Professional Documents

Culture Documents

Ring Blower Vacuum Pump Catalog (Total) 2 PDF

Uploaded by

DSddsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ring Blower Vacuum Pump Catalog (Total) 2 PDF

Uploaded by

DSddsCopyright:

Available Formats

ELMO-F Vacuum Units with Vacuum Pumps,

Range 2BE

Selection example

Application:

Vacuum Pumps

Compressors

100.000

m /h

30.000

10.000

10.000

Hybrid

systems

with roots

fans

Hybrid gas-jet

systems

Single-stage

liquid-ring

vacuum pumps

2BV or 2BE

Single-stage,

double-action

liquid-ring

compressors

2BK, also

combined with

2BE

Single-stage,

single action

liquid-ring

vacuum pumps

2BV or 2BE

100

0,001

0,01

0,03

0,1

1,013

0,2

0,2

a Duty point:

.

V = 570 m3/h at 50 Hz

p1 = 100 mbar

m /h

3

30.000

1000

e.g. foundry machines, casting technology

100.000

Multipump systems

10

Vacuum in bar

14

d Selection and order code:

ELMO-F vacuum unit with

vacuum pump 2BE1 153 - 0

No. 157 E r Type 2BE1 153-0BY4-Z

F43+F44+F97

Motor 1LA5 183 - 4AA60 1)

Note:

When ordering motor, always

indicate as separate item.

1000

Double-stage

liquid-ring

compressors

2BG, also

combined with

2BE

s Choose the performance curve which lies closest to the

duty point a. In this example, No. 157 E

100

ELMO systems as standard

or customer-specific

solutions covering a wide

range of uses:

from

1 mbar to 14 bar,

from

10 to 100,000 m3/h

20

Pressure in bar

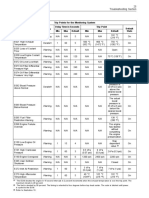

Selection and ordering examples for applications in the machine tools industry

Selection diagram

Suction capacity V

3000

APV-5018e

m3/h

253E

2000

2) Motor should be ordered separately. For prices, other voltages etc.,

see Siemens price list M11.

3) Permissible voltage range:

Degree of

protection

Rated voltage

acc. to

DIN IEC 38

perm. Voltage range

acc. to DIN VDE or

DIN IEC 34-1

IP 55

400 V D / 690 V Y **

EEx e II T3

400 V D / 690 V Y **

380...420 V D /

660...725 V Y ***

400 V D / 690 V Y *

* Voltage tolerance here 5%

** Voltage tolerance here 10%

1500 252E

*** This voltage range is also shown on the rating plate, together with

the currents occuring in this range. For this range, the permissible

voltage tolerance acc. to DIN VDE 0530 or IEC 34-1 is 5%

1000 203E

4) Based on operating duty Standard for inlet pressures:

2BE1: < 200 / W 200 mbar abs.

800

600

400

5) Measuring-surface sound-pressure level acc. to EN 21680-1,

measured at 1 m distance in a free field, at medium inlet pressure

and with inlet and discharge pipes connected. Tolerance: +3 dB.

202E

157E

300

30

1 2

Selection

example

50

6) Special materials of construction, gaskets, motors and expanded

scope of supply available on request.

Suction capacities from

20 to 500 m3 /h on request

80 100

200 300

500 mbar 1013

Inlet pressure (abs.) p 1

1) Scope of supply:

2BE1: vacuum pump with internal sealant supply, complete with

mounted manifold, discharge-liquid separator, coupling, coupling

guard and baseplate; without motor.

7) See accessories.

8) Including motor.

For dimensions, see page 61.

The selection diagram corresponding to PNEUROP with a tolerance of 10% for:

The evacuation of 100% saturated air with a temperature of 20 C (68 F).

Discharge pressure is 1013 mbar.

The operating liquid is water with a temperature of 15 C (59 F).

Selection and ordering information

Curve

No.

Motor

Rated

output

Vacuum pump

Motor - Order No. 2)

Rated

voltage 3)

Rated

current

1LA5 183 - 4AA60

1MA6 186 - 4BC80

1LA5 207 - 6AA60

1MA6 207 - 6BC80

1LA5 223 - 6AA60

1MA6 253 - 6BC80

1LA6 283 - 8AB60

1MJ6 283 - 8CB60

1LA6 313 - 8AB60

1MJ6 313 - 8CB60

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

400 D / 690 Y

35 D / 20.2 Y

33.5 D / 19.3 Y

45.5 D / 26.3 Y

39 D / 22.5 Y

61 D / 35.3 Y

66 D / 38.2 Y

84 D / 48.5 Y

84 D / 48.5Y

138 D / 80 Y

138 D / 80 Y

kW

d

157E

202E

203E

252E

253E

58

18.5

17.5

22

20

30

33

45

45

75

75

Operating

fluid requirement 4)

Soundpressure

level 5)

Degree of

protection

Rated

speed

rpm

m3/h

dB(A)

IP 55

EEx e II T3

IP 55

EEx e II T3

IP 55

EEx e II T3

IP 55

EEx de II C

IP 55

EEx de II C

1460

1470

975

980

980

985

730

1.9 / 1.3

70

2.1 / 1.4

71

2.6 / 1.7

71

4.4 / 2.9

73

740

5.2 / 3.5

73

Order No. 6)

Vacuum pump

Accessories +

mounting 7)

2BE1 153-0 B Y 4 - Z

2BE1 153-0 B Y 4 - Z

2BE1 202-0 B Y 4 - Z

2BE1 202-0 B Y 4 - Z

2BE1 203-0 B Y 4 - Z

2BE1 203-0 B Y 4 - Z

2BE1 252-0 B Y 4 - Z

2BE1 252-0 B Y 4 - Z

2BE1 253-0 B Y 4 - Z

2BE1 253-0 B Y 4 - Z

F43 + F44 + F97

F43 + F44 + F98

F43 + F44 + F97

F43 + F44 + F97

F43 + F44 + F96

F43 + F44 + F97

F43 + F44 + F97

F43 + F44 + F97

F43 + F44 + F97

F43 + F44 + F97

Total

weight 8)

kg

432

500

825

870

815

1000

1690

1710

2110

2150

elmo vacuum technology GmbH

236

266

288

elmo vacuum technology GmbH

14000

316

16000

346

9500

200

18000

390

10700

220

6800

132

All figures are for guidance only.

For precise design, please ask for

our catalogue sheets or contact

your nearest office.

