Professional Documents

Culture Documents

Abu Dhabi Trade Center

Uploaded by

john0 ratings0% found this document useful (0 votes)

9 views1 pageDog cat lion play field

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDog cat lion play field

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageAbu Dhabi Trade Center

Uploaded by

johnDog cat lion play field

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

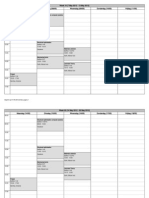

MechEng 352 Manufacturing Systems

Wk.

Month

Monday

Wednesday (11.00 - 12.00)

303-102

Tuesday

July

Course Schedule

Room

Thursday (9.00 - 10.00)

Room 303-102

Lec.1) Inroduction to the course. Course

18

19

20 teaching methodoloy and objectives.

21

Introduction to manufacturing plant layout.

Vers. 1

Lec. 2) Manufacturing systems, Layout

types.

Friday (10.00 - 11.00)

260-051

22

Lec. 3) Systematic methods of plant layout,

Introduction to Facilities Layout task (Task 1).

25

26

27

Lec. 4) Facilities layout/ How a Factory Works,

28 Lec. 5) Materials handling systems.

Video

29

Lec. 6) Simulation and modeling

methodologies.

Lec. 7) Simulation & modeling and demo of

Arena.

Lec. 9) Queues and queueing systems

management.

10

Lec. 10) Intro to manufacturing work station

design & ergonomics.

11 Lec.11) Time study

2

August

3

4

15

17

23

24 Lec. 16) CAD/CAM, CAPP and CNC 1.

5

22

Lec.13) Industrial ergonomics. Industrial

engineering techniques. Work standards.

16

Lec. 8) Simulation and modeling.

Room

Lec.12) Industrial engineering environment

12 management. Work standards, introduction to

Task 2.

18

Lec.14) Industrial ergonomics. Industrial

engineering techniques. Learning curves

19

Lec.15) Industrial ergonomics. Industrial

engineering techniques. Work standards.

25 Lec. 17) CAD/CAM, CAPP and CNC 2.

26 Lec. 18) CAD/CAM, CAPP and CNC 3.

15

16

6

Sept.

Mid. Semester break

12

Lec. 19) CAD/CAM, CAPP and CNC 4,

Introduction to CAM task (Task 3).

Lec. 20) CAD/CAM, CAPP and CNC 5.

Simulation Due 12.00

13

14

20

21 Lec. 21) CAD/CAM, CAPP and CNC 6.

22 Lec. 22) CAD/CAM, CAPP and CNC 7.

26

27

28 Lec. 24) CAD/CAM, CAPP and CNC 8. (XX)

29

Lec. 25) Manufacturing planning and

scheduling

30

Lec.28) JIT and lean manufacturing. Push

and pull systems. Kanban and CONWIP

(2).

7 Lec 29) Revision of Quality Systems.

10

11

12 Lec. 30) Reliability.

17

18

19

7

19

FIELD TRIP

23 Lec. 23) Production planning and scheduling.

9

Oct.

10

11

12

Lec.27) JIT and lean manufacturing. Push and

pull systems. Kanban and CONWIP.

13 Lec. 31) Reliability and Maintenance.

Lec. 33) Supply Chain Problems - Supply chain

20 Lec. 34) Recap

simulation.

Lec. 26) Introduction to Preactor and to Factory

Scheduling task (Task 4),

14 Lec. 32) Preventative Maintenance

21

You might also like

- Systems Engineering Principles and PracticeFrom EverandSystems Engineering Principles and PracticeRating: 3.5 out of 5 stars3.5/5 (4)

- Btech PortionDocument11 pagesBtech PortionNitesh ChhabriaNo ratings yet

- BTech (Mechanical Engineering) Curriculum For 2012 - 2013Document103 pagesBTech (Mechanical Engineering) Curriculum For 2012 - 2013Allen ChandlerNo ratings yet

