Professional Documents

Culture Documents

Saic W 2003

Uploaded by

Mohammed IlliasuddinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic W 2003

Uploaded by

Mohammed IlliasuddinCopyright:

Available Formats

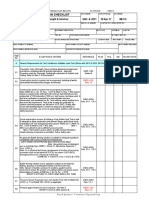

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

REV 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

PROJECT TITLE

SAIC-W-2003

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A

A1

A2

A3

A4

A5

A6

ACCEPTANCE CRITERIA

REFERENCE

General Requirements (Pre-Work)

Contractor shall complete 100% Pressure Piping Design & submit a

Project Specific Design Specification for Welding containing:

A) Summary of Piping Line Classes & Design

Information

B)

Proposed Project PWHT Specification (details, notes, reqmts) that are

SAES-L-310,

based on ASME Code & Saudi Aramco Stds within workscope.

Section 7

C) Proposed Project NDE Specification (Refer to

the NDE SATIPs)

D) Proposed Project Specifications

Last Bullet

for other Special Processes such as PMI, Pressure Testing, Coatings &

Insulation

PWHT Specifications by Line

Class are reviewed & approved by SA, this includes Owner's

Authorized Inspector (PID). Follow checklist & the applicable SATIPs.

Utilize Attachment

PWHT Procedure shall include a step-by-step detail of the PWHT

specified, from initial weld ID & entry of PWHT into the SAEP-1160

Database through final visual acceptance, including reporting per SAEPSAEP-1160,

1160 requirements. Activities shall be tied into the Project

Section 6 &

welding Database. PWHT shall be properly sequenced relative

Procedure

to any NDT performed and Control over activities shall be documented.

See Attachment 2 . Production work, Reporting & Status

(Backlogs, etc) are controlled & documented.

A written procedure describing the general PWHT requirements of

ASME B31.3, shall be submitted for review and approval of CSD Note :

review and approval process is the same as described for welding

procedures (Per Paragraph 7.1 of SAES-W-011).

PWHT procedure shall include descriptions of the equipment,

method of heating,

location and type of heating elements, temperature measurement

method, and thermocouple locations

Prior to start of WORK, Contractor shall prepare a Table listing (see A6

) for each joint or component requiring heat treatment, & submit for PID

review.

See Attachment 3 for a sample PWHT Table, SATR-W-2004.

A) This provides field direction for

PWHT Field Crew / Personnel.

B) PWHT work / results

are controlled & entered daily into the SA approved SAEP-1160

Production Weld Database.

C) Data

specified in the PWHT Table shall meet ASME B31.3 PWHT Table

Table shall include the following info. for each joint or component:

a) location

b) drawing number

c) diameter

d) wall thickness

e) material

f) heating rate

g) cooling rate

h) soak temperature

i) soak time

Page 1 of 14

SAES-W-011,

Para. 13.1

SAES-W-011,

Para. 13.1

SAES-W-011,

Para. 13.2

SAES-W-011,

Para. 13.2

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

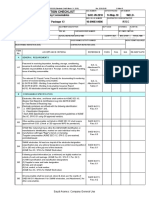

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

REV 4

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

PROJECT TITLE

ITEM

No.

A7

A8

A9

SAIC NUMBER

SAIC-W-2003

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

Carbon & low alloy steel butt welds requiring PWHT for Process

Conditions & Services are as listed in Attachment 1.

A) All caustic soda (NaOH) solutions, incl. conditions

where caustic carryover may occur (e.g. downstream of caustic injection

points).

B) All monoethanolamine (MEA) solutions (all temperatures).

C) All diglycol amine (DGA) solutions above 138C design temp.

D) Rich amino diisoprop (ADIP) solutions above 90C design temp.

E) All lean ADIP solutions above 60C design temperature.

F) Boiler Deaerator serv (ambient temp vacuum deaerator = exempt)

G) Hydrogen service for P-No. 3, 4, and 5A/B/C base materials.

H) All diethanolamine (DEA) solutions.

These reqmts also apply to external welds to attach nonpressure

containing component to piping (e.g., reinforcement pad or sleeve

attached to the pipe) and to seal welds. Seal welds on threaded valves

For applications where PWHT is required by service fluid (Item A7

above) " OR " where hardness limits are specified:

a) Reductions in PWHT temperature or alternative temperatures

below normal holding temps listed in ASME B31.3 are not permitted.

b) Minimum PWHT soak time shall be 1 hour.

c) If hardness limits are specified, production weld soak time shall not be

less than 80% of PQR soak time unless approved by CSD.