20500

500

12400

275

7400

160

Speed performance

area of 2BE1 pumps

Speed of pump in rpm

210

8200

220

5000

110

22500

630

14000

315

330

Selection overviews for range 2BE1

9300

250

5600

132

3400

75

m3/h

kW

15400

390

372

472

530

m3/h

kW

5800

160

3600

80

2100

45

2BE1 403 - 0

2BE1 503 - 0

m3/h

kW

4700

132

4400

110

8000

250

3200

65

1700

38

m3/h

kW

1450

32

m3/h

kW

4000

100

2400

54

1650

38

2650

65

1850

46

1000

23

2950

83

2050

58

1120

27

1240

33

840

22

440

10.8

m3/h

kW

2BE1 153 - 0

760

18

340

8.1

m3/h

kW

2BE1 152 - 0

660

16

290

7

1400

44.2

940

30

510

13.5

400

10.5

360

9

290

7

m3/h

kW

2BE1 103 - 0

m3/h

kW

200

4.9

m3/h

kW

2BE1 102 - 0

1300

150

3.6

1100

m3/h

kW

980

2BE1 101 - 0

920

2BE1 151 - 0

880

2BE1 303 - 0

820

2BE1 353 - 0

m3/h

kW

840

20

m3/h

kW

2BE1 203 - 0

790

580

13.5

740

m3/h

kW

660

2BE1 202 - 0

590

2800

56

1150

26

565

m3/h

kW

2BE1 603 - 0

11600

346

7200

200

4200

90

2BE1 703 - 0

m3/h

kW

10500

275

6400

160

3700

75

2550

50

2BE1 253 - 0

2BE1 252 - 0

420

1450

600

16.5

460

12.4

400

11

330

8.2

235

5.8

175

4.3

1625

660

19.5

500

15

440

13

380

10

270

6.9

190

5

1810

710

24

540

18.1

480

16

2190

490

16

340

11.1

250

8.3

Selection Overviews for Range 2BE1

59

60

190

200

210

18500

270

14900

220

15200

250

13000

190

21000

335

12500

205

10700

160

23500

380

17800

280

9000

kW 130

m3/h

7400

kW 110

m3/h

230

2BE3 52. - 2

2BE3 50. - 2

All figures are for guidance only.

For precise design, please ask for

our catalogue sheets or contact

your nearest office.

Speed performance

area of 2BE3 pumps

Speed of pump in rpm

180

26400

470

20500

345

240

270

17200

295

14100

240

10500

170

8600

138

29400

550

22700

410

2BE3 42. - 2

2BE3 40. - 2

260

300

19100

340

15800

280

20900

395

17100

325

320

330

32500

640

24900 26400 27200

475

525

545

12100

210

10000

170

5600

kW 82

m3/h

4100

kW 63

m3/h

290

170

Selection overviews for range 2BE3

37000

805

13700

245

9200

205

6500

108

4800

80

340

30500

675

370

m3/h

kW

15050

285

12300

287

380

m3/h

2BE3 72. - 2

kW

22800

426

18700

375

350

420

25500

575

21200

470

2BE3 60. - 2

8400

160

6150

113

3750

kW 62

18500

415

9200

180

6750

130

4100

70

490

2900

51

15100

338

470

m3/h

450

m3/h 2700

kW 45

440

m3/h

2BE3 62. - 2

kW

kW

m3/h

16600

335

13600

276

2BE3 32. - 2

2BE3 30. - 2

400

2BE3 67. -2

7500

130

5500

95

390

9950

210

7300

149

530

4700

85

3300

60

560

8400

185

610

10700 11400

230

270

7800

168

570

5200

100

3700

71

630

5600

116

4000

81

690

6000

126

4300

91

740

6500

151

4700

109

810

Selection Overviews for Range 2BE3

elmo vacuum technology GmbH

Dimensions for ELMO-F Units 2BE

and Accessories

Dimensions for 2BE1 15. to 2BE1 25. (mm)

PV-5028

N2.2

N1.1

N4.0

N2.0

H3

H1

N1.0

H2

N3.0

L

L1

2BE1 153 to 2BE1 253

2BE1

Type

Curve No.

For motor size:

H1

H2

H3

L1

Vacuum-/pressure-side pipe socket

N1.0/N2.0

DN

DIN 2501 PN 10

N1.1/N2.2

DN

DIN 2501 PN 10

N3.0

Connection for

op. liquid

ISO 7/1

N4.0

Drain of

separator

ISO 7/1

2BE1 153

157 E

158 E

180M

180L

450

845

325

700

1265

1610

65

100

Rp

Rp 2

2BE1 202

202 E

204 E

203 E

206 E

200L

660

1085

415

940

1625

1755

100

125

Rp 1

Rp 3

225M

250M

660

1110

415

965

1625

1935

2030

100

125

Rp 1

Rp 3

252 E

254 E

253 E

256 E

280M

630

1400

555

1185

1800

2255

125

150

Rp 1

Rp 3

315M

700

1400

555

1185

2060

2540

125

150

Rp 1

Rp 3

2BE1 203

2BE1 252

2BE1 253

Accessories 2BE

For vacuum pump

Type

Order No.

Weight

kg

Compressed-air gauge, loose Chrome-nickel steel

0.8 - 4 m3/h

2BE1 15. to 2BE1 20.

2BX9 284 - 0HX02

for operating liquid

0.8 - 4 m3/h

2BE1 25.

2BX9 284 - 0HX03

14

2BE1

2BX9 012 - 1HD20

Pressure gauge -1 to +0.6 bar

including shutoff tap and gaskets

Order codes

Discharge-liquid separator

F43

Manifold

F44

Coupling, coupling protection, baseplate incl. motor mounting

F96, F97, F98

elmo vacuum technology GmbH

61

ELMO-F Systems

Standard closed-circuit units

Key:

M

010

030

080

130

030

010

PV-5054

N1.0

Connections:

Vacuum pump

Three-phase motor

Separator

Heat exchanger

280

N6.0

130

N1.0

N2.2

N3.3

N4.0

N4.1

N5.0

N6.0

N8.6

Gas inlet

Gas outlet

Make-up

Overflow

Total drain

Cooling water inlet

Cooling water outlet

Measurement point

170

N5.0

260

N2.2

080

N4.0

N3.3

N8.6

N4.1

LG

ELMO-F closed-circuit vacuum pump range 2BW3

The ELMO-F Standard closed-circuit vacuum pumps/compressors

2BW consist of a vacuum pump/compressor with three-phase motor,

liquid separator, heat exchanger, base frame and pipework.

The schematic structure is shown in the picture above right.

With ELMO-F closed-circuit vacuum pumps/compressors 2BW,

the condensate from the extracted process vapours is conveyed as

the operating liquid in a closed circuit (vacuum pump/compressor )

separator ) heat exchanger ) vacuum pump/compressor).

This prevents polluted waste water and avoids the need to use

fresh water. Recovered condensate can be removed for further use.

The cooling water is only heated up, not polluted.

Closed-circuit vacuum pump with roots backing pump

M

020

N1.1

M

010

N2.2

N4.0

163

080

N3.3

Key:

Connections:

010 Vacuum pump

with motor

020 Roots backup

pump

080 Separator,

vertical

130 Heat exchanger

163 Non-return valve

N1.1

N2.2

N3.3

N3.4

N4.0

N4.1

N5.0

N6.0

N8.9

Gas inlet

Gas outlet

Make-up

TI measurement nozzle

Overflow

Total drain

Cooling water inlet

Cooling water outlet

Measurement point

N8.9

N4.1

130

N3.4

PV-5314b

N5.0 N6.0

ELMO-F closed-circuit vacuum pump with roots backing pump

for inlet pressures to 10 mbar abs.

