Professional Documents

Culture Documents

Determining Shovel Truck Productivity

Uploaded by

Galuizu001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determining Shovel Truck Productivity

Uploaded by

Galuizu001Copyright:

Available Formats

By the use of u model of current operatiolls

it is possible to predict future equipment requiren~ents.

Determining Shovel-Truck Productivity

W. C. MORGAN and L. L. PETERSON

his paper discusses some of the problems involved in predicting the productivity of a shovel

and truck fleet in a new set of operating conditions.

More specifically, it concentrates on the problems of

predicting the travel times on the haul and return

portions of the truck cycle under new profile conditions and the prediction of the interaction effect

between the shovel and truck at the loading point.

The ability to calculate the travel times for a new

road profile is not new. Additional corrections of

these calculated times for expected actual operation

can be made. In considering the interaction between

the loader and the hauler, there are two approaches

that can be taken. Probably the most accurate

method of predicting the shovel-truck interaction

is a simulation of the step-by-step operation considering the variation in cycle times of the shovel

and trucks. This is usually called a stochastic simulation and requires input describing how these cycle

times vary. However, by understanding the causes

of this shovel-truck interaction it is possible to

make sufficiently accurate predictions with much

simpler methods.

Haulage Cycle Established from Existing

Operations

For the purpose of this discussion let us assume

that the problem involves trying to predict the

productivity of a single shovel-truck fleet a t some

future time in an existing operation. Let us also assume for simplification that the new operation to be

SME member W. C. MORGAN is Staff Engineer and

L. L. PETERSON is Research Engineer, with the Research

Department of the Caterpillar Tractor Co., Peoria, Ill.

simulated has the same loading and pit conditions

and the same dumping conditions as did the existing

operation. Therefore, the only difference would be

the difference in the hauling profile for the new

operation. The problem then becomes one of predicting the change in the travel times on the haul

and return portions of the cycle, and in determining

the change in interaction between and the shovel

and trucks with the new truck cycle times.

The objectives in making this calculation will be

(1) to predict the productivity of the present truck

and shovel fleet under the new operating conditions

and (2) to vary the number of trucks to determine

the most economical number of trucks.

It would be quite logical that the first step would

be to measure the productivity that is actually being

achieved under the existing set of conditions. To

do this, a cycle study would be required where the

times to accomplish the various portions of the cycle

and the payloads for the trucks would be measured.

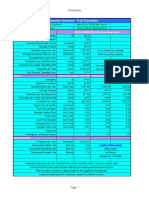

The results of a typical cycle study are shown in

Fig. 1. The hauling unit cycle has broken up into the

following segments:

Loading

Maneuvering out of the pit

Hauling

Dumping

Return

Maneuvering into the pit

The shovel cycle has been simplified to consist of

only two segments: (1) time to load the truck and

(2) transfer time between trucks.

In order to obtain the measured productivity, the

average values for each of the segments were used

(Table I ) to give an average total cycle time of 19.80

minutes. This cycle time, combined with the average

PRESENT l l D FUTURE HAUL PROflLES

'

,%:

,.-,

200'

OY0

PRESENT

LOAD POSlTlOY

1%

, ,

; i ;

I l O I i L 11,1P1I"

,~

1 ' 4

6 ;

TIUCK 18Il-.IP

Fig. 1-Measured

76-MINING

18

cycle dnta.

ENGINEERING, DECEMBER 1968

FUTURE

LOAD

POSITION

I- - - - - ...

2WO'

OSCRADE

2% ROLL. RES

olo+,

lO0l0

200

o01

2'0

24 MPH

DUMP

7

5W

0'0

,TiPH

zoo

I0 M P H

24 MPH

,l oIa o '

3.0

loMPn

2%

24 MPH-SPEED LIMIT

Fig. 2-Present

and future haul profile.

SOCIETY OF

You might also like

- Optimization of Shovel-Truck System in OPDocument7 pagesOptimization of Shovel-Truck System in OPminerito2211100% (1)

- Runge Mining EFH PaperDocument5 pagesRunge Mining EFH PaperVirna Lee Trout100% (1)

- Excavator SelectionDocument10 pagesExcavator SelectionJarvis111No ratings yet

- Improving Truck-Shovel Matching-Nel Kizil and KnightsDocument20 pagesImproving Truck-Shovel Matching-Nel Kizil and KnightsRoger Sucapuca Rondan100% (1)

- Copy of MinexDocument42 pagesCopy of MinexSujib BarmanNo ratings yet

- Dragline Dictionary Apr14Document578 pagesDragline Dictionary Apr14dhowardj100% (1)

- 3 Loading ConsiderationsDocument32 pages3 Loading ConsiderationsHerudi Eng100% (1)

