Professional Documents

Culture Documents

Inhouse Audit on RIMC

Uploaded by

SB0 ratings0% found this document useful (0 votes)

97 views26 pagesThe audit found that RIMC representatives generally met NOSP's HSSEQ requirements for contractors in Singapore with some minor issues. Documentation was available for health and safety targets, legal requirements, public relations, subcontractor management, health care, safety training, chemical storage, safety reporting, and competence requirements. However, the training support person was to be determined, and training records needed updating to indicate awareness of Neste Oil procedures and the last updated version. RIMC representatives agreed to address these issues by June 28.

Original Description:

Original Title

In-house Audit Finding Report

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe audit found that RIMC representatives generally met NOSP's HSSEQ requirements for contractors in Singapore with some minor issues. Documentation was available for health and safety targets, legal requirements, public relations, subcontractor management, health care, safety training, chemical storage, safety reporting, and competence requirements. However, the training support person was to be determined, and training records needed updating to indicate awareness of Neste Oil procedures and the last updated version. RIMC representatives agreed to address these issues by June 28.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

97 views26 pagesInhouse Audit on RIMC

Uploaded by

SBThe audit found that RIMC representatives generally met NOSP's HSSEQ requirements for contractors in Singapore with some minor issues. Documentation was available for health and safety targets, legal requirements, public relations, subcontractor management, health care, safety training, chemical storage, safety reporting, and competence requirements. However, the training support person was to be determined, and training records needed updating to indicate awareness of Neste Oil procedures and the last updated version. RIMC representatives agreed to address these issues by June 28.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 26

Inhouse Audit on RIMC

Audit Date: 22/5/13 (half day documentation audit and half day site inspection)

RIMC representatives: Moe Myint, Das and Zaki

NOSP representatives: Azman and Ishak

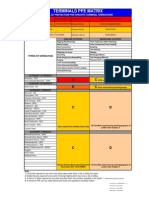

Information required on annual basis based on HSSEQ Requirements for Contractors in Singapore, OQD 8951

(A) Occupational health and safety targets

Inorder

The number of LWI, work hours, or the frequency of

lost work day injuries in a million work hours (LWIF)

for the past two years.

The contractor's HSE management and

organization, occupational safety program, HSSE

management system

The contractors HSSE contact, safety advisor or

equivalent

Review of occupational health care arrangements

and medical surveillance program

Practice for management of subcontractors

Any HSE certificates or awards possibly granted to

the contractor (e.g. SCC, BS 8800, ISO, VCA, DNV

safety certificate, OHSAS, DoC, WSH Award,

BizSafe and SMC or equivalent).

Not in

order

Remarks

(1) The training support was TBN. No person under the

organization was in charge of training.

Document available in IMS manual and procedure (REL-QPPJT-05).

Document available in IMS manual.

(B) 4.1 Legal Requirements

1

Maintains requirements of legislation valid on

permits concerning competence, residence and work

permits concerning the supplies and jobs under

contract with the NOSP.

All the concerning documents have to be available

for the NOSP.

Spreadsheet shows valid certification tracking.

Document available in Safety Training Records file.

(C) 4.4 Public relations and communication

1

Contractor has to handle NOSPs classified

information and documents according to NOSPs

procedures so that they are not available for

unauthorized persons

Contractors shall be obligated to present Toolbox

talks, participate in regular meetings as arranged by

the NOSP and provide representative(s) for HSSE

cooperation groups if needed.

Contractors shall use Appendix 3 as a weekly

reporting format to be submitted to HSSE to achieve

the objective.

(D) 4.5 Use and approval of subcontractors

Target Responsib Actual Date

Date for le Person

Closed

Closure

Document available in Contractor Manhour Record file.

Action item

Document available in Group Meeting file.

Document available in Contractor Manhour Record file.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

In principle, Contractor has to carry out the work

using his/her own human resources. Possible

subcontracting and its length must always be

approved in writing by the NOSP before

commencing the work. The approved subcontractor

neither has a right to further subcontract a work to

another Contractor without a written permit from the

NOSP.

Contractor is responsible for that subcontractors

activities are in compliance with NOSPs

requirements. This document HSSEQ requirements

for Contractors in Singapore", has to be included in

the subcontracts made by the Contractor.

RIMC do not engage sub-contractor

Document available in In-House Rules and Regulations file.

Contractor has to provide the NOSP with the

information needed for evaluation of subcontractor.

Necessary information to be provided is a

description of organisation, resources, competence,

financial condition and safety management system in

accordance with the chapter 4.1 and 4.2.

Leased employees (use of a temporary agency

worker) are parallel to the use of subcontractor and

therefore require a written permit from the NOS.

RIMC do not engage sub-contractor

Use of subcontractor is approved by the NOSPs

contract contact person (Purchaser).

(E) 4.6 Health care and first aid

1

Contractor shall organise a legal/statutory health

care for his personnel.

