Professional Documents

Culture Documents

Ancore Chimice CHEMOFAST

Uploaded by

Popa AndreiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ancore Chimice CHEMOFAST

Uploaded by

Popa AndreiCopyright:

Available Formats

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Content

Page

Product description

Application in non-

Application in hollow

Application in solid

cracked concrete

masonry

masonry

Properties and benefits

Applications and intended use

Handling and storage

Reactivity

Application in concrete

2

3

3

3

Setting instruction

Cleaning

Setting parameter

Design values

Recommended loads

Application in masonry

Setting instruction

Cleaning

Load values

4

6

6

7

9

10

10

11

12

CHEMOFAST Anchoring GmbH

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Hanns-Martin-Schleyer-Str. 23

47877 Willich, Germany

Telephone +49 (0) 21 54 / 81 23-0

Fax

+49 (0) 21 54 / 81 23-3 26

www.chemofast.de

info@chemofast.de

anage

me

Rev. 04 (EN)

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Product description

The PSF is a 2-component reaction resin mortar based on a styrene free polyester and will be delivered in a 2-C cartridge (ST - standard cartridge; PM - Pre-Mix

cartridge; SF-foil tube cartridge) system. This product may be used in combination

of a hand-, battery-, or pneumatic tool and a static mixer. It was designed as a costeffective alternative for the anchoring of threaded rods and internal threaded rod

sleeves for non-approved applications. By using a screen sleeve, an easy and save

application in hollow bricks is guaranteed. The PSF product is characterised by good

applications with an ambiance temperature up to 80C.

STPSF

STV- Polyester

Vinylester

styrene

Styrolfrei

free

TECHNICAL DATA SHEET

Properties and benets

Application in uncracked concrete, solid brick and hollow brick with comercial threaded rods

overhead application

Suitable for attachment points close to the edge, since anchoring is free of expansion forces

styrene free

reduced chemical resistance

high bending- and pressure strength

Cartridge can be reused up to the end of the shelf life by replacing the static

mixer or resealing cartridge with the screw cap

Mechanical properties acc. to EN 196 Part1

+ Density: 1,74 kg/dm2

+ Compressive strength: 75 N/mm2

+ Bending strength: 30 N/mm2

+ Dynamic modulus of elasticity: 4000 N/mm2

Applications samples

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Suitable for the fixation of facades, roofs, wood construction, metal construction;

metal profils, console, railing, sanitary devices, cable trays, piping, etc.

anage

me

Rev. 04 (EN)

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Applications and intended use

Underground:

non-cracked concrete, light-concrete, porous-concrete, solid masonry, hollow

brick, natural stone (Attention! natural stone, can discolour; shall be checked in

advance); hammer drilled holes

Anchor elements:

Threaded rods (zinc plated or hot dip, stainless steel and high corrosion resistance

steel), reinforcing bars, internal threaded rods, profiled rod, steel section with

undercuts (e.g. perforated section)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

Temperature range:

5C up to +35C installation temperature

cartridge temperature min. +5C; optimal +20C

-40C to +80C base material temperature after full curing

Handling and storage

Storage:

store in a cold and dark place, storage temperature: from +5C up to +25 C

Shelf life:

18 months for standard cartridge (ST); 12 months for foil tube cartridge (SF)

Reactivity

er

Gelling- and working

time

Full curing time in dry

base material

Full curing time in wet

base material

+5C

25 Min.

120 Min.

240 Min.

+10C

15 Min.

80 Min.

160 Min.

+20C

6 Min.

45 Min.

90 Min.

+30C

4 Min.

25 Min.

50 Min.

+35C

2 Min.

20 Min.

40 Min.

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Temperature of base

material

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Usage instructions - concrete

1.

Drill with hammer drill mode a hole into the base material to the size and embedment depth required by the selected anchor.

2a.Standing water must be removed bevor cleaning. Starting from the bottom

or

or back of the bore hole, blow the hole clean with compressed air or a hand

pump a minimum of four times. If the bore hole ground is not reached an extension shall be used. The hand-pump can be used for anchor sizes up to bore hole

diameter 20 mm. For bore holes larger then 20mm or deeper then 240mm, compressed air (min. 6 bar) must be used.

