Professional Documents

Culture Documents

Pene Trant

Uploaded by

Babar Manzoor Ghauri0 ratings0% found this document useful (0 votes)

5 views34 pagespene

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpene

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views34 pagesPene Trant

Uploaded by

Babar Manzoor Ghauripene

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 34

CHAPTER 4

PENETRANT TESTING

4. INTRODUCTION

Penetant sting (PT) i ne ofthe ost widely used nondestructive testing methods for

‘he detection of surface escontnuts in noaperous sold meri It almost cern

{ie most commonly wed surface NDT method today becase I ean be applied to vr.

Jy any magnet or oamagnetic material. PT provides mtr with wie range of st

Stvies and techniques that make it expecially adaptable fos brond range of ics and

Shapes I extremely sel fr examination tha are conducted in reo fed loc

tions since itis extremal portable. The mthod i also vey appropri in podction:

type evienment where Insay smaller parts ean be processed na relatively shor period

time Tis method has muberous antes atl limitations st eat be found in See

tion X ofthe capes,

M_ HISTORY AND DEVELOPMENT

‘Albough the exact dat ofthe fst “penetra” test i known, it is genealy bie

‘athe crest ests Were prTomed in the ate 19th cntry and were primary limited

‘othe examination of various ralfoad pars, suchas ales ash Even hough it wa

2 very rudimentary metho, i war capable of revealing fil large cracks tn metalic

Parts by sing what referred to athe“ and whiting method i teresting ona

thatthe oi and whiting method employed the same processing ses th are ae today

‘wih current penta esting procedars. In hs erly penta into, the pat fo be

trained was cleaned and then suberge indy engine oi. The il hat we use i

those days eame fom lige Isomotive engine and was very heyy Iwas generally

luted with Kerosene or leo! so that would be thin enough o penetrate disco

tines. 1 semed thatthe dy ot worked the best nthe presence ofa discontinuity,

‘nce provided a dark cy stan on the text eface. Aer aturton with ot hepa

was allowed to dai, During the draining time, Known fay asthe "dvel” ime, te

‘hind oi would penenaesurtace cracks. Aer the exces ol wa removed a the

surface witha solvent te pt was coated wih “whiting which consisted of o chal tike

[powder suspended in alcool. The ol that was erzapped inthe void woud then bleed

Suto the wing and dark, oy stain nt he presence and location of discon

tiny.

‘Sometimes th whiting used was a whitewash tril simi th wed to wash and

pnt ences, ees the expression ol and whiting” method. salsa believed that a=

um powder was used those early day asa developer to help bring theo ack otto

The ure soit coud be obeerved.

‘Asan be expected, dere were may problems with his ery testnige, There was 2

ten he Mca Coin eC Tr

ener lck of consistency, since tere were no established procedures or stndards and

the del and development ines wee prety mac left upto the jadgment ofthe se.

“The materials varied conten nd use and only he grostest type of scontnitis could

bedetced

‘The ond whiting method had place in the ely examinations of road pats but

‘tse began to diminish wih the introduction of magnetic particle eng (MT) i he

1930s decline was most notable nthe Years from 1925 ina the mil 1930s. At this

‘me, many pas hat were consiored ob eel were made of feremagnetic materiale

andthe advent of MT techniques povided a much more lable and repeatable eto

far the detection of surface discontinuities. BY the mid-1930s, the use of aluminum and

ter matrlsthat cold wt be magnetized wa inresing and twas gu ppc tat

there hd to be another nndestuetve text method for detecting dicots in these

noaeomsgneie materials. Crain, at tat time, itemal discontinuities could be de:

tested using ay techniges, bu many ofthe xray techniques nase were mt cpa of

‘revealing sale ight dlscontnlties atthe surface. lost there ws an obvious

‘eel for method that would be sensitive enough to detect hese small arc discon

“The cary pioneers Can Betz, F.B. Doane, snd Taber Foret, who worked fr the

Magnatox Corporation atthe tite, were expensing with many dilleren pes of oe

‘i and solvents that might fli hs eed forse contin testo, These

carly techniques that were red used rile neqerelestole anodizing. etching. and

‘arious elor-contaspenetrant: Some ofthese ely approaches were dicaded wih

the exception ofthe anoizing proves. Dring this period, th anediang process was

ted for detecting cracks i eres! sain pat, erally associated wih sca

“This rested in the publication of a miliary specication, MIL-LS474, on September