Contractor has to have an Occupational health care

(includes medical surveillance) program approved in

cooperation procedure according to which narcotic

tests may be carried out to personnel when needed.

For emergency transports in sudden accident and

illness cases the Contractor shall make necessary

arrangement to render medical supports that include

transporting the injured to clinics or hospital, first

aider to execute necessary measures and etc. NOS

will assist within the available means.

(F) 4.7 Consideration of restricted work in case

of an occupational injury

1

Contractor shall have a procedure, which can be

followed to provide restricted work for an injured

person in case of an occupational injury.

(G) 4.8 Safety training and Toolbox talks

Stated in Incident Investigation & Analysis procedure.

Contractor is responsible for providing continuous

HSE training to his personnel. It is also Contractors

responsibility to make sure, that his/her personnel

attend training arranged by the NOSP.

Document available in Safety Training Records file.

Contractor has to arrange and document a Toolbox

talk for his personnel at least once a week. The

agenda must always include development of

procedures and work methods so that all accidents

and safety incidents can be prevented.

Contractor has to arrange and document training for

every person working at his/her work site risk

assessments and safety plans concerning the work

site in sufficient extent.

Document available in Group Meeting file.

The contractor shall present certificates of the

required statutory training. The contractor shall also

maintain an education program to assure the

inclusion of HSSE instructions as a part of job

assignment to all contractor and subcontractor

workers.

(H) 4.11 Storage and use of chemicals and

explosives

1

Contractor shall submit Safety Data Sheets (SDS)

and obtain the NOSPs HSSE approval on the use

and storage of all chemical substances and

explosives to be brought to the area. Such materials

shall be properly labeled (eg. compressed gas

cylinders) and strictly controlled by Contractor as to

use and disposal. Proper use of personal protection

for handling such chemicals shall be the

responsibility of the Contractor and this shall be

described while seeking approval for use.

RIMC do not bring in new chemical unless requested by NOSP.

Site Inspection:

(a) fire extinguisher to be hanged outside the storage area

instead of on the floor inside the cage.

Contractor is responsible for safe handling and

storage of chemicals and/or explosives brought to

the NOSPs area by his/her own personnel or his/her

subcontractors. A storage plan shall be submitted to

HSSE.

(I) 4.12 Safety Reporting

1

Contractor is responsible for immediately informing

the NOSP of any injuries, accidents, environmental

releases, ignitions and near miss incidents occurred

to his own personnel or his subcontractors. The

immediate notifications must be completed with a

written report within 24 h after the incident. The

report shall be delivered to the supervisor of the

NOSP.

(J) 4.13 Supervision and execution

No incident for Year 2013.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

The service performance shall be managed and

supervised with regular meetings and evaluations.

All risks of the service shall be evaluated together by

the client and the contractor.

If the NOSP notifies Contractor of any noncompliance during the period of validity notified in

the contractors contract, Contractor shall

(immediately, if so directed; otherwise in not more

than forty-eight (48) hours after receipt of such

notice) take all necessary steps to correct the

existing conditions.

All contractors shall be required to participate in

observation tours and to report issues related to

HSSE. The contractor is obligated to participate in all

safety, quality assurance inspections and audits

(internal or external), concerning its operations. All

the findings from the tours and inspections shall be

presented to the NOSP with plans to rectify them

accordingly.

Document available in Contractor Manhour Record file.

No incident for Year 2013.

Document available in Safety Training Records file.

(K) 5.1 Foreign Work Force

1

Contractor has to present to the NOSP identity

information, employer company and contact address

and a valid permit of residence and working of his

own and possible foreign work force used by a

subcontractor. He is liable to keep these permits

valid.

Contractor is responsible that an accident insurance

has been taken for all his employees, which covers

all the possible damage resulting from occupational

injury or occupational disease and Contractor have

to show these documents to NOSP upon request.

Document available in Safety Training Records file.

(L) 5.3 Competence Requirements

1

Contractor must be able to prove the competence of

his personnel by a training register or equivalent

method. At minimum, all contractors are required to

successfully undergo "Oil and Petrochemical Safety

Orientation Course, and Site Safety Induction

Course. For supervisory level, "Oil and

Petrochemical Safety Induction Course (Supervisor)

is mandatory. Other requirements are as deemed

necessary by regulatory requirements when

stipulated. The Project supervisor must ensure

contractors are qualified in these compulsory

trainings as well as competency requirements under

the law.

Document available in Safety Training Records file.

Contractor is responsible to ensure that all persons

participating in high risk works such as hot work,

confined space work, electrical work and etc. have

undergone the required statutory and internal

trainings to meet the demand from the undertaking

jobs and the competency/qualification of the workers

shall be indicated in the permit-to-work application.