Further versions:

ELMO-F vacuum pumps with backing pumps like gas ejectors, steam

ejectors, roots pumps (see figure above) and ELMO-G for low limit

pressure from 1 to 100 mbar abs.

ELMO-F plants with several parallel vacuum pumps and compressors

for higher suction capacities.

62

To optimize the speed of ELMO-F closed-circuit vacuum pumps and

compressors in accordance with the required process data, the

following drives are possible:

For a flexible matching of ELMO-F closed-circuit vacuum pumps and

compressors to the process data, the following control concepts can

be supplied:

Direct drive via coupling with electrical or other motors

(e.g. Diesel motor)

Drive via belt drive with electrical or other motors

(e.g. Diesel motor)

Drive via gear with electrical or other motors

(e.g. Diesel motor)

Bypass control,

Speed control with frequency converters when using electrical

motors,

Process-bound complete control systems for plants

elmo vacuum technology GmbH

ELMO-F Systems

Vacuum system with roots backing pump and gas ejector

Series-connected ELMO-F compressors

Process

Gas

ejector

Roots

blower

Process

ELMO-F

vacuum pump

Process

Process

ELMO-F

2BE compressor

Separator

ELMO-F

2BG compressor

)

Separator

Heat exchanger

Heat exchanger

1 mbar

1400 mbar

Sets for the range to 1 mbar.

Separator

800 mbar

Heat exchanger

14 bar

Series connection of ELMO-F compressors for use up to 14 bar abs.

When combined with reliable components such as roots pumps or gas ejectors, the area of use of

ELMO-F compressors is considerably extended. Even mixed operation from vacuum to pressure presents

no problems for the machines.

Examples of vacuum/compressor systems with ELMO-F pumps

Double unit 2BW4 203 - 0ZY99 - Z

Suction flow:

N2, Dichlorethane (EDC), VC, HCL

Suction capacity:

105 Nm3/h

Vacuum:

0.16 bar abs.

Pressure:

1.7 bar abs.

Drive capacity:

38 kW

F

Power unit 2BW4 253 - 0BL4. - Z with gas ejector

Condenser evacuation

Suction flow:

Vapour-air mixture

Leakage air flow evaporation: 10.32 kg/h

Vacuum:

0.015 bar abs.

Drive capacity:

47 kW

elmo vacuum technology GmbH

63

Radial Blowers Range 2CF1 and 2CF2

Selection diagram 50 Hz

Pa

40

4000

A PV-5020c

90dB(A)

30

20

16

12

Pressure difference

pf

mbar

3000

86

2000

75

1600

77

76

1200

10

1000

800

600

500

400

300

200

100

1

91

87

71

61

81

82

79

78

68

68

1,5

84

83

80

85

7 8 9 10 12

92

16

96

3

30 m /min 50 60

20

Capacity V

60

80 100

150

200

300

400 500

700

m3/h

1400 2000

1000

3600

Selection diagram 60 Hz

mbar

Pa

40

4000

A PV-5104c

86dB(A)

pf

20

16

12

Pressure difference

30

3000

72

1600

77

77

1200

10

1000

800

600

500

400

300

200

100

1

83

64

84

91

87

63

79

79

70

The performance curves are valid for a medium

with a density r = 1.2 kg/m

(measured on the suction side).

86

77

2000

84

70

1,5

84

5

86

6

87

7 8 9 10 12

96

92

16

30 m3/min 50 60

20

Capacity V

60

80 100

150

200

300

400 500

700

1000

1400

2000

m3/h

3600

elmo vacuum technology GmbH

Radial Blowers Range 2CF1 and 2CF2 and Accessories

Selection and ordering information

Size

Designation

letter

mm

Speed

rpm

Soundpressure

level at

1 m distance 1)

dB(A)

Other voltages

Tempe- Motor

rature of Type

conveying

liquid 2)

max.C

Order No.

Rated

output

kW

Rated

voltage 3)

Rated

current

Weight

approx.

AVAILABLE EX

kg

0.34 5)

0.36 5)

0.52 5)

0.69 5)

1.2 5)

2.6 5)

8.2 5)

2CF1 052 - 0BA1

2CF2 052 - 2EA 1

2CF2 062 - 0EA 1

2CF2 072 - 0EA 1

2CF2 082 - 0EA 1

2CF1 142 - 0EA 1

2CF1 182 - 0EA 6

6.2

4.3

8.8

10.2

12.5

30

74

0.35

0.23

0.58

0.68

1.35

2.3

7.3

2CF1 052 - 0BA8

2CF2 052 - 2EA 8

2CF2 062 - 0EA 1

2CF2 072 - 0EA 8

2CF2 082 - 0EA 8

2CF1 142 - 0EA 8

2CF1 182 - 0EA 8

6.2

4.3

8.8

10.2

12.5

30

74

0.85

0.80

2CF1 052 - 1BH1

6.2

4.5

STOCK

Radial blowers with three-phase motor 50 Hz, IP 54 degree of protection

50

50

63

71

80

140

180

B

C

D

E

F

G

H

7350 4)

2850

2780

2750

2740

2900

2890

79

68

78

82

82

87

91

65

50

110

110

110

65

65

1LA5 053

1PP4 060

1LA5 060

1LA5 063

1LA5 070

1LA5 083

1LA5 113

0.12

0.06

0.18

0.25

0.42

1.17

4.2

230 d/ 400 *

230 d/ 400 *

230 d/ 400 *

230 d/ 400 *

230 d/ 400 *

230 d/ 400 *

400 d/ 690 *

Radial blowers with three-phase motor 60 Hz, IP 54 degree of protection

50

50

63

71

80

140

180

B

C

D

E

F

G

H

7350 4)

3300

3240

3300

3280

3480

3480

79

70

79

83

84

87

91

65

50

110

110

110

65

65

1LA5 053

1LA5 050

1LA5 060

1LA5 063

1LA5 073

1LA5 083

1LA5 113

0.14

0.09

0.24

0.29

0.63

1.27

4.2

460 *

460 *

460 *

460 *

460 *

460 *

460 *

Radial blowers with single-phase AC motor 50 Hz, IP 54 degree of protection

50

50

B

C

7490 4)

2850

79

68

60

50

1LF5 053

1LF4 063

0.12

0.09

230 6)

230 6)

2CF2 052 - 2EH 1

Accessories

for dischargeside

Weight

approx.

Hose

for inletside

Weight

approx.

for dischargeside

Weight

approx.

Metal filter

for inletside

Weight

approx.

Order No.

kg

Order No.

kg

Order No.

kg

Order No.

kg

Order No.

kg

2CF1 052

2CF2 052

2CF2 062

2CF2 072

2CF2 082

2CX3 000

0.45

2CX3000

0.45

1.5

1.2

1.2

1.3

1.4

2CX3 004

1.5

0.7

1.1

1.2

1.2

2CX3 730

2CX3 731

2CX3 732

For type

0.24

0.28

0.30

not necessary

2CX3 705

2CX3 706

2CX3 726

Filter bag

for dischargeside

Weight

approx.

Guard screen

for inletside

Order No.

kg

Order No.