ith, 1946. The il f this specification was “Anodizing Process for lspection of Ali

minum Alloys and Pats

"Yeats before the plication ofthis military standard, Robart Switzer had been work-

ing wa urescent rater, primarily for pricing Aucrescent adverismeats for

‘movie heaters. He ands younger ther, Joseph, were poner nthe ary ae and d=

‘lopment of various Noorescentistrils-Av ely ae 1987, Rober Switzer became

sare of problem that focal esting company Was having with pars forthe Ped Mtoe

‘Company. There was 2 lrge batch of aluminum tatings tha were Found to contin

‘umber of dsconnutis tht were ot cheered ntl afer the surfaces of the castings

Tad been machined. iter realled how the ferent fluorescat meters he wat fi

mar with were capable of clinging losses and oreing when observed sing l=

trvitet (bck) igh He thought at his material would be appropri for detecting te

Surface cracks ht had been uncovered by machining He was able to obtain amare of

Samples and began experimenting with he varios Maoreszent pigment ht he wus de

‘loping. He found that although these pigments were unique inclining fo a person's

hands and other porous-ype materi hey were nt very festive for he detection of

‘ery ine srfse cracks Switzer continued tory diferent combinations a, evel

Ineduced tem io various ligeds tha woul be used to cary the fees pigment

ino the iscominities. His work was lima succes and he sped for pte

‘August of 1938, Ts ineesing to note that be asked his brother, Josep, 1o share the

pentlng fee, which amouried fo 315.00, and Joe detind. Robe then proceed 10

Iie the patent on his ove at ulinstly found islration about the Magnex Crp

ration whi at that tine was sill developing and pionaring the magnetic parle

Section method. He decided to snvesigae te commun and eotacted one of ht sles

representatives New York City to dies he posit of expanding her sfc d+

entity efforts o include a Muoescet pencean,

FENETRANT TESTING 43

Some ofthe amps o demonstrate the Muorescet penetra nethoo Cat Bete

and ates fo th Magnan Cerporation were not scree. Lack of ores in hese

‘nly demonsations wis probably due othe fet hl the esting eng examined were

‘Sipposed ta have discontinuities but those isconiaute ebably did at ext One ote

‘bstrvers, A.V. deForest ho was pioneer in MT, happened to havea specimen c=

‘aiing known dseontnues that he had wed demons MT, and» foorescet pene

‘rant est was prfooned an his specimen. Theindeatios were gt sppaent. Nataly,

allofthe observers were ery impressed hat the known dacontiuis appened In ad

‘other dacontinuties that A.V. deForet was not rare of were ls observed.

‘Subsequent this desoastation, twat fund tht the sass that were ft exa-

ined had been pected, tus closing the discontinuities tht were a the sic, This

‘emonsraon proved unique. The yar 198] became memorable, nt only or he pale

‘hat was awarded o Switzer tht summer, ut besa also marked the Reganing of he

Second Word War. This new test would be widely used in supporting the fre: pr

‘sts hat woul be used by the miliary

Early Penetrant Technique:

Some ofthe ey penetant proceses were suite similar to hoe ine today. The pat

woul be cleaned witha song solvent athe, aster ying ia mere nthe pn

rant fr about 10 minutes. After this penton o dwell dine, he penetatt Was Te

‘moved, usualy with suong solvent, an he part a wpe imi yan sean, The

‘oval sep vas usually perfomed under a blk ght According ery aceounts, the

ts would then be stuck with a hammer, which would cause the entrapped peacoat.

terials "led otto the sctce at which tme the pt would be examined unde

‘Slick lg These early techniques were sll quite arate and the test resus were rot

‘very consistent. Dring the flowing year, inorder to achieve the evel of consistency

‘hat is essential for quality asuranes, many dierent types of materiale wee red and 8

‘arity of echnques were tempted. These edo amt unigue development the wae

‘nasable oe water emovable(perbasa more appropri em) penta

‘Waterasable ponatant maerils and vlaed eqpmen were fit offered around

sone of 1942, There was mich intrest in them snd numberof orpanis sated te

the vatersnsble technique. AS a mater of record, the Ts purchaser of the wale

removable potent equipment was Aluminum Indatnes of Cincinnati, Ohio, wish

‘wou we the equment for the exaination fein casings, Many’ oe applica

Hons and uses followed nelding teresting of propeller les, pistons, valves, at ot

veal aera part esol be noted that 3 ajor ep forvar nto sppition of

Pr occured when it as included in the maintenance and overhal rogram fost

engines. Asaresit ofthis pplication, the PT method of nondestuctve testing was is