To update record and have indication of last updated version.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

(1) There is no training record to indicate that contractors are

aware of the Neste Oil, OQD-8949 Safety rules procedures.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

(M) 5.4 Access Pass Procedure

1

Personnel of the Contractor have to have valid

illustrated Neste Oils identity card

(N) 6 Safety Rules

1

Contractor shall advise and is responsible for that its

employees, servants or agents comply with the

following safety rules of Neste Oil, OQD-9086 Zero

Tolerance Policy and OQD-8949 Safety rules.

(2) Site Inspection:

(a) One worker was found not wearing appropriate PPE while

working in instrument workshop.

(b) Improper storage of PAPR in safety valve workshop. Visor

could be easily scratched and damaged.

(c) Sighted sparks flying off during a grinding work activity in

workshop. To utilise portable fire blanket partition.

(d) Acetylene shut off valve box outside workshop to be labelled

as "Not In Use".

(e) To provde additional label, "The above PPE to be donned

when working." outside the instrument workshop door.

(O) 6.2 Visit to the site area

1

Contractor has no rights to bring visitors to the work

site without a written approval given by the NOSP

Management.

(P) 6.6 Work permit

Form is available if there is such a need.

A written work permit is required for all work carried

out by Contractors. Contractors work permit is

assigned primarily to the supervisor of the workers

and each job task shall have an appointed lead onsite. Exceptions to above-mentioned are to be

agreed by MD, Department manager concerned and

HSSE.

Specific PPE to be indicated in the R.A.

A written work permit is also required for work

carried out by the maintenance organisation within

process and plant areas. In addition there are more

specific procedures for hot work, for work carried out

in electric equipment rooms, for work in confined

spaces and for excavation work as well as for lifting

and scaffolding work.

A risk assessment must be made before carrying out

any work. Only machines, equipment and tools,

which meet the set safety standards are allowed to

be brought to the areas.

All preliminary preparation work, which can be

carried out outside the process area, must be

carried out at the areas reserved for them. Also any

installation and preassembly work which can

reasonably be carried out at the ground level shall

be done so.

It is Contractors responsibility to assure that

protective measures of hot work are at least in

compliance with the terms of the granted hot work

permit and risk assessments so, that caused sparks

are blocked inside the defined hot work place and

can not

spread out

to surroundings.

When carrying

(Q) 6.8

Personal

Protective

Equipment

out hot workis the

requirements

of the

hot work

1 Contractor

responsible

for that

his own

personnel

instruction

of the insurance

companies

have proper

to be

and

his subcontractors

personnel

are using

taken into personal

account. protective equipment required for

approved

the work when working within NOSPs areas.

Contractors shall provide protective equipment

needed for the job to their workers.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

The minimum requirements for personal protective

equipment at process areas are as follows:

Helmet, with chin-strap to secure and tighten the

helmet and the name of the person and the

corresponding company on it

Eye protection

Safety shoes

Full body protective clothing

Hearing protectors within specially marked areas

Safety harness must be used when using a man lift

(hoist), installing scaffolding or working in other

conditions with a risk of falling. Safety harness with

double lanyards must always be used and properly

attached, when it is possible to fall 2 metres or more

and the risk of falling can not be eliminated by other

proper means (guard rails, barriers, etc.). 100% tieof rule is mandatory while working.

Additional protective equipment necessary due to

nature of the work must be used for e.g. grinding,

welding or cutting etc.

Harness inspection record to be continued on a periodic basis.

The minimum set of protective equipment has to be

worn in areas specified by the NOSP.

In addition valid work procedures, protection

specified in the work permit, legal protection

requirements for the work and safety signs at the

area or workstation

must also be obeyed.

Contractor must recognise tasks where minimum

protection is not sufficient to protect the person and

correspondingly provide protective equipment

meeting the requirements.

All protective equipment shall be type approved

(meeting minimum mandatory standards) and

adequate for the job.

To correct what is indicated in the

remarks section.

28th Jun'13

Moe Myint

82%

Evidentiary Document for

action item closed

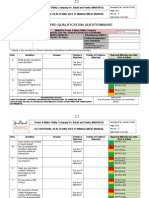

Inhouse Audit on RIMC

Audit Date: 22/5/13 (half day documentation audit and half day site inspection)

xxxx representatives:

xxxx representatives:

Information required on annual basis based on HSSEQ Requirements for Contractors in Singapore,

(A) Occupational health and safety targets

The number of LWI, work hours, or the frequency of

lost work day injuries in a million work hours (LWIF)

for the past two years.

The contractor's HSE management and

organization, occupational safety program, HSSE

management system

The contractors HSSE contact, safety advisor or

equivalent

Review of occupational health care arrangements

and medical surveillance program

5

6

Practice for management of subcontractors

Any HSE certificates or awards possibly granted to

the contractor (e.g. SCC, BS 8800, ISO, VCA, DNV

safety certificate, OHSAS, DoC, WSH Award,

BizSafe and SMC or equivalent).

(B) 4.1 Legal Requirements

1

Maintains requirements of legislation valid on

permits concerning competence, residence and work

permits concerning the supplies and jobs under

contract with the DC.

