Professional Documents

Culture Documents

Asphalt Form

Uploaded by

PedjaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt Form

Uploaded by

PedjaCopyright:

Available Formats

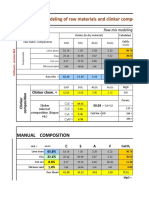

SEBHA - UMMELARANEB HIGHWAY

SUMMARY REPORT

BINDER COURSE

Asphalt layer

ID:

506

km 17+780

Date:

10/26/2009

Source:

Properties

value

Bulk density of Marshall speciment

(g/cm3)

Specified

2.290

Stability of Marshall speciment

(kN)

min 6 kN

Flow of Marshall speciment

(mm)

max 4 mm

Air Voids in Total Mix

Percent Voids Filled

with Bitumen

Bitumen content in Asphalt mix

(%)

5.4

(%)

70.8

(%)

5.5

Thickness of Core speciment

(cm)

6.6

(g/cm3)

2.235

(%)

97.6

Bulk density of Core speciment

Compaction of asphalt layer

3-8%

5.30.3%

min 97 %

100

Aggregate Mix

90

80

Averag

70

60

Passing (%)

50

40

30

REMARKS:

20

10

0

25.0

Tested by Lab - technician

(Contractor)

xx

QR 457-1

19.0

9.5

4.8

2.4

Checked by M.E.

(Contractor) Sieve (mm)

xx

0.6

0.3

0.2

Witness by M.I.

(Consultant)

0.1

SEBHA - UMMELARANEB HIGHWAY

QUANTITATIVE EXTRACTION OF BITUMEN

AND SIEVE ANALYSIS OF AGGREGATE OF BITUMINOUS PAVING

MIXTURES

BINDER COURSE

Source:

Asphalt layer

ID:

506

km 17+780

Date:

10/26/2009

BITUMEN EXTRACTION

1200.0

0.0

22.0

1111.0

1.0

1134.0

66.0

A : Wt of Mix (g)

B : Wt of Filter Paper before test (g)

C : Wt of Filter Paper after test (g)

D : Wt of Aggregate after test (g)

S : Sediment fines

E (D+C-B+S) : Total Wt of Aggregate (g)

F (A-E) : Loss of Wt (g)

5.5

G (100xF/A) : Bitumen Percentage by Wt of Mix (%)

PARTICLE SIZE ANALYSIS OF AGGREGATE

BS

(mm)

25.0

19.0

9.5

4.75

2.36

0.600

0.300

0.150

0.075

ASTM

(in)

1

3/4

3/8

No. 4

No. 8

No. 30

No. 50

No. 100

No. 200

PAN

loss

TOTAL

Retained Weight

cum. (g)

Retained

(%)

Passing

(%)

Tolerance grading

Specification limits

100

89.9 - 99.9

52.9 - 62.9

39.6 - 47.6

25.4 - 33.4

9.6 - 17.6

5.6 - 11.6

3.9 - 7.9

0.9 - 3.9

100

75-100

45-70

30-50

20-35

5-20

3-12

2-8

0-4

REMARKS:

1134.0

1134.0

100

Aggregate Mix

90

80

MIX

70

60

Passing (%)

50

40

30

20

10

0

25.0

19.0

9.5

4.8

2.4

0.6

0.3

0.2

0.1

Sieve (mm)

Tested by Lab - technician

(Contractor)

Checked by M.E.

(Contractor)

xx

xx

QR 457-2a

Witness by M.I.

(Consultant)

SEBHA - UMMELARANEB HIGHWAY

QUANTITATIVE EXTRACTION OF BITUMEN

AND SIEVE ANALYSIS OF AGGREGATE OF BITUMINOUS PAVING

MIXTURES

BINDER COURSE

Source:

Asphalt layer

ID:

506

km 17+780

Date:

10/26/2009

Tolerance grading

Specification limits

100

89.9 - 99.9

52.9 - 62.9

39.6 - 47.6

25.4 - 33.4

9.6 - 17.6

5.6 - 11.6

3.9 - 7.9

0.9 - 3.9

100

75-100

45-70

30-50

20-35

5-20

3-12

2-8

0-4

BITUMEN EXTRACTION

A : Wt of Mix (g)

B : Wt of Filter Paper before test (g)

