Professional Documents

Culture Documents

Article - Stress Relieving Heat Treatments For Austenitic Stainless Steels

Uploaded by

abhishek1983270 ratings0% found this document useful (0 votes)

87 views2 pagesHeat Treatment

Original Title

Article_ Stress Relieving Heat Treatments for Austenitic Stainless Steels

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHeat Treatment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

87 views2 pagesArticle - Stress Relieving Heat Treatments For Austenitic Stainless Steels

Uploaded by

abhishek198327Heat Treatment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

12/24/13

Article: Stress relieving heat treatments for austenitic stainless steels

Stress relieving heat treatments for austenitic stainless steels

Introduction

Unlike martensitic steels, the austenitic stainless steels are not hardenable by heat treatment

as no phase changes occur on heating or cooling.

Softening is done by heating in the 1050/ 1120C range, ideally followed by rapid cooling.

This is of course the complete opposite to martensitic steels, where this sort of treatment would

harden the steel.

Apart from inter-stage annealing during complex or severe forming operations, for many

applications, final stress relieving austenitic stainless steel products is not normally needed.

Effect of residual stresses

Cold worked austenitic stainless steels will contain some 'strain induced' martensite, which, as

well as making the steel partially 'ferro-magnetic', can also reduce the corrosion resistance.

A highly stressed cold worked structure may also have lower general corrosion resistance than

a fully softened austenitic structure.

The main hazard is stress corrosion cracking (SCC), which relies on tensile stresses as part of

the failure mechanism.

Stress relieving removes such residual tensile stresses and so improves the SCC resistance.

The other main reason for stress relieving is to provide dimensional or shape stability. The risk

of distortion can be reduced during forming or machining operations by stress relieving.

The approach to heat treatment selection

A full solution anneal stress-relieving heat treatment will re-transform any martensite formed

back to austenite. (This will also give the lowest magnetic permeability possible for any

particular grade.)

Slow cooling is advisable to avoid introducing distortion problems or residual thermal tensile

stresses and so the risk of sensitisation during a slow cool may have to be accepted.

The temperature ranges used in stress relieving must avoid sensitising the steel to corrosion or

the formation of embrittling precipitates.

As a general guideline, it is advisable that the range 480-900C is avoided.

The low carbon (304L or 316L) or the stabilised (321 or 347) types should not be at risk from

corrosion sensitisation during stress relieving treatments.

Stress relieving treatments for austenitic stainless steels

www.bssa.org.uk/topics.php?article=76

1/2

12/24/13

Article: Stress relieving heat treatments for austenitic stainless steels

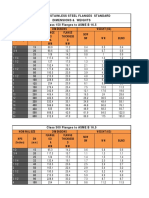

The table shows alternative treatments in order of preference.

Steel Grade Types

Process or Corrosion Hazard

Standard Carbon

304, 316

Low Carbon

304L, 316L

Stabilised

321, 347

Annealing following severe forming

A,C

A,C

Forming interstage annealing

C(A,B)

A,B,C

B,A,C

Post welding heavy sections and/or high service

loading applications

A,C,B

A,C,B

Dimensional stability

Severe SCC risk in service

Note 1

A,B

B,A

Some risk of SCC in service

A,B,C

B,A,C

Note 1

Standard carbon grades are susceptible to intergranular corrosion (ICC) on slow cooling

treatments. Fast cooling treatments are not advisable as residual tensile stresses could result in

SCC.

Note 2

Treatment B is also intended to reduce the risk of "knife-line" attack in the stabilised grades.

This form of attack is due to the solution of titanium or niobium carbides at higher annealing

temperatures.

