Professional Documents

Culture Documents

Goodrich Michael Resume July 2016-1

Uploaded by

api-322800369Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goodrich Michael Resume July 2016-1

Uploaded by

api-322800369Copyright:

Available Formats

MichaelR.

Goodrich

DirectorofEngineeringandSales

6783572140

Emrgood1914rev1@gmail.com

CareerSummary

Internationally experienced Director of Engineering and Sales for a tier 1 automotive exhaust component

supplier. Proven record of identifying new markets and delivering sales growth, developing new products

and technologies, launching manufacturing sites, and driving improvements that lead to significant cost

savings and cash flow gains. Spearheaded company expansion into Europe through new customer

development, effective contract negotiations and technical sales. Unique ability to combine technical

expertise with customer development and sales management. Previous business owner with a broad

knowledge and understanding of what it takes to be successful. Excellent leader, mentor and teacher,

resourceful and unique problem solver and superb engineer.

RecentProfessionalAccomplishments

Established international sales organizations in Sweden, France, Italy,

Norway, Czech Republic and the United Kingdom resulting in new exhaust

related business with major OEM Diesel Truck and Automotive

manufacturers worth $15M in annual sales.

Launched new manufacturing/technical center in Prague Czech Republic.

Designed, developed and implemented multiple new product solutions used

in automotive and heavy duty truck exhaust applications.

Invented new flexible tube manufacturing process that allows for

production brazing without degrading bellows material properties.

Patent Pending.

During my 13 year career at Flexible Metal the engineering and sales

team has grown the business from $3M in annual sales to a booked

sales value in 2018 of $56M.

AccumulatedKnowledge

New business start-up and organic sales growth.

P&L business management.

Acquisitions and company structure optimization.

Multi-site and international management.

Lean manufacturing principles.

Program management using APQP.

Machine design and high speed custom automation.

IndustrySpecificandProductKnowledge

Vibration, thermal fatigue and FEA analysis.

Material applications for high temperature and corrosive applications.

Powdered metal and casting design applications.

Welding, brazing and joint design.

Bellows design and application.

Fabricated exhaust manifold design and welding profiles.

Diesel and gas engine exhaust systems.

Automotive and TS16949 requirements.

GD&T Application.

MichaelR.Goodrich

6783572140

Emrgood1914rev1@gmail.com

DirectorofEngineeringandSales

FlexibleMetalIncorporated

Tucker,Georgia

2003toPresent

Tier1,TS16949,ISO14001,ITARcertifiedmanufacturerofbellows,fabricatedexhaustmanifoldsandhightemperatureexhaust

assembliesfortheAutomotiveandDieselEngineIndustries.Groupsalestotalof$48Mfor2016fiscalyear.Privateownership.

DirectorofEngineeringandSales

ManagementResponsibilitiesTuckerGA,HamburgMI,PragueCzechRepublic

2010toPresent

Engineering and Sales Manager responsible for:

Product engineering design and technical support.

Product costing and competitive evaluation.

Program management using all aspects of APQP.

Prototype engineering and product testing.

Sales and technical engineering support required to maintain and develop new customers.

Outside sales representatives covering the major Automotive manufactures, OEM Diesel manufactures

and major system suppliers in Detroit metro area, US Midwest and Northeast, Sweden, Norway,

France, Italy, Czech Republic and the United Kingdom.

Group Total: 22

ResponsibilitiesandAccomplishments

Established new manufacturing/technical center in Prague Czech Republic and secured initial

production contracts with new international customers.

Completed acquisition and integration of Michigan Tubular Products Division. Implemented

organizational changes and sales strategies that generated new growth worth $20M annually.

Responsible for developing international and domestic growth strategy using engineering technical

support, product design and market evaluation.

Competitive product analysis evaluating price, manufacturing and technical solutions.

New product development solutions for existing design styles and new applications.

Continuous improvement of all engineering systems to enhance effectiveness and efficiency.

Management and professional development of engineering staff.