C : Wt of Filter Paper after test (g)

D : Wt of Aggregate after test (g)

S : Sediment fines

E (D+C-B+S) : Total Wt of Aggregate (g)

F (A-E) : Loss of Wt (g)

G (100xF/A) : Bitumen Percentage by Wt of Mix (%)

PARTICLE SIZE ANALYSIS OF AGGREGATE

BS

(mm)

25.0

19.0

9.5

4.75

2.36

0.600

0.300

0.150

0.075

ASTM

(in)

1

3/4

3/8

No. 4

No. 8

No. 30

No. 50

No. 100

No. 200

PAN

loss

TOTAL

Retained Weight

cum. (g)

Retained

(%)

Passing

(%)

REMARKS:

100

Aggregate Mix

90

80

MIX

70

60

Passing (%)

50

40

30

20

10

0

1

Sieve (mm)

Tested by Lab - technician

(Contractor)

Checked by M.E.

(Contractor)

xx

xx

QR 457-2b

Witness by M.I.

(Consultant)

SEBHA - UMMELARANEB HIGHWAY

LABORATORY DENSITY , PERCENT AIR VOIDS ,

RESISTANCE TO PLASTIC FLOW AND STABILITY OF BITUMINOUS

MIXTURES USING MARSHALL APPARATUS

BINDER COURSE

Marshall Specimen No

Asphalt layer

ID:

506

km 17+780

Date:

10/26/2009

Source:

AVG.=

2.290

AVG=

5.4%

AVG=

70.8%

LABORATORY DENSITY (Bulk Specific Gravity) OF SPECIMEN prepared by 2x75 blows

A : Wt of Dry Specimen in Air

(g)

1165.5

1167.2

1167.7

1165.5

1167.2

1167.7

B : Wt of SSD Specimen in Air

(g)

1170.1

1169.2

1170.3

1170.1

1169.2

1170.3

C : Wt of SSD Specimen in Water

(g)

660.2

660.0

661.0

660.2

660.0

661.0

(cm3)

509.9

509.2

509.3

509.9

509.2

509.3

E (A/D) : Laboratory Density of Specimen

(g/cm3)

2.286

2.292

2.293

2.286

2.292

2.293

AVERAGE LABORATORY DENSITY

(g/cm3)

2.290

2.290

F : Specific Gravity of Bitumen

(g/cm3)

1.01

1.01

G : Spec. Gravity of Aggr. Avg(Bulk,Appar.)

(g/cm3)

2.627

D (B-C) : Volume of Specimen

2.29

AIR VOIDS IN SPECIMEN

H : Bitumen Content

(%)

5.5

5.5

5.5

5.5

5.5

5.5

I : Aggregate Content

(%)

94.5

94.5

94.5

94.5

94.5

94.5

2.422

J [100/(H/F+I/G)] : Max Density (Gmm)

(g/cm3)

K [100x(1-E/J)] : Air Voids in Total Mix

(%)

5.6

5.4

5.3

L [(HxE)/F] : Percent Volume of Bitumen

(%)

12.45

12.48

12.49

12.45

12.48

12.49

M [(IxE)/G] : Percent Volume of Aggregate

(%)

82.2

82.4

82.5

82.2

82.4

82.5

N (100-M) : Percent Aggregate Voids

(%)

17.8

17.6

17.5

17.8

17.6

17.5

O (100xL/N) :Percent Voids Filled

with Bitumen

(%)

70.1

71.1

71.3

70.1

71.1

71.3

70.8

AVERAGE PERCENT VOIDS IN TOTAL MIX (%)

70.8

STABILITY AND FLOW OF SPECIMEN

P : Height of Specimen

(mm)

Q : Dial Reading

(mm)

R : Converter Factor of Load Ring

S (QxR) : Converted Measured Stability

64.5

63.8

64.4

63.5

65.0

61.9

1.00

1.00

1.00

1.00

1.00

1.00

(kN/mm)

(kN)

T : Stability Correlation Ratio (as per volume)

U (SxT) : Corrected Stability

(kN)

V : Flow

(mm)

AVERAGE STABILITY OF SPECIMENS

(kN)

AVG=

AVERAGE FLOW OF SPECIMENS

(mm)

