Professional Documents

Culture Documents

Calcination Temperature of Nano MgO Effect On Base Transesterification of Palm Oil

Uploaded by

Jelita Purnamasari SaroinsongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calcination Temperature of Nano MgO Effect On Base Transesterification of Palm Oil

Uploaded by

Jelita Purnamasari SaroinsongCopyright:

Available Formats

World Academy of Science, Engineering and Technology

International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering Vol:3, No:8, 2009

Calcination Temperature of Nano MgO Effect

on Base Transesterification of Palm Oil

Abdul Rahim Yacob, Mohd Khairul Asyraf Amat Mustajab, and Nur Syazeila Samadi

International Science Index, Chemical and Molecular Engineering Vol:3, No:8, 2009 waset.org/Publication/4342

AbstractNano MgO has been synthesized by hydration and

dehydration method by modifies the commercial MgO. The prepared

MgO had been investigated as a heterogeneous base catalyst for

transesterification process for biodiesel production using palm oil.

TGA, FT-IR and XRD results obtained from this study lie each other

and proved in the formation of nano MgO from decomposition of

Mg(OH)2. This study proved that the prepared nano MgO was a

better base transesterification catalyst compared to commercial MgO.

The nano MgO calcined at 600C had gives the highest conversion of

51.3% of palm oil to biodiesel.

KeywordsHydration-dehydration

transesterification, biodiesel.

method,

nano

MgO,

I. INTRODUCTION

HE world energy supply had relied to non-renewable

fossil crude oil for more than two centuries. Energy

generation for transportation was a major player of about 90%

from total world energy consumed. Highly dependence on this

energy have a negative impacts such as released of green

house gases which comprise of carbon dioxide, carbon

monoxide, nitrogen oxides, unburned hydrocarbon and

sulphur-containing residues. This on the other hand can cause

global warming and other environmental problems such as

pollutions and acid rains [1]. The World Energy Forum has

predicted less than 10 decades more; all these energy supplies

will be exhausted [2]. Added by the uncertainty in crude oil

price and limited resources of fossil oil makes the situation

worsens. As a solutions, identifying and channeling renewable

raw materials into the manufacture of liquid fuel as an

alternatives had been the main focus for researches to cater

new technology and keep in pace with societys need for new

renewable power for the future [1]

Research on biodiesel or monoalkyl ester of long-chain

fatty acids has become more attractive recently, for its

environmental friendly and the fact that it can be produce

from renewable resources, such as vegetables oil, animal fats,

algae and waste cooking oils. Biodiesel has a tremendous

potential in reducing the level of pollutants and carcinogen

agents, because it produces less exhaust emissions in term of

unburnt hydrocarbon, carbon monoxide, carbon dioxide,

particular matter and sulphur-containing particles [3]-[4].

Abdul Rahim Yacob is with the University Technology of Malaysia, Johor

81310 Skudai, Johor Baharu, Johor, Malaysia (corresponding author to

provide phone: +607-5534008/34505; fax: +607-5566162; e-mail:

manrahim@kimia.fs.utm.my).

International Scholarly and Scientific Research & Innovation 3(8) 2009

Biodiesel can be applied on modern diesel engines without

any modification required, thus offer the same performance

and engine durability as petroleum-based diesel [5]-[6]. Usage

of biodiesel will give positive approach in term of stability

between agriculture, economic development and positive

impact to the environment [7].

Transesterification is a process of displacement of an

alcohol group from an ester by another alcohol [8]. Vegetable

oils consist of triglycerides, a bulk molecule that has 3

molecules of fatty acids with high viscosity. Biodiesel on the

other hand, is the transesterification process or reaction of a

fat or oils with an alcohol to form straight chain of ester and

glycerol molecules. This is demonstrated by schematic

reaction Fig. 1. Normally for this reaction methanol or ethanol

was used. This reaction however, required a catalyst to

promote the reaction, such as acid catalyst, sulphuric acid [9],

base catalyst such as sodium hydroxide, sodium methoxide

[10]-[11] and magnesium oxide [12] and lipases [13]-[15].