2b.Check brush diameter acc. to table 5 and attach the brush to a drilling ma-

chine or a battery screwdriver. Brush the hole with an appropriate sized wire

brush of four times. If the bore hole ground is not reached with the brush, a brush

extension shall be used.

2c.Finally blow the hole clean again with compressed air or a hand pump a minimum of four times. If the bore hole ground is not reached an extension shall

be used. The hand-pump can be used for anchor sizes up to bore hole diameter

20 mm. For bore holes larger then 20mm or deeper then 240mm, compressed air

(min. 6 bar) must be used.

or

3.

Attach a supplied static-mixing nozzle to the cartridge and load the cartridge

into the correct dispensing tool. For every working interruption longer than

the recommended working time as well as for new cartridges, a new static-mixer

shall be used.

er

Prior to inserting the anchor rod into the mortar filled bore hole, the position

of the embedment depth shall be marked on the anchor rods.

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

4.

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Usage instructions - concrete

5.

Prior to dispensing into the anchor hole, squeeze out separately a minimum of

three full strokes and discard non-uniformly mixed adhesive components until

the mortar shows a consistent grey colour.

6.

Starting from the bottom or back of the cleaned anchor hole fill the hole up

to approximately two-thirds with adhesive. Slowly withdraw the static mixing

nozzle as the hole fills to avoid creating air pockets. Observe the gel-/ working

times given.

7.

Push the threaded rod or reinforcing bar into the anchor hole while turning

slightly to ensure positive distribution of the adhesive until the embedment

depth is reached. The anchor should be free of dirt, grease, oil or other foreign

material.

8.

Be sure that the anchor is fully seated at the bottom of the hole and that

excess mortar is visible at the top of the hole. If these requirements are not

maintained, the application has to be renewed.

9.

Allow the adhesive to cure to the specified time prior to applying any load or

torque. Do not move or load the anchor until it is fully cured.

10.After full curing, the add-on part can be installed with the max. torque by

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

using a calibrated torque wrench.

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Cleaning of the drill hole - concrete

Brush:

0,20 mm (A2) Steel wire

Brush length: 80 mm

M6 thread for drilling machine

connection

Blower

Threaded rod

Bore hole-

Brush-

min. brush-

Brush length

(mm)

(mm)

db (mm)

db,min (mm)

L (mm)

M8

10,0

12,0

10,5

170

12,5

170

M 12

12,0

14,0

14,0

16,0

14,5

200

M 16

18,0

20,0

18,5

300

M 20

24,0

26,0

24,5

300

M 10

Setting parameter - concrete

Anchor size

Edge distance

M12

M16

M20

Ccr N

[mm]

80

90

110

125

170

5,0 x d

Cmin

[mm]

40

50

60

80

100

2,0 x hef

Scr N

[mm]

160

180

220

250

340

5,0 x d

Smin

[mm]

40

50

60

80

100

Embedment depth

hef

[mm]

80

90

110

125

170

Min. part thickness

hmin

[mm]

[mm]

10

12

16

20

d0

[mm]

10

12

14

18

24

Tinst.

[Nm]

10

20

40

60

120

Axial distance

Min. axial distance

Anchor diameter

Drill diameter

Installation torque

hef + 30 mm

hef + 2d0

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

M10

1,0 x hef

Min. edge distance

er

M8

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Performance data - concrete

TENSION LOADS - Design method A acc. to ETAG 001 Annex C, characteristic values

for tension loading

Anchor size

M8

M10

M12

M16

M20

Steel failure

Characteristic tension resistance, Steel, zinc

plated or hot dip, property class 5.8

NRk,s

[kN]

18

29

42

78

122

Characteristic tension resistance, Steel, zinc

plated or hot dip, property class 8.8

NRk,s

[kN]

29

46

67

125

196

110

172

28

47

Ms,N

Partial safety factor

Characteristic tension resistance, Stainless

steel A4 and HCR

NRk,s

1,50

[kN]

