Professional Documents

Culture Documents

Lubrication System

Uploaded by

Suraj SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lubrication System

Uploaded by

Suraj SinghCopyright:

Available Formats

Lubrication System

Lecture-10

Introduction

In engines, frictional losses are mainly due to sliding as

well as rotating parts

Engine friction is expressed in terms of frictional power

fp=ip-bp

Frictional losses is mainly attributed to the following

mechanical losses

Direct frictional losses

Pumping losses

Power loss to drive the components to change and scavenge

Power loss to drive other auxiliary components

Introduction

A good engine design should not the total frictional

losses to be more than 30% of energy input in

reciprocating engine

It should be the aim of a good designer to reduce

friction and wear of the parts subjected to relative

motion

This is achieved by proper lubrication system

Direct Frictional Losses

It is the power absorbed due to the relative motion of

different bearing surfaces such as

piston rings,

main bearings,

cam shaft bearings etc

The frictional losses are comparatively higher in

reciprocating engine

Pumping Loss

For 4-stroke engines

Considerable amount of energy is spent during the exhaust

processes

The pumping loss is the net power spent by the engine (piston)

on the working medium (gases) during intake and exhaust

strokes

For 2-stroke engines

this is negligible since the incoming fresh mixture is used to

scavenge the exhaust gases

Power Loss to drive the components to

change and scavenge

4-stroke engine

In turbo/super charged engines the intake charge is supplied at

a higher pressure than the aspirated engines

For this purpose mechanically driven compressor or turbine

driven compressor us used accordingly the engine is called

Supercharged or turbocharged engine

These devices take away a part of engine output. This loss is

considered as negative frictional losses

2-stroke engine

With a scavenging pump, the power to drive the pump is

supplied by the engine

Power loss to drive other auxiliary

components

A good percentage of the generated power

output is spent to drive auxiliaries such as

Water pump

Lubricating oil pump

Fuel pump

Cooling fan

Generator etc

Mechanical Efficiency

The mechanical losses can be written in terms of mep

The frictional mep (fmep) can be expressed as

fmep=mmep+pmep+amep+cmep

mmep- mep required to overcome mechanical friction

Pmep- mep required for charging and scavenging

amep- mep required to drive the auxiliary components

Cmep-mep required to drive the compressor or scavenging

pump

Mechanical efficiency is defined as the ratio of bp to ip or

bmep to imep m = bp = bmep

ip

imep

Mechanical Friction

Friction losses comes into picture in the bearing surfaces

of the engine components due to their relative motion

Mechanical friction in engine may be divided in to 6

classes

Fluid-film or Hydrodynamic Friction

Partial-film Friction

Rolling Friction

Dry friction

Journal bearing friction

Friction due to piston motion

Mechanical Friction

Friction due to Piston Motion

Friction due to the motion of the piston can be divided in to

Viscous friction due to piston

Non-viscous friction due to piston ring

The non-viscous piston ring friction can be further

subdivided in to

Friction due to ring tension

Friction due to gas pressure behind the ring

Blowby Losses

It is the phenomenon of leakage of combustion products

(gases) from the cylinder to the crankcase past the

piston and piston rings

It depends on the

Compression ratio

Inlet pressure

The condition of the piston rings

In the case of worn out piston rings this loss is more

This loss is usually accounted in the overall frictional

losses

Blowdown Loss

To reduce the work spent by the piston to drive out the exhaust

gases the exhaust valve is made to open before piston reaches

BDC on its expansion stroke

During this period the combustion gases rush out of cylinder due to

pressure difference

BeCoz of this there is a certain loss of power induced. This loss is

called the blowdown loss

This loss mainly depend on

The exhaust valve timing and size

With large valve area and earlier exhaust valve opening, the blowdown

loss will be higher whereas with increasing in speed this loss tends to

be lower

Factors affecting Mechanical Friction

Various factors affecting the engine friction

Engine Design

Stroke-bore Ratio

Effect of Engine Size