AVG=

QR 457-3

Tested by Lab - Engineer

(Contractor)

Checked by M.E.(Contractor)

xx

xx

Witness by M.I. (Consultant)

70.8%

SEBHA - UMMELARANEB HIGHWAY

COMPACTION TESTING OF ASPHALT

LAYER

BINDER COURSE

CORE Specimen No

Asphalt layer

ID:

506

km 17+780

Date:

10/26/2009

Source:

CH:

16+680

Location:

CL

AVG.=

6.6

AVG.=

2.235

AVG.=

97.6

CORE Specimen position

Thickness

(cm)

6.4

6.6

6.7

LABORATORY DENSITY (Bulk Specific Gravity) OF SPECIMEN

A : Wt of Dry Specimen in Air

(g)

1084.8

1118.5

1124.6

B : Wt of SSD Specimen in Air

(g)

1089.0

1124.2

1128.5

C : Wt of SSD Specimen in Water

(g)

604.3

623.9

624.3

D (B-C) : Volume of Specimen

(cm3)

484.7

500.3

504.2

E (A/D) : Density of Specimen

(g/cm3)

2.238

2.236

2.230

AVERAGE

(g/cm3)

2.235

G : Bulk Specific Gravity of

Marshall specimen

(g/cm3)

2.290

F : (E/G*100): Compaction

(%)

Density of Core specimen

COMPACTION

AVERAGE COMPACTION

(%)

97.7

2.290

97.6

97.4

97.6

REMARKS:

QR 457-4

Tested by Lab - Engineer

(Contractor)

Checked by M.E.(Contractor)

xx

xx

Witness by M.I. (Consultant)

You might also like

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceDocument45 pagesPrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

- Petar Subotic - Prirucnik Za Asfalt I DeoDocument308 pagesPetar Subotic - Prirucnik Za Asfalt I DeoPedjaNo ratings yet

- PrEN 12273 - Slurry Surfacing - Product StandardDocument25 pagesPrEN 12273 - Slurry Surfacing - Product StandardPedjaNo ratings yet

- Cement Calculus 28Document2 pagesCement Calculus 28PedjaNo ratings yet

- PrEN 13020 - Road Surface Treatment MachinesDocument20 pagesPrEN 13020 - Road Surface Treatment MachinesPedjaNo ratings yet

- Klinker Composition CalculationProt 231bDocument28 pagesKlinker Composition CalculationProt 231bPedjaNo ratings yet

- Aggregate Pop OutDocument0 pagesAggregate Pop Outتوان امتياس سامسدينNo ratings yet

- Matematika Jedan Nikic Comic RP22Document152 pagesMatematika Jedan Nikic Comic RP22PedjaNo ratings yet

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaNo ratings yet

- NRMC CIP 44prDocument2 pagesNRMC CIP 44prPedjaNo ratings yet

- Maturity Method To Estimate Concrete StrengthDocument2 pagesMaturity Method To Estimate Concrete StrengthRV Vimal100% (1)

- NRMC CIP 13pDocument2 pagesNRMC CIP 13pPedjaNo ratings yet

- PrEN 12271 - Surface DressingDocument54 pagesPrEN 12271 - Surface DressingPedjaNo ratings yet

- NRMC CIP 32pDocument2 pagesNRMC CIP 32pPedjaNo ratings yet

- NRMC CIP 26pDocument2 pagesNRMC CIP 26pPedjaNo ratings yet

- NRMC CIP 28pDocument2 pagesNRMC CIP 28pPedjaNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- GuidelinesDocument2 pagesGuidelinesMike2322No ratings yet

- Cold Weather ConcretingDocument2 pagesCold Weather ConcretingBoris DikovNo ratings yet

- NRMC CIP 43pDocument2 pagesNRMC CIP 43pPedjaNo ratings yet

- NRMC CIP 23pDocument2 pagesNRMC CIP 23pPedjaNo ratings yet

- NRMC CIP 20pDocument2 pagesNRMC CIP 20pPedjaNo ratings yet

- NRMC CIP 17pDocument2 pagesNRMC CIP 17pPedjaNo ratings yet

- NRMC CIP 29pDocument2 pagesNRMC CIP 29pPedjaNo ratings yet

- High Strength ConcreteDocument0 pagesHigh Strength ConcreteAris Co AbergosNo ratings yet