26

41

Ms,N

Partial safety factor

59

1,87

Pullout and concrete cone failure 1)

Characteristic bond resistance in concrete C20/25

50C/80C2)

uncracked concrete

Partial safety factor

(dry and wet)

NRk,p =N0Rk,c

[kN]

12

18

25

Mp = Mc

1,8

Embedment depth

hef

[mm]

80

90

110

125

170

Edge distance

ccr,N

[mm]

80

90

110

125

170

Axial distance

scr,N

[mm]

2 x ccr,N

Increasing factors for non-concrete concrete

c

Splitting failure

(fck0,30)/2,63

Edge distance

ccr,sp

[mm]

ccr,N O 2 hef (2,5 - h/hef) O 2,4 hef

Axial distance

scr,sp

[mm]

2 x ccr,sp

Partial safety factor

(dry and wet)

Msp

1,8

The data in this table are intended to use together with the design provisions of ETAG 001 Annex C

1) shall be determined acc. this table or acc. to 5.2.2.4, Annex C of ETAG 001. The smaller value is decisive.

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

2) short term temperature / Long term temperature . Long term concrete temperatures are roughly constant over signicant periods of time.

Short term elevated temperatures are those that occur over brief intervals, e.g. as a result of diurnal cycling.

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Performance data - concrete

SHEAR LOADS - Design method A acc. to ETAG 001 Annex C, characteristic values for

shear loading

Anchor size

M8

M10

M12

M16

M20

Steel failure without leaver arm

Characteristic shear resistance, Steel, zinc

plated or hot dip, property class 5.8

VRk,s

[kN]

15

21

39

61

Characteristic shear resistance, Steel, zinc

plated or hot dip, property class 8.8

VRk,s

[kN]

15

23

34

63

98

55

86

Ms,V

Partial safety factor

Characteristic shear resistance, Stainless

steel A4 and HCR

VRk,s

1,25

[kN]

13

20

Ms,V

Partial safety factor

30

1,56

Steel failure with leaver arm

Characteristic bending moment, Steel, zinc

plated or hot dip, property class 5.8

M0Rk,s

[Nm]

19

37

65

166

324

Characteristic bending moment, Steel, zinc

plated or hot dip, property class 8.8

M0Rk,s

[kN]

30

60

105

266

519

232

454

Ms,V

Partial safety factor

Characteristic bending moment, Stainless

steel A4 and HCR

M0Rk,s

1,25

[kN]

26

52

Ms,V

Partial safety factor

92

1,56

Concrete Pryout failure

Factor k

2,0

Mcp

Partial safety factor

1,5

Concrete edge failure

Eective length of anchor in shear loading

Outside diameter of anchor

Partial safety factor

lf

[mm]

80

90

110

125

170

dnom

[mm]

10

12

14

18

24

Mc

1,5

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

The data in this table is intended to used together with the design provisions of ETAG 001 Annex C.

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

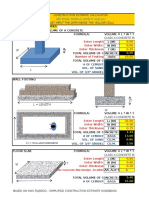

Recommended loads - concrete

The recommended loads are only valid for single anchor for a roughly design, if the

following conditions are valid:

dry or wet bore hole, uncracked concrete C20/25, steel 5.8

c P ccr,N

s P scr,N

h P 2 x hef

If the conditions are not fulfilled the loads must be calculated acc. to ETAG 001

Annex C.

The safety factors are already included in the recommended loads.

Anchor size

M8

M10

M12

M16

M20

80

90

110

125

170

Embedment depth

hef

[mm]

Edge distance

ccr,N

[mm]

1,5 x hef

Axial distance

scr,N

[mm]

3,0 x hef

NRec

[kN]

4,7

7,1

10,0

11,2

18,8

VRec

[kN]

5,1

8,6

12,0

22,3

34,9

Recommended tension load

50C/80C2)

Recommended shear load without

leaver arm for Steel property class

5.81)

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

1) Shear load with leaver arm acc. Annex C of ETAG 001.