0.19

0.22

0.24

2CX3 004

2CX3 717

2CX3 717

2CX3 720

2CX3 721

2CX3 722

2CX3 723

2CX3 724

2CX3 725

2CX3 003

2CX3 733

Weight

approx.

Connecting elbow

Weight

approx.

Heating cartridge

AVAILABLE EX

for dischargeWeight

STOCK

side

approx.

kg

Order No.

Order No.

kg

kg

2CF1 052

2CF2 052

2CX3 002

2CX3 713

0.75

1.5

2CX3 001

1.8

2CX3 005

0.75

2CF2 062

2CF2 072

2CF2 082

2CX3 714

2CX3 715

2CX3 716

1.5

1.5

1.5

2CX3 735

2CX3 736

2CX3 737

0.22

0.25

0.27

Features

The blower and motor form a single unit with the impeller mounted

directly on the motor shaft. Only the types 2CF1 052-0BA. and 2CF1

052-1BH. have a gearbox between the impeller and the motor.

Drive

The blowers have surface-cooled, three-phase or single-phase motors

with IP 55 class of protection. They are suitable for continuous

operation.

elmo vacuum technology GmbH

Voltage

code number

500 V *, 50 Hz

Required voltage and frequency: C

C Please indicate in plain text and add L1 Y.

1) The tabulated values are with medium throttling.

2) Max. ambient temperature 40 C.

3) Permissible voltage range.

Rated voltage

acc. to

DIN IEC 38*

Permissible voltage range

acc. to DIN VDE 0530 or

DIN IEC 34-1**

Frequency

Hz

230 V D / 400 V Y 220...240 V D / 380...420 V Y 50

400 V D / 690 V Y 380...420 V D / 660...725 V Y 50

460 V Y

460 V D

440...480 V Y

440...480 V D

60

60

* Voltage tolerance here 10%.

** This voltage range is also shown on the rating plate, together

with the currents occuring in this range. For this range, the

permissble voltage tolerance acc. to DIN VDE 0530 or

DIN IEC 34-1 is 5%.

5) At 400 V, 50 Hz.

Duct connector

for inletWeight

side

approx.

not necessary

2CX3 726

2CX3 727

2CX3 728

Voltage,

frequency

4) 2-pole motor with gearbox.

Selection and ordering information

For type

2CF ... ... c

C

The rated

voltages shown

alongside are

available at no

extra cost.

Noise

In the performance curves and selection tables, the noise values given

are for an average sound-pressure level, measured at a distance of

1 m. The noise levels given are for a steadily-running machine,

connected for extraction, and are evaluated according to DIN 45 635,

Part 13. Tolerance is + 3 dB.

1.2

2.4

1.8

2

2

6) Permissible voltage tolerance 5%.

For dimensions, see page 66.

Selection example

Required air performance:

[ = 6 m3/min,

at 50 Hz

}pf = 1100 Pa

Two selections are possible:

Type 2CF2 072 ([ : -15 %), curve E

Type 2CF2 082 ([ : +5 %), curve F

Eventual choice depends on cost and performance priorities.

Applications

The extraction of gases from moulding presses and injection

machines.

The extraction of dust, chips, fibres and threads when using a

preseparator.

Holding of paper, cardboard.

Cooling.

Other designs

Radial blowers with 3-phase motors for other voltages and/or

frequencies are available on request. Accessories can also be

supplied.

65

Dimensions for Radial Blowers 2CF1 and 2CF2

Dimensions for 2CF1 0, 2CF1 1, 2CF2 0 (mm)

D2

D1

D3

B4

B2

B2

B3

M8

A5

B3

N

K

A3

A1

D4

D4

A1

A3

B4

A5

D3

D2

D1

PV-5145

A4

A2

A6

PV-5146c

A2

A4

C3

C7

C5 C6

C6

C7

C1

C3

C2

2CF1 052

C2

2CF1 142 to 2CF1 182

Type

Curve

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

C1

C2

C3

2CF1 052 - 0BA.

2CF1 052 - 1BH.

2CF1 142 - 0EA.

2CF1 182 - 0EA.

B

B

G

H

70

70

210

260

70

70

180

230

50

50

140

180

100

100

275

350

80

80

250

320

100

100

85

85

180

230

50

50

140

180

22

22

35

45

300

400

70

70

360

480

12

12

18

18

C4

C5

C6

C7

D1

D2

D3

D4

55

80

62

62

125

170

90

90

230

310

96

96

263

337

111

111

301

386

103

103

284

364

120

120

360

460

250

250

302

376

4 x 11.5

4 x 14

15

15

M 10

M 12

12

12

B4

D1

D2

D2

D1

D3

4 x M6

A5

A3

A2

D4

D4

A3

A5

B3

B2

B1

B1

D3

26

B4

PV-5148

Curve

B

B

G

H

PV-5147a

Type

2CF1 052 - 0BA.

2CF1 052 - 1BH.

2CF1 142 - 0EA.

2CF1 182 - 0EA.

A1

Pg 16

26

16

C5

4x

A4

A4

C1

C1

2CF2 052 - 2EA1, 2CF2 052 - 2EH.

C6

C3 x C4

2CF2 062 to 2CF2 082

C2

C3 x C4

C7

C7

C5

C2

Type

Curve

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

C1

2CF2 052 - 2EA.

2CF2 052 - 2EH.

2CF2 062 - 0EA.

2CF2 072 - 0EA.

2CF2 082 - 0EA.

C

C

D

E

F

110

120

130

92

100

108

42.3

42.3

63

71

80

143

143

155

172

192

96

96

138

156

175

80

80

130

140

150

108

118

129

80

90

100

95

95

32

35

39

73

73

120

160

160

Type

Curve

C2

C3

C4

C5

C6

C7

D1

D2

D3

D4

2CF2 052 - 2EA.

2CF2 052 - 2EH.

2CF2 062 - 0EA.

2CF2 072 - 0EA.

2CF2 082 - 0EA.

C

C

D

E

F

120

120

160

200

200

12

12

12

12

12

16

16

16

16

16

62

62

51

54

57

40

40

40

60

60

80

80

80

120

120

153

171

191

125

125

161

180

201

123

123

157

175

196

140

140

195

220

245

214

214

217

219

243

66

elmo vacuum technology GmbH

Dimensions for Accessories for Radial Blowers 2CF1 and 2CF2

Dimensions (mm)

D

C

65

4x 7

PV-5042

B

A

PV-5043

B

A

Connection piece for suction and pressure-side

(to be used for hose, filter bag or heater cartridge)

60

D

C

Connection piece for 2CF1

Connection piece for 2CF2

For

ventilator

Type

Connection piece

for suction side

Order No.

A

for pressure-side

Order No.

A

2CF1 052

2CF2 062

2CF2 072

2CF2 082

2CX3 000

2CX3 726

2CX3 727

2CX3 728

46

73

88

93

84

108

118

129

100

130

140

150

2CX3 000

2CX3 705

2CX3 706

2CX3 726

46

63

68

73

84

92

100

108

100

110

120

130

54

80

95

100

54

70

75

80

Temperature range -55 to +150 C: bending radius 12 to 75 mm;

Hose can be compressed to 60 % of total length.

