Professional Documents

Culture Documents

Reduce Fouling

Uploaded by

JeEJyZaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reduce Fouling

Uploaded by

JeEJyZaCopyright:

Available Formats

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Page 1 of 6

COPYING AND DISTRIBUTING ARE PROHIBITED WITHOUT PERMISSION OF THE PUBLISHER

Reduce fouling in shell-and-tube heat exchangers

07.02.2004 | Bennett, C. A., Heat Transfer Research, Inc., College Station, Texas; Nesta, J., Fluor Corp. Ltd., Calgary, Alberta, Canada

Proper design lowers capital costs and increases both efficiency and onstream time

Keywords:

Accumulation of scale, organic matter, corrosion products, coke, particulates or other deposits on the heat transfer surface causes fouling and costs industry

billions of dollars each year. These deposits will degrade exchanger performance over time compared with "clean" conditions at startup.

The fouling layer is a conductive resistance to heat transfer that must be accounted for in the design heat transfer coefficient. Fouling thickness and thermal

conductivity both contribute to the resistance. Reduced cross-sectional flow area also increases pressure drop in the fouled region. This additional pressure drop

must be accounted for in the pump design. Using the guidelines presented here will reduce the fouling layer thickness and mitigate the effect on heat transfer

efficiency and pressure drop.

Common fouling mechanisms are:1

Particulate fouling results from sedimentation of dust, rust, fine sand or other entrained solids.

Precipitation fouling is a solids deposition at the heat transfer surface from a supersaturated fluid. A common example is salt crystallization from an

aqueous solution. Precipitation can also occur via sublimation, e.g., ammonium chloride in overhead and effluent vapors.

Chemical reaction fouling is the breakdown and bonding of unstable compounds at the heat transfer surface. Oil sludge and polymerization are

examples of chemical reaction fouling.

Coking is a subset of chemical reaction fouling. It is one of the most problematic types of fouling. In the extreme, the coke deposit is a very hard layer of

carbon, salts and other compounds.

Corrosion fouling is the accumulation of corrosion products, such as iron oxide, on the heat transfer surface.

Biological fouling is the growth of living organisms, like algae and mussels, on the heat transfer surface.

Fouling in service is often a combination of two or more mechanisms. Also, one mechanism may be an initiator for another mechanism. Fluids may be

categorized into three groups according to their potential for fouling:1

Nonfouling fluids do not require regular cleaning. Some examples are nonpolymerizing light hydrocarbons, steam and subcooled boiler feed water.

Asymptotic fouling fluids reach a maximum constant fouling resistance after a short run time. The fluid velocity imparts a shear stress at the fouling

layer that removes some of the deposit. As the fouling layer thickens, flow area is reduced and velocity increases, thereby increasing the removal rate. When the

removal rate equals the deposition rate, fouling reaches an asymptotic limit. Thickness of the final asymptotic fouling layer is inversely proportional to the

original velocity. Cooling tower water is an example of an asymptotic fouling fluid.

Linear fouling fluids have a fouling layer that is too tenacious to prevent with economic design velocities. The fouling layer continues to build as a roughly

linear function of time. The fouling rate depends on velocity. At low velocity, fouling is controlled by mass diffusion to the surface. Increasing velocity in this

range increases mass diffusion and, thus, promotes fouling. At high velocity, fouling is controlled by deposit shearing and residence time, and decreases with

increasing velocity. Linear fouling mechanisms are also strongly dependent on surface temperature. Crude oils and polymerizing hydrocarbons are examples of

linear fouling fluids.

The traditional method to accommodate fouling is to assign an individual fouling resistance, or "fouling factor," to each stream. This fouling factor is the

expected resistance due to fouling at end of run, based on user experience. The sum of the fouling, fluid and metal resistances provides a total design resistance

to calculate required surface area. Although the Tubular Exchanger Manufacturers Association (TEMA) publishes fouling factors by service, these values have

been the subject of considerable debate.2

The problem with this approach is that the fouling resistance is not static. Fouling depends on many factors, especially velocity, surface temperature and

chemistry. Actual fouling in service can vary greatly about the mean performance predicted by static fouling factors. This is most noticeable in exchanger

performance where the fouling margin is large. Problematic services, or "frequent foulers," can reach the performance limit in a matter of days, rather than the

full run cycle. Thereafter, the user must clean the exchanger or live with reduced performance.