2) short term temperature / Long term temperature. Long term concrete temperatures are roughly constant over signicant periods of time.

Short term elevated temperatures are those that occur over brief intervals, e.g. as a result of diurnal cycling.

anage

me

Rev. 04 (EN)

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Usage instructions - hollow bricks

1.

Drill without hammer drill mode a hole into the base material to the size and

embedment depth required by the selected anchor.

2.

In case of a water filled bore hole, the water has to be removed from the hole

(e.g. by compressed air or vacuum cleaner). Starting from the bottom or back

of the hole, blow the hole clean with a hand pump a minimum of two times. Then

brush the hole with nylon brush a minimum of two times. Finally clean the hole

again with a hand pump a minimum of two times.

3.

Attach a supplied static-mixing nozzle to the cartridge and load the cartridge

into the correct dispensing tool. After every working interruption longer than

the recommended working time as well as for new cartridges, a new static-mixer

shall be used.

4.

Prior to inserting the anchor rod into the filled bore hole, the position of the

embedment depth shall be marked on the anchor rods.

5.

Prior to dispensing the mortar into the bore hole, squeeze out separately a

minimum of three full strokes and discard non-uniformly mixed adhesive components until the mortar shows a consistent grey colour.

6.

Insert the perforated sleeve into the bore hole. Make sure that the sleeve fits

well into the hole. Never cut the sleeve! Only use sleeves that have the right

length.

7.

Starting from the back fill the sleeve completely with adhesive. Observe the

gel-/ working times.

8.

er

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Push the threaded rod or reinforcement bar into the sleeve while turning it

slightly to ensure a distribution of the adhesive until the back of the sleeve is

reached. The anchor should be free of dirt, grease, oil or other foreign material.

anage

me

Rev. 04 (EN)

10

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

9.

Allow the adhesive to cure to the specified time prior to applying any load to

torque. Do not move or load the anchor until it is fully cured.

10.After full curing, the add-on part can be installed with the max. torque by

using a calibrated torque wrench.

er

Brush:

20 mm Nylon; Length: 80 mm

Blower

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Cleaning - masonry

anage

me

Rev. 04 (EN)

11

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Performance data - masonry

Stone

Strength class

Recommended

loads

Wing sleeve

M6

M8

M10

M12

M8

M10

0,3

0,3

0,3

0,3

0,3

0,3

0,4

0,4

0,4

0,4

0,4

0,4

Hlz 12

0,7

0,8

0,8

0,8

0,8

0,8

KSL 4

0,3

0,3

0,3

0,3

0,3

0,3

Hlz 4

Hollow brick

Hlz 6

Sand -lime hollow brick

Standard sleeves

KSL 6

Frec

Frec

[kN]

[kN]

KSL 12

0,4

0,4

0,4

0,4

0,4

0,4

0,7

0,8

0,8

0,8

0,8

0,8

Sand -lime solid

brick1)

KS 12

Frec

[kN]

0,5

1,7

1,7

1,7

1,7

1,7

Solid brick1)

Mz 12

Frec

[kN]

0,5

1,7

1,7

1,7

1,7

1,7

Light concrete

hollow brick

Hbl 4

Frec

[kN]

Hbn 4

Frec

[kN]

Hbl 2

Concrete hollow

brick

0,3

0,3

0,3

0,3

0,5

0,6

0,6

0,6

0,5

0,6

0,6

0,6

Installation parameters

Axial distance plug group

scr,N Group [mm]

Hlz, KSL, MZ, KS = 100

Hbl, Hbn = 200

100

Min. axial distance plug group2)

smin Group [mm]

Hlz, KSL, MZ, KS = 50

Hbl, Hbn = 200

50

Axial distance between single plugs

scr,N Single [mm]

250

250

Edge distance

ccr,N

[mm]

250

200 (250)3)

Min. edge distance4)

cmin

[mm]

250

50 (60)3)

with sleeve

hef

[mm]

50

85

85

85

80

90

without sleeve

hef

[mm]

60

80

90

110

80

90

with sleeve

h0

[mm]

55

90

90

90

105

105

without sleeve

h0

[mm]

65

85

95

115

85

95

hmin

[mm]

Drill diameter

do

[mm]

11

16

16

16

14

16

Hole diameter in xed element

df

[mm]

12

14

12

Tinst

[Nm]

Embedment

depth of rod

Drilling depth

Minimum part thickness

Installation torque

110

125

110

1) Anchoring in masonry of solid lime-sand bricks (KS) and masonry bricks (Mz) does not require perforated sleeve.