Piston Rings

Compression Ratio

Journal bearings

Engine Speed

Engine load

Cooling water temperature

Oil viscosity

Function of Lubrication

To reduce friction and wear

between the moving parts

To provide sealing action

To cool the surfaces by carrying

away the heat generated in

engine components

To clean the surfaces by washing

away carbon and metal particles

caused by wear

Lubrication System

The function of Lubrication system

Is to provide sufficient quantity of cooled & filtered oil

to give +ve and adequate lubrication to all the

moving parts

The various lubrication system used for IC engine

Mist Lubrication

Wet sump Lubrication

Dry sump Lubrication

Mist Lubrication System

This system is used where crankcase lubrication is not

suitable

In 2-stroke engine as the charge is compressed in the

crankcase, it is not possible to have the lubricating oil

oil in the sump

In such engines the lubricating oil is mixed with the

fuel, the usual ratio being 3% to 6%

The oil and the fuel induced through the carburetor the

fuel is vaporized and the oil is in the form of mist goes

via the crankcase in to the cylinder

Mist Lubrication System

Advantage of this system

simplicity,

low cost (does not required oil pump, filter)

Disadvantages

Causes heavy exhaust smoke

Get contaminated with acids and result in the corrosion of bearings

surface

Calls for through mixing for effective lubrication (this requires either

separate mixing prior to use of some additive to give the oil good

mixing characteristics)

The engine will suffer from insufficient lubrication as the supply of

fuel is less

Wet Sump lubrication System

The bottom of the crankcase contains an oil pan or

sump from which the lubricating oil is pumped to

various components by a pump

After lubricating the parts the oil flows back to the

sump by gravity

There are 3 varieties in wet sump lubricating system

The splash system

The splash and pressure system

The pressure feed system

Splash System

This type of lubrication system is used in light duty

engines.

The lubricating oil charged in to the bottom of the

crankcase and maintained at predetermined level.

The oil is drawn by a pump and delivered through a

distributing pipe in to the splash troughs

A splasher or dipper is provided under each

connecting road cap

Splash Lubrication System

Splash & pressure lubrication system

The lubricating oil is supplied under pressure to main

and camshaft bearings

The oil is also supplied under pressure to pipes which

direct a stream of oil against the dippers on the big end

connecting rod bearing cup

The crankpin bearings are lubricated by the splash or

spray of oil thrown up by dipper

Splash & pressure lubrication system

Pressure feed system

The oil is forced to all the main bearings of

crankshaft

Pressure relief valve is fitted to maintain the

predictable pressure values

Oil hole is drilled from the center of each crankpin to

the center of an adjacent main journal through which

oil can pass from the main bearing to the crankpin

Pressure feed system

Dry sump lubrication system

In this system the oil is carried in an external tank

An oil pump draws oil from the supply tank and circulates it

under pressure to the various bearings of the engine

Oil dripping from the cylinders and bearings in to the sump

is removed by a scavenging pump which in turn the oil is

passed through a filter and fed back to the supply tank

The capacity of scavenging pump is always greater than

the oil pump

A separate oil cooler provided to remove heat from the oil

Dry sump lubrication system

Crankcase ventilation

During the compression and expansion strokes the gas

inside the cylinder gets past the piston rings and enters the

crankcase which is called blow-by

It contains water vapor and sulfuric acid

If this contamination is appreciable amount it causes

corrosion of steel parts in the crankcase

This may also promote sludge formation in the lubricating oil

When the amount of water vapor condensed becomes

considerable, in cold weather this may freeze and may

cause damage to the lubricating oil pump

Crankcase ventilation

Crankcase ventilation

This removal of the blowby can be achieved effectively by

passing a constant stream of fresh air through the crankcase

known as Crankcase ventilation

By doing so not only all the water vapor but also a considerable

proportion of fuel in the blow-by may be removed from the crank

case.

