick, blows plastic

fibers from a mold used to

make intergrated circuit chips.

Standard Air Knife

Standard Air Knife

Hard hitting curtain of

air for web, sheet and

part blowoff

30:1 Air Amplification

Standard Air Knife

What is the Standard Air Knife?

A quiet, energy efficient way to clean, dry or cool parts, webs or

conveyors.

Utilizes the coanda effect (wall attachment of a high velocity fluid)

to create air motion in its surroundings.

Air amplification ratios (entrained air to compressed air) of 30:1

are produced

Meets OSHA maximum dead-ended pressure and noise

requirements

Standard Air Knife - Applications

A Model 2006 6" (152mm)

Standard Air Knife blows water

off of product in carousel-style

parts washer

Airflow from a Model 2012 12"

(305mm) Standard Air Knife

blows open packets in a form, fill

and seal machine.

Full-Flow Air Knife

Full-Flow Air Knife

This low cost choice

provides a curtain of air

for blowoff, cleaning,

drying and cooling

30:1 Air Amplification

Full-Flow Air Knife

What is the Full-Flow Air Knife?

An effective way to clean, dry or cool parts, webs or conveyors.

Utilizes the coanda effect to pull in large volumes of surrounding

air, producing a high flow, high velocity curtain of air.

The "Full-Flow" provides airflow across the entire length.

A 12" (305mm) Full-Flow Air Knife measures 12 " (305mm).

It has the compressed air inlet(s) on the rear.

Full-Flow Air Knife - Applications

Three Full-Flow Air Knives dry

automotive batteries following a

rinse operation

EXAIR AIR Knife - Comparison

Which Air Knife Is Best For You?

Super Air Knife

Standard Air Knife

Full Flow Air Knife

Best choice for all

applications

Good choice, lower

purchase price

Good choice, lowest

purchase price

Lowest operating cost

Higher operating cost

than Super Air Knife

Higher operating cost

than Super Air Knife

Quietest (69 dBA at 80

PSIG)

Higher dBA rating (83

dBA at 80 PSIG)

Higher dBA rating (80

dBA at 80 PSIG)

Airflow length and

overall length the

same

Highest efficiency

Overall length is

25.4mm (1inch) longer

than airflow length

Good velocity

Airflow length and

overall length the

same

Smallest size

40:1 amplification

30:1 amplification

30:1 amplification

Air inlets on each end

and bottom

Inlets on each end

Most even airflow

Copyright 2007 EXAIR Corporation.

All Rights reserved.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PTDF StatementDocument1 pagePTDF Statementjesufem50% (2)

- Qatar - Stadium Plan To Host 2022 World Cup FootballDocument11 pagesQatar - Stadium Plan To Host 2022 World Cup Footballnazmul20No ratings yet

- How Does A Refrigerator WorkDocument3 pagesHow Does A Refrigerator WorkrizkyyaagungNo ratings yet

- Gayan Solar Mini Grid TeaserDocument17 pagesGayan Solar Mini Grid TeaserPSL TradingNo ratings yet

- Building The Grätzel Solar Cell: - CEBC Summer Workshop, June and July 2008Document20 pagesBuilding The Grätzel Solar Cell: - CEBC Summer Workshop, June and July 2008jprpower104No ratings yet

- 14 Bus ReferenceDocument6 pages14 Bus ReferenceArifah HamidunNo ratings yet

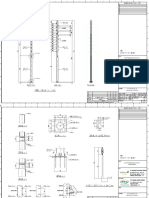

- STEEL POLE 14M 350 DanDocument2 pagesSTEEL POLE 14M 350 DanJuragan IwalNo ratings yet

- The W Engine Concept: Self-Study Program Course Number 821203Document64 pagesThe W Engine Concept: Self-Study Program Course Number 821203Alwarsamy RamasamyNo ratings yet

- Hazardous Area ClassificationDocument9 pagesHazardous Area ClassificationAdeel Afzal100% (1)

- Power Factor: Why 50 HZDocument3 pagesPower Factor: Why 50 HZYogesh KumarNo ratings yet

- Nigeria Renewable Energy MasterplanDocument18 pagesNigeria Renewable Energy MasterplanKivuti100% (1)

- How To Write Argumentative Essay SampleDocument7 pagesHow To Write Argumentative Essay Sampleezmv3axt100% (2)

- DD Unable Complete RegenDocument6 pagesDD Unable Complete RegenJOHN Wright100% (3)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- KPIs Energy EfficiencyDocument6 pagesKPIs Energy Efficiency3238NDNo ratings yet

- Donald Smith Devices Too Good To Be TrueDocument16 pagesDonald Smith Devices Too Good To Be TrueSilviu CorcanNo ratings yet

- Tecumseh 2 Cycle Engines ManualDocument68 pagesTecumseh 2 Cycle Engines Manualpaul20000100% (2)

- Grundfosliterature 1322Document56 pagesGrundfosliterature 1322Syed IhyaNo ratings yet

- Padmapat Engineers Pvt. Ltd.Document23 pagesPadmapat Engineers Pvt. Ltd.Padmapat EngineerNo ratings yet

- Geothermal Powerplants in The Philipiines ListDocument3 pagesGeothermal Powerplants in The Philipiines ListJohn WhallyNo ratings yet

- BPW82 Data SheetsDocument5 pagesBPW82 Data SheetstarpinoNo ratings yet

- 3400 Cylinder Head To Block Joint Repair Procedure (1124)Document38 pages3400 Cylinder Head To Block Joint Repair Procedure (1124)A z D100% (3)

- Abbreviations HydraulicDocument1 pageAbbreviations HydraulicAbdul Junaedi0% (1)

- Juncker Investment Plan: Project List Member States FinalDocument610 pagesJuncker Investment Plan: Project List Member States FinalMichelReimon100% (1)

- O & M ManualDocument131 pagesO & M Manualt_syamprasadNo ratings yet

- Electrical EnergyDocument35 pagesElectrical EnergyLloyde DonaireNo ratings yet

- Masterflux Europe MetricDocument2 pagesMasterflux Europe MetricsoorajthevallyNo ratings yet

- Pelton Turbine ReportDocument10 pagesPelton Turbine ReportShea Cheng Kuang100% (2)

- Sol Armed ConfDocument6 pagesSol Armed ConfMorris KellerNo ratings yet

- Sample Che Board Exam QuestionsDocument2 pagesSample Che Board Exam QuestionsGerry Lou Quiles93% (14)