2) It is permissible to go below the axial spacing to the minimum value for anchor pairs and groups of four, if the permissible loads are reduced.

The maximum loads must not be exceeded.

er

4) Applies to masonry with top load or proof of tilt. Does not apply to shear loads directed towards a free edge.

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

3) Value in brackets applies to solid bricks (Mz and KS).

anage

me

Rev. 04 (EN)

12

STPSF - Polyester styrene free

TECHNICAL DATA SHEET

STPSF

SFPSF

PMPSF

2K

Reaction resin mortar based on Polyester styrene free

Performance data - masonry

Reduced permissible loads with reduced axial spacing per anchor in anchor groups

scr,N Group s > smin

Anchor pairs:

red F = s F rec

s = (1 + s/scr,N Group) 1,0

Groups of four:

red F = s1 s2 F rec

s1,2 = (1 + s1,2/scr,N Group) 1,0

F rec

red F

scr,N Group

s

= Permissible load per anchor

= Reduced load per anchor

= Axial spacing

= Reduced axial spacing

Permissible load in [kN] for each single brick

er

< 4 DF

4 bis 10 DF

10DF

Without top load

max F [kN]

1,0

1,4

2,0

With top load

max F [kN]

1,4

1,7

2,5

tifizierte

sy

DIN EN ISO

9001:2008

nt

Qualitt

stem

Brick format

anage

me

Rev. 04 (EN)

13

You might also like

- Anclaje Quimico HILTIDocument84 pagesAnclaje Quimico HILTIWuceirNo ratings yet

- Technical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553Document31 pagesTechnical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553ing urban100% (2)

- 2014 Hilti Hit-Hy 200 With Hit-ZDocument5 pages2014 Hilti Hit-Hy 200 With Hit-ZDifa LiuNo ratings yet

- 2013 Hilti Hit-Hy 200 With His - (R) NDocument4 pages2013 Hilti Hit-Hy 200 With His - (R) NDifa LiuNo ratings yet

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Document85 pagesTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanNo ratings yet

- 1 MMP METI Fit CatalogueDocument16 pages1 MMP METI Fit CataloguemohdnazirNo ratings yet

- 2013 Hilti Hit-Hy 200 With Hit-VDocument4 pages2013 Hilti Hit-Hy 200 With Hit-VDifa LiuNo ratings yet

- Anchor Fastening Technology Manual: RebarDocument12 pagesAnchor Fastening Technology Manual: Rebarcart_thick100% (1)

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Deep Hole Drlling On Maching Centres BOTEKDocument2 pagesDeep Hole Drlling On Maching Centres BOTEKmapalptsNo ratings yet

- MYKAnchor HF66Document2 pagesMYKAnchor HF66cekicdjNo ratings yet

- Catalogue Ipsi EpDocument70 pagesCatalogue Ipsi EprachedscribNo ratings yet

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Gautam PaulNo ratings yet

- Hilti Hit-Hy 200 With Hit-V RodDocument20 pagesHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNo ratings yet

- JCP Resin Data SheetDocument2 pagesJCP Resin Data SheetgijimmyyoNo ratings yet

- Hy-200 FTM 2012-09Document70 pagesHy-200 FTM 2012-09Inhinyero SibilNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Gk23a Umb Manual eDocument16 pagesGk23a Umb Manual ejultur4oNo ratings yet

- Sika AnchorFix 1 PDSDocument8 pagesSika AnchorFix 1 PDSSkerdi MucoNo ratings yet