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDocument0 pagesSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNo ratings yet

- NRMC CIP 18pDocument2 pagesNRMC CIP 18pPedjaNo ratings yet

- CIP 19 - Curling of Concrete SlabsDocument2 pagesCIP 19 - Curling of Concrete SlabsMaestroColicus100% (1)

- CIP 12 Hot Weather ConcretingDocument2 pagesCIP 12 Hot Weather ConcretingTim_CNo ratings yet

- Finishing Concrete FlatworkDocument0 pagesFinishing Concrete Flatworkتوان امتياس سامسدينNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IGACOS Marine Sanctuary Park and ResortDocument74 pagesIGACOS Marine Sanctuary Park and ResortPlusNo ratings yet

- Registration of Hindu Marriage: A Project On Family Law-IDocument22 pagesRegistration of Hindu Marriage: A Project On Family Law-Iamit dipankarNo ratings yet

- Pipe TobaccoDocument6 pagesPipe TobaccoVictorIoncuNo ratings yet

- Polymer LedDocument14 pagesPolymer LedNaveenNo ratings yet

- Solved Rail Chapter 1Document7 pagesSolved Rail Chapter 1spectrum_48No ratings yet

- Battle Healing PrayerDocument9 pagesBattle Healing PrayerSolavei LoanerNo ratings yet

- Sikament®-4101 NS: Product Data SheetDocument2 pagesSikament®-4101 NS: Product Data SheetShihab AhamedNo ratings yet

- Atomic Structure Worksheet: Name PeriodDocument4 pagesAtomic Structure Worksheet: Name Periodapi-496534295100% (1)

- OSCE Pediatric Dentistry Lecture-AnswersDocument40 pagesOSCE Pediatric Dentistry Lecture-AnswersR MNo ratings yet

- National Step Tablet Vs Step Wedge Comparision FilmDocument4 pagesNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarNo ratings yet

- Cell Organelles 2Document13 pagesCell Organelles 2Sadeeq ur RahmanNo ratings yet

- Microbiiology Lab LayoutDocument9 pagesMicrobiiology Lab LayoutNageswara raoNo ratings yet

- WaterproofingDocument38 pagesWaterproofingPranay GandhiNo ratings yet

- Fishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerDocument23 pagesFishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerAli AliNo ratings yet

- ms1471pt5-99 - Vocabulary Smoke ControlDocument8 pagesms1471pt5-99 - Vocabulary Smoke ControlBryan Ng Horng HengNo ratings yet

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldDocument12 pages(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationNo ratings yet

- FPSB 2 (1) 56-62oDocument7 pagesFPSB 2 (1) 56-62ojaouadi adelNo ratings yet

- ErostorysDocument19 pagesErostorysMayLiuNo ratings yet

- Moody's Financial Metrics 2007Document35 pagesMoody's Financial Metrics 2007Adrian IlieNo ratings yet

- Hemorrhagic Shock (Anestesi)Document44 pagesHemorrhagic Shock (Anestesi)Dwi Meutia IndriatiNo ratings yet

- Electro Acupuncture TherapyDocument16 pagesElectro Acupuncture TherapyZA IDNo ratings yet

- Elephantgrass Bookchapter PDFDocument22 pagesElephantgrass Bookchapter PDFMuhammad rifayNo ratings yet

- Colonel SandersDocument17 pagesColonel SandersAmandaNo ratings yet

- Test Unit 2 Urbanisation L P 12Document9 pagesTest Unit 2 Urbanisation L P 12Xuân NguyenNo ratings yet

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDocument51 pagesFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESNo ratings yet

- Wetted Wall Gas AbsorptionDocument9 pagesWetted Wall Gas AbsorptionSiraj AL sharifNo ratings yet

- 2006 SM600Document2 pages2006 SM600Ioryogi KunNo ratings yet

- People v. Jerry BugnaDocument1 pagePeople v. Jerry BugnaRey Malvin SG PallominaNo ratings yet

- P13Document21 pagesP13Saeful AzizNo ratings yet

- Steen Kamp 2021Document16 pagesSteen Kamp 2021LARANSA SOLUNA GOGO SIMATUPANGNo ratings yet