EngineeringManager

ManagementResponsibilities

2003to2010

Program Manager responsible for product launch management, customer sales and engineering technical

support.

Product Design Engineering Manager responsible for product design engineering, bill of materials, product

testing and prototype development.

Manufacturing Engineering Manager responsible for new project launches, capital expenditures, existing

process improvements and technical maintenance staff.

Group Total: 14

ResponsibilitiesandAccomplishments

Designed, implemented and launched 12 new exhaust related products within a 16 month period resulting

in new annual sales worth $18M.

Implemented over $2.5M in capital equipment and new process hydro-forming technology, automated

welding processes and laser technology.

Cost reduced through both design and process improvements 3 product families resulting in $630K annual

savings.

Created APQP system for cradle to grave project management (quote through production)

Responsible for all PPAP documentation including control plans, process flow, FMEAs and customer

specific requirements.

MichaelR.Goodrich

6783572140

Emrgood1914rev1@gmail.com

DirectorofEngineeringandSales

MSCAutomation

Wilmington,NorthCarolina

1996to2003

Highspeedassemblymachinedesignandbuilder,$2Mannualsales.

Owner

Establishedallfinancialregulation,costcontrolsystemsandP&Lmanagement.Developednewbusiness

opportunitiesandmarketstrategiestosecurefuturegrowth.Designedandbuiltcustommachineryand

performedallnecessaryfunctionstoinsurecompanysuccess.CustomersincludedTycoElectronics,Cooper

BussmannFuseandPurolatorFilters.

SeniorFlexonics

Bartlett,Illinois

1991to1996

Tier1automotivesupplier,$150Mannualsales.

ProductCenterDirectorFlexibleTubingDivision

ManagementResponsibilities

General management and P&L responsibilities for all aspects and operational functions of a selfsufficient business group.

Responsible for group of over 300 employees.

Geographic responsibilities included Pacific Rim and North American applications.

ResponsibilitiesandAccomplishments

Managed and directed a rapid period of growth that saw the companys sales increase from $13m to $60M.

BusinessUnitManagerAutomotiveGroup

ManagementResponsibilities

Managed 12 person group consisting of district sales managers, sales service representatives, product

design engineers, manufacturing engineers and project engineers.

SeniorProductDesignEngineerAutomotiveGroup

Responsibilities

Acted as main interface with customer engineer for design and engineering requirements, prototype parts

and engineering cost estimates.

MachinedProductsCompany

Skokie,Illinois

1989to1991

Customdesignedandbuiltmachiningcentersforsecondarymachiningoperations.PrivateOwnership.

Project/DesignEngineer

Responsibilities

Conceptualization, layout and design of high speed production machining centers, tube bending machines

and assembly units.

EducationandIndustrySpecific

B.S.

SAE

SAE

SAE

SAE

Mechanical Engineering

Diesel Engine Technology

Exhaust Flow Performance

Engineering Project Management

PFMEA/DFEMA Application

University of Illinois Chicago

1989

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Designing Your Life - Stanford Life Design LabDocument7 pagesDesigning Your Life - Stanford Life Design LabnicNo ratings yet

- FPGA Architecture, Technologies, and Tools: Neeraj Goel IIT DelhiDocument63 pagesFPGA Architecture, Technologies, and Tools: Neeraj Goel IIT DelhiAnuj BhattNo ratings yet

- Timetable - 2023 08 03Document22 pagesTimetable - 2023 08 03loai aghbariNo ratings yet

- What Is Mechatronics?: Ieee/Asme Transactions On Mechatronics, Vol. MARCH 1996Document5 pagesWhat Is Mechatronics?: Ieee/Asme Transactions On Mechatronics, Vol. MARCH 1996Daniel Martinez100% (1)

- Arne JacobsenDocument4 pagesArne JacobsenLucas TurmenaNo ratings yet

- الإبداع الفكرى للتصميم الداخلي والمتطلبات الوظيفيةDocument19 pagesالإبداع الفكرى للتصميم الداخلي والمتطلبات الوظيفيةmalak elmeligyNo ratings yet