All the concerning documents have to be available

for the DC.

(C) 4.4 Public relations and communication

1

Contractor has to handle DCs classified information

and documents according to DCs procedures so

that they are not available for unauthorized persons

Contractors shall be obligated to present Toolbox

talks, participate in regular meetings as arranged by

the DC and provide representative(s) for HSSE

cooperation groups if needed.

Contractors shall use Appendix 3 as a weekly

reporting format to be submitted to HSSE to achieve

the objective.

(D) 4.5 Use and approval of subcontractors

Inorder

Not in

order

Remarks

Action item

Target Responsib Actual Date

Date for le Person

Closed

Closure

In principle, Contractor has to carry out the work

using his/her own human resources. Possible

subcontracting and its length must always be

approved in writing by the DC before commencing

the work. The approved subcontractor neither has a

right to further subcontract a work to another

Contractor without a written permit from the DC.

Contractor is responsible for that subcontractors

activities are in compliance with DCs requirements.

This document HSSEQ requirements for

Contractors in Singapore", has to be included in the

subcontracts made by the Contractor.

Contractor has to provide the DC with the

information needed for evaluation of subcontractor.

Necessary information to be provided is a

description of organisation, resources, competence,

financial condition and safety management system in

accordance with the chapter 4.1 and 4.2.

Leased employees (use of a temporary agency

worker) are parallel to the use of subcontractor and

therefore require a written permit from the NOS.

Use of subcontractor is approved by the DCs

contract contact person (Purchaser).

(E) 4.6 Health care and first aid

1

Contractor shall organise a legal/statutory health

care for his personnel.

Contractor has to have an Occupational health care

(includes medical surveillance) program approved in

cooperation procedure according to which narcotic

tests may be carried out to personnel when needed.

For emergency transports in sudden accident and

illness cases the Contractor shall make necessary

arrangement to render medical supports that include

transporting the injured to clinics or hospital, first

aider to execute necessary measures and etc. NOS

will assist within the available means.

(F) 4.7 Consideration of restricted work in case

of an occupational injury

1

Contractor shall have a procedure, which can be

followed to provide restricted work for an injured

person in case of an occupational injury.

(G) 4.8 Safety training and Toolbox talks

Contractor is responsible for providing continuous

HSE training to his personnel. It is also Contractors

responsibility to make sure, that his/her personnel

attend training arranged by the DC.

Contractor has to arrange and document a Toolbox

talk for his personnel at least once a week. The

agenda must always include development of

procedures and work methods so that all accidents

and safety incidents can be prevented.

Contractor has to arrange and document training for

every person working at his/her work site risk

assessments and safety plans concerning the work

site in sufficient extent.

The contractor shall present certificates of the

required statutory training. The contractor shall also

maintain an education program to assure the

inclusion of HSSE instructions as a part of job

assignment to all contractor and subcontractor

workers.

(H) 4.11 Storage and use of chemicals and

explosives

1

Contractor shall submit Safety Data Sheets (SDS)

and obtain the DCs HSSE approval on the use and

storage of all chemical substances and explosives to

be brought to the area. Such materials shall be

properly labeled (eg. compressed gas cylinders) and

strictly controlled by Contractor as to use and

disposal. Proper use of personal protection for

handling such chemicals shall be the responsibility of

the Contractor and this shall be described while

seeking approval for use.

Contractor is responsible for safe handling and

storage of chemicals and/or explosives brought to

the DCs area by his/her own personnel or his/her

subcontractors. A storage plan shall be submitted to

HSSE.

(I) 4.12 Safety Reporting

1

Contractor is responsible for immediately informing

the DC of any injuries, accidents, environmental

releases, ignitions and near miss incidents occurred

to his own personnel or his subcontractors. The

immediate notifications must be completed with a

written report within 24 h after the incident. The

report shall be delivered to the supervisor of the DC.

(J) 4.13 Supervision and execution

The service performance shall be managed and

supervised with regular meetings and evaluations.

All risks of the service shall be evaluated together by

the client and the contractor.

If the DC notifies Contractor of any non-compliance

during the period of validity notified in the

contractors contract, Contractor shall (immediately,

if so directed; otherwise in not more than forty-eight

(48) hours after receipt of such notice) take all

necessary steps to correct the existing conditions.

All contractors shall be required to participate in

observation tours and to report issues related to

HSSE. The contractor is obligated to participate in all

safety, quality assurance inspections and audits

(internal or external), concerning its operations. All

the findings from the tours and inspections shall be

presented to the DC with plans to rectify them

accordingly.

(K) 5.1 Foreign Work Force

1

Contractor has to present to the DC identity

information, employer company and contact address

and a valid permit of residence and working of his

own and possible foreign work force used by a

subcontractor. He is liable to keep these permits

valid.

Contractor is responsible that an accident insurance

has been taken for all his employees, which covers

all the possible damage resulting from occupational

injury or occupational disease and Contractor have

to show these documents to DC upon request.