Heat Treatment Codes

Code

Treatment Cycle

1050 / 1120C, slow cool

900C, slow cool

1050 / 1120C, fast cool

210 / 475C slow cool (approx. 4 hours per 25mm of section)

www.bssa.org.uk

http://www.bssa.org.uk/topics.php?article=76

http://goo.gl/ffgS

www.bssa.org.uk/topics.php?article=76

2/2

You might also like

- Crude Oil Storage Tanks-BasicsDocument176 pagesCrude Oil Storage Tanks-BasicsPandipperumal Sankaralingam100% (44)

- Heat Treatment of SteelDocument59 pagesHeat Treatment of SteelNaman ShethNo ratings yet

- Acero para BarcosDocument39 pagesAcero para BarcosviyfNo ratings yet

- Heat Treatment of Welded JointsDocument11 pagesHeat Treatment of Welded JointsMuhammed SulfeekNo ratings yet

- NDT of Precipitation Hardened SteelsDocument12 pagesNDT of Precipitation Hardened SteelsMahade Hasan DipuNo ratings yet

- Heat Treating Titanium Alloys for Strength and PropertiesDocument10 pagesHeat Treating Titanium Alloys for Strength and PropertiesPutu Calista Gitta100% (1)

- Expansion JointsDocument15 pagesExpansion Jointsaop10468No ratings yet

- Austenitic stainless steels properties and welding guideDocument4 pagesAustenitic stainless steels properties and welding guideandy1036No ratings yet

- 06 - Weld Ability and Defects in WeldmentsDocument50 pages06 - Weld Ability and Defects in Weldmentsamitjee138463No ratings yet

- What Every Engineer Should Know About Welding ProceduresDocument13 pagesWhat Every Engineer Should Know About Welding Proceduresarash59_4uNo ratings yet

- Heat Treatment Jominy TestDocument12 pagesHeat Treatment Jominy Testmayur_mechNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Precipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticDocument3 pagesPrecipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticClaudia MmsNo ratings yet

- Solvent RecoveryDocument22 pagesSolvent RecoveryNikul Rathod100% (1)

- Heat Treatment of Steel TTT CurveDocument59 pagesHeat Treatment of Steel TTT CurveINSTECH Consulting100% (1)

- Heat Treatment GC - 08Document54 pagesHeat Treatment GC - 08kr_abhijeet72356587No ratings yet

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- Annealing Stainless Steel 304-316Document4 pagesAnnealing Stainless Steel 304-316nepcom9541No ratings yet

- Engg Metallurgy Lecture 5Document54 pagesEngg Metallurgy Lecture 5Patil Sudheer GowdNo ratings yet

- Samsung Refrigerator and Whaser Repair 2011Document416 pagesSamsung Refrigerator and Whaser Repair 2011nibble1974No ratings yet

- Flange Weight ChartDocument1 pageFlange Weight Chartabhishek198327No ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Geotextile BookDocument63 pagesGeotextile BookIsparmoNo ratings yet

- Heat Treatment of Welded JointsDocument17 pagesHeat Treatment of Welded JointsErick HoganNo ratings yet

- Aerodynamic Characteristics of NACA 4412 AirfoilDocument19 pagesAerodynamic Characteristics of NACA 4412 AirfoilMuhammad HattaNo ratings yet

- Practical Proteins and Amino Acids Identification PDFDocument23 pagesPractical Proteins and Amino Acids Identification PDFFarahDeebaNo ratings yet

- 316LNDocument3 pages316LNGanesh KcNo ratings yet

- Material Science QuestionsDocument40 pagesMaterial Science QuestionsLucky KapoorNo ratings yet

- Types of PumpsDocument68 pagesTypes of PumpsVicky JeganNo ratings yet

- Duplex Stainless Steel Guide - Strengths, Uses & LimitationsDocument7 pagesDuplex Stainless Steel Guide - Strengths, Uses & LimitationsRizalzi BachtiarNo ratings yet

- Stainless Steels For Cryogenic Applications - KEY To METALS ArticleDocument3 pagesStainless Steels For Cryogenic Applications - KEY To METALS Articlekumarpankaj030No ratings yet