‘af psiing wide aecepiance, A patent onthe "water-wadhale”ehnigue ws spied

{erin Jne 1942 and was isd i uy 194, The aly developer compounds were ye

Iowish mates consieing mainly oft. The wet develope tshnague began Tobe wed

‘nate 1944 a ary 1945,

‘One ofthe problems associated withthe wner-emovabetshniqe wae the potenti

fox remavel of enreped penetration dicontinues ns result 2 vigorows wet

rinse step this ed oconcems abou “overwashing” This overvashing Was the vsult of

fm emaliie ht had been mixed n sith the penetra fat, some eat penerants

‘were marketed a promting “super washabiity” nhc resulted in exremely lea se

faces but also produced a rete danger of te penetra being removed fom sre de

omtinity openings. The solution to this overwashing concem was to remove the ems

Sie from the penetant and to apply it late. This fall occured in 1952 when this

process was etre tas the psteulsication of FE technique

“Theft ostmlifction penetrant wer ntoced in (953, With hie ecigue,

the emulsifier was applied afer the penetat dell te and carly controlled 50 tat

the penetant inthe dsconsnuties was ot enulsiied would remain nthe discontno=

ity even ater the emulsified surface penetra wes moved with war ins. Alou

tsadded an ational se ae an ational lid ote proces, dd provide bie

level of eons over the detstion of small, shall somtimes fa may not have

‘tected wit the use ofa ypial water removable ecniqu cntsinng emulsifiers

Visible Penetrants

‘The penta echniques described to this point were ofthe foresent type. The ores

ent penn fechnigueregued tas, 2 water supl, electri forthe Hack iis,

‘nud dened area forte evaluation oFindeaions. fn ode to pet para es 10

be pesToamed nthe Feld nto provide ori, ample, visible dead to be deve

‘ope In the 19405, a Nedop metus ned Rebees Smith developed 9 visible

She penerant approach. Rebecca Smith who would be ater Known as Becky String,

‘collaborate wih Northrop chemists Lloyd Stockman and Eliot ody, who alo asied

inthe development ofa visible dje penetra. This was considered neeesry fr examin

ingest jt engine pars outdoors, where creating’ darkened ares nocestry forthe se

‘of tuorscetpentrants was inconvenient. Te cevelopment of he visible de peta

{echnigoe would ke several years Stockman spp (ora pte my Mach 1989, By thi

tine, thee were several choices of pencran:Hoescel water removable, Suortcent

rll, and vinble ye,

Other Developments

Inthe late 1950 and ery 1960s, auch work was done to uaniy and analyze the vai

ous penetra that were available By the early 1960s, varity of techniques were bing

Used witha ange of senses that would say the demanding eguremens of many

industries. Many of te variable associated with the ponent ests Were ealsted a

the eatze proces Was mprove, so that consistency abd sensitivity would Be a inisic

Dar ofthe proces. One ofthe most widely wed itary standard, MI-L6886, ae t=

‘ied in 1950 ang isl nue i x murber of indie toay, with vary fe changes

Hom the original desment Crrerly. there hasbeen a shift vay ern military sane

arc abd eventually all itary saad wil be replaced wit standard developed by

the American Society for Testing and Matsials (ASTM), The remains of hs chapter

‘lea om the mater ad techmgies that asin se the pest tie and will de

Seebe the many aplicaon fr which hs unique NDT method can be effstively ap

pile

Il THEORY AND PRINCIPLES

“The tsi principle upon which pnarant esting based is that of apy “aac”

‘or action” Capllry acon is surface tention plenorienon tat pei liquids to be

‘ra in tight openings a a est of the energies tht are preset te sues of he

‘openings Ia met high school physics clase, he principle fear atone demon

strated by pacing a glass saw it a beaker filed wit colored wate. The sufice tee

Sin assoclated wi he opening othe las sao capil. cases the ig level o

‘move ta higher level nid tat esplry than the level ofthe gu in te beaker, A

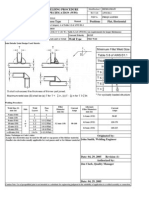

Simple demonstration of apr ston using two gsi panels camped ogee i l=

‘ated ia Figure aan

‘One can consider tat discontinuities open the surface behave ia meh the same

fashion as shown by th glass panel n Figure 1b. The iid sod in this example 2

cy

FIGURE 41 Desiastaton of epi ction. (A istratons in his cape oatesy C.