PV-5046a

PV-5045

2000

2500

Hose

Hose for 2CF1

Hose for 2CF2

For

ventilator

Type

Hose for

suction side

Order No.

2CF1 052

2CF2 052

2CX3 004

2CX3 717

54

83

2CF2 062

2CF2 072

2CF2 082

2CX3 717

2CX3 720

2CX3 721

83

95

102

for pressure-side

Order No.

A

58

72

2CX3 004

2CX3 722

54

51

58

51

72

102

102

2CX3 723

2CX3 724

2CX3 725

70

76

83

75

80

85

PV-5041

Metal filter complete with connection piece

4x

7

Metal filter

for 2CF1 and 2CF2

B

C

For

ventilator

Type

Order No.

2CF1 052

2CF2 052

2CX3 003

2CX3 730

50

70

2CF2 062

2CF2 072

2CF2 082

2CX3 731

2CX3 732

2CX3 733

70

100

102

84

1)

130

130

1)

108

118

129

130

180

180

165

180

180

140

1) The metal filter is supplied without connection piece, but with 2 m long plastic hose NW 83.

A

50

Filter bag complete with connection piece

PV-5048

PV-5047

Filter bag for 2CF1

Filter bag for 2CF2

Flow resistance of empty bag

500 Pa at [ = 2 m3/min

For

ventilator

Type

Order No.

2CF1 052

2CF2 052

2CX3 002

2CX3 713

55

48

250

250

500

500

2CF2 062

2CF2 072

2CF2 082

2CX3 714

2CX3 715

2CX3 716

71

76

81

300

300

350

600

600

700

C

A

PV-5044

Guard screen for suction-side

Guard screen

for 2CF2

For

ventilator

Type

Order No.

2CF2 062

2CF2 072

2CF2 082

2CX3 735

2CX3 736

2CX3 737

130

140

150

108

118

129

84

Connecting elbow

for 2CF1

elmo vacuum technology GmbH

PV-5040

55

57

57

130

PV-5039

270

Heater cartridge for 2CF1 052

Heating capacity: 1000 W; power connection: 230 V

Flow resistance: approx. 550 Pa at [ = 1.2 m3/min

67

Radial Blower, Range 1BA

Selection diagram

1BA4 420 - 6FE04

1BE4 425 - 6JE03

300

270

4,5

4

210

3,5

180

150

2,5

120

90

60

30

These single-circuit radial blowers are particularly

suitable for vacuum cleaners, small vacuum-transfer

machines and pneumatic mail systems with short

running times.

The blowers have motors without fans. The air is

sucked through a prefilter and simultaneously cools

the motor. The blowers have commutator motors

which are suitable for a 230 V, 50 Hz electrical

supply. The service-life of the brushes (before

re-machining the commutator) is given in the table

below. The motor rotor, with bearings, should be

replaced at the end of this period. Phase control and

radio interference suppression are both possible.

0

300

Suction capacity V

Suction capacity V

240

300

270

4,5

m3/min

m3/h

m3/min

m3/h

240

210

3,5

180

150

2,5

120

1,5

90

1,5

60

0,5

30

0

300

APV-5333b

50

0

mbar 200 150 100

p Total pressure difference (vacuum)

0,5

APV-5334a

mbar 200 150

100 50

0

p Total pressure difference (vacuum)

Selection and ordering information

Motor

Suction capacity

max.

Vacuum

max.

Order No.

Weight

approx.

Average

power

consumption

Rated

voltage

Frequency

Speed

Service life

of brushes

Hz

rpm

m3/h

mbar

1100

230

50

32000 to 43200

850

184

235

1BA4 420 - 6FE01

1.6

1400

230

50

34000 to 47 000

850

206

271

1BA4 425 - 6JE03

1.7

Dimensions (mm)

PV-5331b

1BA4 420 - 6FE01

138.8

97.5

121.7

24.5

110.2

63.25

1BA4 425 - 6JE03

138.8

97.5

121.7

24.5

110.2

63.25

b

a

Type

kg

Radial blower

68

elmo vacuum technology GmbH

Conversion Tables

Suction capacity

Pressure

Multiplication of the value

with units

With conversion

factor

Results in the value

with units

Multiplication of the value

with units

With conversion

factor

Results in the value

in units

Pa

0.01

mbar

l/min

0.06

m3/h

hPa

1.0

mbar

gal/min

0.227

m3/h

kPa

10.0

mbar

ft3/min

1.699

m3/h

mm H2O

0.098

mbar

m3/h

16.667

l/min

m H2O

98.07

mbar

m3/h

4.403

gal/min

at

980.7

mbar

m3/h

0.588

ft3/min

inch H2O

2.491

mbar

PSI lpf/in2

68.948

mbar

mbar

100

Pa

mbar

10.2

mm H2O

Multiplication of the value

with units

With conversion

factor

Results in the value

in units

mbar

10.2 10-3

m H2O

hp

0.746

kW

mbar

1.02 10-3

at

Btu/h

293.1

kW

mbar

0.4016

inch H2O

kW

1.341

hp

mbar

14.505 10-3

PSI lpf/in2

kW

3.41 10-3

Btu/h

Electrical power

Example of conversion:

Weight

250 [inch H2O] 2.491 = 622.5 [mbar]

Multiplication of the value

with units

With conversion

factor

Results in the value

in units

lbm

0.454

kg

kg

2.205

lbm

Multiplication of the value

with units

With conversion

factor

Results in the value

in units

in.

25.4

mm

in.

0.0254

ft

305

mm

ft

0.305

39.37

in.

3.28

ft

The following formula is used to convert values in the

unit inch of mercury vacuum to values in the unit mbar abs.ii:

1013 - X [inches of mercury vacuum] 33.8 q Y [mbar abs.]

Length

Types of pressure

Absolute pressure

The pressure measured from absolute zero, using ideal vacuum as the datum.

The measured pressure is always greater than the reference pressure.

Total pressure difference, pressure

The pressure measured above the prevailing atmospheric pressure. The datum is the prevailing

atmospheric pressure and the measured pressure is always higher than the datum.

Total pressure difference, vacuum

The pressure measured lower than the prevailing atmospheric pressure. The datum is the

prevailing atmospheric pressure and the measured pressure is always lower than the datum.

Total pressure

difference

(vacuum)

Temperature conversion

Total pressure

difference

(gauge)

to

t [F] = 1.8 T [K] - 459.67

t [F] = 1.8 t [C] + 32

T [K] =

t [F] + 459.67

1.8

t [C] =

t [F] - 32

1.8

A PV-5057a

Absolute pressure

Conversion

from

100% vacuum

0 mbar

elmo vacuum technology GmbH

Atmosphere

Biometric pressure

approx. 1013 mbar

69

General Safety Information

NOTE:

The products in this catalogue are used in the

capital goods industry

consumer goods industry

and in such sectors as

agriculture

the building industry and

allied trades.

