Professional Documents

Culture Documents

Fastener Fundamentals

Uploaded by

Iho1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fastener Fundamentals

Uploaded by

Iho1Copyright:

Available Formats

AISCLiveWebinar

January23,2014

FastenerFundamentals

FASTENER

FUNDAMENTALS

Chad Larson

Vice President

LeJeune Bolt Company

AISC Live Webinars

Thank you for joining us. The presentation

will begin shortly. Please standby.

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

AISC Live Webinars

Todays audio will be broadcast through the

internet.

Alternatively, to hear the audio through the phone,

dial 800 272 5460.

Theres always a solution in steel

AISC Live Webinars

Todays live webinar will begin shortly.

Please standby.

As a reminder, all lines have been muted. Please type any

questions or comments through the Chat feature on the left

portion of your screen.

Todays audio will be broadcast through the internet.

Alternatively, to hear the audio through the phone, dial

800 272 5460..

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

AISC Live Webinars

AISC is a Registered Provider with The American Institute of

Architects Continuing Education Systems (AIA/CES). Credit(s)

earned on completion of this program will be reported to AIA/CES

for AIA members. Certificates of Completion for both AIA members

and non-AIA members are available upon request.

This program is registered with AIA/CES for continuing professional

education. As such, it does not include content that may be

deemed or construed to be an approval or endorsement by the AIA

of any material of construction or any method or manner of

handling, using, distributing, or dealing in any material or product.

Questions related to specific materials, methods, and services will

be addressed at the conclusion of this presentation.

Theres always a solution in steel

AISC Live Webinars

Copyright Materials

This presentation is protected by US and International

Copyright laws. Reproduction, distribution, display and

use of the presentation without written permission of AISC

is prohibited.

The American Institute of Steel Construction 2013

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

Course Description

Fastener Fundamentals

January 23, 2014

Structural fasteners are a critical part of most steel structures. This

webinar will cover a broad range of topics including fastener strength,

selection criteria, available coatings and testing. This overview will go

beyond the standards and specifications and provide users and

specifiers with helpful background information and intent, as well as

practical strategies to keep projects trouble free.

Theres always a solution in steel

Learning Objectives

Gain an understanding of the basics of bolting.

Gain an understanding of the background and intent

of standards and specifications for fasteners.

Become familiar with fastener coatings and testing.

Gain an understanding of practical design strategies

for fasteners.

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

FASTENER

FUNDAMENTALS

Chad Larson

Vice President

LeJeune Bolt Company

ABOUT THE PRESENTER

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

Chad Larson

25 years in fastener manufacturing and distribution with an

emphasis on continuous improvement

Background in production, quality, sales and management

Former RCSC/ASTM Liaison

Former Secretary/Treasurer of the Research Council on

Structural Connections

Vice Chair of ASTM F16 Fastener Committee

Chair of ASTM F16.02 Bolt, Nut, Washer Subcommittee

Chair of the F16.02.02 Structural Bolt Task Group

Chair of the Rotational Capacity Testing Task Group

What We Will Cover

Why should you know more about bolts

Organizations responsible for bolted connections

How nuts and bolts are made basics

Bolting basics rules of thumb

Threads understanding terms

Shear

Lubrication

Bolt types

Coatings

Jobsite requirements - basic

Installation methods - overview

Rotational capacity testing

12

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

What We Will Not Cover

Hydrogen embrittlement

Stress corrosion cracking

Fatigue

Deformation or embedment

Prying action

Load reversal or compressive forces

Heat Treatment

Hole sizes

Washer requirements

Inspection methods

Arbitration inspection

13

Forces on a Bolted Connection

See Geoff Kulaks presentation - AISC

http://www.aisc.org/content.aspx?id=4502

14

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

Why You Should Know

Understanding bolts will help you make more informed

engineering decisions

Understanding bolts will help make your intentions and

requirements clear downstream

Making informed decisions will decrease the likelihood of

problems down the road

Preventing problems prevents compromise

The difference between panic and understanding is slight,

but can mean thousands of dollars

Your intentions do not always make it to the project

15

IT TAKES AN ARMY

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

Bolted Connection

AISC

Bolted

Connection

RCSC

ASTM

17

Organizations

AISC American Institute of Steel Construction

Not-for-profit technical institute and trade association established in

1921 to serve the structural steel design community and

construction industry in the United States. AISCs mission is to

make structural steel the material of choice by being the leader in

structural-steel-related technical and market-building activities

Research

Standardize

Educate

Promote

18

Copyright2014

AmericanInstituteofSteelConstruction

AISCLiveWebinar

January23,2014

FastenerFundamentals

Organizations

RCSC Research Council on Structural Connections

The RCSC is a non-profit, volunteer organization, comprised of

over 90 leading experts in the fields of structural steel connection

design, engineering, fabrication, erection and bolting. Research

projects funded by the RCSC serve to provide safety, reliability, and

standard practice for the steel construction industry throughout the

world.

