Professional Documents

Culture Documents

Strength Calculation of Lifting Eye

Uploaded by

Jacky TamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength Calculation of Lifting Eye

Uploaded by

Jacky TamCopyright:

Available Formats

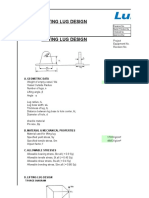

Strength calculation of Lifting eye

From MarineWiki

Jump to: navigation, search

More Sharing Services Share Share on facebookShare on twitter

Share on linkedinShare on tumblrShare on stumbleuponShare on redditShare on email

All ships have lifting eye provided for lifting motors, their parts, and other

equipments. The following procedure describes how to verify the strength of the

lifting eye

Design load (P) = Safe Working Load (SWL) x Dynamic coefficient (Dynamic

coefficient is taken as 1.3. recommended by Classification society rules)

Allowable stress

Tensile stress, a = Yield limit / (1.5 k) = 235 1 / (1.5 k)

Shear stress, a = a / 3 = 235 1 / (1.5 k x 3 )

where k = 0.85 (mild steel) and 1.0 for high tensile steel, and 1 = 1.0 (mild steel),

1.08 (AH27), 1.28 (AH32), 1.35 (AH34), 1.39 (AH36), 1.43 (AH40)

Required section area for shear stress, Ars

For shear stress the area shown by the hatch on the righ section is applicable.

Ars = P / a = 1.3 x SWL / (235 1 / (1.5 k x 3 )) = (3.38 x k x SWL) / 235 1

Actual section area for shear stress, Aas

Aas = b x t (as shown in the shaded area on the right section)

Required section for tensile stress, Art

For tensile stress, the area is shown by two shaded hatch on the lower part is

applicable.

Art = P / a = 1.3 x SWL / ( 235 1 / (1.5 k)) = (1.95 x k x SWL) / 235 1

Actual section area for tensile stress, Aat

Aat = 2 x b x t (as shown by two shaded hatch on the lower drawing)

Evaluation

Aas Ars (satisfies shear stress requirement )and

Aat Art (satisfies tensile stress requirement)

AAA

You might also like

- PadEye Genset 300kvaDocument3 pagesPadEye Genset 300kvadandy imam fauziNo ratings yet

- Lifting Lug Design-MrDocument5 pagesLifting Lug Design-MrMiguelRagasNo ratings yet

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Marine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102Document22 pagesMarine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102leelarama100% (1)

- 750mm X-Beam CalculationDocument13 pages750mm X-Beam CalculationapollocradlesNo ratings yet

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationsalman1566No ratings yet

- Lifting Calculation REV ADocument1 pageLifting Calculation REV APohn Myint HanNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- Pad Eye Design CalculationDocument7 pagesPad Eye Design CalculationLưu Xuân0% (1)

- Spreader Bar For LiftingDocument1 pageSpreader Bar For LiftingTran ThoNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- 01 Horizontal Angle CalculationDocument3 pages01 Horizontal Angle CalculationMbalekelwa MpembeNo ratings yet

- Lifting A Pressure Vessel With Two Main Lift Cranes and One Tail CraneDocument12 pagesLifting A Pressure Vessel With Two Main Lift Cranes and One Tail Cranezeusvares100% (1)

- Monorail DesignDocument24 pagesMonorail DesignBolarinwadeNo ratings yet

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Lifting Sets Calculation - API RP 2ADocument11 pagesLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Crane Runway Beam Design - Crane Load CalculationDocument6 pagesCrane Runway Beam Design - Crane Load CalculationMuhammed ShamseerNo ratings yet

- Beams Spreader PDFDocument4 pagesBeams Spreader PDFravikumarangNo ratings yet

- Lifting Lug Design (3064)Document37 pagesLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- Design Lifting Beam (80 MT)Document10 pagesDesign Lifting Beam (80 MT)hardeep SinghNo ratings yet

- Fem 1001 - 98 Booklet 2Document62 pagesFem 1001 - 98 Booklet 2DavidRanieriNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationAndy Chan100% (1)

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- As 2359.15-2005 Powered Industrial Trucks Fork-Arm Extensions and Telescopic Fork Arms - Technical CharacteriDocument8 pagesAs 2359.15-2005 Powered Industrial Trucks Fork-Arm Extensions and Telescopic Fork Arms - Technical CharacteriSAI Global - APACNo ratings yet

- Lecture 14.4: Crane Runway Girders: Objective/ScopeDocument22 pagesLecture 14.4: Crane Runway Girders: Objective/ScopeScooby DooNo ratings yet

- Lifting Eye DesignDocument1 pageLifting Eye DesignFabio Okamoto0% (1)

- Gantry Alignment PDFDocument9 pagesGantry Alignment PDFAfzaalUmairNo ratings yet

- NR 17 BBP Ergonomics Training Program Part4Document28 pagesNR 17 BBP Ergonomics Training Program Part4CPSSTNo ratings yet

- MonorailDocument13 pagesMonorailleodegarioporralNo ratings yet

- Lift Lug AnalysisDocument2 pagesLift Lug AnalysisTito FebriantoNo ratings yet

- Results PDFDocument1 pageResults PDFRajNo ratings yet

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- NBR 13541-2 EnglishDocument10 pagesNBR 13541-2 EnglishCinthia BazethNo ratings yet