1 Het) Cs as camped mgt) Vs cnr ota ent pid 0

tas of el

a6 ‘oumrrenrouR

‘gpa visible contrat penetra. The capillay action frees ae very strong and, in fa,

Ifa peneuat est were being performed ons specimen nan eve poston the pene

‘rant would be dr ito the opening, game fe force of rity. The expla forces

‘much stronger than gavty andthe dscontinaties wil be detected even though hey my

bein an overeat specimen,

1. PENETRANT EQUIPMENT AND MATERIALS:

Penetrant Equipment

Penetan systems ane fiom simple portale Kits to large, comples fine test systems,

‘The is contain pressurized cans ofthe poner, clesneemaver, solve, nd even

and in some ease, brushes, swabs, and cloths. lager Muoescent penta it Wil

Include a lack it These hs ar eed when examinations ae to be conducted ine

mot areas, the fd fra small ares ofa teat race. contrat o these portable

Peet ils, there are number of diverse saonary ype systems, These range rom 8

Framully operated pencrant line wih 9 amber ofan, o very expensive scm

Fines, in which most steps inh proces ae performed astral. The pent ines

‘ante very simple as ilstatd in Figure #2.

‘Inthis pair stam there sa ak forthe penetra, a tak foe he water sine, &

Aryng oven, abd a develope ston. The inal ston i th examiton ee, which i

les black igh. This manvallyeperted system is» type small watersemovabe

enean Ine. The steps in he tein process would be clesing of th art pplication

{tthe peony, removal of he pentant with water spray, dying application of the

‘developer, nd ally inspetion. This ete process severed n mvc gente ein

Section V,Teeigus.

FIGURE 42 Typical Moorescetpeserant line srangemet

fa pstemulsifabe penesans obo used the manvaly operate ine wil ee an

sia ak Ths tank wll conan ak emai ht wil ender the sre pentane

Temovable afters specifi emulsification tine. Again, dus techngue wl be covered

uch greater dea later in this chapter The tomatic peta lines n we oy vay

fom sll rater simple systems to very lp complex Hnes that af computer co

tolled Figre 43 illustrates lage auionate penta line.

Altouph the steps in an stented penevant stem have been somewhat mecha

ized itis nerestingw note th the examinations stil mst be conde by inspectors

‘vio ve Been tained abd ae quale the process, The arangement of hse large

!utomated penetra ines vary With fren aout wo permit the most lexi from

thestandpotnt of processing te pas. Normally, the ystems wil he sranged ina staight

lines however a U shape or ote configuration may Be used provide more eTacvee

aoa space.

Other Equipment

‘The lack igh (se Figure 44 is an essential accessory for Muorescent pentane

sion. Black lghs used in penerant esting ypicalyprodice wavelegte nthe ange of

FIGURE 43. Automat Porson pent ins

a8 couarrenrour

FIGURE 4-4 Black ht

315 to 400 am (3150-4000 Angstrom nis) and tlize mercury vapor lbs of the

Sealed-selctor type. These is are povided with "Wood fier, which eliminates

the undesirable longer wavelengths: Bsc light inesiyrequiemens wil range fom

00-1500 microwats per square centimeter (Wem?) at the ts sure. Specie te:

‘quirements wil ary, depending upon the ee r specication) being ed. Recent de

Yelopmens in black light teshnology provide lights Wal ean produce intensies up 0

4300 Wier a 18° B81 om).

Ligh intensity meter ar se 9 measre both whit light intensities when visible PT

{suse ad lack ight menses fr fuorescet penetra technique. Ths mearement

{is neceairy to very code compliance and to asur that tae a eos deraton

oft lights Some meters redesigned to measre Doth white ight and lack ight ine

Test panes including comparator blosks, conzlled cracked panes tered pate

mets dnote fo specific industries sh athe TAM pane (Spey aed i aro

Spoce, are employed to contol te varios atebutes ofthe PT system. They ls provide