One approach to this problem is to further increase the margin for fouling. Unfortunately, this has diminishing returns.2 Use of large fouling factors can be a self

-fulfilling prophecy. Large fouling factors or other safety margins result in added surface area. A design with large surface area will always have lower fluid

velocity than a design with less area at the same given pressure drop. As surface area is added, velocity decreases. As velocity decreases, fouling increases. Thus,

the prophecy is fulfilled.

An alternate approach is to avoid fouling altogether by designing for critical velocity, surface temperature, and/or other factors that preclude significant fouling.

Heat Transfer Research, Inc. (HTRI) is leading the effort to determine these critical design parameters.3,4 Due to the complexity of fouling, it may be some time

before these criteria are fully developed. However, partial results are available now for some problematic refinery applications.

PART 1 LIQUID HYDROCARBON SERVICE

HTRI has deduced that fouling in crude oil preheat service depends primarily on velocity, surface temperature and the relative amounts of Saturates,

Asphaltenes, Resins and Aromatics (SARA).3,4 As a general rule, most crude oils will not foul excessively when both of these conditions are present:

Tube side velocity is greater than 6.6 ft/s (2 m/s).

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Page 2 of 6

Wall temperature is less than 570F (300C).

This guideline presumes no fouling due to other mechanisms such as sedimentation or precipitation. HTRI has also concluded that, depending on conditions,

crude oil fouling can be either much greater or much less than the TEMA recommended fouling factor.3

It is tempting to extrapolate this finding to other problematic refinery services such as vacuum residue product coolers. The authors feel that this is a reasonable

conclusion, given that coking is so problematic, and the no-foul guideline noted previously is probably conservative for other mechanisms. There are two

qualifiers:

Fluids do not have heavy particulate matter such as catalyst fines.

Fluids do not have high salt content as would be present with desalting malfunctions.

The tube side velocity criterion may also be extrapolated to the shell side by providing a design that results in similar shear force. Putting this all together results

in the following generalized design method for liquid hydrocarbon service in refinery applications. It has been successfully implemented by at least two users to

date.

The crux of the no-foul method is to provide velocity equal to, or greater than, a critical velocity that precludes significant fouling. Allowable pressure drop must

be whatever it takes to get the desired velocity. Another essential feature is that fouling factors are not used. This reduces excess surface area requirements and

the required pressure drop. However, a safety margin may be added to account for statistical variation in predictive methods, uncertainty of physical properties

and/or a small amount of fouling.

NO-FOUL DESIGN METHOD

Scope. The no-foul design method is applicable to medium-through-high boiling point liquid hydrocarbon mixtures with API gravity less than 45. This API

gravity cutoff was chosen from experience.

Application. Apply this method when short maintenance cycles, problematic hydraulic and/or thermal performance, vibration or other problems are

related to fouling. The user may also consider this method to reduce exchanger capital cost. In this case, exchanger installed cost shall be evaluated against the

cost to provide the necessary pressure drop.

System operation. The process scheme shall prevent premature shutdown due to fouling by providing the means to continue operation with shell(s) out of

service, if needed, for online cleaning. Need for shells in parallel, or bypass around single shells, shall be evaluated. This is not to imply that the no-foul method

has higher risk than traditional design methods. Rather, this is good design practice for problematic services in any event.

The no-foul method should, in fact, provide much longer run time than traditional designs. The process scheme shall also consider turndown operation and the

need for shells in parallel, pump recycle or other means to maintain critical velocity during turndown operation. Where fluid bypass is used for process

temperature control, the resultant exchanger velocity shall be maintained above the critical minimum velocity.