- Heat Treatment of Welded Joints GuideDocument26 pagesHeat Treatment of Welded Joints Guidelinhcdt3No ratings yet

- Prepare by Nasrizal Mohd Rashdi Senior Lecturer Welding & Quality Inspection Universiti Kuala LumpurDocument39 pagesPrepare by Nasrizal Mohd Rashdi Senior Lecturer Welding & Quality Inspection Universiti Kuala LumpurFaiz IshakNo ratings yet

- API 571 Notes ImportantDocument6 pagesAPI 571 Notes ImportantMalik Ansar Hayat100% (1)

- Standard Carbon & Stainless Steel Flange DimensionsDocument4 pagesStandard Carbon & Stainless Steel Flange Dimensionsl kishore100% (2)

- Grade 316 316LDocument9 pagesGrade 316 316LvsajuNo ratings yet

- Helium Leak Testing FundamentalsDocument2 pagesHelium Leak Testing Fundamentalsabhishek198327100% (1)

- Heat Treatment of Welded JointsDocument4 pagesHeat Treatment of Welded JointskingstonNo ratings yet

- Stress Relieving Heat Treatments For Austenitic Stainless SteelsDocument1 pageStress Relieving Heat Treatments For Austenitic Stainless SteelsVijay BedakihaleNo ratings yet

- HEAT TREATMENT GUIDE FOR WELDED JOINTSDocument10 pagesHEAT TREATMENT GUIDE FOR WELDED JOINTSdokumen qcNo ratings yet

- North American Stainless: Long Products Stainless Steel Grade SheetDocument8 pagesNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314No ratings yet

- Is Post Weld Heat Treatment Normally Required When Welding Chromium-Nickel Austenitic Stainless Steels?Document1 pageIs Post Weld Heat Treatment Normally Required When Welding Chromium-Nickel Austenitic Stainless Steels?kalyan1976No ratings yet

- Welding of Austenitic Stainless Steel - Part 2 - TWIDocument6 pagesWelding of Austenitic Stainless Steel - Part 2 - TWISumantaNo ratings yet

- Heat Treatment Steel: ObjectDocument10 pagesHeat Treatment Steel: ObjectKetut Rizki FirmandanuNo ratings yet

- Heat Treatment of SteelsDocument6 pagesHeat Treatment of SteelsSrinivas LaishettyNo ratings yet

- Guidelines For Hard Facing Onto SteelsDocument7 pagesGuidelines For Hard Facing Onto SteelsmohamedfirozNo ratings yet

- Stress RelievingDocument1 pageStress RelievingManjadi MaverickNo ratings yet

- Background: Table 1. Some Standard Designations For Duplex Stainless SteelalloysDocument3 pagesBackground: Table 1. Some Standard Designations For Duplex Stainless SteelalloysBharat TailorNo ratings yet

- API Self NotesDocument13 pagesAPI Self NotesOwais AlamNo ratings yet

- Material Science and Engineering Heat TRDocument18 pagesMaterial Science and Engineering Heat TRSamit NagNo ratings yet

- Chapter 8 - Stainless Steels - 2016 - Applied Welding EngineeringDocument8 pagesChapter 8 - Stainless Steels - 2016 - Applied Welding EngineeringJhair Jhamidh Aquino PortocarreroNo ratings yet

- The ABC's of Arc Welding: Weld DecayDocument4 pagesThe ABC's of Arc Welding: Weld DecayLakshmi KanthNo ratings yet

- Welding Technology - Pre and Post Weld Heat TreatDocument19 pagesWelding Technology - Pre and Post Weld Heat TreatNowsherwan MazariNo ratings yet

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocument12 pages1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Technical Bulletin - ECOSS - FAQDocument3 pagesTechnical Bulletin - ECOSS - FAQINPNo ratings yet