The crankcase must have an air inlet and outlet for the effective

crankcase ventilation

It is possible to connect the crankcase outlet to the air cleaner,

where the inlet suction serves to ventilate the crankcase and

unburned fuel, gases as well as the water vapor are then drawn

in to the cylinder where the fuels has another chance to burn

Lubricants

Classification of Lubricant

Animal

Vegetable

Mineral

Synthetic

Animal Lubricants

Lubricants with animal origin:

Tallow

Tallow oil

Lard oil

Neats foot oil

Sperm oil

Porpoise oil

These are highly stable at normal temperatures

Animal lubricants may not be used for internal

combustion because they produce fatty acids.

Vegetable Lubricants

Examples of vegetable lubricants are:

Castor oil

Olive oil

Cottonseed oil

Animal and vegetable oils have a lower

coefficient of friction than most mineral oils

but they rapidly wear away steel

Mineral Lubricants

These lubricants are used to a large extent in

the lubrication of internal combustion engines

There are three classifications of mineral

lubricants:

Solid

Semisolid

Fluid

Synthetic Lubricants

Because of the high operating temperatures of

engines, it became necessary to develop

lubricants

which

would

retain

their

characteristics at temperatures that cause

petroleum lubricants to evaporate and break

down

Synthetic lubricants do not break down easily

and do not produce coke or other deposits

Lubricating Oil Properties

Gravity

Flash Point

Viscosity

Cloud Point

Pour Point

Carbon-Residue Test

Ash Test

Precipitation Number

Corrosion and

Neutralization Number

Oiliness

Extreme-Pressure

(Hypoid) Lubricants

Chemical and Physical

Stability

Additives

Viscosity index improvers

Detergents/dispersants

Extreme pressure, anti wear & friction modifiers

Oxidation inhibitors

Rust corrosion inhibitors

Foam inhibitors

Pour point depressants

You might also like

- Zone VacancyDocument3 pagesZone VacancySuraj SinghNo ratings yet

- Government of India, Ministry of Railways Government of India, Ministry of Railways Government of India, Ministry of RailwaysDocument1 pageGovernment of India, Ministry of Railways Government of India, Ministry of Railways Government of India, Ministry of RailwaysAnkurPatelNo ratings yet

- ConservationDocument3 pagesConservationSuraj SinghNo ratings yet

- GMAW Advantages and Disadvantages Welding ClassroomDocument1 pageGMAW Advantages and Disadvantages Welding ClassroomSuraj SinghNo ratings yet

- Parameters in Resistance Welding PDFDocument2 pagesParameters in Resistance Welding PDFAnonymous dXwsDDFS6V100% (1)

- Chapter 2 Dynamic Force AnalysisDocument22 pagesChapter 2 Dynamic Force AnalysissreeshpsNo ratings yet

- Overflow Tank: by Lorne GoldmanDocument2 pagesOverflow Tank: by Lorne GoldmanSuraj SinghNo ratings yet

- Fundamentals of Resistance Welding PDFDocument8 pagesFundamentals of Resistance Welding PDFSuraj SinghNo ratings yet

- The Principles of CastingDocument2 pagesThe Principles of CastingSuraj SinghNo ratings yet

- Design & ManufacturingDocument11 pagesDesign & ManufacturingSuraj SinghNo ratings yet

- 1341896367340-Vacuum Brake SystemDocument14 pages1341896367340-Vacuum Brake SystemPrachetash SrivastavaNo ratings yet

- Amazing IndiansDocument10 pagesAmazing IndiansSuraj SinghNo ratings yet

- Mathematical Modelling of Surface RoughnessDocument8 pagesMathematical Modelling of Surface RoughnessSuraj SinghNo ratings yet

- Amazing IndiansDocument10 pagesAmazing IndiansSuraj SinghNo ratings yet

- Syllabus For AutoCADDocument2 pagesSyllabus For AutoCADSuraj SinghNo ratings yet