Exchanger design. The no-foul method follows as a numbered guideline:

1.0 Minimum liquid velocity:

1.1

Tube side velocity of 6.6 ft/s (2 m/s). This velocity limit is applicable for tubes with outside diameters of 0.75 in. (19.05 mm) and 1 in. (25.4 mm).

Increase velocity to 7.2 ft/s (2.2 m/s) for diameters 1.25 in. (31.75 mm) and 1.5 in. (38.1 mm) to maintain shear stress.

1.2 Shell side cross flow stream (B-stream) should be at least 2 ft/s (0.6 m/s).

2.0 Maximum temperature:

The maximum tube wall temperature shall be 570F (300C).

3.0 Shell side design5 :

3.1 The B-stream fraction shall be at least 0.65.

3.2 Use single segmental baffles.

3.3 Baffle cut orientation shall normally be horizontal for TEMA type E and J shells. Baffle cut orientation for TEMA type G and F shells shall be

vertical.

3.4 Baffle cut for tubes in the window shall be 20% to 25% of the shell diameter, where 20% is preferred. Increase cut up to 25% if required to reduce

leak streams. See 3.7 for no tubes in window designs (NTIW).

3.5 Where impingement protection is required, use impingement rods. One row of rods is acceptable for 90 layouts. Use two rows for staggered

pitch. Do not use impingement plates.

3.6 Large baffle end spaces and low resultant velocity are sometimes unavoidable due to geometry constraints. Where this occurs, the designer may

make a judgment call to consider the end space surface area largely ineffective. Provide additional area to compensate. Consider an annular

distributor if the affected surface area is large.

3.7 The ratio of window velocity to cross flow velocity (including leak streams) shall be less than 2 for designs with tubes in the window (1 1.5 is

preferred). For NTIW, the ratio of window velocity to cross flow velocity shall be less than 3 (1.5 2 is preferred). This is a soft guideline at this

time. The optimum ratio is intuitive and, thus, is an area for further quantitative investigation.

4.0 Excess surface:

4.1 Where both fluids are within the scope of this practice, provide approximately 20% excess surface, but do not apply a fouling factor. This safety

margin may be reduced where the designer has confidence in predictive methods and successful mitigation of fouling (usually based on prior

experience for a similar service).

4.2 Where only one fluid is within the scope of this practice, consider a fouling factor for the fluid outside the scope. Omit the fouling factor if the

fluid is nonfouling. For the fluid within scope, multiply the heat transfer coefficient by 0.83 and do not use a fouling factor. As above, the safety

margin may be reduced based on designer experience.

5.0 Allowable pressure drop:

Pressure drop shall be provided as required to meet the minimum critical velocities noted in 1.0.

6.0 Longitudinal baffles:

If a longitudinal baffle is used in fouling service, the baffle shall be welded to the shell. For removable bundles, this requires the use of U-tubes with

the U-bends in a horizontal plane (normally four or more tube passes). The designer should investigate differential thermal stresses across the shell. In

general, a welded longitudinal baffle is probably acceptable where the shell side temperature difference across one shell does not exceed 160F (89C).

Provide bundle slide rails in both top and bottom portions of the bundle.

Design tricks of the trade. Consider these construction features to improve shell side performance:

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Page 3 of 6

American Petroleum Institute Standard 660 requires a seal device (dummy tubes, rods or strips) to be implemented from 1 in. to 3 in. (25 mm to 75 mm)

from the baffle tips, and for every 5 to 7 tube pitches thereafter. Increase the number of seals, if required, to limit the bundle and pass lane leak streams.

Where the tube-to-baffle diametral tolerance (per TEMA) is 0.0313 in. (0.8 mm), the tolerance may be reduced 0.0156 in. (0.4 mm) if required to reduce the

leak stream between tube and baffle hole.