Note : A copy of

the CSD approved WPS shall be cross checked

The PWHT heating and cooling rates > 316C shall not exceed 222C/hr

weld thickness in inches, but in no case > 222C/hr.

SAES-W-011,

Para. 13.3

SAES-W-011,

Para. 13.9

SAES-W-011,

Para. 13.4

A10

The specified PWHT shall be applied over an area extending at least 3 x

thickness of the material being welded from each weld toe, but not less

than 25 mm from each weld toe, whichever is greater.

SAES-W-011,

Para. 13.5

A11

For PWHT not performed in a furnace, insulation shall be applied a

minimum of 300 mm on either side of the weld to be PWHT'd. Insulation

shall not be removed before temp. has cooled to < 150C.

SAES-W-011,

Para. 13.6

A12

Ends of open lines shall be closed off in order to eliminate drafts or

air circulation that could lower temperatures on inside surface of joints

unless the internal surface is also insulated.

SAES-W-011,

Para. 13.6

A13

All temperatures within the heated zone for furnace or localized PWHT

shall exceed the specified minimum holding temperature.

SAES-W-011,

Para. 13.10

A14

The actual temperature range for the soak period, as recorded by TC's,

shall not have a spread of more than 40C.

SAES-W-011,

Para. 13.10

A15

Welding or heating to joints already PWHT'd requires re-PWHT. PWHT

shall follow all welding and repairs, but shall precede any hydrotest. Note

: SAEP-1160 requires Weld ID change on repair.

SAES-W-011,

Para. 13.11

A16

PWHT shall be carried out using one or more of the following types:

a) Permanent or semi-permanent furnaces (gas/oil/electric heaters)

b) Electrical resistance heaters.

c) Induction heaters.

SAES-W-011,

Para. 13.12

Thermocouple Requirements

B1

If localized PWHT is used, the following minimum number of equally

spaced recording thermocouples (T/C) shall be used:

a) Pipe diameter of 305 mm or less: 1 T/C.

b) Pipe diameter above 305 mm up to and including 610 mm: 2 T/C.

c) Pipe diameter above 610 mm: 4 T/C.

SAES-W-011,

Para. 13.13

B2

Additional TCs are required if multiple heat control zones are used, in

which a control zone is not monitored by any of the primary T/Cs.

SAES-W-011,

Para. 13.13

B3

Thermocouples and a calibrated temperature chart recorder shall be

used to provide an accurate and legible record of all PWHTs.

SAES-W-011,

Para. 13.14

B4

All charts shall be marked with the date and sufficient information to

uniquely identify the joint/component being heat treated.

SAES-W-011,

Para. 13.14

B5

Multipoint chart recorders clearly differentiate/identify each channel /point

by use of different colored inks or automatic # stamping.

SAES-W-011,

Para. 13.14

B6

Temperature recorders shall be calibrated every three months & a

current calibration sticker shall be maintained on the recorder.

SAES-W-011,

Para. 13.15

Page 2 of 14

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

REV 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

PROJECT TITLE

31-Mar-10

DATE APPROVED

SAIC-W-2003

ACCEPTANCE CRITERIA

REFERENCE

B7

Calibration frequency may be extended to 12* months with PID

approval if documented calibration checks for recorder demonstrate

acceptable accuracy for a suitable period. *Sch Q M&TE limit.

SAES-W-011,

Para. 13.15 &

Sch Q,

M&TE

B8

Only Type K (Chromel-Alumel) or Type J (iron-Constantan) TCs are

permitted. All extension, compensating, and jumper cables in the

measurement or control circuits shall be the specified TC wire or

matching extension wire, i.e., KX or JX, as appropriate.

SAES-W-011,

Para. 13.16.1

B9

For Type K TCs, copper- Constantan (Type T) compensating cables may

be used with the following conditions:

a) Junction between the copper-Constantan compensating cable

and the Type K thermocouple lead shall be a minimum of 0.5 m*

outside the insulated area. (*Inspection to verify each weld)

b) Acceptable temperature range of the junction between the

compensating cable & thermocouple lead is from 0 to +80C.

SAES-W-011,

Para. 13.16.1

B10

The national standard that the thermocouple conforms to shall be

indicated in the PWHT procedure.