Research

Convert research to practical application

Specification for Structural Joints Using High-Strength Bolts

Can be found in your AISC manual, at http://aisc.org/freepubs or at

http://boltcouncil.org/files/2009RCSCSpecification.pdf

19

Organizations

ASTM International Formerly known as American

Society of Testing and Materials

Globally recognized leader in the development and delivery of

international voluntary consensus standards. Today, some 12,000

ASTM standards are used around the world to improve product

quality, enhance safety, facilitate market access and trade, and

build consumer confidence.

F16 Fastener Committee is 225 of the 30,000 ASTM members.

Maintain Structural Bolt, Nut, Washer and related standards

All Volunteer

No Technical Staff

20

Copyright2014

AmericanInstituteofSteelConstruction

10

AISCLiveWebinar

January23,2014

FastenerFundamentals

Organizations

ASTM and RCSC are all volunteer

Are never aligned in real time

A number of errors in ASTM structural bolt standards,

updates and balloting take a long time

21

HOW ARE BOLTS AND

NUTS MADE?

Copyright2014

AmericanInstituteofSteelConstruction

11

AISCLiveWebinar

January23,2014

FastenerFundamentals

Typical Cold Forming Progression

23

Cold Forming

24

Copyright2014

AmericanInstituteofSteelConstruction

12

AISCLiveWebinar

January23,2014

FastenerFundamentals

Cold Forming Progression

Steel Coils

(Typical)

Anneal

(Depends)

Pickle and

Coat

Quench and

Temper Heat

Treatment

Cold Form by

Heading &

Roll Threading

Draw Wire to

Size

Plating or

Coating if

required

Inspection

Packaging

25

Cold Forming

http://youtu.be/3kxcw08p_oY

Cold Forming

Good for high volume runs, often highly automated

Typically done on 4 or 5 station high speed cold forming machines,

with 60 to 120 ppm typical

Expensive tooling

Long changeover time

Generally very good tolerance control

Generally longer tool life than hot forging

Almost always rolled threads

Generally cleaner surface finish

26

Copyright2014

AmericanInstituteofSteelConstruction

13

AISCLiveWebinar

January23,2014

FastenerFundamentals

Bolt Hot Forging

27

Hot Forging/Forming

Hot Forging/Hot Forming

Better for low volume runs, large diameters or long lengths

High temperature via electric induction heaters or gas

Hot forged bolts more likely to have seams, fins or swells

Hot forged bolts more likely to have cut threads, but rolled threads

are available from many manufacturers

In most instances hot forging is a very manual process

Greater range of diameters and lengths available with hot forging

Bolts often made from blanks to speed delivery

Some mill and heat scale

28

Copyright2014

AmericanInstituteofSteelConstruction

14

AISCLiveWebinar

January23,2014

FastenerFundamentals

Thread Rolling

29

How Are Nuts Made?

30

Copyright2014

AmericanInstituteofSteelConstruction

15

AISCLiveWebinar

January23,2014

FastenerFundamentals

Hot Forming Progression

Steel in Bars

Hot Form

Nut Blank

Descale

(Sometimes)

Plating or

Coating if

Required

Tapping

Quench and

Temper Heat

Treat

Lubrication if

Required

Inspection

Packaging

31

BOLTING BASICS

Things you should understand

Copyright2014

AmericanInstituteofSteelConstruction

16

AISCLiveWebinar

January23,2014

FastenerFundamentals

Terms

Clamp Force: the cumulative compressive force between joint

members due to the tensile force created in tightened fasteners

Elastic Interaction: in a bolted joint with multiple fasteners,

variation in individual fastener preload due to tightening of the

other fasteners

Embedment: localized yielding of bolted joint components

resulting in a change of grip length consequently causing

relaxation of the bolted joint

Grip Length: the combined thickness of all components joined

together between the bolt head and nut

Nut Factor: an empirically determined constant that models

many variables, such as friction, that affect the torque-tension

relationship.

Preload: the tensile force developed during installation

33

Understanding the Curve

Image courtesy of Fastenal

34

Copyright2014

AmericanInstituteofSteelConstruction

17

AISCLiveWebinar

January23,2014

FastenerFundamentals

Torque Tension Angle Curve

35

Bolting Basics

Nuts should be stronger than bolts

The more bolt threads in the grip the better, worry more about

shank-out than stick-out

Lubrication is essential to performance

Torque can be a good indicator of tension if controlled

Roll threaded bolts are stronger than cut threaded bolts

Fine threaded bolts are stronger and more vibration resistant

36

Copyright2014

AmericanInstituteofSteelConstruction

18

AISCLiveWebinar

January23,2014

FastenerFundamentals

Bolting Basics

Large parts are much more difficult to heat treat properly

For large diameters be sure to consider die fins or

possible body swells and hole size

Long bolts can be difficult to keep straight, consider this

when going through many thick plies

Most stress on the first few nut threads nearest the grip

Many quality problems are a result of poor heat treatment

or thread quality/fit

37

Torque is Valuable, but Complicated

Torque is a great means of fit up and snugging

Torque is very accurate when controlled

Torque can provide very uniform loading

Torque is wildly variable and cumbersome the way our

industry uses it

Torque when installing from the head can be quite

different that torque when installing from the nut, how did

you do your pre-installation test?