The TEMA baffle-to-shell diametral clearance may be reduced to limit the baffle-to-shell leak stream. A clearance of 0.0035 0.004 times the shell

diameter is achievable for shells rolled from plate, but use this extra tight clearance only if necessary since it is hard to guarantee compliance. Extra tight

clearance is not recommended for shells made from pipe (typically NPS 24 and smaller).

Consider baffled TEMA type F and G shells to increase shell side velocity, reduce number of shells in series and/or improve the baffle spacing-to-shell

diameter aspect ratio.

Comparison of no-foul and conventional designs. Our no-foul method was used to design three items on a recent project. These services were known to

be problematic frequent foulers and had fouling fluids on both the shell and tube sides. Table 1 compares the no-foul design with a standard design using fouling

factors and typical allowable pressure drop. A third design utilizing conventional methods with a 10% heat transfer coefficient safety factor is also compared.

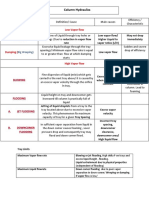

Table 1. Benefits of no-foul versus standard exchanger designs

Parameter

Surface area, ft2

Estimated cost, US$

Standard design

with 10%

No-foul Standard

coefficient

design

design

safety factor

8,960

16,829

996,000 1,527,000

20,185

1,775,000

Clean overall coefficient, Btu/ft2 hr F

63.5

40.6

36

Total fouling resistance, ft2 hr F/Btu

0.0036

0.0113

0.0152

22

46

55

Pressure drop, psi

25.4

9.7

9.2

Velocity, ft/s

2.0

1.1

1.0

20.6

7.0

5.9

26.9

9.6

8.0

7.3

3.7

3.0

22.6

6.5

4.8

Fouling margin, % excess surface

Shell side

Shear stress 104, psi

Tube side

Pressure drop, psi

Velocity, ft/s

Shear stress 104, psi

Notes: Service is residue stripper bottoms/pre-flash bottoms exchanger.

Shell side shear stress is weighted for window and cross flow.

Shear stress is the metric to evaluate fouling tendency, rather than absolute velocity. Lower margins for fouling in the no-foul design are justified by shear

stresses that are approximately three times greater than shear stresses of the conventional designs. Table 1 illustrates the futility of adding surface area with

typical pressure drops to provide more safety margin for fouling.

On the other hand, use of the no-foul method has an "increasing returns effect." Lowering the fouling margin results in less surface area. Lower surface area

yields a higher velocity at a given pressure drop. Higher velocities increase the heat transfer coefficient, which further reduces surface area, and so on.

Table 2 compares the no-foul design with an enhanced standard design using fouling factors and the same allowable pressure drop. This enhanced design is not

quite as bad as the conventional designs in Table 1. More pressure drop helps, but the design still falls short of achieving the critical no-foul shear stresses. Part

of the allowable pressure drop is lost to the extra surface required for the fouling factor.

Table 2. Benefit of no-foul versus enhanced standard exchanger design

No-foul design

Standard design

with increased

pressure drop

8,960

13,495

996,000

1,273,000

Clean overall coefficient, Btu/ft2 hr F

63.5

55.6

Total fouling resistance, ft2 hr F/Btu

0.0036

0.0113

22

62

Pressure drop, psi

25.4

17.7*

Velocity, ft/s

2.0

1.5

Parameter

Surface area, ft2

Estimated cost, US$

Fouling margin, % excess surface

Shell side

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Shear stress 104, psi

20.6

12.3

26.9

24.1

Page 4 of 6

Tube side

Pressure drop, psi

Velocity, ft/s

Shear stress 104, psi

7.3

6.1

22.6

16.2

* Did not use all of the allowable pressure drop, because smaller spacing and additional

pressure drop resulted in leak streams that reduced overall exchanger efficiency.

Shell side versus tube side. Conventional wisdom is to place fouling fluids on the tube side. This makes sense when the bundle is cleaned in place, because

the tube side is accessible without removing the bundle. Shell side cleaning requires more maintenance hours since piping has to be uncoupled and the bundle

removed. However, most users clean the bundle at a remote cleaning station, rather than in place. If this is the case, the bundle has to be removed anyway, and it

takes more time to clean the tube side because it is generally done one tube at a time.