- Production Summary - Full SimulationDocument20 pagesProduction Summary - Full SimulationJorli Reyes SanchezNo ratings yet

- Productivity Considerations For Shovels and ExcavatorsDocument4 pagesProductivity Considerations For Shovels and ExcavatorsRohit DewanganNo ratings yet

- Talpac Tutorial - MetricDocument52 pagesTalpac Tutorial - MetricAndrew OlsonNo ratings yet

- Cost Models of Theoretical Mining Operations - CostMine PDFDocument5 pagesCost Models of Theoretical Mining Operations - CostMine PDFVidya Sagar0% (1)

- Mining ProductivityDocument176 pagesMining Productivityykharchi88% (8)

- Reliance Case StudyDocument38 pagesReliance Case Studyhihimanshu70100% (2)

- 0510 Performance Metrics For Mining EquipmentDocument64 pages0510 Performance Metrics For Mining EquipmentLorenzoNoePerezRodriguez75% (4)

- Mine HaulageDocument54 pagesMine HaulageStef Torcedo100% (5)

- Talpac Tutorial - ImperialDocument52 pagesTalpac Tutorial - ImperialWalter Carbonel Julian50% (2)

- Mining Cost Service Ex 1Document3 pagesMining Cost Service Ex 1theresia_ksNo ratings yet

- Haulage Calculation - Minesight HaulageDocument12 pagesHaulage Calculation - Minesight HaulageNurlanOruzievNo ratings yet

- Haulroad: Design and Maintenance Guide Design and MaintenanceDocument11 pagesHaulroad: Design and Maintenance Guide Design and MaintenanceAdie Survei PemetaanNo ratings yet

- Mine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs - CostMine PDFDocument3 pagesMine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs - CostMine PDFArturo Allende0% (3)

- Excavator SelectionDocument10 pagesExcavator SelectionMario HezkeeaNo ratings yet

- Mine Plan - UnejDocument73 pagesMine Plan - UnejFanteri Aji DharmaNo ratings yet

- Effective Shortterm Planning - KPCDocument38 pagesEffective Shortterm Planning - KPCdinasameidwiyaniNo ratings yet

- Mine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs CostMineDocument1 pageMine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs CostMineglenraven52833% (3)

- Share Lect 01 MINE FLEET-1Document98 pagesShare Lect 01 MINE FLEET-1Goodluck AnaniaNo ratings yet

- Idle Time Analysis of Mining Equipment Using Pareto Principle - A Case StudyDocument5 pagesIdle Time Analysis of Mining Equipment Using Pareto Principle - A Case StudyIAEME PublicationNo ratings yet

- Modelling of In-Pit Crusher Conveyor AlternativesDocument8 pagesModelling of In-Pit Crusher Conveyor AlternativesJosue GonzalezNo ratings yet

- 0737 Open Pit Mining Sys EquipDocument28 pages0737 Open Pit Mining Sys EquipSivaraman SelvapandianNo ratings yet

- Mining EquipmentDocument6 pagesMining EquipmentAbhishek Sahu67% (3)

- Capacity Utilization of Mining MachineryDocument19 pagesCapacity Utilization of Mining MachinerykhaninNo ratings yet

- White Paper - Trends in Performance of Open Cut Mining EquipmentDocument36 pagesWhite Paper - Trends in Performance of Open Cut Mining EquipmentGbi Mining Intelligence100% (2)

- Caterpillar Performance Handbook: English - Cover - BW2.indd 1Document4 pagesCaterpillar Performance Handbook: English - Cover - BW2.indd 1ali alilouNo ratings yet

- Introduction To TalpacDocument34 pagesIntroduction To TalpacRoger Sucapuca Rondan100% (3)

- Dozer Production ImperialDocument7 pagesDozer Production Imperialelson siraitNo ratings yet

- Introduction To FPCDocument25 pagesIntroduction To FPCBenito Lionel ZoboNo ratings yet

- Working GeometryDocument1 pageWorking Geometrydidi setiawanNo ratings yet

- Queuing Shovel TruckDocument91 pagesQueuing Shovel Truckفردوس سليمانNo ratings yet

- AA - Monograph 12Document12 pagesAA - Monograph 12Jessica Kovacic100% (1)

- Reference Guide To Mining Machine Applications (Modo de Compatibilidad)Document54 pagesReference Guide To Mining Machine Applications (Modo de Compatibilidad)José R. Castro75% (4)

- Machine Performance: Dump Truck - 40 Ton ClassDocument2 pagesMachine Performance: Dump Truck - 40 Ton ClassHerman AbdullahNo ratings yet

- Determining Truck Speeds Using Rimpull and Retarder CurvesDocument17 pagesDetermining Truck Speeds Using Rimpull and Retarder Curvesalfri121100% (3)