38

Copyright2014

AmericanInstituteofSteelConstruction

19

AISCLiveWebinar

January23,2014

FastenerFundamentals

THREADS

Bolt and Nut Threads

There are over 120 elements to thread design

Standards allow us to ignore most of those elements, but

a few are important to understand

Inch series structural bolts are always Unified Coarse,

Class 2A tolerance

Threads do not load evenly

40

Copyright2014

AmericanInstituteofSteelConstruction

20

AISCLiveWebinar

January23,2014

FastenerFundamentals

Threads Continued

Rolled threads can be 5 to 15 percent stronger,

depending on the grade of fastener, but cut threads can

meet specifications

Many quality issues are the result of threads or functional

thread fit

Structural bolts have much shorter threads than standard

cap screws

41

Understanding Threads

42

Copyright2014

AmericanInstituteofSteelConstruction

21

AISCLiveWebinar

January23,2014

FastenerFundamentals

Basic Thread Terms

43

Pitch vs. Pitch Diameter (P.D.)

Pitch is simply thread spacing

Inch series in TPI or 7/8-9 x 2 is 9 Threads Per Inch

Metric series in individual spacing M22 x 2.5 x 40 is 2.5mm

between threads

Ex. UNF is 7/8-14 x 2

Ex. UNC is 7/8-9 x 2

Pitch does not equal fit

You cannot put a 1-8 nut on a 2-8 bolt

44

Copyright2014

AmericanInstituteofSteelConstruction

22

AISCLiveWebinar

January23,2014

FastenerFundamentals

Pitch vs. Pitch Diameter (P.D.)

We need a means of determining the physical thread size

for a given pitch (spacing) and nominal diameter

The thread pitch diameter is the diameter of a cylindrical surface,

axially concentric to the thread, which intersects the thread flanks

at equidistant points.

Diameter across threads from theoretic thread centerlines

Pitch diameter is the functional size of a given thread form

Many manufacturers do not measure pitch directly

Coatings significantly change pitch diameter but not pitch

45

Understanding Threads

46

Copyright2014

AmericanInstituteofSteelConstruction

23

AISCLiveWebinar

January23,2014

FastenerFundamentals

Understanding Thread PD

47

Thread Profile Standard Tap

48

Copyright2014

AmericanInstituteofSteelConstruction

24

AISCLiveWebinar

January23,2014

FastenerFundamentals

Thread Profile Over-Sized

49

Thread Profile Over-Sized

50

Copyright2014

AmericanInstituteofSteelConstruction

25

AISCLiveWebinar

January23,2014

FastenerFundamentals

Thread Profile Over-Sized

51

Single Point Measurement

52

Copyright2014

AmericanInstituteofSteelConstruction

26

AISCLiveWebinar

January23,2014

FastenerFundamentals

Multi Point Measurement

53

Thread Class

54

Copyright2014

AmericanInstituteofSteelConstruction

27

AISCLiveWebinar

January23,2014

FastenerFundamentals

Thread Lengths Not All Equal

55

Mating Components

Improperly mated

Improperly mated

56

Copyright2014

AmericanInstituteofSteelConstruction

28

AISCLiveWebinar

January23,2014

FastenerFundamentals

SHEAR

Understanding Shear

58

Copyright2014

AmericanInstituteofSteelConstruction

29

AISCLiveWebinar

January23,2014

FastenerFundamentals

Understanding Shear

Threads EXcluded

Threads INcluded

59

LUBRICATION

Understanding the K or Nut Factor

Copyright2014

AmericanInstituteofSteelConstruction

30

AISCLiveWebinar

January23,2014

FastenerFundamentals

K

Within the elastic range, before permanent stretch, the

relationship between torque and tension is linear

Over 50 variables have an effect on this relationship:

surface roughness, temperature, rate of installation, helix

angle, stiffness, and humidity to name a few.

Typical values for applications are:

K = 0.20 as-received bolts and nuts, no supplemental lubrication

(This can be highly variable)

K = 0.10 to 0.17 bolts and nuts with wax or other lubricant

K = 0.28 bolts with HDG coating, no lubricant

61

K Factor or Nut Factor

The friction relationship or K-factor between applied torque and the resulting

fastener tension. The following formula can be used to get the K factor if the torque

and tension are known.

K= T/N * 12/D

Where:

K = K or nut factor

T = Torque

N = Bolt Tension

D = Nominal bolt diameter

Example: x 2 TC Bolt. 300 ft. lbs. torque at 35,000 lbs. clamp load.