Therefore, when the plant standard maintenance practice is to clean removable bundles at a remote location, it is actually preferable to place fouling fluids on

the shell side. 5 Another bias is that "the shell side will foul to a greater extent than the tube side." However, application of the no-foul design recommendations

to the shell side should mitigate fouling to the same extent as the tube side, given the same shear stress.

Having said this, the authors agree with the conventional wisdom for two services:

. Tenacious, linear fouling deposits, e.g., crude oil preheat, are difficult to clean via standard hydroblasting on the shell side, especially in large bundles. Linear

fouling fluids should be placed on the tube side, unless user experience indicates that these deposits can be softened with a preliminary chemical wash or the

bundle diameter is less than 30 in. (760 mm).

. Fluids with heavy solids such as catalyst fines or other slurries are generally placed on the tube side. In cases where shell side flow is unavoidable, there has been

some success using vertical cut baffles to allow sedimentation to exit the shell. Velocity sufficient to remove sedimentation, but avoid erosion, is a matter of

experience for the particular slurry service.

Future investigation. The following areas would benefit from further investigation:

Maximizing velocity by itself is not enough to ensure low fouling on the shell side. Designs should eliminate "dead areas" (e.g., under impingement plates),

maximize the number of tubes in cross flow, minimize leak paths and minimize centrifugal force in the window turnaround. The shell side design guidelines

are an attempt to do all this, but they are admittedly intuitive at this point. A serious investigation with computational fluid dynamics is suggested to

quantify the optimum design guidelines.

Fouling studies of services other than crude oil preheat to expand the generalized guidelines for velocity and temperature in liquid service.

Fouling studies of condensing and boiling services.

Fouling studies to quantify the effect of low-fin tubes and tube inserts on fouling.

Part 2 Cooling water

System design. Cooling water flowrate is normally based on a maximum temperature rise. For cooling tower water, this would be a maximum temperature of

about 110F (43C) minus the summer cold water temperature from the tower. This range gives the least amount of cooling water without an exchanger outlet

temperature that causes corrosion and/or fouling problems in the heat exchanger, or other design problems for the cooling tower. The designer will maximize

the allowable pressure drop where possible, but actual pressure drop used will vary between items in the cooling water loop.

We suggest a different approach. All items in the cooling water loop should be designed to use the maximum allowable pressure drop. The cooling water flowrate

for each item is adjusted to get the same pressure drop, more or less. When the adjusted flowrate is less than the desired target rate noted previously, the

designer must be mindful not to exceed the critical tube wall temperature, which may cause corrosion and/or fouling. A tube wall temperature not greater than

140F (60C) is a safe upper limit for treated cooling water.

Thus, the cooling water flowrate is based on equal pressure drop, not equal temperature range. The reason for this is that the cooling water will distribute itself

to equalize the system pressure drop from inlet header to outlet header. If design pressure drop varies from exchanger to exchanger, the resulting cooling water

flow to a given item may not be that required on the data sheet; some coolers will get more, others less. A large cooling water user at low design pressure drop

can rob cooling water from the other users. Designing all to the same pressure drop prevents this. Poor performance due to unexpected low cooling water

velocity is avoided. For new installations, do not skimp on allowable pressure drop. Allow at least 15 psi (100 kPa) for the exchanger clean pressure drop to

achieve high cooling water velocity.

Process control. Cooling water should never be throttled to control the exchanger duty or process outlet temperature. The resulting low velocity and/or high

outlet temperature will quickly result in problematic fouling. Where process control is required, it is preferable to bypass the process side. If the process stream

is a fouling fluid, this may merely be the lesser of two evils. However, it may be possible to design the process side for the minimum critical no-foul velocity in

the bypass mode, depending on how much fluid needs to be bypassed.