Fig. 1 General equation transesterification of vegetable oil to

biodiesel

Production of biodiesel using base catalyst has become

more favorable compared to other catalysts and has been up

scale applied to industries. Even though faster with percentage

of conversion around 95 % after 90 min, they had several

drawback such as need extra neutralization by mineral acids,

washing of the product biodiesel and glycerol. Here the

catalyst cannot be reutilized, large amounts of wastewater and

the process becomes costly [14]. To overcome this problem

heterogeneous base catalyst was introduced. Heterogeneous

base catalysts bring several advantages such as the catalyst

can easily be separated from the reaction mixture, easy

regeneration, less corrosive character of products, no washing

required and leading to safer, cheaper and more environmental

friendly approach [5]. The total cost of biodiesel production

using heterogeneous base catalyst was more economical with

a higher quality of methyl ester [15].

408

scholar.waset.org/1999.2/4342

World Academy of Science, Engineering and Technology

International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering Vol:3, No:8, 2009

This research will be conducted to study the

transesterification reaction of palm oil to biodiesel using

prepared nanosized MgO as a heterogeneous base catalyst.

Study will be focused on the preparation of nanosized MgO

via different heating temperatures and their effect towards the

basic catalytic activity for the transesterification of palm oil.

mobile phase and column DB-Wax with specification 0.25m

thicknesses, 30 m length and 0.20 mm internal diameter as the

stationary phase with Flame Ionization Detector (FID). The

percentage conversion of biodiesel was calculated using the

following equation:

Peak area of Oil Peak area of Methyl Ester

A. Preparation of Nano Magnesium Oxide via HydrationDehydration Method

About 12.0 g of commercial MgO was dispersed in 150 mL

distilled water and refluxed at about 100C for 24 h to yields

magnesium hydroxide, Mg(OH)2. The Mg(OH)2 precipitate

was then collected by filtration and dried in oven of 100 5C

for overnight to remove any excess water. Dried Mg(OH)2

was grinded using mortar and pastel and this process is named

hydration method. For dehydration method, the formation

MgO, about 0.2 to 0.5 g of the prepared sample was then

transferred into a quartz tube attached to a vacuum line system

of 10-3 mbar. The sample in the quartz tube is then heated at

selected temperature of 100, 200, 300, 400, 500, 600, 700 and

800 C respectively using a heating mantel. This activation

steps will be carried out for 4 hours to study the

decomposition of Mg(OH)2.

B. Characterization of Prepared Nano MgO

The prepared nanosized MgO will characterize using

several methods.Thermal decomposition of Mg(OH)2 was

analyzed using Mettler-Toledo Q100 with heating rate

10C/min in air condition FTIR spectra were recorded using

Thermo Nicolet Avatar 370 DTS in the range of 400 to

4000cm-1. The XRD analysis was carried to determine the

crystallinity and the particle size for the prepared MgO while

commercial MgO and Mg(OH)2 for comparison The XRD

diffractograms were acquired on a Siemens D5000 powder

instrument using Cu-K radiation ( = 0.15148nm, kV = 40,

mA = 40).