SAES-W-011,

Para. 13.16.2

B11

Procedure shall also include a listing of the insulation coloring of each

core wire & the overall sheath for both the compensating cable & TC.

Site inspectors to verify that the proper wires have been used and

are connected in the proper polarity.

SAES-W-011,

Para. 13.16.2

B12

Thermocouples shall be attached to the component by capacitive

discharge welding only.

SAES-W-011,

Para. 13.16.3

Preparation for PWHT

C1

Thermocouples shall not be in direct contact with electrical heating

elements or subjected to flame impingement by gas or oil burners.

SAES-W-011,

Para. 13.16.3

C2

Prior to the start of the PWHT, components shall be checked to ensure

that all restraints are removed and the component is free to expand and

contract, and suitable and sufficient supports are used.

SAES-W-011,

Para. 13.17

C3

In addition, the PWHT chart should be marked, prior to PWHT, with

identification number of the weld(s).

SAES-W-011,

Para. 13.17

C4

All machined surfaces, such as flange faces, threaded bolt holes,

threads, etc., shall be protected from oxidation during the heat treatment

by coating with deoxaluminite or other suitable material.

SAES-W-011,

Para. 13.18

C5

All PWHT chart records shall be submitted to Saudi Aramco Inspection

for review and approval. All records shall be submitted as part of the

equipment file for permanent record.

SAES-W-011,

Para. 13.19

C6

After completion of the PWHT all thermocouples shall be removed and

the attachment areas ground smooth to clean and sound metal. If

specified by PID, the areas shall be MT or PT after grinding.

SAES-W-011,

Para. 13.20

WELD-

31-Aug-11

WBS / BI / JO NUMBER

ITEM

No.

QR NUMBER

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

NOTES: 1. Code exemptions for PWHT for P-No. 4 & P-No. 5 materials are not allowed at Saudi Aramco. PWHT all P-No. 4 & P-No. 5 mat'l

welds & pressure boundary attachments when Sour Service exists or nominal chrome content is above 1.5%. (SAES-W-011, Para. 13.8

2. Condition of PWHT Insulation blankets shall be monitored for deterioration & burn damage. Deteriorated blankets and those without wire

mesh coverings release Ceramic fibers into the immediate work area and are a great health hazard (Safety & Quality Concern).

3. Strict controls for work sequence and work segregation are required.

4. For Recording of Results & Final Acceptance, utilize checklist SAIC-W-2004 R3 to cover any points in the Procedure deemed necessary.

ATTACHMENTS:

Attachment 1 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011

Attachment 2 - SAEP-1160 DATABASE, PROCESS CONTROL TRACKING (By Weld)

Attachment 3 - SATR-W-2004 - SAMPLE PWHT TABLE (PROCESS CONTROL TRACKING BY WELD)

REFERENCE DOCUMENTS:

1. SAES-W-011, Welding Requirements for On-Plot Piping, (4 Oct 2009)

2. ASME B31.3, Process Piping (Latest Edition)

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Name, Initials and Date:

T&I Witnessed

Name, Initials and Date:

Work / Rework May Proceed

Name, Initials and Date:

Page 3 of 14

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

REV 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

PROJECT TITLE

ITEM

No.

SAIC-W-2003

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

Name, Initials and Date:

31-Mar-10

DATE APPROVED

REFERENCE

31-Aug-11

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

T&I Witnessed

QC Record Reviewed

Y = YES

Page 4 of 14

Work Verified

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

REV 4

SAIC NUMBER

SAIC-W-2003

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

WELD-

Attachment 1 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011, Section 13

Attachment 2 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011

Attachment 2 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011

Attachment 2 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011

Attachment 2 - Requirements for Heat Treatment (ASME B31.3, Table 331.1.1) & SAES-W-011

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March2010

SAUDI ARAMCO INSPECTION CHECKLIST

REV 4

SAIC NUMBER

31-Mar-10

DATE APPROVED

QR NUMBER

Review Post Weld Heat Treatment (PWHT) Specification,

SAIC-W-2003

31-Aug-11

WELDProcedure, & Table for On-Plot Piping

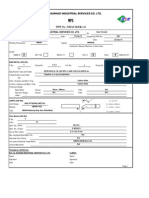

Attachment 2 - SAEP-1160 DATABASE, PROCESS CONTROL TRACKING (By Weld)