Exchanger design. It is preferable to use a dynamic calculation for fouling resistance based on velocity, rather than a static fouling factor. Like hydrocarbon

fouling, water fouling depends on velocity, temperature and composition. Tube metallurgy is also a variable for untreated water where biological growth and

corrosion are part of the fouling mechanism. Fouling factors may be predicted with design software, or developed empirically using a portable fouling test unit.

For example, fouling for treated cooling water inside carbon steel tubes might be something like this:

(1)

where R is the fouling factor in Btu/ft2 hr F and V is velocity in ft/s.

Actual fouling resistance can vary significantly from the static value of 0.002 Btu/ft2 hr F that is typically specified. It is preferable to design for high velocity,

say 6 7 ft/s (1.8 2.1 m/s) in order to minimize fouling, rather than accommodate low velocity with a large fouling factor. In the absence of predictive software

or an empirically derived correlation, Equation 1 gives useful results for most treated cooling tower water.

Shell side versus tube side. It is preferable to place cooling water on the tube side. Fouling is asymptotic, implying a soft deposit. However, there is a

tenacious underlying layer that may be difficult to clean on the shell side. Also, heavy solids such as silt are handled better on the tube side. Where cooling water

on the shell side is unavoidable, use the design guidelines for liquid hydrocarbons in Part 1.

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Page 5 of 6

Tube metallurgy. Rough surface is a fouling precursor for organic growth and sedimentation. Reduced fouling rates have been observed with noncorrosive

alloys and smooth surface obtained from surface treatment such as chrome plating.5 Copper and its alloys also reduce organic growth since this material is toxic

to the organisms.

Summary. Recommendations for heat exchanger design and operation outlined in this article are theoretically sound and field proven for minimizing fouling.

Regardless of service, one wants to minimize wall temperature and maximize shear stress by maximizing fluid velocity. Distribute pressure drop across trains to

maximize velocity in problem exchangers when possible. Material selection also has a pronounced effect on fouling, particularly when biological fouling is a

concern. HP

LITERATURE CITED

1

Watkinson, A. Paul, Critical Review of Organic Fluid Fouling, Final Report Contract 73212402, Argonne National Laboratory, December

1988.

2

Palen, J. W., Improved use of fouling allowances in heat exchanger design, F-12, Heat Transfer Research, Inc., College Station, Texas, 2002.

Longstaff, D. C., and J. W. Palen, Fouling data for six crude oils, F-10, Heat Transfer Research, Inc., College Station, Texas, 2001.

Palen, J. W., Heat Transfer Research, Inc., presentation at the HTRI annual stockholder meeting, Salt Lake City, Utah, July 21, 2002.

Gilmour, G. H., "No Fooling No Fouling," CEP 61(7), pp. 49 54, 1965.

John M. Nesta is a technical director specializing in heat transfer equipment at Fluor Canada, Ltd. He holds a BS degree in chemical

engineering from the University of Southern California. His practical experience includes over 30 years of designing, evaluating and

procuring heat exchangers used in the process industries. Mr. Nesta is a member of the American Petroleum Institute committees for heat

transfer equipment: Standards 660, 661 and 662. Correspondence should be sent to john.nesta@fluor.com.

Christopher A. Bennett is a researcher specializing in fouling at Heat Transfer Research, Inc. He holds BS, MS and PhD degrees in

chemical engineering from the University of Toledo and the University of Michigan, respectively. His diverse research experience

encompasses wet chemistry, surface chemistry, materials science, mathematical modeling and aquatic biology and has proven very useful to

understanding heat exchanger fouling. Applying computational fluid dynamics (CFD) to fouling is just beginning, but appears quite

promising. Dr. Bennett is a member of the American Institute of Chemical Engineers (AIChE) and the Materials Research Society (MRS).

Correspondence should be sent to CAB@HTRI.net.

Dadi ramakrishna

04.10.2015

in our refinery we observed some CW exchangers are getting low flow velocity of 0.8 m/sec and some of the units NO signal

found.

what is it means but exchanger is in service.

pradeep

01.18.2014

i need full details of problem in shell and tube heat exchanger like fouling, baffles,turbulence

ROBERTO ABARILLA

01.26.2012

Nice update on HE design development regarding fouling.