This equipment has bare parts that are

dangerous because they are live during

operation, in some cases these are moving or

rotating parts. Such parts could cause severe

injury to persons and severe damage to

property, for example in the event of

unauthorised removal of protective covers,

improper use, wrong operation or insufficient

maintenance.

The people in charge of safety must therefore

guarantee that

only qualified personnel are allowed to work

on or around this equipment;

supplied with the equipment, and are under

an obligation to systematically follow the

instructions given therein;

unqualified personnel are not allowed to work

on these machines or equipment or in the

vicinity thereof.

Qualified personnel are persons who on

account of their training, experience,

instruction, knowledge of the appropriate

standards, specifications, accident prevention

regulations and the operating enviroment

have been authorised by those responsible for

plant safety to perform the necessary work and

at the same time to recognise and circumvent

potential hazards.

Knowledge of first aid and familiarity with the

pertinent life-saving equipment are also

necessary.

The debarring of unqualified personnel from

work on heavy-current equipment is regulated

by DIN VDE 0105 or IEC 364.

variations, or to provide for every

possible contingency that might arise in

installation, operation or maintenance.

The operating instructions therefore

only contain the information necessary

to enable qualified personnel (see

above) to operate the machines or

equipment correctly in industrial

applications.

In the event that the machines or

equipment are intended for service

outside of industry, where more

exacting demands may be placed on

them (such as touch protection for

children), the installation work must be

supplemented by further protective

measures that are to be implemented

by others.

Where clarifications are necessary,

particularly with respect to lack of

product-specific detailed information,

please contact the sales office

concerned, quoting the type

designation of the machine or

equipment.

It is advisable to arrange for our service

centres to take charge of the necessary

planning, installation, commissioning

and after-sales service.

this personnel have access at all times while

working on the equipment to the appropriate

operating instructions and other documents

70

For the sake of clarity, the operating

instructions supplied with the machines are not

intended to cover all details of equipment

elmo vacuum technology GmbH

Conditions of Sale and Delivery,

Export Regulations

Small orders

With small orders, the costs of handling the

order exceed the value of the order. It is

recommended that requirements are added

together. If this is not possible, we will be

obliged to charge a handling supplement of EUR

20.- for orders with a net goods value of less

than EUR 100. to cover a proportion of our

costs for order handling and invoicing.

Ordering special versions

If products are orders that are different

from the versions given in the

catalogue, a Z is to be added to the

order number given in the catalogue,

and the required characteristic is then

also to be added in full text.

Conditions of Sale and Delivery

Within Germany:

For export:

The General Conditions of Sale apply,

plus the

The General Conditions of Delivery for products

and services from the electrical industry and all

other conditions agreed with the recipients of

the price lists.

General Conditions of Delivery

for electrical products and services.

Prices are given in EURO ex factory,

excluding packaging; this is charged at cost.

a

Unless otherwise stated on the individual pages of this catalogue, we reserve

the right to make changes, especially to

the given values, dimensions and

weights.

Illustrations are not binding.

Value-added tax is not included

in the prices.

It will be charged at the rate valid at the

time in accordance with the requirements

of the law.

We also reserve the right to make price

modifications and will charge the prices

valid on delivery.

Export regulations

According to the current provisions (09/98) of

the German and US export regulations, the

products listed in this catalogue do not require

any export permit. Export or re-export is

therefore allowed without the permission of the

competent authorities unless the Order on

Trade marks

Foreign Trade lays down country-specific

restrictions. The markings given on the delivery

slip and invoice are the decisive criteria. An

export permit obligation may arise for specific

countries as a result of the intended use of the

products.

All product designations are trade marks or product names of

elmo vacuum technology GmbH or other companies.

elmo vacuum technology GmbH

Responsible for the

technical content

Lutz Kasimir

elmo vacuum technology GmbH

Marketing Communication

71

Only Quality Has a Future

Electronic check of the dimension accuracy of an

ELMO-G impeller.

Fully automatical final check of endshields of

ELMO-F and -G drives.

Technical progress and market success

are inseparable from the high quality of

ELMO vacuum pumps and compressors.

To guarantee this high quality level, a

reliable quality assurance system has

been established for monitoring all

phases of production from development to delivery.

This quality assurance system meets

the worldwide requirements, corresponds with the relevant standards

and specifications and fulfils the

requirements of ISO 9001.

This gives our customers the

following advantages:

maximum operational safety;

high, consistent supply reliability;

compliance with the requirements of

the European Market;

participation in national and

international tenders.

Check of performance data and printing of the test

protocol.

72

elmo vacuum technology GmbH

Your direct contact to elmo

Sales region

Address

Contact

Telephone

Fax

elmo vacuum technology GmbH

A Siemens Company

Humboldtstrae 59

D-90459 Nrnberg

Germany

Mr. J. Mller, Dep. M BD2

Juergen.Mueller@nbg7.siemens.de

+49 (911) 433-7773

+49 (911) 433-6935

Siemens E&A, Inc

Dep. IPD/VP&C

4620 Forest Ave

Norwood, OH 45212

USA

vpcsales@sea.siemens.com

www.siemensvpc.com/sales

+1 (513) 841-3300

+1 (513) 841-3302

Mr. Leslie J. Croyston

Leslie.Croyston@sae.siemens.com.sg

+65 845-4780

+65 845-4789

Siemens Ltd.

885, Mountain Highway

Bayswater, Vic. 3153

Australia

Mr. Glenn Plymin, Dep. A&D

Glenn.Plymin@siemens.com.au

+61 (3) 9721-7542

+61 (3) 9721-7908

Siemens Vacuum Pump &

Compressor Co. Ltd.

No. 448, BaiYucheng

ZiBo 255213

BoShan, ZiBo, ShangDong

Rep. of China

Mrs. Qiulan Liu, Dep. elmo GM

qiulan.liu@pek1.siemens.com.cn

+86 (533) 465-4800

+86 (533) 465-0166

Europe

Headquarters Europe

America

Headquarters NAFTA

Asia

Headquarters Asia Pacific elmo vacuum technology Pte. Ltd.

A Siemens Company

Blk 164 Kallang Way, #04-38

Singapore 349248

Australia

Headquarters Australia

China

Headquarters China

The above table shows our regional headquarters worldwide.

For your local contact partner, please take a look in our Internet site under www.elmo-vacuum.com >> contacts

or contact the regional office for further assistance.