C. Transesterification Reaction

About 0.1 g of the prepared nanosized MgO and 10-15g of

methanol added into two-neck round bottle flask. Reaction

mixture will be refluxed at 65 5 C for 30 minutes. About

20g of palm oil was added into the reaction vessel and

continued refluxed for 4 hours to completing the

transesterification reaction. Upon completion, cool the

mixture at room temperature and centrifuged at 6000 rpm for

30 minutes to separate the product biodiesel or fatty acid

methyl esters with the byproduct of glycerol and any excess of

methanol. After centrifugation, 3 layers will be obtained

which comprised of the upper layer of excess methanol,

middle layer the biodiesel and the bottom layer the prepared

MgO and glycerol. The first and second layer will be collected

and transferred into separation funnel and allow for better

separation of biodiesel and methanol. As for comparison,

commercial MgO will also be used to study the activity and

reactivity in the transesterification process. The gas

chromatogram was recorded using a Hewlett Packed Gas

Chromatography model 6890. Helium gas was used as the

International Scholarly and Scientific Research & Innovation 3(8) 2009

x 100

Peak area of Oil

III. RESULTS AND DISCUSSIONS

A. Thermogravimetry Analysis

This analysis was done in order to determined the

temperature profile for the formation of MgO via dehydration

of Mg(OH)2 at different temperatures. Fig. 2 shows the total

weight lost with different temperature regions.

P ercentage of weight lost (% )

International Science Index, Chemical and Molecular Engineering Vol:3, No:8, 2009 waset.org/Publication/4342

II. EXPERIMENTAL

30

25

20

15

10

5

0

40 - 120

300 - 485

512 - 558

610 - 640

640 - 682

Temperature range(C)

Fig. 2 Percentage of weight lost at different temperature regions from

TGA

Based on this graph, first region of weight lost occurred at

temperature 40 to 120 C, around 3.2%, correlative to the

removal of adsorbed water molecule. The major weight lost

happens at temperature 300 to 485 C; with almost 26.4%

indicating the decomposition of magnesium hydroxide to

magnesium oxide. This decomposition steps may be illustrated

as starting point for the formation of MgO from their

hydroxide with water molecules as the by-product. The

chemical equation of the decomposition process may be

desscribe below:

Mg(OH)2

MgO + H2O

For the temperature regions of about 512 to 682 C, less

then 1 % of weight lost took place and this might be

associated to the complete decomposition of Mg(OH)2 to form

MgO. Following on the TGA thermogram, the total weight

lost for the decomposition Mg(OH)2 from temperature 40 to

700C, approximately 31.2% is the formation of water. This

result was very close to the stoichiometric value for the

decomposition of magnesium hydroxide to magnesium oxide

of about 30.8% [16].

409

scholar.waset.org/1999.2/4342

World Academy of Science, Engineering and Technology

International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering Vol:3, No:8, 2009

The particle size for the prepared surface modified MgO

was calculated using Sherrers equation [18] and the resulting

particle size was of approximately 10 nm. Thus, the prepared

surface modified MgO was actually at nano size [19].

Hexagonal Mg(OH)2

Intensity

Cubic MgO

(d)

(c)

(b)

(a)

MgO-600

MgO-500

Fig. 4 XRD diffractogram for (a) Mg(OH)2 (b) MgO-400, (c) MgO500 and (d) MgO-600

MgO-400

%T

Mg(OH)2

4000.0

3600

3200

2800

2400

2000

1800

1600

1400

1200

1000

800

600

399.2

cm-1

Fig. 3 FT-IR spectrum of Mg(OH)2 and the prepared MgO which

heated at temperature 400 to 600 C

D. Biodiesel Yield

The heterogeneous base catalysis transesterification

reaction using various temperatures of calcinations of nano

MgO is shown by Fig. 5. The production of biodiesel or also

known as FAME from palm oil was successfully plotted. In

this experiment no saponification was observed and proved

that the catalyst is free from any absorbed water. Fig. 5 also

depicts the percentage conversion of palm oil to biodiesel for

all catalysts.

The spectra also show water molecules adsorbed at surface

MgO and this is proven by the present of broadband at 3600 3200cm-1 representative to O-H stretching band and bending

band of O-H at 1639.70cm-1. This occurrence happens due to

the special characteristic of MgO, which may adsorb moisture

from the environment. These FT-IR spectra also support the

TGA thermogram (Fig. 1) which designates the formation of

MgO from the decomposition of Mg(OH)2 which begin at

300C and completed at temperature 500C and above.