(L) 5.3 Competence Requirements

1

Contractor must be able to prove the competence of

his personnel by a training register or equivalent

method. At minimum, all contractors are required to

successfully undergo "Oil and Petrochemical Safety

Orientation Course, and Site Safety Induction

Course. For supervisory level, "Oil and

Petrochemical Safety Induction Course (Supervisor)

is mandatory. Other requirements are as deemed

necessary by regulatory requirements when

stipulated. The Project supervisor must ensure

contractors are qualified in these compulsory

trainings as well as competency requirements under

the law.

Contractor is responsible to ensure that all persons

participating in high risk works such as hot work,

confined space work, electrical work and etc. have

undergone the required statutory and internal

trainings to meet the demand from the undertaking

jobs and the competency/qualification of the workers

shall be indicated in the permit-to-work application.

(M) 5.4 Access Pass Procedure

1

Personnel of the Contractor have to have valid

illustrated Neste Oils identity card

(N) 6 Safety Rules

1

Contractor shall advise and is responsible for that its

employees, servants or agents comply with the

following safety rules of Neste Oil, OQD-9086 Zero

Tolerance Policy and OQD-8949 Safety rules.

(O) 6.2 Visit to the site area

1

Contractor has no rights to bring visitors to the work

site without a written approval given by the DC

Management.

(P) 6.6 Work permit

1

A written work permit is required for all work carried

out by Contractors. Contractors work permit is

assigned primarily to the supervisor of the workers

and each job task shall have an appointed lead onsite. Exceptions to above-mentioned are to be

agreed by MD, Department manager concerned and

HSSE.

A written work permit is also required for work

carried out by the maintenance organisation within

process and plant areas. In addition there are more

specific procedures for hot work, for work carried out

in electric equipment rooms, for work in confined

spaces and for excavation work as well as for lifting

and scaffolding work.

A risk assessment must be made before carrying out

any work. Only machines, equipment and tools,

which meet the set safety standards are allowed to

be brought to the areas.

All preliminary preparation work, which can be

carried out outside the process area, must be

carried out at the areas reserved for them. Also any

installation and preassembly work which can

reasonably be carried out at the ground level shall

be done so.

It is Contractors responsibility to assure that

protective measures of hot work are at least in

compliance with the terms of the granted hot work

permit and risk assessments so, that caused sparks

are blocked inside the defined hot work place and

can not

spread out

to surroundings.

When carrying

(Q) 6.8

Personal

Protective

Equipment

out hot work the requirements of the hot work

instruction of the insurance companies have to be

taken into account.

Contractor is responsible for that his own personnel

and his subcontractors personnel are using proper

approved personal protective equipment required for

the work when working within DCs areas.

Contractors shall provide protective equipment

needed for the job to their workers.

The minimum requirements for personal protective

equipment at process areas are as follows:

Helmet, with chin-strap to secure and tighten the

helmet and the name of the person and the

corresponding company on it

Eye protection

Safety shoes

Full body protective clothing

Hearing protectors within specially marked areas

Safety harness must be used when using a man lift

(hoist), installing scaffolding or working in other

conditions with a risk of falling. Safety harness with

double lanyards must always be used and properly

attached, when it is possible to fall 2 metres or more

and the risk of falling can not be eliminated by other

proper means (guard rails, barriers, etc.). 100% tieof rule is mandatory while working.

Additional protective equipment necessary due to

nature of the work must be used for e.g. grinding,

welding or cutting etc.

The minimum set of protective equipment has to be

worn in areas specified by the DC.

In addition valid work procedures, protection

specified in the work permit, legal protection

requirements for the work and safety signs at the

area or workstation

must also be obeyed.

Contractor must recognise tasks where minimum

protection is not sufficient to protect the person and

correspondingly provide protective equipment

meeting the requirements.

All protective equipment shall be type approved

(meeting minimum mandatory standards) and

adequate for the job.

###

Evidentiary Document for

action item closed

You might also like

- Health & Safety ManualDocument37 pagesHealth & Safety Manualgs_humboldt50% (2)

- Emergency Responce Plan For Gulf CryoDocument22 pagesEmergency Responce Plan For Gulf CryoHabib ur rahman0% (1)

- Safe Driving & Nutrition MonthDocument12 pagesSafe Driving & Nutrition Monthkashifbutty2kNo ratings yet

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- Accident Reporting PolicyDocument2 pagesAccident Reporting PolicybmkallarackalNo ratings yet

- Weekly excavator checklist template for construction projectsDocument4 pagesWeekly excavator checklist template for construction projectssamiran RouthNo ratings yet

- 7.2.5.b. Qhse Ims ManualDocument30 pages7.2.5.b. Qhse Ims ManualYani EsbeNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (12) Tower Bolt TighteningDocument11 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (12) Tower Bolt Tighteningmohammed tofiqNo ratings yet