Please read our Term and Conditions and Privacy Policy before using the site. All material subject to strictly enforced copyright laws.

2016 Hydrocarbon Processing. 2016 Gulf Publishing Company.

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

Reduce fouling in shell-and-tube heat exchangers | Hydrocarbon Processing | July 2004

Page 6 of 6

http://www.hydrocarbonprocessing.com/Article/2599305/Reduce-fouling-in-shell-and-t... 25-Jul-16

You might also like

- Technical Training ManualDocument225 pagesTechnical Training ManualJeEJyZaNo ratings yet

- Baffle Selection PDFDocument7 pagesBaffle Selection PDFmaruthigabbita100% (3)

- Water Cooled Chiller Operation & Maintenance ManualDocument13 pagesWater Cooled Chiller Operation & Maintenance ManualPaul KwongNo ratings yet

- Piping Design Articles by Robert Kern PDFDocument53 pagesPiping Design Articles by Robert Kern PDFDiego IQ100% (1)

- 02 - Condensers & Cooling Towers PDFDocument61 pages02 - Condensers & Cooling Towers PDFVimleshKumarSharmaNo ratings yet

- Method Bell DelawareDocument12 pagesMethod Bell DelawareAurelio Poletto100% (1)

- 1.vendor List - Rev.6Document174 pages1.vendor List - Rev.6arianaseri100% (1)

- Allowable Loads On Equipment Process Nozzles: Company Technical StandardDocument29 pagesAllowable Loads On Equipment Process Nozzles: Company Technical StandardEmanueleMoriccaNo ratings yet

- BaffelsDocument7 pagesBaffelsNila GamaNo ratings yet

- Eg 21 019Document155 pagesEg 21 019agaricusNo ratings yet

- Relief Valve Tutorial Spirax SarcoDocument16 pagesRelief Valve Tutorial Spirax SarcoamokhtaNo ratings yet

- Air Cooled Exchangers PDFDocument18 pagesAir Cooled Exchangers PDFRaghav SharmaNo ratings yet

- 545Document11 pages545hiyeonNo ratings yet

- Particle Collection: Design Practices Fluid Solids Exxon EngineeringDocument67 pagesParticle Collection: Design Practices Fluid Solids Exxon EngineeringPaula RiveraNo ratings yet

- Flare DesignDocument10 pagesFlare DesignAndri SaputraNo ratings yet

- Selection of Heatexchanger TypesDocument65 pagesSelection of Heatexchanger TypesRaghav SharmaNo ratings yet

- Heat Exchanger Design Using HTRI PDFDocument30 pagesHeat Exchanger Design Using HTRI PDF966571016208No ratings yet

- Advance Boiler Control SystemDocument44 pagesAdvance Boiler Control SystemJeEJyZaNo ratings yet

- Heat Requirement CalculationsDocument5 pagesHeat Requirement CalculationsTrishul Nath PallayNo ratings yet

- Heat Transfer Predictions For Forced Convective BoilingDocument7 pagesHeat Transfer Predictions For Forced Convective Boilingoas217No ratings yet

- API Standard 521 New Alternative Method To Evaluate Fire Relief For Pressure Relief Device Sizing and Depressuring System Design 2014 Journal of Loss PDFDocument11 pagesAPI Standard 521 New Alternative Method To Evaluate Fire Relief For Pressure Relief Device Sizing and Depressuring System Design 2014 Journal of Loss PDFminhy100% (1)

- Restricted Access Notice: Due To Third Party Proprietary InformationDocument95 pagesRestricted Access Notice: Due To Third Party Proprietary InformationTala RamezaniNo ratings yet

- CHE BP - Best Practices For The Control of Fuel Gas - May 2014Document4 pagesCHE BP - Best Practices For The Control of Fuel Gas - May 2014John UrdanetaNo ratings yet

- PRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeDocument19 pagesPRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeKorcan ÜnalNo ratings yet