C. X-Ray Powder Diffraction

X-Ray Powder Diffraction (XRD) gives information of the

structure transformation on crystallization. Powder XRD

patterns were collected in order to investigate diversification

before and after heating process to the sample. The

diffractogram were useful to determine the type of crystallite

as well as the purity of the sample. Fig. 4 (a)-(d) show the

XRD diffractogram of Mg(OH)2 and the prepared MgO.

Based on Fig. 4 (a), there are seven typical diffraction peaks

at 18.582, 38.059 , 51.009, 58.707 , 61.965 , 72.157 and

81.400 which may be assigned to the characteristic peak of

hexagonal Mg(OH)2 crystals. As the temperature increased

(b)-(d), decomposition begins, with all the previous peaks

become smaller, whilst cubic MgO crystal start to appears.

This result again supports those of TGA and FTIR.

International Scholarly and Scientific Research & Innovation 3(8) 2009

60

P e rc e n ta g e o f C o n v e rs i o n (% )

International Science Index, Chemical and Molecular Engineering Vol:3, No:8, 2009 waset.org/Publication/4342

B. FTIR Spectra

Fig. 3 shows the FTIR spectra for Mg(OH)2 and the

prepared MgO which was heated at temperature 400 to 600C

in vacuum. There are two types of OH bonding exist in these

spectra. First, is the O-H stretching and bending bonded with

Mg and secondly, O-H stretching and bending attached at the

surface of the samples. The O-H stretching bonded with Mg

will be appeared as a sharp peak at 3702.62cm-1, bending

bond at 1490.38cm-1. For the second, O-H stretching appears

as a broad band at 3600 - 3200cm-1 while the bending at

1639.70cm-1. These bands had been previously characterized

by several researchers [17]. As the temperature was raised, the

peak intensity of O-H stretching bonded with Mg become

smaller at temperature 400C and finally disappears when the

temperature reaches 600C.

51.3

50

40

39.5

35.9

Series1

30

20

10

3.5

0

Commercial MgO

MgO-400

MgO-500

MgO-600

Samples

Fig. 5 Percentage conversion of biodiesel using different prepared

MgO

From this line graph Fig. 5, the percentage conversion was

increase when the temperature of preparation nano MgO

increases. The MgO-400 only manages 35.9% conversion of

palm oil to biodiesel, while the percentage increases to 39.5%

when using nano MgO-500. The highest conversion was

recorded when MgO-600 took place as the catalyst, with

51.3% conversion. Commercial MgO however managed only

3.5% [14]. This finding proved that this base catalyst had a

410

scholar.waset.org/1999.2/4342

World Academy of Science, Engineering and Technology

International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering Vol:3, No:8, 2009

(1)

O Mg

H O CH3

O Mg

CH3

H+

O Mg

-

O

O C

CH3

H+

O-

R1

OH

-

O

O C

O

R2

International Science Index, Chemical and Molecular Engineering Vol:3, No:8, 2009 waset.org/Publication/4342

O C

R2

O C

O

R3

O C

(2)

CH3

R2

O C

(3)

R3

O C

reaction is as shown by Fig. 6. Another advantage in using

this nano MgO is the reaction took place at mild condition,

safe, easy to upscale and low cost-production compared to

supercritical conditions of high temperature and pressure [21][23]. As in theory, the catalysts can act as a base toward the

reactants, either by abstraction of proton from the reactants as

in Bronsted base, or by donation of an electron pair to the

reactants as in Lewis base, to form anionic intermediates,

which undergo catalytic cycle and start the reactions [24].

Initially, the mechanism started by abstraction of H+ from

methanol to produce anionic intermediates, known as the

methoxide ion. The carbonyl group of the fatty acids will then

attacked by the methoxide and breaks the bonds between fatty

acids and glycerol, which produce fatty acid methyl ester and

diglyceride. O- at diglyceride will then abstract a proton from

MgO to form -OH group. This reaction will continue till

completion when three moles of fatty acid methyl ester and

glycerol were formed.