- Runaya Refining LLLP IMS Internal Audit Checklist ReviewDocument2 pagesRunaya Refining LLLP IMS Internal Audit Checklist Reviewdeep maliNo ratings yet

- Annexure - 1 PPE Requirement MatrixDocument1 pageAnnexure - 1 PPE Requirement MatrixAshok PatelNo ratings yet

- Accident, Incident and Near-Miss Reporting ProcedureDocument11 pagesAccident, Incident and Near-Miss Reporting ProcedureSalim MuftahNo ratings yet

- Lone Working Risk AssessmentDocument3 pagesLone Working Risk AssessmentMuhammed yahiyaNo ratings yet

- HSE Audit Checklist - Site BasedDocument19 pagesHSE Audit Checklist - Site BasedOws Anish100% (1)

- Loto Implementation Procedure Plan PDFDocument18 pagesLoto Implementation Procedure Plan PDFgilNo ratings yet

- All Forms HSE Docs by Hseprof Com 1697423389Document76 pagesAll Forms HSE Docs by Hseprof Com 1697423389ahmedalderbi801No ratings yet

- PPE MatrixDocument4 pagesPPE Matrixb_chiradipNo ratings yet

- List of Operational Control ProcedureDocument1 pageList of Operational Control ProcedureRam Naidu PenNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- Oil India Limited: Onshore Emergency Response PlanDocument23 pagesOil India Limited: Onshore Emergency Response Planaji sathyanandanNo ratings yet

- OSH Risk Register - 01Document28 pagesOSH Risk Register - 01M.usmanNo ratings yet

- Spill Response Procedures OCLDocument14 pagesSpill Response Procedures OCLThusithaNo ratings yet

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- Sample PPE Policies: InstructionsDocument9 pagesSample PPE Policies: InstructionsrejilkumarNo ratings yet

- PPEA-WI-012 - B Consultation and Communication at SiteDocument6 pagesPPEA-WI-012 - B Consultation and Communication at SiteDeepakNo ratings yet

- Ethics of Experimental ResearchDocument16 pagesEthics of Experimental Research유웃No ratings yet

- Environmental Aspect Evaluation FormDocument4 pagesEnvironmental Aspect Evaluation Form逍逾No ratings yet

- Project Potential HazardsDocument10 pagesProject Potential Hazardsmichael nortonNo ratings yet

- CK Ee Ebook (Trend Trading Made Easy)Document58 pagesCK Ee Ebook (Trend Trading Made Easy)SBNo ratings yet

- Chemical LabelsDocument11 pagesChemical LabelsAriel Dela CruzNo ratings yet

- Emergency Response Plan Sri City Project Rev 00Document23 pagesEmergency Response Plan Sri City Project Rev 00HSE OFFICENo ratings yet

- Water blasting SWMSDocument5 pagesWater blasting SWMSjohney2No ratings yet

- Medivac Drill MAn Over Boat-2Document2 pagesMedivac Drill MAn Over Boat-2yogakharismaNo ratings yet

- FILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERDocument170 pagesFILE-3.1.3-SCT-BAR-C2170-VOL-ID-SCC-HSEP14 - HSE Plan For Subcontractor - ERHitesh KoolwalNo ratings yet

- Health and Safety Risks on School Farm VisitsDocument46 pagesHealth and Safety Risks on School Farm Visitsshan123455555555No ratings yet

- Labdesign GuideDocument126 pagesLabdesign GuiderwbbartonNo ratings yet

- Secusrity DutiesDocument2 pagesSecusrity DutiesSBNo ratings yet

- Sitespecificsafetyplanmaster 150620153514 Lva1 App6891Document30 pagesSitespecificsafetyplanmaster 150620153514 Lva1 App6891Steven SengNo ratings yet

- Lock Out Tag Out Procedure For - : TitleDocument12 pagesLock Out Tag Out Procedure For - : TitleerwinNo ratings yet

- PpeDocument1 pagePpeBryan Rey Del Fierro100% (1)

- PPE MatrixDocument1 pagePPE MatrixcaptainphihungNo ratings yet

- HSE Equipment Inspection RegisterDocument1 pageHSE Equipment Inspection RegistersubhanmusadiqNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- ISO 45001 HSE Manual and Forms ListDocument5 pagesISO 45001 HSE Manual and Forms ListWAN NORASHIKIN WAN MUSANo ratings yet

- Marafiq OHSMS Pre-Qualification QuestionnaireDocument17 pagesMarafiq OHSMS Pre-Qualification QuestionnairemedobasNo ratings yet

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Assessment Centre GuideDocument35 pagesAssessment Centre GuideSandip Grover100% (3)

- Contractor Safety RequirementsDocument24 pagesContractor Safety RequirementseastNo ratings yet

- Lock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorDocument1 pageLock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorShailendraNo ratings yet