K= (300/35000) * (12/.750) = .137

Solving for Torque the equation becomes T= KDN/12

62

Copyright2014

AmericanInstituteofSteelConstruction

31

AISCLiveWebinar

January23,2014

FastenerFundamentals

Lubrication

63

Lubrication or Coating K Factor

64

Copyright2014

AmericanInstituteofSteelConstruction

32

AISCLiveWebinar

January23,2014

FastenerFundamentals

Lubrication

Lubrication

Paint

adhesion

65

Lubrication

66

Copyright2014

AmericanInstituteofSteelConstruction

33

AISCLiveWebinar

January23,2014

FastenerFundamentals

STRUCTURAL BOLTS

Structural Bolt Grades

120 KSI Min

Tensile

Group A

150 KSI Min

Tensile

Group B

A325

A490

A325M

A490M

F1852

F2280

68

Copyright2014

AmericanInstituteofSteelConstruction

34

AISCLiveWebinar

January23,2014

FastenerFundamentals

Structural Bolt Types

Type 1

Carbon Steel

Type 3

Weathering Steel

A325

Group A

A325

Group A

A325M

Group A

A325M

Group A

F1852

Group A

F1852

Group A

A490

Group B

A490

Group B

A490M

Group B

A490M

Group B

F2280

Group B

F2280

Group B

69

Structural Bolt Styles

Heavy

Hex Head

Twist-Off

A325

Group A

F1852

Group A

A325M

Group A

F2280

Group B

A490

Group B

A490M

Group B

70

Copyright2014

AmericanInstituteofSteelConstruction

35

AISCLiveWebinar

January23,2014

FastenerFundamentals

Structural Bolts

Strength

Ductility

71

Structural Bolts

150 KSI

Group B

120 KSI

Group A

72

Copyright2014

AmericanInstituteofSteelConstruction

36

AISCLiveWebinar

January23,2014

FastenerFundamentals

Other Standards Used

Heavy hex nuts

A563 Grade C, C3 - Group A, plain only

C3 for weathering applications

A563 Grade DH, DH3 - Group A or B, plain or coated

DH3 for weathering applications

Washers

F436 T1 - Group A or B, plain or coated

F436 T3 Group A or B for weathering applications

73

Other Standards Used

When to use other bolt grades

A449

A354

Head dimensions, configuration or geometry

Over 1-1/2 A490

Thread length deviation

Coatings

74

Copyright2014

AmericanInstituteofSteelConstruction

37

AISCLiveWebinar

January23,2014

FastenerFundamentals

What you should know about A354BD

Dimensions not heavy hex unless you specify

Consider specifying max tensile

Consider Carb/Decarb testing

Consider Magnetic Particle testing

Be careful with thread length

From ASTM A354 When bolts of Grade BD of this specification are

considered for pretentioned applications in excess of 50 % of the bolt

tensile strength, the additional requirements of head size, maximum

tensile strength, nut size and strength, washer hardness, tests, and

inspections contained in Specification A490 should be carefully

considered.

75

COATINGS

Copyright2014

AmericanInstituteofSteelConstruction

38

AISCLiveWebinar

January23,2014

FastenerFundamentals

Coatings on Structural Bolts

B695 Zinc Mechanically Deposited Group A Only

F2329 Zinc Hot Dip Group A except Twist-Off

F1136 Zinc/Aluminum Group A or B except Twist-Off

F2833 Zinc Rich Base Coat and Aluminum

Organic/Inorganic Type Group A or B except Twist-Off

F1941 Electrodeposited Coatings Group A Hex Only

77

Coatings on Structural Bolts

Others possible for 120KSI Grades (Group A)

Others coming for 150KSI Grades (Group B)

Not always done by the manufacturer

Significantly effect thread fit and K Factor

78

Copyright2014

AmericanInstituteofSteelConstruction

39

AISCLiveWebinar

January23,2014

FastenerFundamentals

Coatings on Structural Bolts

Thickness only measured on significant surfaces

Not typically corrosion tested on a lot by lot basis

HDG on external threads only

Thread oversizing tolerances for newer coatings on A490

fasteners have not been standardized yet

79

Understanding Thread Fit - Coatings

Nut threads need to be oversized for most coatings

Oversizing the pitch diameter for clearance increases the

nut minor diameter

Oversized nuts have less proof load capacity

Oversizing may change failure modes from bolt tensile

failure to thread stripping

Bolt tensile and nut proof load testing are performed with

fixtures, results do not correlate to fastener assemblies

Care should be taken not to over-tension coated

fasteners

Understand the specifics of your selected coating

80

Copyright2014

AmericanInstituteofSteelConstruction

40

AISCLiveWebinar

January23,2014

FastenerFundamentals

Coatings Example Zinc Aluminum Flake

Bolt

Grade 3

Washer

F1136

Grade 5

Nut

http://www.boltcouncil.org/files/F1136Bulletin.pdf

81

Coatings Are Not Elastic

82

Copyright2014

AmericanInstituteofSteelConstruction

41

AISCLiveWebinar

January23,2014

FastenerFundamentals

JOBSITE REQUIREMENTS

See RCSC specification for details

Storage and Handling

Properly Stored

Properly Stored

84

Copyright2014

AmericanInstituteofSteelConstruction

42

AISCLiveWebinar

January23,2014

FastenerFundamentals

Storage and Handling

Not Properly Stored

Not Properly Handled

85

Pre-installation Testing

86

Copyright2014

AmericanInstituteofSteelConstruction

43

AISCLiveWebinar

January23,2014

FastenerFundamentals

Tension Measuring Device

87

Should Be Present When Bolt Tension is

Required

88

Copyright2014

AmericanInstituteofSteelConstruction

44

AISCLiveWebinar

January23,2014

FastenerFundamentals

INSTALLATION METHODS

See RCSC specification for more details

Installation Types Tensioned or SC

Turn of Nut

Twist Off

RCSC

Calibrated

Wrench

Direct Tension

Indicator

90

Copyright2014

AmericanInstituteofSteelConstruction

45

AISCLiveWebinar

January23,2014

FastenerFundamentals

Snug Tight What is it?