R3

IV. CONCLUSION

O

H3C

O C

R1

OH

OH

O Mg

H+

OH

-

(4)

O C

O-

CH3

The results obtained proved that nano MgO was

successfully prepared via hydration and dehydration method

using commercial MgO. The XRD, TGA and FT-IR data

shows the optimum temperature for the decomposition

Mg(OH)2 to form nano MgO. Calculation from XRD proved

the formation of nano MgO with particle size ca 10 nm. The

percentage of conversion palm oil to biodiesel was about

51.8% when applied MgO-600 as a heterogeneous base

catalyst.

ACKNOWLEDGEMENT

R3

O C

This research was supported by the E-Science Grant (VOT

no: 79070) and National Science Fellowship from Ministry of

Science, Technology and Innovation (MOSTI), Malaysia.

R3

O

[1]

OH

H3C

O C

R2

OH

[2]

-

O Mg

O

[3]

H+

[4]

OH

O

H3C

O C

[5]

OH

R2

O Mg

O

[6]

OH

(5)

Fig. 6 Proposed mechanism reaction for transesterification of palm

oil to biodiesel using the prepared nano MgO

[7]

[8]

better activity, compared to work done by Wang et al., [20].

The ability of the prepared MgO to abstracted H+ from

methanol to produce anionic intermediates was the basic idea

for the transesterification process. The proposed schematic

International Scholarly and Scientific Research & Innovation 3(8) 2009

[9]

411

REFERENCES

A. Ishizaki, K. Sonomoto, G. Kobayashi, C. Nolasco-Hipolito and E.

Crabbe. Biodiesel production from crude palm oil and evaluation of

butanol extraction and fuel properties. Process Biochemistry, vol 37

(1). pg 65 71.2001.

Y.C. Sharma, B. Singh and S.N. Upadhyay. Advancements in

Development and Characterization of Biodiesel: A review. Fuel, vol

87. pg 2355 2373.2008.

E.G. Shay. Diesel Fuel from Vegetable Oils: Status and Opportunities.

Biomass and Bioenergy, vol 4.pg 227 242. 1993.

T. Krawczyk. Biodiesel Alternative Fuel Makes Inroads but Hurdles

Remain. INFORM, vol 7. pg 801 829. 1996

T.F. Dossin, M.F. Reyniers and G.B. Marin. Kinetics of

Heterogeneously

MgO-Catalyzed

Transesterification.

Applied

Chemistry B: Environmental, vol 61. 35 45. 2006

T.F. Dossin, M.F. Reyniers, R.J. Berger and G.B. Marin. Simulation of

Heterogeneously MgO-Catalyzed Transesterification for Fine-chemical

and Biodiesel Industrial Production. Applied Chemistry B:

Environmental, vol 67. pg 136 148. 2006.

L.C. Meher, D. Vidya Sagar and S.N. Naik. Technical Aspects of

Biodiesel Production by Transesterification A Review. Renewable

and Sustainable Energy Reviews, vol 10. pg 248 268. 2006.

A. Srivastava and R. Prasad. Triglyceride-based Diesel Fuels.

Renewable and Sustainable Energy Reviews, vol 4. pg 111 133. 2000.

S. Zheng, M. Kates, M.A. Dube and D.D. McLean. Acid-Catalyzed

Production of Biodiesel from Waste Frying Oil. Biomass and

Bioenergy, vol 30. pg 267 272. 2006.

scholar.waset.org/1999.2/4342

International Science Index, Chemical and Molecular Engineering Vol:3, No:8, 2009 waset.org/Publication/4342

World Academy of Science, Engineering and Technology

International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering Vol:3, No:8, 2009

[10] F. Ma and M.A. Hanna. Biodiesel Production: A Review. Bioresource

Technology, vol 70. pg 1 15. 1999.