2means for montering the mateals snd the process. This is discussed in Sexton X,

Quality Conte! Considerations

Tn sunny, the equipment used willbe greatly ifloenced by the size, shape, snd

«quantity of products hat are to be examined. the are large quate involved on 8

Continuing bass, the use of an aufomated system may be appropriate, Wheres With

Small quate of parts, the we of penetra iis maybe more stable. The sie and

‘figuration of he pat wl lo iiunce the typeof pentane tat wil be most ap

propre

Penetrant Materials

The various materi tht wil be wed inthe diferent penetant processes must exhibit

cetain characterises. Above all these matils must be compatible wth exch ther and

‘Seat Beep te emir is hype

(Fines 417

0 A ‘Water eemoate pene agus or songs eek

(isi, (arene)

folrcenrst) Pose eet cous rd gues

Pigwess) soaguou evap

c Sventremorle pest solvent clawecanorr ens

(Figure t6) _oenomgeois deeper

4. When te puso he examina have srfics tat are rough, sch ae with snd casings

for weld conditions

‘Advanages:

1. Higher sensitivity

2, Excess penetra is easly emoved wi couse say

3, Easily adapable for large sures and large quant of smal prs

4. The costs relatively ow

1. A garkened ara is requied for evaluation

2. Under-oroveremoval of penta teri s possible

5 Water contamiaton can deyade te effectiveness ofthe penetrant

4. Notefetve for brood or hallow discontinue

5. Dryers are required (usually) when using develops

6 This technique sully ot portable

Technique | Process B (Lipophilic) and Process D (Hydrophilic)

“eetnigu |, Procestes Band D use a fvresent postmulsifable penta lipopitic

(or yaropiie EH emulsiie, and dy, aqueous, onaious developers. Pigs

44:18 and 417 sls overviews of Processes B and, respectively.) The mates

‘sed ate very similar o those dseribed for Tecngue 1 Process A excep sa thse pen:

‘rants ae not watr-temovablewitho emulsion A pops or rope ele

Prerequistes

L

Ty Ge

L

Dry

L

Apo

TT serena

enetrant

Daina

Fenoval

cess ponetant

vith water spray

[ 1

Dy ‘pplication

i of aqueous

“pplication coven

of developer T T

L Dy

i L

Drypowser] [Nonaqueons]

Development

time

T

Tntrpretation

‘evaluation

i

Post dean

FIGURE 4-14, Wate-emovable chaque Proce -A or I-A)

siir must be wed alr the dvel sme has expired. This ecnigue i generally wed in

the following stations

tu

s

‘When large guanity of parts must be examina

‘When dscominites tha re bread an shallow ate anscpated

For the deteton of ress racks or intergranular corsion

Forthe detection of small iscontnues such as ringing cracks

Applitons reiting higher-sensiviy technics

422 coarren rou

Prerequisos

T

VW Preciean

‘Applaton of past

| entice ponent

1

wal ine

I

“Repicaion of

HL teoshtc emir

i

Enulseaion ime

i

Removal ot

emulsed povetrant

wth water pray

Dy “pieaion

ofaauoous

ai ceveloper

ot developar v L

1 Dy

[ 1

Dypowder] [Nonaaueous]

Development

me

I

Tnerpretation

‘valuation

I

Post dean

FIGURE4-15-Posenulible wehnigu pole) (oees HB

Advonage:

High sensitiv forthe detection of smaller dscotinites

2. For oad or sallow discontinuities (when they are expect)

/Adapiable for igh-qantiy testing

ot easily affected by cis

Less susceptible to overemoval than Tecgue A

evermanrsesnN0 zs

Prerequistes

L

—-— Preclean

T

Panowant application

s T

Dall tine:

T

Fomoval of eros

‘surface penetrant

‘th eaan cloth

oe

= Bee

oa

I

Saas

7

—y [Ee

cae

Development

time.

————

“Ye Teton

vlan

I

Poa cean

FIGURE16-Solvent-semoraieteiniqe (Process LC or IEC).