- Introduction to Algorithms & Data Structures 3: Learn Linear Data Structures with Videos & Interview QuestionsFrom EverandIntroduction to Algorithms & Data Structures 3: Learn Linear Data Structures with Videos & Interview QuestionsRating: 5 out of 5 stars5/5 (1)

- Csscheme2010 (VTUPlanet - Com) SchemesDocument10 pagesCsscheme2010 (VTUPlanet - Com) SchemesAkhil Kumar JhaNo ratings yet

- TEU, 2019time TableDocument18 pagesTEU, 2019time TableTHEOPHILUS ATO FLETCHERNo ratings yet

- Modeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationFrom EverandModeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationNo ratings yet

- Process Piping Drafting Course Outlines (FINAL)Document13 pagesProcess Piping Drafting Course Outlines (FINAL)andrew myintmyatNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- Mechanical CurriculumDocument103 pagesMechanical CurriculumPremsai Tadisetti100% (1)

- BtechaDocument104 pagesBtechamathewsivin5266No ratings yet

- Project and Production Management (Video)Document3 pagesProject and Production Management (Video)Sreekanth Reddy NarapareddyNo ratings yet

- FKE S3 1011 BUKU LOG Amalan KejuruteraanDocument80 pagesFKE S3 1011 BUKU LOG Amalan Kejuruteraanng soo keeNo ratings yet

- Schedule - 1 5 2012Document7 pagesSchedule - 1 5 2012Bereket TadeseNo ratings yet

- ST 03 Module Information SheetDocument1 pageST 03 Module Information SheetJoyce Saddhu MeettooNo ratings yet

- Mechanical PDFDocument144 pagesMechanical PDFPrad UpNo ratings yet

- Syllabus 2016Document1 pageSyllabus 2016Anonymous 0eEiyZcNo ratings yet

- Course Structure ME 423 2023Document2 pagesCourse Structure ME 423 2023Supritha EagaNo ratings yet

- Syllabi and Scheme of TeachingDocument41 pagesSyllabi and Scheme of TeachingAshutosh ChaturvediNo ratings yet

- Course Plan PRJ101 CJ Spring 2013 Block 2Document8 pagesCourse Plan PRJ101 CJ Spring 2013 Block 2An LêNo ratings yet

- Group B COE PDFDocument124 pagesGroup B COE PDFParas GargNo ratings yet

- Bda 30903 - Solid Modeling ModuleDocument179 pagesBda 30903 - Solid Modeling ModuleIzwan SaifudinNo ratings yet

- Mechanicalscheme2010 (VTUPlanet - Com) SchemesDocument8 pagesMechanicalscheme2010 (VTUPlanet - Com) SchemesanitatippanagoudarNo ratings yet

- Cive 1006y Building ConstructionDocument6 pagesCive 1006y Building ConstructionAvinaash VeeramahNo ratings yet

- Description Any Other Contributary Institution/Industry Developed/organ Ized by Duration Resource Persons Target Audience Usage and CitationDocument3 pagesDescription Any Other Contributary Institution/Industry Developed/organ Ized by Duration Resource Persons Target Audience Usage and CitationYajur VananNo ratings yet

- Table of Contents Template For ProjectDocument1 pageTable of Contents Template For ProjectJohnMercNo ratings yet

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyNo ratings yet

- Unit Test - I & Ii Unit Test - I & Ii: Prepared by Checked by Approved byDocument1 pageUnit Test - I & Ii Unit Test - I & Ii: Prepared by Checked by Approved byAnonymous vvO0nZWflrNo ratings yet

- EMM3223 Assignment1 2010 2011 2Document4 pagesEMM3223 Assignment1 2010 2011 2Emoxie X - StabyielzNo ratings yet

- Orion Is Perfect For Automating The Design of Concrete Building Schemes.Document1 pageOrion Is Perfect For Automating The Design of Concrete Building Schemes.Alden CayagaNo ratings yet