- Chapter 3 Mine PumpsDocument29 pagesChapter 3 Mine PumpsOolasyar KhattakNo ratings yet

- Suitability Study of Ripper-Dozer Combination in Indian MinesDocument58 pagesSuitability Study of Ripper-Dozer Combination in Indian MinesRavikanth AluriNo ratings yet

- BWEDocument16 pagesBWEMas YoanNo ratings yet

- Pit OptimisasiDocument38 pagesPit OptimisasiAbraam Sagoes100% (3)

- Advanced Open Pit Planning and Design 20Document167 pagesAdvanced Open Pit Planning and Design 20Gbenga AdewumiNo ratings yet

- Tabel 8.7 Sasaran Produksi Penambangan Batubara Dan Penggalian OverburdenDocument38 pagesTabel 8.7 Sasaran Produksi Penambangan Batubara Dan Penggalian OverburdenSean ChoiNo ratings yet

- Productivity BW211D-40 2,456.50 m2/hr Owning Cost BW211D-40 5.84 USD/hr Operating Cost BW211D-40 14.82 USD/hr Total OO Cost BW211D-40 20.66 USD/hrDocument4 pagesProductivity BW211D-40 2,456.50 m2/hr Owning Cost BW211D-40 5.84 USD/hr Operating Cost BW211D-40 14.82 USD/hr Total OO Cost BW211D-40 20.66 USD/hrNur JannahNo ratings yet

- Owning and Op CostDocument18 pagesOwning and Op Costilham pramanaNo ratings yet

- Mine Planning and Scheduling42Document228 pagesMine Planning and Scheduling42Martin JanuaryNo ratings yet

- KPC - Productivity Improvement 2014Document37 pagesKPC - Productivity Improvement 2014fransdaun100% (1)

- Simulasi Cycle TimeDocument2 pagesSimulasi Cycle TimeZulfikar Habib SiregarNo ratings yet

- MME 2010 Contents and Introduction PDFDocument13 pagesMME 2010 Contents and Introduction PDFAmaraaZoyaNo ratings yet

- Mining EarthmovingDocument17 pagesMining EarthmovingLatha100% (1)

- MODEL - Lerchs-Grossman OptimizationDocument41 pagesMODEL - Lerchs-Grossman OptimizationDouglas Yusuf0% (2)

- Models For Mining Equipment SelectionDocument7 pagesModels For Mining Equipment SelectionMuwafaq2002100% (2)

- Efh Ausimm PaperDocument7 pagesEfh Ausimm PaperSunny SouravNo ratings yet

- Simulation: Planning Open Pit Mining Operations UsingDocument6 pagesSimulation: Planning Open Pit Mining Operations UsingHenry ContrerasNo ratings yet

- Impact of Blast Fragmentation On Truck Shovel Fleet PerformanceDocument6 pagesImpact of Blast Fragmentation On Truck Shovel Fleet PerformancepaulocouceiroNo ratings yet

- 01volume1 PDFDocument330 pages01volume1 PDFIsaac VisualNo ratings yet

- Mine DesDocument21 pagesMine DesGaluizu001No ratings yet

- Estimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit Definition PDFDocument6 pagesEstimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit Definition PDFGaluizu001No ratings yet

- Capital and Operating Cost EstimationDocument48 pagesCapital and Operating Cost EstimationGaluizu00167% (3)

- Cash Flow Grades - Scheduling Rocks With Different Troughput CharacteristicsDocument8 pagesCash Flow Grades - Scheduling Rocks With Different Troughput CharacteristicsGaluizu001No ratings yet

- SAIMM - Economic Evaluation of Optimum Bench HeightDocument10 pagesSAIMM - Economic Evaluation of Optimum Bench HeightedwinwillyNo ratings yet

- Technical Operating Flexibility in The Analysis of Mine Layouts and SchedulesDocument8 pagesTechnical Operating Flexibility in The Analysis of Mine Layouts and SchedulesGaluizu001100% (1)

- How To Improve The Ramp-Up of Block Caving MinesDocument29 pagesHow To Improve The Ramp-Up of Block Caving MinesGaluizu001No ratings yet

- Estimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit DefinitionDocument6 pagesEstimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit DefinitionGaluizu001No ratings yet

- A KPI-driven Approach To Tactical and Operational ControlDocument12 pagesA KPI-driven Approach To Tactical and Operational ControlGaluizu001No ratings yet

- Open Pit Strategic Mine PlanningDocument8 pagesOpen Pit Strategic Mine PlanningGaluizu001No ratings yet

- Footprint and Economic Envelope Calculation For Block/Panel CavingDocument23 pagesFootprint and Economic Envelope Calculation For Block/Panel CavingGaluizu001No ratings yet