- Tube FittingsDocument60 pagesTube FittingsHermanNo ratings yet

- Hilti Hit Hy70 System DS GBDocument9 pagesHilti Hit Hy70 System DS GBikirby77No ratings yet

- R-Kem II Masonry - OptDocument7 pagesR-Kem II Masonry - OptGnomo GnominNo ratings yet

- Manual Spray GunDocument6 pagesManual Spray GunSyazwan KhairulNo ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- Fiberstrong Piping System Above Ground Installation ManualDocument32 pagesFiberstrong Piping System Above Ground Installation ManualIbrahim Habiba100% (1)

- Hilti HIT-HY 150 With HIT-V or HAS PDFDocument19 pagesHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dNo ratings yet

- Sika AnchorFix S 2012-06-1Document6 pagesSika AnchorFix S 2012-06-1orgaNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- RTM Accessories MatrasurDocument3 pagesRTM Accessories MatrasurThanh TruongNo ratings yet

- Montavimo Technika Armaturos StrypamsDocument5 pagesMontavimo Technika Armaturos StrypamsHafidh BaequnieNo ratings yet

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarNo ratings yet

- Vxf2aidrDocument132 pagesVxf2aidrSamira Adnan HalilovićNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Bondstrand - Instructions For Butt and Strap JointsDocument2 pagesBondstrand - Instructions For Butt and Strap Jointsao185029No ratings yet

- Fis V 360 SDocument4 pagesFis V 360 Sanwarali1975No ratings yet

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoNo ratings yet

- L-Dens 427F Ex Density Sensor SpecificationsDocument6 pagesL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNo ratings yet

- FreyssibarDocument12 pagesFreyssibarFelix Untalan Ebilane JrNo ratings yet

- Polyken 4000 PrimerlessDocument2 pagesPolyken 4000 PrimerlessKyaw Kyaw AungNo ratings yet

- Flupec Catalog Etansari Translatie PDFDocument446 pagesFlupec Catalog Etansari Translatie PDFRadu VasileNo ratings yet

- Hilti HIT MM Plus 1Document14 pagesHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNo ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- Trident Rotary Drill BitsDocument6 pagesTrident Rotary Drill BitsLGT LLCNo ratings yet

- Load Testing and Testing of Shock Absorption and Vertical Deformation of Test Floors For Sports Purposes, Round 2Document10 pagesLoad Testing and Testing of Shock Absorption and Vertical Deformation of Test Floors For Sports Purposes, Round 2Paulo BravoNo ratings yet

- Enz Nozzle Catalog 2012Document97 pagesEnz Nozzle Catalog 2012ryanvlopezNo ratings yet

- Section 610-Pipe Underdrain and Pavement Base DrainDocument5 pagesSection 610-Pipe Underdrain and Pavement Base Drainذوالفقار كريم الابراهيميNo ratings yet

- Standard Specification For Weirs and Baffles: Fiberglass Fabricators, IncorporatedDocument5 pagesStandard Specification For Weirs and Baffles: Fiberglass Fabricators, IncorporatedM Nur SalimNo ratings yet

- Application Instructions Denso Butyl Tape System1Document4 pagesApplication Instructions Denso Butyl Tape System1Khoh Kai ShengNo ratings yet

- MS3770 - EN - DS008REV02 - IS (FT Electromagnetico de Insercion)Document9 pagesMS3770 - EN - DS008REV02 - IS (FT Electromagnetico de Insercion)cacr_72No ratings yet

- 4safebarriera ENG H2 W4 A BP - 3n32122Document6 pages4safebarriera ENG H2 W4 A BP - 3n32122TBPNo ratings yet

- Chemical Anchoring DataDocument8 pagesChemical Anchoring DataAnonymous QG76ewHJNo ratings yet

- CMB Iso 6020-2Document63 pagesCMB Iso 6020-2David AlbellaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Fischer Technical DataDocument6 pagesFischer Technical DataAnonymous CgJzschNo ratings yet

- Pad Foundation Design Example Eurocode 2Document30 pagesPad Foundation Design Example Eurocode 2mahalakshmiNo ratings yet