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

SAUDI ARAMCO INSPECTION CHECKLIST

Review Post Weld Heat Treatment (PWHT) Specification,

Procedure, & Table for On-Plot Piping

REV 4

SAIC NUMBER

SAIC-W-2003

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

WELD-

Attachment 3 - SATR-W-2004 R-3- SAMPLE PWHT TABLE (PROCESS CONTROL TRACKING BY WELD)

Instructions for PWHT Table (Line List) Use: 1. Perform Heat Treatment in conjunction with SAIC-W-2012 and

SAIC-W-2014 for Brinnell Hardness Testing and the applicable NDE SATIP & Project NDE Specification.

2. Localized PWHT = 100% Brinnell Hardness Testing. Furnace Batch PWHT = 10% Brinnell Hardness Testing.

3. PWHT Crew & QC Responsible utilize this Work Sheet to perform field work under close supervison/Witness.

4. Results are entered into the SAEP-1160 Database for Welds on Projects. Verify Weld ID numbers carefully.

5. Such Databases are not needed when 500 welds or less are in the Project Work Scope (SAEP-1160 Reqmt).

6. PWHT shall be performed per approved Project Welding & PWHT Specification including all notes.

7. Those responsible for work and data entry have been approved by Saudi Aramco to perform work on IK Projects.

8. Rework shall require a new Weld ID Number (suffix added = R 1, etc) per SAEp-1160 Requirements.

You might also like

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- SAIC-A-2003 Rev 0Document3 pagesSAIC-A-2003 Rev 0bluelions_19No ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- 175 100100 PDFDocument2 pages175 100100 PDFThaksenNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- 175 030100Document2 pages175 030100Abu Anas M.Salaheldin100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saic A 2001Document21 pagesSaic A 2001Dilshad AhemadNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNo ratings yet

- 175 012000Document2 pages175 012000Abu Anas M.SalaheldinNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- SAIC-W-2084 Buttering or Build-Up of JointsDocument1 pageSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- 175 325100Document2 pages175 325100sridhar100% (1)

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- 175 060100Document1 page175 060100Abu Anas M.SalaheldinNo ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDocument7 pagesSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- SAIC-D-2005 Rev 2Document4 pagesSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATR-J-6406 Rev 0 PDFDocument10 pagesSATR-J-6406 Rev 0 PDFAdel KlkNo ratings yet

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- Welding Manual Nov 2010Document187 pagesWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Api 653Document3 pagesApi 653Mohammed IlliasuddinNo ratings yet

- Objective Type 2017Document4 pagesObjective Type 2017Mohammed IlliasuddinNo ratings yet

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument3 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeMohammed IlliasuddinNo ratings yet

- ALPHA BGAS Grade 2 Schedule - 2016Document1 pageALPHA BGAS Grade 2 Schedule - 2016Mohammed IlliasuddinNo ratings yet

- 3.4 Arc Length: The Distance From The Tip of The WeldingDocument7 pages3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinNo ratings yet

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Document7 pagesResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinNo ratings yet

- Resume of Qaqc Mech InspectorDocument5 pagesResume of Qaqc Mech InspectorMohammed IlliasuddinNo ratings yet

- Spare Parts Data Package Status Report (SPDPSR) : Abqaiq Plants Maintain Gas Compression Capacity ProjectDocument5 pagesSpare Parts Data Package Status Report (SPDPSR) : Abqaiq Plants Maintain Gas Compression Capacity ProjectMohammed IlliasuddinNo ratings yet

- Resume of Qaqc Welding-Mechanical InspectorDocument5 pagesResume of Qaqc Welding-Mechanical InspectorMohammed Illiasuddin100% (1)

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument3 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeMohammed IlliasuddinNo ratings yet

- Riddor: Health and Safety Advice For StonemasonsDocument12 pagesRiddor: Health and Safety Advice For StonemasonsMohammed IlliasuddinNo ratings yet

- Equipment Auxiliary Equipment Remarks: Spare Parts Data Package (SPDP) ChecklistDocument11 pagesEquipment Auxiliary Equipment Remarks: Spare Parts Data Package (SPDP) ChecklistMohammed IlliasuddinNo ratings yet

- Powerpoint Risk AssessmentDocument11 pagesPowerpoint Risk AssessmentMohammed IlliasuddinNo ratings yet