All tensioning methods depend on achieving snug tight

condition first.

2000 2004 Rev. RCSC Specification

The snug-tightened condition is the tightness that is attained with a

few impacts of an impact wrench or the full effort of an ironworker

using an ordinary spud wrench to bring the plies into firm contact.

2009 Rev. RCSC Specification

Snug tight is the condition that exists when all of the plies in a

connection have been pulled into firm contact by the bolts in the

joint and all of the bolts in the joint have been tightened sufficiently

to prevent the removal of the nuts without the use of a wrench.

92

Snug Tight Process

93

Copyright2014

AmericanInstituteofSteelConstruction

46

AISCLiveWebinar

January23,2014

FastenerFundamentals

Snug Complete

94

Heavy Hex Assembly

95

Copyright2014

AmericanInstituteofSteelConstruction

47

AISCLiveWebinar

January23,2014

FastenerFundamentals

Heavy Hex Assembly

Snug only

Shear/bearing connection

Tensioned

Turn of Nut tension by elongation

Calibrated Wrench tension by calibrated torque

DTI (direct tension indicator) washer tension by compression

96

Non-impacting, Non-reacting Tools

Reaction arm to neighboring bolt

Reaction arm to steel or other

97

Copyright2014

AmericanInstituteofSteelConstruction

48

AISCLiveWebinar

January23,2014

FastenerFundamentals

Turn of The Nut

98

DTI Washer

99

Copyright2014

AmericanInstituteofSteelConstruction

49

AISCLiveWebinar

January23,2014

FastenerFundamentals

DTI

100

Twist Off Bolts

101

Copyright2014

AmericanInstituteofSteelConstruction

50

AISCLiveWebinar

January23,2014

FastenerFundamentals

Twist-Off Bolts

Single side installation

Visual indicator

Calibrated torque

102

103

Copyright2014

AmericanInstituteofSteelConstruction

51

AISCLiveWebinar

January23,2014

FastenerFundamentals

104

105

Copyright2014

AmericanInstituteofSteelConstruction

52

AISCLiveWebinar

January23,2014

FastenerFundamentals

Single Side, Non-impacting, Non-reacting

Pneumatic

Electric

106

ROTATIONAL CAPACITY

Copyright2014

AmericanInstituteofSteelConstruction

53

AISCLiveWebinar

January23,2014

FastenerFundamentals

Rotational Capacity Test

Applicable to coated fasteners by ASTM

Required on all assembly lots for bridge work

Good, but extreme functional test of fasteners

What if connection only requires snug tight

Test generally tied to double the Turn of Nut installation

requirement

Should be modified for Group B fasteners

108

Rotational Capacity Test

ASTM

Established by F16.02 for HDG bolts as a result of research that showed galvanized fasteners

could not reliably reach minimum installation tension prior to torsional failure when HDG.

Expanded to cover Mechanically Galvanized fasteners when B695 was added to A325.

A means to test lubrication, which is required to prevent galling at the thread interface and

bearing surface.

Simple Pass/Fail test. You never know if you almost failed.

Vague manufacturer requirement in A325, A325M and RCSC.

End user confusion and difficult enforcement.

Assuming bolt meets specification, test is primarily a function of nut (or coating) lubrication but is

part of bolt specification

Loosely based on the required degrees of turn for the Turn of Nut RCSC installation method, x2.

Primary criteria tested

Thread fit (proper oversize to avoid interference fit)

Mating thread strength (functional overlap) not using fixtures, considers zipper effect

Lubrication (too little causes torsional failure)

Bolt ductility (Extreme plastic performance or stretch beyond yield)

109

Copyright2014

AmericanInstituteofSteelConstruction

54

AISCLiveWebinar

January23,2014

FastenerFundamentals

Rotational Capacity Testing

AASHTO and FHWA, recognizing the benefits of the test, lubrication in particular, established a similar

test, adding the requirement that the test be performed on ALL fasteners.