1, This ehnique has an aditonal step, which egies an emulsifier. Therefore, more

‘ime and material necessary

2. Iignotas effective for pas with complex shapes, teas) or rough sarees as

is Technique LA,

5. The emulsification tine mst be closely contri

4. As with Teeique I-A itequizes dyin pir tote application of dy or nonaqueous

Akvlopers

5. Itisusualy no portable

‘Technique |, Process C (LC)

“Teehnque Process C uses Nuorescent penetra, which sslsent-removable, a solvent

cleanerfemover, apd « ponaqucous developer. The excess srfae penta i fist T=

Prerequitos

— oo

“App post elaabia

I LO rca

oy Fenoalal =

Se ee

[Apply hydrophilic pplication

2]

—__

tine A

ee tr

‘Application v

2s, Byars

Diypowder] [Nonaqueous|

Cd

Deveioament

tine

L

Interpretation

‘evaluation

T

Pos dean

FIGURE 417 Postenulsifabl tcbgueydopie) (Pees LD).

renereaer TESTING 428

‘moved with a dy cloth, flowed by cleaning wih cloth dampened with a solvent re

rover (Figure 416 ustates an overview of Techniguc LC) Ths proves is poeraly

‘eed when removal with water isnot desiabe due opt size weigh sulace condition,

‘water valli or when a ea source not realy avalable for drying.

Advanage:

1, Can be used for spt examinations on large parts

2. Bective when water removal ino fesible

Limitations

1. Thee of solvent fr removal init thi tecnigue to smaller areas

2. Ablack ight and darkened area we required

3. The sensvty ean be reduced ifexessive remover i applied

4 A bockgroun” may oocur with this technique, which cold aet the contrast ato,

specially with rougher surfaces

Technique ll Process A (ILA)

‘eetnigy I Proces A uses a vsble ol-contns,wate-removable penetra anda

squeout or nonaqueous developer. Dry develope soot usually used with Technique T

Drserant. Some specications, in fc, do at permit the use of dey developers ih

Technique i pnerants, gue 4-14 states Technique I-A

“The ponent contains st emulsifier, making it watersremovabl, This technigne is

enerally sed forthe flowing aplicaons!

1. Examination ofa large suanity of pat or arge sree areas

2. Fordizcontnites tat re generally Hight

3. Forthe examination of ars with heads, keyways and other complex acometies

4. For parts with generally rowgh seices

Advantages:

1. No blaklgh or drksned are seated for evan.

2 Min slatively quik and inexpensive

3. The excess penta is esly removed with conse water sry.

“4 Is effective forte examinations ofa age qui of prs

5. Iteanbe use for rough surfaces, Keyways, treads and other complex geometries

Linens

1s sensitivity is inferior to Taeique A

2. Pensa can be averemoved.

3. Wate contamination can dogade to effectiveness ofthe penetra

4, Teisnot sally eztv for he detection af bod or sallow dsconinite.

Technique Il Process B (1-8)

‘Technique Process Buses visible color conat, postemulsifible penetra, an eml-

sft and an aqueous o nnagusous developer. The materia used excep forthe pane

426 ‘cuarren Four

‘rant ae very sina to those described for Tetiqu [Process B (ita in Fg-

‘ue 415) An emulsifier aay Hipophi) i applied othe suricepentan fer the

bell ime to make it water-embvabe. Tengu It Process genealy wed fo the

{allowing appitions

1, When lage quantity of parts must be examined

2, Whenever lower seasiivity than dt achieved with Techni is acceptable

3. When broad and shallow discontinue are anieiated

Advantages:

1 No blak ligt or darkened are for evalation is eqid.

2. Broad or sallow dsconutes maybe detected

3. Usefl whe there ae lg quantities of parts to be examined

4 This ehnique isnot as suscepibleo overemoval, a ae the Proces A penetans,

Limitations:

|. Theadtional stp ofan emulsifier requires more tine and addons ater

2. lis potas effective fr pars with complex geome (eg, treads, at is Poses A,

5. The emulsification tine is very etal and mut be coely contol

4, Drying isrquied if nonaqueous dovelopes ae wed

Technique l, Process € (H-C)

Technique Process C use a visible, olo-contas, solventemovabe penaant, asl

‘ear clenesemover, and an aqueous or nonaguents develope. Figure #16 stats

thisechngue

“Tho eee poetant i ot waterremovable and must be renoved with a solvent r=

rover This tecigus is widely sed for Rel! spplientons when water real is no

feasible, or when examination aro be condute ina remo lesion,

Advaninges:

1. Thistecnigue is very potable and can be used vial anywhere

2. Iheanbe used when water removal is ot possible,

5. Black lights o darkened evaluation area are wo required ston i done in vs

We light

4. Wis very adaptable for wide range of pps

“imitations:

1, The use of solvent to remove excess surface ponent limits the examinations to

salle res and part witht complen seams.