- Trends and Recent Advancements in Bridge Launching TechniquesDocument7 pagesTrends and Recent Advancements in Bridge Launching TechniquesavseqNo ratings yet

- Computer Standards & Interfaces: David C. ChouDocument7 pagesComputer Standards & Interfaces: David C. ChouAndrés LizarazoNo ratings yet

- Abet Syllabus Me 536-1Document2 pagesAbet Syllabus Me 536-1Mohamed Al-OdatNo ratings yet

- Typography Rules and Terms That Every Designer Must KnowDocument11 pagesTypography Rules and Terms That Every Designer Must KnowChristopher ErnstNo ratings yet

- 8 Principles To Achieve OpEx by Kevin DugganDocument11 pages8 Principles To Achieve OpEx by Kevin DugganAlberto ForteNo ratings yet

- 3 Mark - Tekla BIM in SingaporeDocument13 pages3 Mark - Tekla BIM in Singaporehieu49xfNo ratings yet

- DMC College FoundationDocument13 pagesDMC College FoundationEarl Russell S PaulicanNo ratings yet

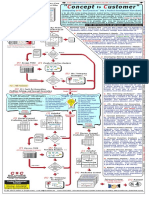

- " Oncept Ustomer": SolutionsDocument1 page" Oncept Ustomer": SolutionsJac DNo ratings yet

- Jewellery Design Brief National 4 and 5Document10 pagesJewellery Design Brief National 4 and 5Shweta KNo ratings yet

- MOSFET (Handwritten) (Untill MOSFET As A Switch)Document25 pagesMOSFET (Handwritten) (Untill MOSFET As A Switch)Aniruddh100% (1)

- القالبDocument120 pagesالقالبمنوعات سكسNo ratings yet

- National Institute of Technology, Silchar: Presentation ON Turnkey ConstructionDocument18 pagesNational Institute of Technology, Silchar: Presentation ON Turnkey ConstructionShashank MishraNo ratings yet

- Tka Scrum HandbookDocument21 pagesTka Scrum HandbookAbdulNo ratings yet

- Unit 4 Working With Text in AutoCADDocument7 pagesUnit 4 Working With Text in AutoCADRmesh jhaNo ratings yet

- 3 5Document5 pages3 5Deepika DhimanNo ratings yet

- UEME 1253 E CAD: Ngineering Drawing andDocument6 pagesUEME 1253 E CAD: Ngineering Drawing andXiyue ZhangNo ratings yet

- THESIS2Document9 pagesTHESIS2Charo GironellaNo ratings yet

- KG 2 1Document10 pagesKG 2 1prashantkumar1lifeNo ratings yet

- Nified Rchitectural HeoryDocument30 pagesNified Rchitectural HeoryR.No ratings yet

- Housing, Space and Quality of Life:: Ricardo García-Mira, David L. Uzzell, J. Eulogio Real and José RomayDocument5 pagesHousing, Space and Quality of Life:: Ricardo García-Mira, David L. Uzzell, J. Eulogio Real and José RomayalonurNo ratings yet

- User Interface Analysis & DesignDocument11 pagesUser Interface Analysis & DesignRianiNo ratings yet

- Civil Engineering All Software Information PDFDocument43 pagesCivil Engineering All Software Information PDFSonaliNo ratings yet

- 2 Presentation Material PO Co PSODocument46 pages2 Presentation Material PO Co PSONeelabh KumarNo ratings yet

- (Innovation and Change in Professional Education 9) Stefania Baroncelli, Roberto Farneti (auth.), Stefania Baroncelli, Roberto Farneti, Ioan Horga, Sophie Vanhoonacker (eds.)-Teaching and Learning the.pdfDocument245 pages(Innovation and Change in Professional Education 9) Stefania Baroncelli, Roberto Farneti (auth.), Stefania Baroncelli, Roberto Farneti, Ioan Horga, Sophie Vanhoonacker (eds.)-Teaching and Learning the.pdfAshNo ratings yet