- HARGA SUBKON Hotel IndonesiaDocument79 pagesHARGA SUBKON Hotel IndonesiaRajinda BintangNo ratings yet

- DBRDocument36 pagesDBRMudit VermaNo ratings yet

- ITP & Ceklis Bored PileDocument5 pagesITP & Ceklis Bored Pilefari_civil06No ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- Design of Columns As Per IS 456-2000Document68 pagesDesign of Columns As Per IS 456-2000S Praveenkumar87% (93)

- 250 MW - VoThermal Power Station Spec-2Document447 pages250 MW - VoThermal Power Station Spec-2Rohit GoyalNo ratings yet

- Quality Systems Manual Method StatementDocument8 pagesQuality Systems Manual Method StatementLloyd MariNo ratings yet

- Civil Earthquake Resistent Building Construction ReportDocument25 pagesCivil Earthquake Resistent Building Construction ReportAjay WaswaniNo ratings yet

- D2D - MechanicalDocument160 pagesD2D - MechanicalPablo SandovalNo ratings yet

- 3m&6m&9m Pole Calculation - With Od Bts Slab-1Document12 pages3m&6m&9m Pole Calculation - With Od Bts Slab-1Pankaj SherwalNo ratings yet

- Dextra Ground Engineering Interactive Brochure 2023 EN - CompressedDocument41 pagesDextra Ground Engineering Interactive Brochure 2023 EN - CompressedVetriselvan ArumugamNo ratings yet

- Project Activities With Start-Up MaterialDocument6 pagesProject Activities With Start-Up MaterialJOSHUA MASHETI WENDONo ratings yet

- LFD Box Culvert Design and Rating: User'S Manual ForDocument150 pagesLFD Box Culvert Design and Rating: User'S Manual ForMiguel valdivia rosasNo ratings yet

- Reinforced Concrete Structures - Lesson 5Document9 pagesReinforced Concrete Structures - Lesson 5Almedin CuricNo ratings yet

- Stress Ratio Summary - Jembatan Cimanuk BaratDocument82 pagesStress Ratio Summary - Jembatan Cimanuk BaratFadhana A PutraNo ratings yet

- Const-Estimate-Made-Easy, by Engr. Ronald John R. CajillaDocument54 pagesConst-Estimate-Made-Easy, by Engr. Ronald John R. CajillaAr John Bernard Abad100% (2)

- Hilti Hit Re 500-Sd - Esr-2322Document45 pagesHilti Hit Re 500-Sd - Esr-2322zuccoloNo ratings yet

- Comparison Between Reinforced Concrete Design Based On The ACI318 and BS8110 CodesDocument11 pagesComparison Between Reinforced Concrete Design Based On The ACI318 and BS8110 CodesBilly LiNo ratings yet

- Ebcs 4 PDFDocument140 pagesEbcs 4 PDFAbera Mulugeta100% (4)

- Steps For RCC Design 10.01.08 PDFDocument12 pagesSteps For RCC Design 10.01.08 PDFSACHIDANANDA SNo ratings yet

- Bridge Design PhilosophyDocument21 pagesBridge Design PhilosophyAddrien Daniel100% (1)

- Earthquake BNBC 2020Document48 pagesEarthquake BNBC 2020Shantonu Dey100% (1)

- 302 Volume - 5.2 GAD Bridges PDFDocument15 pages302 Volume - 5.2 GAD Bridges PDFAnonymous ofum2rGsPNo ratings yet

- ECCS - 2005 - Charles de Gaulle Building in BucharesDocument26 pagesECCS - 2005 - Charles de Gaulle Building in BucharesmihaidelianNo ratings yet

- 7H Prestressed Double TeesDocument10 pages7H Prestressed Double TeesSughanyaa VeNo ratings yet

- ANCON - Stainless Steel ReinforcementDocument8 pagesANCON - Stainless Steel Reinforcementstavros_stergNo ratings yet

- Example Rapid Mix Design LabDocument19 pagesExample Rapid Mix Design Labbrischik100% (1)

- ST 02Document1 pageST 02Anas Hasan KhanNo ratings yet