2. Sensitviy is reduced when an excessive amount of remover is usd during the r=

moval ep

3. Excess penctrant removal eiffel on rough sufices, sich as sa catng and

welded surfaces and usally ess a “background

4. Thisechnigue has lower evel of sensitivity compared to Teeigue I penetra

5. Itismore opertn-dependen” due tothe ails involved inthe removal sep

‘Summary

(Fal he tecigues described in Sesion VI, the mst widely used Aurescent penta

technique PA (water-emevae). Teli ILC i th mom widely sed visible color

orks pene,

Vil. EVALUATION AND DISPOSITION

Affe the pentant proses has teen completed and the indications are observed and

‘corded te ial tp wil be to ctblish wheter or ot hee condition are acceptable

‘reece, The sie of the natn cn ally e related othe mount of penta

raped in te disconimaty. The lrger the dicotinty volume, the erstr the

mount of penetan that wil be entrapped an, therefore he larger the blew-ot afer

‘evelopment. The shape ofthe ideation is inperant because eas oe ype or

ture ofthe diconinuly eg ersek or ack of sion wil show yp ae near Diet

rather thin rounded one. A liner indication, by mest codes and apeiintions 1s de

fing asa bleed-ut whose length is thee ines of greats than is wid. The intent oF

the bled-ou gives some evidence ato how tht the dsconinty x, Aboad hallo

"ype discontinuity wil tend tobe due, to an exe, bythe remover igh snd ot Be

as bellan as leos.ou fom avery tight scone eset that eonective se

Ton be taken o remove rrp the discon x deemed to be eet a ost,

‘eases, crack or ter serious dscontnuty willbe ease or he ejeton or crapping of

‘he pat Repairs to disontinates wil often be accomplished by grinding. A recom

‘mended technique io asa complete removal of an inntion a rinding is merely

‘eappty the developer. This usually verifier wheter the disconsiuity hasbeen eave,

‘ing the beedou wl eappeae fit has ot (Se Figure 4-18).

“This proces shuld be epested, se, riding. repplieation of develope, and thea

trinding senn unl no fer Mesdoutocee At tat point the ave fon hs bee

round out must be recxamined following the penta procedure om the begining,

{sure ht in face, the dscotnty has been tty removed. ei futher recommended

that the grining be peTormod inthe same diction asthe longest mension a the dit

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralDocument4 pagesCBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralfallalovaldesNo ratings yet

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Welding Procedure Specification Review and Approval ProcessDocument4 pagesWelding Procedure Specification Review and Approval ProcessfallalovaldesNo ratings yet

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- Welding Procedure SpecificationDocument1 pageWelding Procedure Specificationfallalovaldes100% (1)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerNo ratings yet

- Testing and Inspection of WeldsDocument20 pagesTesting and Inspection of Welds7harma V1swaNo ratings yet

- XA00048720 Stainless HandbookDocument92 pagesXA00048720 Stainless HandbookThanis SurapapwongNo ratings yet

- Penetrant TestingDocument43 pagesPenetrant TestingVineet JeswaniNo ratings yet

- Welding Procedure 2Document1 pageWelding Procedure 2lovaldes62No ratings yet

- Study of The Factors Affecting The Sensitivity of Liquid PenetrantDocument59 pagesStudy of The Factors Affecting The Sensitivity of Liquid PenetrantfallalovaldesNo ratings yet

- Visual Inspection of WeldDocument1 pageVisual Inspection of Weldfallalovaldes100% (1)

- RED Dye PenetrantDocument3 pagesRED Dye Penetrantlovaldes62No ratings yet

- Catalogo MagnafluxDocument78 pagesCatalogo MagnafluxfallalovaldesNo ratings yet

- Welding ProcedureDocument2 pagesWelding ProcedurefallalovaldesNo ratings yet

- Welding Procedure Specification (WPS) of The ManufacturerDocument9 pagesWelding Procedure Specification (WPS) of The ManufacturerfallalovaldesNo ratings yet