[11] A.K. Dalai, A. DCruz, M.G. Kulkarni and L.C. Meher. Synthesis of

Biodiesel from Canola Oil using Heterogeneous Base Catalyst. J. Am.

Oil Chem. Soc, vol 84. pg 937 943. 2007.

[12] J.M. Marchetti, V.U. Miguel and A.F. Errazu. Possible Methods for

Biodiesel Production. Renewable and Sustainable Energy Reviews, vol

11. pg 1300 1311. 2007

[13] L.A. Nelson, T.A. Foglia and W.N. Marmer. Lipase-Catalyzed

Production of Biodiesel. Journal American Oil Chemistry Society, vol

8(73). pg 1191 1195. 1996.

[14] G. Arzamendi, E. Arguiarena, I. Campo, S. Zabala and L.M. Gandia.

Alkaline and Alkaline-earth Metals Compounds as Catalysts for the

Methanolysis of Sunflower Oil. Catalysis Today, vol 133 - 135. pg 305

313. 2008.

[15] E. Santacesaria, R. Tesser, G. Minutillo, M. Cozzolino, M.Ledda and

M.Di Serio. From Homogeneous to Heterogeneous Catalysts in

Biodiesel Production. Ind. Eng. Chem. Res, vol 46. pg 6379 - 6384.

2007.

[16] M.S. Melgunov, V.B. Fenelonov, E.A. Melgunova, A.F. Belido, and

K.J. Klabunde. Textural Changes during Topochemical Decomposition

of Nanocrystalline Mg(OH)2 to MgO. The Journal of Physical

Chemisty B, vol 107(11). pg 2427 2434. 2003.

[17] H.S. Jung, J.K. Lee, J.Y. Kim and K.S Hong. Crystallization Behaviors

of Nanosized MgO Particles from Magnesium Alkoxides. Journal of

Colloid and Interface Science. vol 259. pg 127 132. 2003.

[18] K. Itatani, M. Nomura, A. Kishioka, and M. Kinoshita. Sinterability of

Various High-purity Magnesium Oxide Powders. Journal of Materials

Science. vol 21. pg 1429 1435. 1986.

[19] G. Duan, X. Yang, J. Chen, G. Huang, L. Lu, and X. Wang. The

Catalytic Effect of Nanosized MgO on the Decomposition of

Ammonium Perchlorate. Powder Technology. vol 172. pg 27 29.

2007.

[20] Y. Wang, S. Zhu, H. He and X. Liu. Transesterification of Soybean Oil

to Biodiesel using SrO as a Solid Base Catalyst. Catalysis

Communications. vol 8. pg 1107 -1111. 2007.

[21] L. Wang, and J. Yang. Transesterification of Soybean Oil with NanoMgO or Not in Supercritical and Subcritical Methanol. Fuel. vol 86. pg

328 333. 2007.

[22] S. Ngamprasertsith, R. Sawangkeaw, S. Makmee and K. Bunyakiat.

Continuous Production of Biodiesel via Transesterification from

Vegetable Oils in Supercritical Methanol. Energy and Fuels. vol 20. pg

812 817. 2006.

[23] A.K. Singh and S.D. Fernando. Transesterification of Soybean Oil

Using Heterogeneous Catalysts. Energy Fuel. vol 22(3). pg 2067

2069. 2008.

[24] H. Hattori. Solid Base Catalysts: Generation of Basic Sites and

Application to Organic Synthesis. Applied Catalysis A: General. vol

222. pg 247 259. 2001.