- OTT Advt Final 1Document6 pagesOTT Advt Final 1Devesh Pratap ChandNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Must-Have Guide to Centrifugal PumpsDocument24 pagesThe Must-Have Guide to Centrifugal PumpsStacy Wilson100% (1)

- William Liller - Space AstrophysicsDocument290 pagesWilliam Liller - Space Astrophysicsmuhamad dimas arifin a.k.a Ahmd El ArfNo ratings yet

- Triton X 100Document2 pagesTriton X 100jelaapeNo ratings yet

- Exp 4 Chem 17 LabDocument7 pagesExp 4 Chem 17 LabGabrielle CatalanNo ratings yet

- Quantum Mechanics Module NotesDocument12 pagesQuantum Mechanics Module NotesdtrhNo ratings yet

- Dost Jls S PrimerDocument17 pagesDost Jls S PrimerShaunrey SalimbagatNo ratings yet

- 6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEDocument3 pages6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEaissmsNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- BKI Vol2 - Section38Document5 pagesBKI Vol2 - Section38Erwin Paulian SihombingNo ratings yet

- 11 HW ChemistryDocument6 pages11 HW ChemistryJ BalanNo ratings yet

- Jet EngineDocument15 pagesJet EngineViswanathan SrkNo ratings yet

- d270 PDFDocument8 pagesd270 PDFศิวาเวช อบมาNo ratings yet

- Astm D 2036-98 Standard Test Methods For Cyanides in Water PDFDocument20 pagesAstm D 2036-98 Standard Test Methods For Cyanides in Water PDFGianinaRoncalChávezNo ratings yet

- Exponential Functions and Their Graphs PDFDocument2 pagesExponential Functions and Their Graphs PDFCarrieNo ratings yet

- Surveying Section 7Document14 pagesSurveying Section 7Beltran KathNo ratings yet

- Physical Computing NotesDocument2 pagesPhysical Computing NotesAnonymous W9MgRBVtYCNo ratings yet

- Thermocouple Temperature Sensors ExplainedDocument2 pagesThermocouple Temperature Sensors ExplainedRaymond Yonathan HutapeaNo ratings yet

- TankDocument24 pagesTankUDayNo ratings yet

- Kinetic Energy DefinitionDocument6 pagesKinetic Energy DefinitionudayshankarsNo ratings yet

- Newtonian Fluid - WikipediaDocument5 pagesNewtonian Fluid - Wikipediaamit kumar guptaNo ratings yet

- Armfield F1 Fluid Mechanics Series Brochure V2a Download 1Document30 pagesArmfield F1 Fluid Mechanics Series Brochure V2a Download 1paul contrerasNo ratings yet

- Ntttechnical 2019.12Document51 pagesNtttechnical 2019.12Dimas Cabré i ChacónNo ratings yet

- Orbital Velocity Formula - Solved Example With EquationsDocument5 pagesOrbital Velocity Formula - Solved Example With Equationsmohamad magdyNo ratings yet

- RFID OverviewDocument7 pagesRFID Overviewfelis132No ratings yet

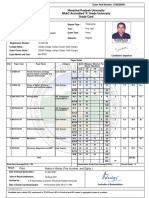

- Serial Number:1920110212668 Exam Roll Number Grade CardDocument2 pagesSerial Number:1920110212668 Exam Roll Number Grade Cardsimran vaidNo ratings yet

- Fastener Process SimiulationDocument4 pagesFastener Process SimiulationMehran ZaryounNo ratings yet

- Experiment 1 (Equilibrium of Turning Forces)Document5 pagesExperiment 1 (Equilibrium of Turning Forces)shark eye100% (1)

- Savi TancetDocument3 pagesSavi TancetJasmine DavidNo ratings yet

- Math 070838Document13 pagesMath 070838Jeric Boy GarampilNo ratings yet

- Catalog WefatermDocument55 pagesCatalog WefatermAlin NicolaeNo ratings yet