- 3.stress ReliefDocument2 pages3.stress ReliefRajeevSangamNo ratings yet

- Through Hardening ProcessesDocument3 pagesThrough Hardening ProcessesPurushothama Nanje Gowda100% (2)

- Stress relieving steel at 650°C for 1 hour removes 90% internal stressesDocument4 pagesStress relieving steel at 650°C for 1 hour removes 90% internal stressesAshish BoraNo ratings yet

- Everything You Need to Know About Duplex Stainless SteelsDocument4 pagesEverything You Need to Know About Duplex Stainless SteelsAndy PhoenixNo ratings yet

- 05 HeattreatmentDocument39 pages05 HeattreatmentHaerul AtamimiNo ratings yet

- Literature ReviewDocument23 pagesLiterature ReviewRISHAVNo ratings yet

- Stainless SteelDocument8 pagesStainless SteelEdgarDavidDiazCampos100% (1)

- 3 Eng Stainless Steel Tube AnnealingDocument16 pages3 Eng Stainless Steel Tube AnnealingVictor HugoNo ratings yet

- Grade 2205 DuplexDocument9 pagesGrade 2205 Duplexkresimir.mikoc9765No ratings yet

- Heat TreatmentDocument2 pagesHeat TreatmentUsman MuhammadNo ratings yet

- Plasma Nitriding Process - DataDocument11 pagesPlasma Nitriding Process - Datayadu kumar singhNo ratings yet

- Stainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)Document6 pagesStainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)ganmosesNo ratings yet

- Heat Treatment of Steels (Power Point Presentation)Document14 pagesHeat Treatment of Steels (Power Point Presentation)Armando Lopez Bond75% (4)

- Prevention From Inter-Granual CorrosionDocument7 pagesPrevention From Inter-Granual CorrosionDevashish JoshiNo ratings yet

- 904L (Valbruna)Document2 pages904L (Valbruna)Claudia MmsNo ratings yet

- Heat Treatment of Carbon SteelDocument23 pagesHeat Treatment of Carbon SteelArielle Joyce de JesusNo ratings yet

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- CR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To NoharaDocument2 pagesCR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To Noharaabhishek198327No ratings yet

- Welding Rod Selection 1 PDFDocument1 pageWelding Rod Selection 1 PDFabhishek198327100% (2)

- Hem PlasticsDocument3 pagesHem Plasticsabhishek198327No ratings yet

- ModulesDocument5 pagesModulesabhishek198327No ratings yet

- SQ - HD Plug For HeaderDocument1 pageSQ - HD Plug For Headerabhishek198327No ratings yet

- Specialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Document1 pageSpecialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Carlos Abril FlorezNo ratings yet

- Dish Drg. - 2.9.2014Document1 pageDish Drg. - 2.9.2014abhishek198327No ratings yet

- Air TankDocument1 pageAir Tankabhishek198327No ratings yet

- Welcome To Our WebsiteDocument5 pagesWelcome To Our Websiteabhishek198327No ratings yet

- DCMS Engineering CompanyDocument1 pageDCMS Engineering Companyabhishek198327No ratings yet

- ASTM Flange DimensionsDocument2 pagesASTM Flange DimensionsjacquesmayolNo ratings yet

- Packed Bed Column MS DWG ModelDocument1 pagePacked Bed Column MS DWG Modelabhishek198327No ratings yet

- App - Copy WPSDocument2 pagesApp - Copy WPSabhishek198327No ratings yet

- Helium TestingDocument1 pageHelium Testingabhishek198327No ratings yet

- Specialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Document1 pageSpecialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Carlos Abril FlorezNo ratings yet

- Jyoti Architectural Products PVT LTDDocument1 pageJyoti Architectural Products PVT LTDabhishek198327No ratings yet

- Basics of Stress RelievingDocument5 pagesBasics of Stress Relievingabhishek198327No ratings yet