- Jan To Oct GK HUDDLE (IIFT 2019 Expected QS)Document99 pagesJan To Oct GK HUDDLE (IIFT 2019 Expected QS)Stephanie LucasNo ratings yet

- A Project Report ON Ratio Analysis at Raddy'S LaboratoryDocument31 pagesA Project Report ON Ratio Analysis at Raddy'S LaboratoryKalpana Gunreddy100% (1)

- Summer Training ReportDocument82 pagesSummer Training ReportKomal SharmaNo ratings yet

- Entrep Mind Chapter 8Document3 pagesEntrep Mind Chapter 8Yeho ShuaNo ratings yet

- Apeejay Institute of Management Technical Campus Rama-Mandi, Hoshiarpur Road, JalandharDocument3 pagesApeejay Institute of Management Technical Campus Rama-Mandi, Hoshiarpur Road, JalandharSahil DewanNo ratings yet

- Rental Agreement - Trivik Developesr LLP On 18.12.2023Document4 pagesRental Agreement - Trivik Developesr LLP On 18.12.2023Vijay Varma RNo ratings yet

- JLN Pending, Kuching 1 30/11/22Document4 pagesJLN Pending, Kuching 1 30/11/22Jue tingsNo ratings yet

- Bill of Quantities PDFDocument81 pagesBill of Quantities PDFTuoyo MebaghanjeNo ratings yet

- St. Paul University Surigao: Performance TaskDocument2 pagesSt. Paul University Surigao: Performance TaskRoss Armyr Geli100% (1)

- Google Adwords Advanced Search Advertising Exam Answers PDFDocument46 pagesGoogle Adwords Advanced Search Advertising Exam Answers PDFVinit ErangaleNo ratings yet

- NCR - T-245-ND - Aug 40 To Sept 2Document25 pagesNCR - T-245-ND - Aug 40 To Sept 2April Jay BederioNo ratings yet

- KWL HomeworkDocument2 pagesKWL HomeworkPatricia SantosNo ratings yet

- Please DocuSign Independent Contractor AgreeDocument9 pagesPlease DocuSign Independent Contractor AgreeAkankshaNo ratings yet

- 2012 Water Distribution Bulk Water Filling Station Bid Doc - 201205301523587116Document7 pages2012 Water Distribution Bulk Water Filling Station Bid Doc - 201205301523587116ayaz hasanNo ratings yet

- The Hospitality Business ToolkitDocument17 pagesThe Hospitality Business ToolkitOanaa ComanNo ratings yet

- Strengthening Internal Brand Equity With Brand Ambassador Programs: Development and Testing of A Success Factor ModelDocument16 pagesStrengthening Internal Brand Equity With Brand Ambassador Programs: Development and Testing of A Success Factor ModelmelianNo ratings yet

- Engineering Economics, Chapter 8Document23 pagesEngineering Economics, Chapter 8Bach Le NguyenNo ratings yet

- Accounting and Finance For The International Hospitality Industry PDFDocument319 pagesAccounting and Finance For The International Hospitality Industry PDFGede Panca Ady SapputraNo ratings yet

- É Þé®Úé ) Åõ ºé Éçºéévéé®Úhé Éê É Éêxé Ééç Þ Êxévéò Êxé É ÉDocument115 pagesÉ Þé®Úé ) Åõ ºé Éçºéévéé®Úhé Éê É Éêxé Ééç Þ Êxévéò Êxé É ÉSHIVGOPAL KULHADENo ratings yet

- Casestudy 2Document8 pagesCasestudy 2Sugaintheran MuniandyNo ratings yet

- MP Topics - IIIDocument1 pageMP Topics - IIIAnjana PriyaNo ratings yet

- Applications of Business AnalyticsDocument10 pagesApplications of Business AnalyticsMansha YadavNo ratings yet

- "Stock Control and Inventory Management": Project Report OnDocument36 pages"Stock Control and Inventory Management": Project Report OnAradhana AndrewsNo ratings yet

- 2014-GE Leap Nozzle PaperDocument2 pages2014-GE Leap Nozzle PaperRamji RaoNo ratings yet

- Chart Reading 101Document32 pagesChart Reading 101stowfank100% (1)

- Regional Growth, Factor Allocation and Balance of PaymentsDocument13 pagesRegional Growth, Factor Allocation and Balance of PaymentsEka Pratiwi ArnazNo ratings yet

- List of Table and Figures: Outline Development Plan, AgraDocument12 pagesList of Table and Figures: Outline Development Plan, AgrageetNo ratings yet

- Usa ListDocument50 pagesUsa ListBhavika MishraNo ratings yet

- Report On DAReWRODocument18 pagesReport On DAReWROSaeed Agha AhmadzaiNo ratings yet

- IHR PlanningDocument17 pagesIHR PlanningSphoorthi Iruvanti100% (1)