- Sem 6Document11 pagesSem 6Brahat SinghNo ratings yet

- Adithya Institute of Technology Coimbatore - 107 Internal Assessment TestDocument1 pageAdithya Institute of Technology Coimbatore - 107 Internal Assessment Testhakkem bNo ratings yet

- CourseDesc - PDF IskandariaDocument1 pageCourseDesc - PDF IskandariaMohammad AmmarNo ratings yet

- Course Plan I2I Fall 2013 Block 3Document6 pagesCourse Plan I2I Fall 2013 Block 3Đào Duy TúNo ratings yet

- (B.E. Production Engineering Sem - VII & VIII) : Revised Syllabus ofDocument41 pages(B.E. Production Engineering Sem - VII & VIII) : Revised Syllabus ofAbhinandan KolhapureNo ratings yet

- TRIZ - Improve Your Problem Solving Skills (Tetris Org)Document312 pagesTRIZ - Improve Your Problem Solving Skills (Tetris Org)julyhim100% (5)

- Real Time Operating System (IDE) : USN TEE02Document2 pagesReal Time Operating System (IDE) : USN TEE02MallikarjunNo ratings yet

- Industrial EngineeringDocument9 pagesIndustrial Engineeringrjrahul25No ratings yet

- CS. 1st RoundDocument1 pageCS. 1st RoundYared AyeleNo ratings yet

- MTechPDD Autonomous Syllabus Wef 17-18Document63 pagesMTechPDD Autonomous Syllabus Wef 17-18BVoc AutomobileNo ratings yet

- BEMechanicalProduction Engineering2015SchemeDocument37 pagesBEMechanicalProduction Engineering2015SchemerajatjainkkjNo ratings yet

- 2888 SampleAgenda IC L1 ContentWeekDocument5 pages2888 SampleAgenda IC L1 ContentWeekbalakaleesNo ratings yet

- Pd9211-Quality Concepts in Design 2Document2 pagesPd9211-Quality Concepts in Design 2Vignesh VickyNo ratings yet

- III Semester: (AUTONOMOUS) 2008 - 09 Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsDocument5 pagesIII Semester: (AUTONOMOUS) 2008 - 09 Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsNarasimha KudvaNo ratings yet

- Chapter 01Document42 pagesChapter 01Dominique Serge AmbassaNo ratings yet

- B.E. Information Science and Engineering (Common To CSE & ISE) Iii SemesterDocument2 pagesB.E. Information Science and Engineering (Common To CSE & ISE) Iii SemesterKumar SourabhNo ratings yet

- QTNPPR 1Document2 pagesQTNPPR 1Shruthi BhatNo ratings yet

- Industrial EngineeringDocument1 pageIndustrial EngineeringsvkindiaNo ratings yet

- Design and Performance Evaluation of Solar Liquid Desiccant SystemDocument6 pagesDesign and Performance Evaluation of Solar Liquid Desiccant SystemGRD JournalsNo ratings yet

- Sheet 07Document1 pageSheet 07Ahmed AymanNo ratings yet

- Assessment 2Document7 pagesAssessment 2achumakotishiniNo ratings yet

- 22ESC144Document4 pages22ESC144Naveen S BasandiNo ratings yet

- Sample Agenda: Siemens Mechatronic Systems Certification ProgramDocument5 pagesSample Agenda: Siemens Mechatronic Systems Certification ProgrambalakaleesNo ratings yet

- Materi # 14 - Line Balancing-1Document35 pagesMateri # 14 - Line Balancing-1Nopporn WiseschatNo ratings yet

- Individual Timetable For 2012-2013Document6 pagesIndividual Timetable For 2012-2013Kumaran PalaniNo ratings yet

- Courses Scheme & Syllabus: B.E. (Computer Engineering)Document124 pagesCourses Scheme & Syllabus: B.E. (Computer Engineering)rajesh adhikariNo ratings yet

- Katalog Teknik Buku ImportDocument21 pagesKatalog Teknik Buku ImportMuhammad RidwanNo ratings yet

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)