International Scholarly and Scientific Research & Innovation 3(8) 2009

412

scholar.waset.org/1999.2/4342

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Earthbag House For HaitiDocument22 pagesEarthbag House For HaitiRaymond KatabaziNo ratings yet

- Hydraulic Power Steering System Design PDFDocument16 pagesHydraulic Power Steering System Design PDFAdrianBirsan100% (1)

- Dimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Document7 pagesDimensions and Relations of The Dentogingival Junction in Humans. Gargiulo 1961Linda Garcia PNo ratings yet

- Global Warming Is The Term Used To Describe A Gradual Increase in The Average Temperature of The EarthDocument6 pagesGlobal Warming Is The Term Used To Describe A Gradual Increase in The Average Temperature of The EarthSaswataBhattacharyaNo ratings yet

- 20 N 60 C 3Document13 pages20 N 60 C 3rashidmirzaNo ratings yet

- Answer Section B and C and Paper 3Document21 pagesAnswer Section B and C and Paper 3Adnan ShamsudinNo ratings yet

- Mercedes ManDocument7 pagesMercedes Manien yeyenNo ratings yet

- Datasheet De14h (II) HC 1500v May2019 NTDocument2 pagesDatasheet De14h (II) HC 1500v May2019 NTkrishnakumar paamireddyNo ratings yet

- Dcom QuestionDocument3 pagesDcom Questionsushant sahooNo ratings yet

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet

- Matrix Algebra by A.S.HadiDocument4 pagesMatrix Algebra by A.S.HadiHevantBhojaram0% (1)

- Ex Ophtalmo Eng 1Document4 pagesEx Ophtalmo Eng 1Roxana PascalNo ratings yet

- Kaustubh Laturkar Fuel Cell ReportDocument3 pagesKaustubh Laturkar Fuel Cell Reportkos19188No ratings yet

- Clay ShonkwilerDocument9 pagesClay ShonkwilerJeoff Libo-onNo ratings yet

- S10 Electric Power PackDocument12 pagesS10 Electric Power PackrolandNo ratings yet

- Mathematics 5 Q1 W10Document31 pagesMathematics 5 Q1 W10Aices Jasmin Melgar BongaoNo ratings yet

- Design of Steel BeamsDocument4 pagesDesign of Steel BeamsSankalp LamaNo ratings yet

- Total Tattoo-June 2021Document114 pagesTotal Tattoo-June 2021Comicgek100% (2)

- MACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSDocument1 pageMACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSsensoham03No ratings yet

- Carl Sagan Wonder and Skepticism SecDocument13 pagesCarl Sagan Wonder and Skepticism SecAndreea BanagaNo ratings yet

- MATERIAL SAFETY DATA SHEET FOR PREVENTOL-D6 PRESERVATIVEDocument3 pagesMATERIAL SAFETY DATA SHEET FOR PREVENTOL-D6 PRESERVATIVEAkshay PushpanNo ratings yet

- The Blue Hotel PDFDocument22 pagesThe Blue Hotel PDFGabriel OvidorNo ratings yet

- 1 s2.0 S2214860417301148 Main PDFDocument16 pages1 s2.0 S2214860417301148 Main PDFQuy Hoang KimNo ratings yet

- General Psychology - Unit 2Document23 pagesGeneral Psychology - Unit 2shivapriya ananthanarayananNo ratings yet

- ###Questions Model PDFDocument2 pages###Questions Model PDFDave DMNo ratings yet

- HistorydylaneditDocument6 pagesHistorydylaneditapi-19858424No ratings yet

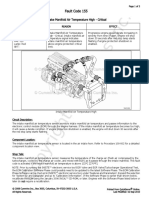

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDocument3 pagesFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- Medication - Safety - v4 Last Update 2015Document81 pagesMedication - Safety - v4 Last Update 2015Retno PalupiNo ratings yet

- Wyoming County Fair (2022)Document20 pagesWyoming County Fair (2022)Watertown Daily TimesNo ratings yet

- NTE56004 Thru NTE56010 TRIAC, 15 Amp: FeaturesDocument2 pagesNTE56004 Thru NTE56010 TRIAC, 15 Amp: FeaturesFreddy SarabiaNo ratings yet