- Safety Signs RevisionDocument53 pagesSafety Signs RevisionMohammed IlliasuddinNo ratings yet

- Ap RP 572Document3 pagesAp RP 572Mohammed IlliasuddinNo ratings yet

- API CalculationsDocument11 pagesAPI CalculationsMohammed Illiasuddin100% (1)

- CompressorDocument63 pagesCompressorRajneesh Patel100% (1)

- Koyo Oil SealDocument119 pagesKoyo Oil Sealvicksgeorge100% (1)

- Four Bar Mechanism and Analysis in CreoDocument9 pagesFour Bar Mechanism and Analysis in CreoJigneshNo ratings yet

- Chapter 1 BC SC Probe 8Document36 pagesChapter 1 BC SC Probe 8api-265180883No ratings yet

- Rabia7 Base 28.02 EmbedDocument7 pagesRabia7 Base 28.02 EmbedvengadNo ratings yet

- BN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesDocument13 pagesBN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesGiftObionochieNo ratings yet

- Regulation 391ADocument6 pagesRegulation 391Adnageshm4n244100% (1)

- Soal US GanjilDocument25 pagesSoal US GanjilRick DoNo ratings yet

- Flux Cored Arc Welding I (Gas Shielded)Document38 pagesFlux Cored Arc Welding I (Gas Shielded)greatsteelNo ratings yet

- Study of Reflex Klystron CharacteristicsDocument8 pagesStudy of Reflex Klystron CharacteristicsakashNo ratings yet

- Digital Signal ProcessingDocument2 pagesDigital Signal ProcessingAnonymous HyOfbJ60% (1)

- Slides OctaveDocument24 pagesSlides Octaveamru_rzlNo ratings yet

- Physcis Unit Test 3Document5 pagesPhyscis Unit Test 3Yuta NeyaNo ratings yet

- Autoeng Advising Document Fall 2013 Entry or EarlierDocument11 pagesAutoeng Advising Document Fall 2013 Entry or Earlieranonimus19No ratings yet

- Energy TypesDocument3 pagesEnergy TypesSuki TsangNo ratings yet

- Kcet Chemistry 2015Document11 pagesKcet Chemistry 2015BURHAN0% (1)

- Astrology WebcourseDocument310 pagesAstrology Webcoursexlearner100% (18)

- Pirs509a BeamnrcDocument289 pagesPirs509a BeamnrcskcomhackerNo ratings yet

- TCRT 1000Document7 pagesTCRT 1000Costel MirzacNo ratings yet

- Ashby - Biomaterials PDFDocument26 pagesAshby - Biomaterials PDFPao FrancavillaNo ratings yet

- Method Statement For Bridge Load Test: 1. PurposeDocument10 pagesMethod Statement For Bridge Load Test: 1. PurposeAnonymous HN7WMQBmcNo ratings yet

- Analysis of Non-Uniform Torsion in Curved Incrementally Launched PDFDocument14 pagesAnalysis of Non-Uniform Torsion in Curved Incrementally Launched PDFYONAS GOSANo ratings yet

- STANDARD TEST METHOD: Thermostable Alpha-AmylasesDocument5 pagesSTANDARD TEST METHOD: Thermostable Alpha-Amylasesamithg33No ratings yet

- QTMS Brochure Rev2Document8 pagesQTMS Brochure Rev2ManibalanNo ratings yet

- Cse169 01Document49 pagesCse169 01hhedfiNo ratings yet

- Model 549: General & Small Parts PhantomDocument3 pagesModel 549: General & Small Parts PhantomMiguel De Los Santos PavisicNo ratings yet

- Accelerator Physics at The Tevatron Collider: Valery Lebedev Vladimir Shiltsev EditorsDocument496 pagesAccelerator Physics at The Tevatron Collider: Valery Lebedev Vladimir Shiltsev EditorsAurelian Solon100% (1)

- A7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalsDocument17 pagesA7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalssantoshNo ratings yet

- Zoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemDocument3 pagesZoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemyeniNo ratings yet

- Harry G. Brittain (Ed.) - Analytical Profiles of Drug Substances and Excipients, Vol. 28-Elsevier, Academic Press (2001) PDFDocument349 pagesHarry G. Brittain (Ed.) - Analytical Profiles of Drug Substances and Excipients, Vol. 28-Elsevier, Academic Press (2001) PDFngochieu_909No ratings yet