- HSE-000-PLN-0017 Plan To Control Chemical HazardsDocument13 pagesHSE-000-PLN-0017 Plan To Control Chemical Hazardsernesto100% (1)

- CONTRACTOR HSE REPORTDocument2 pagesCONTRACTOR HSE REPORTRollyNo ratings yet

- HSE Auditing ProcedureDocument15 pagesHSE Auditing Proceduresudeesh kumarNo ratings yet

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- WHS P11 Fatigue Management ProcedureDocument8 pagesWHS P11 Fatigue Management Procedurehse bptNo ratings yet

- Storm Water SOPDocument3 pagesStorm Water SOPGrady HopkinsNo ratings yet

- Executive Summary: "Emotional Intelligence at Work Place"Document3 pagesExecutive Summary: "Emotional Intelligence at Work Place"rabail gulNo ratings yet

- Accuracy and FluencyDocument4 pagesAccuracy and FluencyZurain YusofNo ratings yet

- Microbiology Lab DesignDocument14 pagesMicrobiology Lab DesignLau Guo Wei100% (2)

- MajChoh What FSM Needs To Know Abt Means of EscapeDocument41 pagesMajChoh What FSM Needs To Know Abt Means of Escapejo_eli_No ratings yet

- HSE Plan - HB2NP Habeeb (New)Document81 pagesHSE Plan - HB2NP Habeeb (New)nsadnanNo ratings yet

- Health and SafetyDocument5 pagesHealth and SafetyAnand Sai KingNo ratings yet

- 2016 ContractorSafetyMeetingDocument176 pages2016 ContractorSafetyMeetingLedo HoussienNo ratings yet

- Job Safety Environmental Analysis Pre-Task BriefingDocument5 pagesJob Safety Environmental Analysis Pre-Task BriefingFerman TokgözoğluNo ratings yet

- PTW Audit Report SummaryDocument1 pagePTW Audit Report SummarybhaskarNo ratings yet

- Hsem-Sp-0014 Nidaa Journey ManagementDocument6 pagesHsem-Sp-0014 Nidaa Journey ManagementAhmed Imtiaz RaoNo ratings yet

- HSE Engineer Interview QuestionsDocument1 pageHSE Engineer Interview QuestionsEmil0% (1)

- Subcontractor Competence / Resource Questionnaire: Commercial Services To CompleteDocument31 pagesSubcontractor Competence / Resource Questionnaire: Commercial Services To CompleteNaba majeadNo ratings yet

- Safety BoardDocument1 pageSafety BoardsunilNo ratings yet

- JOB SAFETY ANALYSIS FORMDocument7 pagesJOB SAFETY ANALYSIS FORMIulian Costin IonNo ratings yet

- EtiquaDocument4 pagesEtiquaSBNo ratings yet

- (Ebook - English) Opening Lines For Conversation PDFDocument2 pages(Ebook - English) Opening Lines For Conversation PDFSBNo ratings yet

- National Cert Standard (290917)Document1 pageNational Cert Standard (290917)SBNo ratings yet

- Media Summary: A. Social Impacts 1. For Minorities/oppressed To Be HeardDocument3 pagesMedia Summary: A. Social Impacts 1. For Minorities/oppressed To Be HeardSBNo ratings yet

- SEHS 2019-03 Update SummaryDocument86 pagesSEHS 2019-03 Update SummarySBNo ratings yet

- (TC: Good Link) - (TC: Good Transition)Document4 pages(TC: Good Link) - (TC: Good Transition)SBNo ratings yet

- (TC: Good Link) - (TC: Good Transition)Document4 pages(TC: Good Link) - (TC: Good Transition)SBNo ratings yet

- Rutgers English Conversation Program GuideDocument15 pagesRutgers English Conversation Program GuideJuan Pardo GómezNo ratings yet

- SEHS 2019-03 Update SummaryDocument5 pagesSEHS 2019-03 Update SummarySBNo ratings yet

- Physics DefinitionsDocument7 pagesPhysics DefinitionsSBNo ratings yet

- Instructions: Payment Note:: FSSD-TP01 (Sep 2005)Document3 pagesInstructions: Payment Note:: FSSD-TP01 (Sep 2005)SBNo ratings yet

- Reducing Sprain and Strain Injuries AttendanceDocument5 pagesReducing Sprain and Strain Injuries AttendanceSBNo ratings yet

- Montie Safety VideosDocument1 pageMontie Safety VideosSBNo ratings yet

- Launch of SS 603: 2014 Overview and ChangesDocument12 pagesLaunch of SS 603: 2014 Overview and ChangesSBNo ratings yet

- MPA Act summaryDocument44 pagesMPA Act summaryJayce TangNo ratings yet

- Accident Prevention Vision - Understanding Different Interpretations of Vision ZeroDocument6 pagesAccident Prevention Vision - Understanding Different Interpretations of Vision ZeroSBNo ratings yet

- Workplace Safety Meeting RecapDocument4 pagesWorkplace Safety Meeting RecapSBNo ratings yet