- Lifting Lug DesignDocument4 pagesLifting Lug DesignRohith V VNo ratings yet

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 pagesDesign Aid For Triangular Bracket Plates Using AISC SpecificationsRicardo MendozaNo ratings yet

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Lifting Beam ManualDocument30 pagesLifting Beam ManualpandiangvNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Lifting BEAMSDocument90 pagesLifting BEAMSGogyNo ratings yet

- Lug DesignDocument1 pageLug DesignFandy SipataNo ratings yet

- Lifting Beam DesignDocument4 pagesLifting Beam DesignX100% (1)

- Selecting Spreader Beam Check Beam For ES/EEC 1 Compression StressDocument2 pagesSelecting Spreader Beam Check Beam For ES/EEC 1 Compression StressSudar MyshaNo ratings yet

- Lifting LugDocument5 pagesLifting LugFarid Tata100% (1)

- Outrigger Pads Brochure Low ResDocument8 pagesOutrigger Pads Brochure Low Resfcesar1986No ratings yet

- Lifting LugsDocument3 pagesLifting Lugssatyenlala100% (3)

- Strength Calculation of Lifting EyeDocument2 pagesStrength Calculation of Lifting EyeJacky TamNo ratings yet

- Base Plates For Concentrically Loaded ColumnsDocument16 pagesBase Plates For Concentrically Loaded ColumnsSabih Hashim AlzuhairyNo ratings yet

- Tensio Member Part-1Document14 pagesTensio Member Part-1syed muneeb haiderNo ratings yet

- G.Curved BeamDocument7 pagesG.Curved BeamChimdi GadafaNo ratings yet

- Module 2 Compression MemberDocument10 pagesModule 2 Compression MemberMichael James ll Banawis100% (1)

- Steel Design: Stress and Strain can be computed f= P A Є= ∆ L LDocument23 pagesSteel Design: Stress and Strain can be computed f= P A Є= ∆ L Lnathan fajardo100% (2)

- KT TablesDocument8 pagesKT TablesdnddownloaderNo ratings yet

- Tension Member LRFDDocument9 pagesTension Member LRFDgullipalliNo ratings yet

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- Different Parties in Contract AdministrationDocument4 pagesDifferent Parties in Contract AdministrationJacky TamNo ratings yet

- Cost EstimateDocument1 pageCost EstimateJacky TamNo ratings yet

- Fill Loading in Structural Design of Pipeline (For Rigid Pipe Only)Document1 pageFill Loading in Structural Design of Pipeline (For Rigid Pipe Only)Jacky TamNo ratings yet

- Simpson - 05 - Sustainable DevelopmentDocument15 pagesSimpson - 05 - Sustainable DevelopmentJacky TamNo ratings yet

- Why Concrete Is Used?: Normal QuestionDocument3 pagesWhy Concrete Is Used?: Normal QuestionJacky TamNo ratings yet

- Simpson - 02 - Information About Hong Kong Insitution of EngineersDocument3 pagesSimpson - 02 - Information About Hong Kong Insitution of EngineersJacky TamNo ratings yet

- Simpson - 03 - Planning and Design of SewerageDocument37 pagesSimpson - 03 - Planning and Design of SewerageJacky TamNo ratings yet

- Discussion On Health InequalityDocument1 pageDiscussion On Health InequalityJacky TamNo ratings yet

- Appendix H - Strap Beam and Pile Cap CalDocument4 pagesAppendix H - Strap Beam and Pile Cap CalJacky TamNo ratings yet

- Simpson - 01 - Information About Institution of Civil EngineersDocument3 pagesSimpson - 01 - Information About Institution of Civil EngineersJacky TamNo ratings yet

- Simpson - 04 - Design and Construction of Water Retaining StructuresDocument13 pagesSimpson - 04 - Design and Construction of Water Retaining StructuresJacky TamNo ratings yet

- At The End of Each Monthly Period, Contractor Will Submit A Statement and DetailedDocument1 pageAt The End of Each Monthly Period, Contractor Will Submit A Statement and DetailedJacky TamNo ratings yet

- Strength Calculation of Lifting EyeDocument2 pagesStrength Calculation of Lifting EyeJacky TamNo ratings yet

- Part 1: To Be Signed by The Temporary Woks CoordinatorDocument2 pagesPart 1: To Be Signed by The Temporary Woks CoordinatorJacky TamNo ratings yet

- Long Title: The Format of The Ordinance Has Been Updated To The Current Legislative StylesDocument94 pagesLong Title: The Format of The Ordinance Has Been Updated To The Current Legislative StylesJacky TamNo ratings yet

- PE Inception Report Final EDocument21 pagesPE Inception Report Final EJacky TamNo ratings yet

- 29/06/2016 8:00pm arrive airport - 2hrs of travelling 10:30pm 墾丁大街 30/06/2016Document2 pages29/06/2016 8:00pm arrive airport - 2hrs of travelling 10:30pm 墾丁大街 30/06/2016Jacky TamNo ratings yet

- Cedd Nullah MJDocument1 pageCedd Nullah MJJacky TamNo ratings yet

- 2015-09-17 Comments On Natural Stone Wall For KAT Station and SUADocument2 pages2015-09-17 Comments On Natural Stone Wall For KAT Station and SUAJacky TamNo ratings yet

- Kaden - Chun Wo Joint VentureDocument2 pagesKaden - Chun Wo Joint VentureJacky TamNo ratings yet