Test is more involved

Torque component

Max torque permitted at minimum tension (via max K factor)

Minimum tension at final rotation of 1.15 design tension

This test is a good general bolt performance requirement

These agencies primarily use bolts subject to high tension

Primary criteria tested

Strength (tensile)

Thread fit (proper oversize to avoid interference fit)

Thread strength (functional overlap) not using fixtures, considers zipper effect

Lubrication (too little causes torsional failure)

Ductility (Extreme plastic performance or stretch beyond yield)

110

Rotational Capacity Testing

Problems with the current RC tests

Required by ASTM at the manufacturer level, but should be at the

distribution and end user level

No way to place blame with the ASTM test. Hardware/Software dilemma

ASTM does not address plain fasteners, which can have the same issues

with lack of lubrication, particularly with Type 3 fasteners

Nature of the test makes variability inevitable. Particularly number of

washers, +/- angle tolerance, and number of threads in the grip

Not all fastener assemblies need this level of performance by design

Coatings often provide more lubricity than plain parts

3 different rotations for A325 inch, 5 different rotations for A325M

A490 often held to same criteria as A325, but A490 is much less ductile

AASHTO, FHWA cannot use ASTM test so they maintain their own

version

111

Copyright2014

AmericanInstituteofSteelConstruction

55

AISCLiveWebinar

January23,2014

FastenerFundamentals

112

113

Copyright2014

AmericanInstituteofSteelConstruction

56

AISCLiveWebinar

January23,2014

FastenerFundamentals

114

115

Copyright2014

AmericanInstituteofSteelConstruction

57

AISCLiveWebinar

January23,2014

FastenerFundamentals

116

117

Copyright2014

AmericanInstituteofSteelConstruction

58

AISCLiveWebinar

January23,2014

FastenerFundamentals

GENERAL

Unusual Aspects of Structural Bolting

Bolts are tensioned well into yield, this is a no-no in

virtually every other engineered fastener application

Bolts are not sold as matched sets in many cases

Thread lengths are very short, bolts tend to perform better

with longer threads

Acceptance testing done in the field, which is often the 1st

point of assembly

There is no industry requirement for K Factor

Snug tight as it pertains to fully tensioned bolts is highly

variable

119

Copyright2014

AmericanInstituteofSteelConstruction

59

AISCLiveWebinar

January23,2014

FastenerFundamentals

PROBLEMS

Most projects go as planned, but

What Can Happen?

Fatigue

Rust or Weathering

Coating Adhesion

Reamed Nut Threads

White Rust

Seams

Bursts

Poor Coating Thickness

Welded Parts

Storage and Handling Issues

Quench Cracks

Improper Washer Usage

Bolt Binding

Paint Adhesion

No Pre-installation Testing

Tensile Failure

Torsional Failure

Stress Corrosion Cracking

Hydrogen Embrittlement

Shank Out/Negative Stick-out

Low Tension

RC Test Failure

Inadequate Installation Tools

Lack of Installer Training

High or Low Hardness

Thread Stripping

No Control of Snug Tight

No Installation Clearance

Improper Mating Components

No Verification on Site

121

Copyright2014

AmericanInstituteofSteelConstruction

60

AISCLiveWebinar

January23,2014

FastenerFundamentals

Surface Discontinuities

Burst

Seam

122

Bursts Are Quite Common

Head burst

Head burst

123

Copyright2014

AmericanInstituteofSteelConstruction

61

AISCLiveWebinar

January23,2014

FastenerFundamentals

Burst, Seam or Crack?

Seam

Quench crack

124

Call Somebody

Quench crack

Quench crack

125

Copyright2014

AmericanInstituteofSteelConstruction

62

AISCLiveWebinar

January23,2014

FastenerFundamentals

Other Problems

Bad threads or lack of

engagement?

Adhesion or excessive impacting

or bound bolt?

126

Too brittle?

127

Copyright2014

AmericanInstituteofSteelConstruction

63

AISCLiveWebinar

January23,2014

FastenerFundamentals

Or Wrong Size?

128

Hot Forged, Split Die

Fin in specification

Fin profile with a bit of swell

129

Copyright2014

AmericanInstituteofSteelConstruction

64

AISCLiveWebinar

January23,2014

FastenerFundamentals

Misc. Problems

Coating Fixture Marks

Reamed Nut

130

Workmanship

Bolt problem or hole problem?

Wow

131

Copyright2014

AmericanInstituteofSteelConstruction

65

AISCLiveWebinar

January23,2014

FastenerFundamentals

Unfortunately Very Typical

132

Trained Installer, Match-Marked,

Witnessed, Signed-off, didnt break.

133

Copyright2014

AmericanInstituteofSteelConstruction

66

AISCLiveWebinar

January23,2014

FastenerFundamentals

Trained Installer, Match-Marked,

Witnessed, Signed-off, didnt break.

134

Same Connection Weeks Later

135

Copyright2014

AmericanInstituteofSteelConstruction

67

AISCLiveWebinar

January23,2014

FastenerFundamentals

Rust - How Much is Too Much?

Might be OK, but need

requalification

These are scrap

136

Good Reading

John H. Bickford, An Introduction to the Design and Behavior of

Bolted Joints. 3rd Edition.

Industrial Fasteners Institute, Fastener Standards, 8th Edition.

Industrial Fasteners Institute.

Geoffrey L. Kulak, John W. Fisher, John H. A. Struik, Guide to

Design Criteria for Bolted and Riveted Joints, second edition.

Geoffrey L. Kulak, High Strength Bolts: A Primer for Structural

Engineers, AISC.

PCB Load & Torque Knowledge Library

Understanding Torque-Angle Signatures of Bolted Joints

Fundamentals of Torque-Tension and Coefficient of Friction Testing

Engineering Fundamentals of Threaded Fastener Design and Analysis

137

Copyright2014

AmericanInstituteofSteelConstruction

68

AISCLiveWebinar

January23,2014

FastenerFundamentals

What Else Can You Do?