You might also like

- Teikoku Pump Manual PDFDocument8 pagesTeikoku Pump Manual PDFWan ZahirNo ratings yet

- Air 4 Bar PlantDocument7 pagesAir 4 Bar PlantAbu ZakaNo ratings yet

- Jeppsen 080 - Principles of FlightDocument296 pagesJeppsen 080 - Principles of FlightSadcat100% (24)

- Chapter 2 Dry Gas Reservoir: Example 1Document8 pagesChapter 2 Dry Gas Reservoir: Example 1Muhammad Nizam50% (2)

- What Is The Best Silicon Carbide Wear Face Material For My Mechanical SealDocument3 pagesWhat Is The Best Silicon Carbide Wear Face Material For My Mechanical SealMahmoud Al HomranNo ratings yet

- NASH VectraXL enDocument4 pagesNASH VectraXL enJohn UrdanetaNo ratings yet

- CPC Chapter 7 IllustrationsDocument26 pagesCPC Chapter 7 Illustrationsmnt6176No ratings yet

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 pagesOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoNo ratings yet

- Canadian Red Seal Refrigeration and Air Conditioning Practice QuestionsDocument95 pagesCanadian Red Seal Refrigeration and Air Conditioning Practice QuestionsVictor Kavhendekete, MTechMgt, BTech100% (1)

- John Deere Mangueiras PDFDocument43 pagesJohn Deere Mangueiras PDFAmanda Rezende100% (1)

- Elmo Pack IOMDocument61 pagesElmo Pack IOMErick Fabian Carrillo Revilla100% (1)

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- 2GDocument8 pages2GGaurav Panditrao UdanshivNo ratings yet

- LPHX Serie 4500 SIHIDocument11 pagesLPHX Serie 4500 SIHIJorge FernandezNo ratings yet

- 4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFDocument16 pages4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFmiguel callataNo ratings yet

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- NTT Om PDFDocument24 pagesNTT Om PDFrpichoNo ratings yet

- API 610 - Why BEP Should Be Between Normal Point and Rated PointDocument7 pagesAPI 610 - Why BEP Should Be Between Normal Point and Rated PointMuhammad ImranNo ratings yet

- System OneDocument4 pagesSystem OnerasottoNo ratings yet

- Catalog Serie LEMA 25 - 50Document8 pagesCatalog Serie LEMA 25 - 50Lenin MisariNo ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- 905 Series Liquid Ring Vacuum Pumps & CompressorsDocument4 pages905 Series Liquid Ring Vacuum Pumps & CompressorscarlosNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- Dry Vacuum PumpsDocument10 pagesDry Vacuum PumpsWade ColemanNo ratings yet

- Wilden Pump p8Document47 pagesWilden Pump p8RUBERTH ALEXANDER OCHOANo ratings yet

- What Is DampenerDocument12 pagesWhat Is DampenerReyNo ratings yet

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- Pressure Surges and Air Valve Specification PDFDocument22 pagesPressure Surges and Air Valve Specification PDFTONNo ratings yet

- Pump OnlineDocument62 pagesPump OnlineAlWaleed KhalidNo ratings yet

- ksb غاطسDocument5 pagesksb غاطسGhassan ABO ALINo ratings yet

- TECHNICAL Layne Engineering ManualDocument34 pagesTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNo ratings yet

- 3a Index PDFDocument4 pages3a Index PDFraluntitled0% (1)

- NPSH Calculations For Reciprocating PumpDocument1 pageNPSH Calculations For Reciprocating PumpMadan YadavNo ratings yet

- Hi Fab Mechanical SealDocument1 pageHi Fab Mechanical SealVarun MalhotraNo ratings yet

- Submersible Turbine Pumps Franklin and Red Jacket Part CompatibilityDocument3 pagesSubmersible Turbine Pumps Franklin and Red Jacket Part CompatibilitySarge ChisangaNo ratings yet

- Minimum Piping SubmergenceDocument3 pagesMinimum Piping SubmergencesksghNo ratings yet

- Pipe System DesignDocument64 pagesPipe System DesignRonald GeorgeNo ratings yet

- Nash CL 6002 Vacuum Pump (2° Part)Document14 pagesNash CL 6002 Vacuum Pump (2° Part)Teodor Kovaci50% (2)

- Midrange Pump Station Design RecommendationsDocument8 pagesMidrange Pump Station Design Recommendationsalan toomeyNo ratings yet

- Submersible Borehole Pumps - 50 HZDocument118 pagesSubmersible Borehole Pumps - 50 HZanirbanpwd76No ratings yet

- Limits and Fits Pr1171 - 1172Document1 pageLimits and Fits Pr1171 - 1172Teguh Nugraha KusnanNo ratings yet

- Process Pumps: Made by KSBDocument16 pagesProcess Pumps: Made by KSBEdgar CalatayudNo ratings yet

- Agitator - Mixer For VesselsDocument26 pagesAgitator - Mixer For VesselsSri AmshaNo ratings yet

- Understand The Basics of Centrifugal Pump Operation: Fluids/Solids HandlingDocument5 pagesUnderstand The Basics of Centrifugal Pump Operation: Fluids/Solids HandlingViệt Đặng XuânNo ratings yet

- Air Vacuum ValvesDocument4 pagesAir Vacuum ValvesmariuspiNo ratings yet

- Condensate PumpsDocument1 pageCondensate Pumpstricky11No ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- ANSI Vs APIDocument2 pagesANSI Vs APIMohd Effiezool YaserNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- Sulzer Vertical Turbine PumpDocument6 pagesSulzer Vertical Turbine PumpJericho Parulian SitumorangNo ratings yet

- WKF 100 5Document1 pageWKF 100 5Wagih Abd El-Aziz100% (1)

- Presentation On - : Horizontal Centrifugal PumpDocument78 pagesPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Air Release 2014Document4 pagesAir Release 2014Aly AnisNo ratings yet

- ESP Excel PAD Rev01 - 5628121 - 01Document37 pagesESP Excel PAD Rev01 - 5628121 - 01Geraldo Soemaschris SoewarnoNo ratings yet

- Resources Mechanical AESSEAL Guides AUTODocument16 pagesResources Mechanical AESSEAL Guides AUTOmanoNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- Durco Mark 3 71569102 English 03-17Document72 pagesDurco Mark 3 71569102 English 03-17Triod jackson0% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Bry-Air Dehumidifier FFB SeriesDocument6 pagesBry-Air Dehumidifier FFB Seriesmfisol2000No ratings yet

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocument4 pagesData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990No ratings yet

- Bombas Pentax SADocument48 pagesBombas Pentax SAAgustin CahuanaNo ratings yet

- Ec Fans 2012 WebDocument14 pagesEc Fans 2012 WebOscar Alvitez DominguezNo ratings yet

- 50bp520 (May Dieu Hoa Cong Nghiep Carrier)Document37 pages50bp520 (May Dieu Hoa Cong Nghiep Carrier)Frank Wilson100% (1)

- 2BH1900 Ie2 122010 enDocument2 pages2BH1900 Ie2 122010 enChan Chi Wong PenNo ratings yet

- Financial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 29112018Document36 pagesFinancial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 29112018DSddsNo ratings yet

- XBRL Financial Statements Duly Authenticated As Per Section 134 (Including BoardDocument196 pagesXBRL Financial Statements Duly Authenticated As Per Section 134 (Including BoardDSddsNo ratings yet

- Financial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 30112018Document36 pagesFinancial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 30112018DSddsNo ratings yet

- Financial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 27122018Document25 pagesFinancial Staements Duly Authenticated As Per Section 134 (Including Boards Report, Auditors Report and Other Documents) - 27122018DSddsNo ratings yet

- Affidavit As Per Rule 65 (3) - 13042021Document2 pagesAffidavit As Per Rule 65 (3) - 13042021DSddsNo ratings yet