- Information On Fire CertifcateDocument3 pagesInformation On Fire CertifcateSBNo ratings yet

- Fire Drill Assembly Point SignDocument3 pagesFire Drill Assembly Point SignSBNo ratings yet

- Abrasive BlastingDocument11 pagesAbrasive BlastingSBNo ratings yet

- ITIL Change Management Process OverviewDocument23 pagesITIL Change Management Process Overviewjust_checkingNo ratings yet

- EnheasaDocument6 pagesEnheasaSBNo ratings yet

- 2012 Sec 3 Physics PDFDocument270 pages2012 Sec 3 Physics PDFSBNo ratings yet

- Tank Inventory ReportDocument4 pagesTank Inventory ReportSBNo ratings yet

- E-Performance Management System-A Study On IOCL EmployeesDocument8 pagesE-Performance Management System-A Study On IOCL EmployeesAngelick PrinceNo ratings yet

- Human Resource Planning StaffingDocument19 pagesHuman Resource Planning StaffingMustafaNo ratings yet

- RWC 10th GradeDocument27 pagesRWC 10th Gradeapi-239644263No ratings yet

- English For Science and Technology - Learner S Approach PDFDocument10 pagesEnglish For Science and Technology - Learner S Approach PDFŽana Knežević100% (2)

- HR Management Functions and CompetenciesDocument13 pagesHR Management Functions and CompetenciesDiane DominiqueNo ratings yet

- NTPEP Geotextile Audit Work-Plan - tcm29-27577Document15 pagesNTPEP Geotextile Audit Work-Plan - tcm29-27577Mohammed AlkhateebNo ratings yet

- Fast Food Simulation: Reported by Group 27Document9 pagesFast Food Simulation: Reported by Group 27Sang ToNo ratings yet

- Competency Iceberg Model 180328040806Document51 pagesCompetency Iceberg Model 180328040806Dung NguyenNo ratings yet

- Ihrm Module 2 Strategies For International Growth - 2017Document30 pagesIhrm Module 2 Strategies For International Growth - 2017Bushra AhtabNo ratings yet

- Understanding Culture, Society and Politics: Module For Class Simulation /dry RunDocument12 pagesUnderstanding Culture, Society and Politics: Module For Class Simulation /dry RunAngelyn LingatongNo ratings yet

- Work Immersion Learner's PerformanceDocument1 pageWork Immersion Learner's PerformanceCarl Jefferson' BepoNo ratings yet

- G H Raisoni Academy For Human Excellence Pvt. LTD.: College Teachers TrainingDocument14 pagesG H Raisoni Academy For Human Excellence Pvt. LTD.: College Teachers TrainingmumergeeNo ratings yet

- Proficiency On The Use of Technological Knowledge, Skills and Attitude of The Contemporary Academic Librarians in Selected Libraries in Metro ManilaDocument44 pagesProficiency On The Use of Technological Knowledge, Skills and Attitude of The Contemporary Academic Librarians in Selected Libraries in Metro Manilagina irasgaNo ratings yet

- Training the Public Health WorkforceDocument3 pagesTraining the Public Health WorkforceAfriza Bin Yuana ArifinNo ratings yet

- Project ReportDocument63 pagesProject Reportrishikesh kumarNo ratings yet

- Human Resources Practices Bharat Electronics Limited MachiliptnamDocument66 pagesHuman Resources Practices Bharat Electronics Limited MachiliptnamChandra Sekhar Jujjavarapu100% (1)

- MTP CaseDocument10 pagesMTP CaseJanak ShuklaNo ratings yet

- Chapter 1 Meeting Present and Emerging Strategic Human Resource Challenges Q&ADocument62 pagesChapter 1 Meeting Present and Emerging Strategic Human Resource Challenges Q&AAhmad FarooqNo ratings yet

- Release 6.0 BSB07 Business Services Training Package Header InformationDocument141 pagesRelease 6.0 BSB07 Business Services Training Package Header Informationrsdiamz100% (1)

- Landscape Gardening PECs PlanDocument36 pagesLandscape Gardening PECs Plansanchezroman100% (1)

- Henzi Etal (2006) - Perspectives Dental Students About Clinical EducationDocument17 pagesHenzi Etal (2006) - Perspectives Dental Students About Clinical EducationMiguel AraizaNo ratings yet

- Chapter 1 - Introduction ToDocument30 pagesChapter 1 - Introduction ToCostAcct1No ratings yet

- NEBOSH Certificate in Environmental ManagementDocument10 pagesNEBOSH Certificate in Environmental ManagementakramNo ratings yet

- Iste Stds Self AssessmentDocument5 pagesIste Stds Self Assessmentapi-468878589No ratings yet

- TP - 5562e - July 2013 - Navigation Cadet Training Program PDFDocument164 pagesTP - 5562e - July 2013 - Navigation Cadet Training Program PDFmrraj69No ratings yet