Get additional fastener training, a number of options exist

Get more familiar with the standards

Ask questions

Get involved in committee work

Work with reputable contractors and suppliers

Be willing to work through problems

138

Thank You

Copyright2014

AmericanInstituteofSteelConstruction

69

AISCLiveWebinar

January23,2014

FastenerFundamentals

CEU Certificates

Within 1 business day

You will receive an email on how to report attendance

from: steel@wyndhamjade.com

Be on the lookout: Check your spam filter! Check

your junk folder!

Completely fill out online form. Dont forget to check

the boxes next to each attendees name!

OR

Theres always a solution in steel

CEU Certificates

Access available in 24 hours

Go to:

http://www.wynjade.com/aisc14/webinarceu

Username: Your Attendee ID (found on your reg. receipt)

Password: Your Last Name

Completely fill out online form. Dont forget to check

the boxes next to each attendees name!

Questions? Please email us at webinars@aisc.org.

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

70

AISCLiveWebinar

January23,2014

FastenerFundamentals

AISC Webinars

February 13, 2014:

Design of Reinforcement for Steel Members Part II

Presented by Bo Dowswell, Arc International

www.aisc.org/webinars

Theres always a solution in steel

AISC Seminars

Spring 2014 Schedule has been released!

Seismic Design Manual and Application of the 2010 Seismic

Provisions

24 cities this spring

www.aisc.org/seminars

Theres always a solution in steel

Copyright2014

AmericanInstituteofSteelConstruction

71

AISCLiveWebinar

January23,2014

FastenerFundamentals

AISC Night School

Fundamentals of Earthquake Engineering for Building Structures

Presented by Rafael Sabelli, Walter P Moore

Class begins February 24, 2014!

www.aisc.org/nightschool

Theres always a solution in steel

Thank You

Please fill out a brief survey at the conclusion of the

webinar. Your feedback is greatly appreciated.

Copyright2014

AmericanInstituteofSteelConstruction

72

You might also like

- Stiffeners and Doublers Handout - 2per PDFDocument61 pagesStiffeners and Doublers Handout - 2per PDFIho1No ratings yet

- Building Strengthening, Repair and ReconstructionDocument23 pagesBuilding Strengthening, Repair and ReconstructionPraveesh AmbalathodyNo ratings yet

- AISC (Iwankiw&Griffis) Comparison Struct Perform Multistory Bldgs 2004Document60 pagesAISC (Iwankiw&Griffis) Comparison Struct Perform Multistory Bldgs 2004Iho1No ratings yet

- Bu Mat 05VCC PJostDocument19 pagesBu Mat 05VCC PJostIho1No ratings yet

- Betonski KolovozDocument40 pagesBetonski KolovozНенад СтијељаNo ratings yet

- Strength of In-Place ConcreteDocument3 pagesStrength of In-Place ConcreteIho1No ratings yet

- Concrete Repair & Restoration (Sika)Document37 pagesConcrete Repair & Restoration (Sika)Dinn Ns100% (2)

- Module A Structural Analysis Suscos 2013 2014 l4 WaDocument23 pagesModule A Structural Analysis Suscos 2013 2014 l4 Waec04017No ratings yet

- WLG2445 - Chain Link FenceDocument38 pagesWLG2445 - Chain Link FenceIho1No ratings yet

- Design of An Industrial Crane Building Session 5 PDFDocument18 pagesDesign of An Industrial Crane Building Session 5 PDFIho1100% (1)

- The Infrastructure Crisis: A Trillion Dollar Challenge: Nemy Banthia and Axel MeisenDocument37 pagesThe Infrastructure Crisis: A Trillion Dollar Challenge: Nemy Banthia and Axel MeisenIho1No ratings yet

- Where Did That Force Come FromDocument54 pagesWhere Did That Force Come FromIho1No ratings yet

- Discussion - Failure of Simply-Supported Flat Roofs by Ponding of RainDocument1 pageDiscussion - Failure of Simply-Supported Flat Roofs by Ponding of RainIho1No ratings yet

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Modelling of Diaphrams in STAAD Pro PDFDocument13 pagesModelling of Diaphrams in STAAD Pro PDFragalwarNo ratings yet

- Large SpanDocument27 pagesLarge SpanManishJangidNo ratings yet

- Design of Reinforcement For Steel Members-1Document58 pagesDesign of Reinforcement For Steel Members-1Iho1No ratings yet

- Stainless Steel BrochureDocument42 pagesStainless Steel BrochureNedret BajramovicNo ratings yet

- Diaphragm Presentation3Document78 pagesDiaphragm Presentation3Iho1100% (3)

- Response of Floor Systems Due To Walking - Vibration PDFDocument91 pagesResponse of Floor Systems Due To Walking - Vibration PDFIho1No ratings yet

- ASCE Anchor Bolt Design For Petrochemical Facilities PDFDocument27 pagesASCE Anchor Bolt Design For Petrochemical Facilities PDFIho1No ratings yet