- Grain SizeDocument2 pagesGrain Sizeprabhjot singh1No ratings yet

- Kjlced09 Sec01 Pages129-145 Bellowstubing&WeldfittingsDocument17 pagesKjlced09 Sec01 Pages129-145 Bellowstubing&Weldfittingsabhishek198327No ratings yet

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- Heat Treatment of Welded JointsDocument4 pagesHeat Treatment of Welded Jointsabhishek198327No ratings yet

- Stress Concentration Factors and Design GuidelinesDocument4 pagesStress Concentration Factors and Design Guidelinesabhishek198327No ratings yet

- Magnetic Field Effect on Weld PropertiesDocument54 pagesMagnetic Field Effect on Weld PropertiesSarthak sainiNo ratings yet

- Aspl 2011 PDFDocument29 pagesAspl 2011 PDFRajkumar ANo ratings yet

- Masterfiber: Monofilament Polypropylene Fibres For Cementitious SystemDocument2 pagesMasterfiber: Monofilament Polypropylene Fibres For Cementitious SystemHsaam Hsaam100% (1)

- Advantages and Disadvantages of Stainless Steel CookwareDocument15 pagesAdvantages and Disadvantages of Stainless Steel CookwareFaIz FauziNo ratings yet

- Sect 5Document25 pagesSect 5PuneetNo ratings yet

- Glassy Carbon - Wikipedia, The Free Encyclopedia PDFDocument5 pagesGlassy Carbon - Wikipedia, The Free Encyclopedia PDFNaveen PalaNo ratings yet

- Optional Strain Rate Forms For The Johnson CookDocument17 pagesOptional Strain Rate Forms For The Johnson CookTien KimNo ratings yet

- Carbon Compounds Chemistry GuideDocument20 pagesCarbon Compounds Chemistry Guideirisyyy27No ratings yet

- Chapter-2-LEVEL MEASUREMENTDocument26 pagesChapter-2-LEVEL MEASUREMENTMohammed YusufNo ratings yet

- QIAexpress Detection and Assay HandbookDocument104 pagesQIAexpress Detection and Assay HandbookghadbaneNo ratings yet

- Density PhET Lab SheetDocument5 pagesDensity PhET Lab SheetJasper Johnston100% (1)

- Predictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineDocument14 pagesPredictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineJoel E ValenciaNo ratings yet

- Lab Manual BT3120Document27 pagesLab Manual BT3120Amit KumarNo ratings yet

- Zener BZX83CDocument2 pagesZener BZX83CPelotaDeTrapoNo ratings yet

- Standby battery product overviewDocument2 pagesStandby battery product overviewHillary McgowanNo ratings yet

- Weberdry 130 PR Grey-WhiteDocument2 pagesWeberdry 130 PR Grey-WhiteabbNo ratings yet

- How The Concept of The Element Evolved From Ancient Greek To The PresentDocument23 pagesHow The Concept of The Element Evolved From Ancient Greek To The PresentPineda, Sean AlfredNo ratings yet

- FastLUBE lubricants guide for anti-galling and corrosion protectionDocument1 pageFastLUBE lubricants guide for anti-galling and corrosion protectionneubofren600No ratings yet

- IIT-JEE Syllabus: RSM79 PH I PP CH 1Document34 pagesIIT-JEE Syllabus: RSM79 PH I PP CH 1NayanKishorkumarThakkerNo ratings yet

- Évfolyam Dolgozat - Peterke ReginaDocument6 pagesÉvfolyam Dolgozat - Peterke ReginaRegina PeterkeNo ratings yet

- Tutorial 1 - AnswersDocument8 pagesTutorial 1 - AnswersRaymond Kakala100% (6)

- Inlab MC X5 Accessories: Order FormDocument1 pageInlab MC X5 Accessories: Order FormCiprian SarivanNo ratings yet

- ApplicationNote PH Measurement JamJellies EN 30538204Document4 pagesApplicationNote PH Measurement JamJellies EN 30538204MarcinNo ratings yet