- Financial Staements Duly Authenticated As Per Section 134 (Including Boards RepoDocument43 pagesFinancial Staements Duly Authenticated As Per Section 134 (Including Boards RepoDSddsNo ratings yet

- 1 s2.0 S019689049900103X MainDocument32 pages1 s2.0 S019689049900103X MainAndreza CardosoNo ratings yet

- Wind Turbine Wake AerodynamicsDocument44 pagesWind Turbine Wake AerodynamicsCarlos AméricoNo ratings yet

- MGT-8-141220201Document3 pagesMGT-8-141220201DSddsNo ratings yet

- Steady and UnsteadyDocument9 pagesSteady and UnsteadyDSddsNo ratings yet

- Form - AOC-4 Sign PDFDocument13 pagesForm - AOC-4 Sign PDFamit kumarNo ratings yet

- Seositecheckup Analysis Report 2016 02 25 12 10 14 PDFDocument26 pagesSeositecheckup Analysis Report 2016 02 25 12 10 14 PDFDSddsNo ratings yet

- Xfoil UserguideDocument33 pagesXfoil UserguideankitkarwaNo ratings yet

- Optimization Design Modeling and Dynamic Analysis For Composite Wind Turbine BladeDocument7 pagesOptimization Design Modeling and Dynamic Analysis For Composite Wind Turbine BladeAryan TomarNo ratings yet

- Introduction Letter - Gardner Denver Nash GroupDocument2 pagesIntroduction Letter - Gardner Denver Nash GroupDSddsNo ratings yet

- Ris R 1024 AirfoilDesignDocument30 pagesRis R 1024 AirfoilDesignDSddsNo ratings yet

- 0Hwkrgviru3Uredelolvwlf'Hvljqri:Lqg7Xuelqhv: +%UDDP - 'YDQ'DP (&1 &-&KULVWHQVHQ0/7K¡JHUVHQ &/DUVHQ5LV¡ .25RQROG'19Document18 pages0Hwkrgviru3Uredelolvwlf'Hvljqri:Lqg7Xuelqhv: +%UDDP - 'YDQ'DP (&1 &-&KULVWHQVHQ0/7K¡JHUVHQ &/DUVHQ5LV¡ .25RQROG'19DSddsNo ratings yet

- Rotor MakingDocument11 pagesRotor MakingDSddsNo ratings yet

- 2ke4 Series PDFDocument2 pages2ke4 Series PDFDSddsNo ratings yet

- KDS Series BrouchureDocument5 pagesKDS Series BrouchureDSddsNo ratings yet

- Drawing 1Document1 pageDrawing 1DSddsNo ratings yet

- Authorization GD USADocument1 pageAuthorization GD USADSddsNo ratings yet

- Edwards Product Catalog English Liquid Ring Pumps PDFDocument68 pagesEdwards Product Catalog English Liquid Ring Pumps PDFAnthonyNo ratings yet

- Liquid Ring Vacuum Pumps and Compressors PDFDocument20 pagesLiquid Ring Vacuum Pumps and Compressors PDFDSddsNo ratings yet

- Greenko Investment Company - Financial Statements 2017-18Document93 pagesGreenko Investment Company - Financial Statements 2017-18DSddsNo ratings yet

- Ukba Photograph Guidance: For Immigration Applications Made in The UK (Version 04/2009)Document2 pagesUkba Photograph Guidance: For Immigration Applications Made in The UK (Version 04/2009)adu_daduNo ratings yet

- Date HS Code Description Origin Countr y Port of Discharge Unit Quantit y Value (INR) Per Unit (INR)Document1 pageDate HS Code Description Origin Countr y Port of Discharge Unit Quantit y Value (INR) Per Unit (INR)DSddsNo ratings yet

- Physicalscience q1 Mod6 Effectsofintermolecularforcesonpropertiesofsubstances v2Document35 pagesPhysicalscience q1 Mod6 Effectsofintermolecularforcesonpropertiesofsubstances v2Marivic Garvida0% (1)

- Fitting Loss CalculationDocument6 pagesFitting Loss CalculationSvetla NikolovaNo ratings yet

- Grade 10 ActivityDocument52 pagesGrade 10 Activityapi-340407914100% (1)

- G11re Toc TZ1Document14 pagesG11re Toc TZ1Mohammad BaqerNo ratings yet

- PRO PCP Data SheetDocument1 pagePRO PCP Data SheetJude RodriguesNo ratings yet

- Riopipeline2019 1469 201906211211ibp1469 19 PDFDocument10 pagesRiopipeline2019 1469 201906211211ibp1469 19 PDFMarcelo Varejão CasarinNo ratings yet

- Design Horizontal Pressure Vessel - 1Document2 pagesDesign Horizontal Pressure Vessel - 1evrim77100% (1)

- Additional Course Material: Physical Properties of FluidsDocument43 pagesAdditional Course Material: Physical Properties of Fluidssilswal1988No ratings yet

- SA-W-DW-SP-001A - Grouting Comm ZINWA - FINALDocument27 pagesSA-W-DW-SP-001A - Grouting Comm ZINWA - FINALDannyNo ratings yet

- Math Calculator Permitted Sample SetDocument100 pagesMath Calculator Permitted Sample SetTala LoayNo ratings yet

- Lab Report 2 Merged PDFDocument11 pagesLab Report 2 Merged PDFInnah Gabrielle AldayaNo ratings yet

- TM4112 - 10 Building The Dynamic Model - SCALDocument91 pagesTM4112 - 10 Building The Dynamic Model - SCALRay YudaNo ratings yet

- Blood Pressure by Height & Age PDFDocument4 pagesBlood Pressure by Height & Age PDFFinda RedhizaNo ratings yet

- Reciprocating Pump Catalog PDFDocument109 pagesReciprocating Pump Catalog PDFDaniel Erasmo Avellaneda SanchezNo ratings yet

- Groeneveld General Manual Twin-3Document64 pagesGroeneveld General Manual Twin-3JasonNo ratings yet

- 03 SM6 - General Parameter IntroductionDocument12 pages03 SM6 - General Parameter IntroductionThức VõNo ratings yet

- CAT 3516 B and 3516 B High Displacement EnginesDocument1 pageCAT 3516 B and 3516 B High Displacement EnginesHemant RasamNo ratings yet

- Rotary Screw Compressor Units: "Mini" Microprocessor ControlDocument20 pagesRotary Screw Compressor Units: "Mini" Microprocessor ControlChrise5502No ratings yet

- 050 MHB 1Document19 pages050 MHB 1sishu21No ratings yet

- B.Divya Krishna: 3 Btech ECEDocument12 pagesB.Divya Krishna: 3 Btech ECEdivya biccavoluNo ratings yet

- Ibp2132 12Document14 pagesIbp2132 12Marcelo Varejão CasarinNo ratings yet

- Reservoir Fluid Study Report GulfaksDocument10 pagesReservoir Fluid Study Report GulfaksAngelo Kristoff MacarioNo ratings yet

- Rv-Rvalve NF00033 1111Document12 pagesRv-Rvalve NF00033 1111David MoleroNo ratings yet