- Failure of Steel-Concrete ConnectionDocument7 pagesFailure of Steel-Concrete ConnectionIho1No ratings yet

- 7 1Document69 pages7 1Ardian Rizardhi SatyagrahaNo ratings yet

- DN 11Document6 pagesDN 11tastaman123No ratings yet

- Cruciform Sections + NSCApril06 - TechDocument3 pagesCruciform Sections + NSCApril06 - TechIho1No ratings yet

- Kalzip ConstructiondetailsDocument87 pagesKalzip ConstructiondetailsIrina PlopeanuNo ratings yet

- Checkered PlateDocument2 pagesCheckered PlateIho1No ratings yet

- Thru Anchors - French BookDocument1 pageThru Anchors - French BookIho1No ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- Slotted Holes and Expansion Joint FailureDocument1 pageSlotted Holes and Expansion Joint FailureIho1No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CHE-026L: Identify Organic and Inorganic CompoundsDocument12 pagesCHE-026L: Identify Organic and Inorganic CompoundsZeian Jacob BaylaNo ratings yet

- 03.ASTM A572-15 - Eqv. A709Gr50Document4 pages03.ASTM A572-15 - Eqv. A709Gr50Mauricio_Vera_525950% (2)

- Dissolution Improvement of Telmisartan by Surface Solid Dispersion MethodDocument5 pagesDissolution Improvement of Telmisartan by Surface Solid Dispersion MethodHafidz PrasetyaNo ratings yet

- Carbon CompositesDocument30 pagesCarbon CompositesVIbhav GuptaNo ratings yet

- Iso 16373-1-2015Document24 pagesIso 16373-1-2015Irfan ShafiqNo ratings yet

- Laporan Lengkap Analitik Unit 3Document55 pagesLaporan Lengkap Analitik Unit 3Fitri NurkhalizaNo ratings yet

- Slip Form HandbookDocument301 pagesSlip Form HandbookAhmed Mostafa AL-Aboudy67% (3)

- ProblemsDocument2 pagesProblemsJoisy Sarco CondoriNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelmalsttarNo ratings yet

- Protocol Calcofluor MutDocument3 pagesProtocol Calcofluor Mutrck46No ratings yet

- IEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireDocument12 pagesIEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireEnzo Ochoa100% (1)

- MEC102 Engineering Mechanics Course OverviewDocument1 pageMEC102 Engineering Mechanics Course OverviewVkrthirumalai RamanathanNo ratings yet

- THE HIGH PRESSURE ROLLER PRESSDocument27 pagesTHE HIGH PRESSURE ROLLER PRESSThaigroup Cement100% (10)

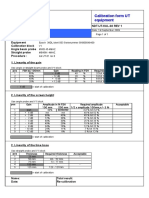

- Calibration Sheet Ultrasonic Test EquipmentDocument1 pageCalibration Sheet Ultrasonic Test EquipmentjohnNo ratings yet

- ISA-TR20.00.01 CD-ROM Table of Contents PDFDocument5 pagesISA-TR20.00.01 CD-ROM Table of Contents PDFmegojasNo ratings yet

- c1 - Intermolecular ForcesDocument69 pagesc1 - Intermolecular ForcesNabilah MustafaNo ratings yet

- Role of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless SteelDocument5 pagesRole of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless Steelherschel5No ratings yet

- SSS076 Bioreactors and FermentersDocument1 pageSSS076 Bioreactors and Fermentersasim zeshanNo ratings yet

- A Snapshot of The Drilling and Completio N Practices in High Temperature Geothermal Wells - SarmientoDocument13 pagesA Snapshot of The Drilling and Completio N Practices in High Temperature Geothermal Wells - SarmientoAdil AytekinNo ratings yet

- Tutorial - Gas Turbine CyclesDocument3 pagesTutorial - Gas Turbine CyclesSuchi Suchi SuchiNo ratings yet

- Enthalpy Method PDFDocument2 pagesEnthalpy Method PDFsimmaNo ratings yet

- How to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreDocument2 pagesHow to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreNo PersonNo ratings yet

- Polishing DefectsDocument6 pagesPolishing DefectsDaole VanNo ratings yet

- Fluoride, SPADNS Method 8029, 02-2009, 9th EdDocument7 pagesFluoride, SPADNS Method 8029, 02-2009, 9th EdAnonymous FRAdEnNo ratings yet

- Properties of SoilDocument18 pagesProperties of Soiltouqeer AbroNo ratings yet

- BMW Fault Codes OBDDocument15 pagesBMW Fault Codes OBDtitibacsiNo ratings yet

- Material QuizDocument22 pagesMaterial QuizMr Nerd100% (3)

- Briggs and Stratton Model Series 90000Document20 pagesBriggs and Stratton Model Series 90000b0beiiiNo ratings yet

- Fresher Course Chemistry Practice ProblemsDocument2 pagesFresher Course Chemistry Practice ProblemsHarsh Agarwal0% (1)

- Chapter 8 EXERGYDocument37 pagesChapter 8 EXERGYzabidullahNo ratings yet