- Modular Air Cooled Chillers PDFDocument22 pagesModular Air Cooled Chillers PDFBehnamNo ratings yet

- Condensate & Feedwater System - Steam Turbine & Condenser PDFDocument37 pagesCondensate & Feedwater System - Steam Turbine & Condenser PDFjhchung1110% (1)

- 26565e PDFDocument528 pages26565e PDFJeEJyZaNo ratings yet

- NTPC 500 Power Plant Operation Pipe LineDocument84 pagesNTPC 500 Power Plant Operation Pipe LineJoselin Leo100% (1)

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- Mitigation of Heat Exchanger FoulingDocument5 pagesMitigation of Heat Exchanger Foulingbabak mirNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- A Review On Heat Exchanger Thermal Hydraulic Models For Cryogenic ApplicationsDocument14 pagesA Review On Heat Exchanger Thermal Hydraulic Models For Cryogenic ApplicationsbcshendeNo ratings yet

- Dynamic Modeling of Heat Exchanger Tube RaptureDocument20 pagesDynamic Modeling of Heat Exchanger Tube RaptureRajesh NimmakayalaNo ratings yet

- Code of Practice forThermalOilHeaters PDFDocument56 pagesCode of Practice forThermalOilHeaters PDFarjmandquestNo ratings yet

- Polybed PSADocument2 pagesPolybed PSAJeEJyZaNo ratings yet

- IAMI Revision Answers AuxiliaryDocument19 pagesIAMI Revision Answers AuxiliaryStewart LongNo ratings yet

- PHA and What-If Checklist Questions: AppendixDocument18 pagesPHA and What-If Checklist Questions: Appendixrachit singhNo ratings yet

- Equilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DDocument5 pagesEquilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DjcortezcNo ratings yet

- 01) Pressure Vessels and Piping-NewDocument242 pages01) Pressure Vessels and Piping-NewHaytham Mohamed0% (1)

- Helix ChangerDocument8 pagesHelix Changerprad_21ad100% (1)

- 4 5791748654033275598 PDFDocument141 pages4 5791748654033275598 PDFAgung Pramu Aji100% (1)

- On The Design of Thermal BreathingDocument6 pagesOn The Design of Thermal BreathingLizbeth Fiallos AvilaNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Selecting Tube Inserts For Shell-and-Tube Heat ExchangersDocument7 pagesSelecting Tube Inserts For Shell-and-Tube Heat Exchangerskamranonline999No ratings yet

- Furnace Heater DesignDocument7 pagesFurnace Heater DesignAaAaA_88No ratings yet

- Coalescer PallDocument16 pagesCoalescer PallJeEJyZaNo ratings yet

- To Foul or Not To FoulDocument8 pagesTo Foul or Not To FoulkcdeguzmanNo ratings yet

- PP Aaa PP1 122Document19 pagesPP Aaa PP1 122Rabah AmidiNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- 13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsDocument29 pages13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsxinghustNo ratings yet

- Circulating Fluidized Bed Technology: Proceedings of the Second International Conference on Circulating Fluidized Beds, Compiègne, France, 14-18 March 1988From EverandCirculating Fluidized Bed Technology: Proceedings of the Second International Conference on Circulating Fluidized Beds, Compiègne, France, 14-18 March 1988No ratings yet

- Relief Device Inlet Piping Beyond The 3 Percent Rule - HP - Nov 2011 PDFDocument7 pagesRelief Device Inlet Piping Beyond The 3 Percent Rule - HP - Nov 2011 PDFonizuka-t2263No ratings yet

- Selecting The Proper Flare System PDFDocument6 pagesSelecting The Proper Flare System PDFjdgh1986100% (1)

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- Valve Philosophy Valve Application GeneralDocument3 pagesValve Philosophy Valve Application GeneralWade ColemanNo ratings yet

- Design Guidelines For Proplyene Splitters - Rev inDocument10 pagesDesign Guidelines For Proplyene Splitters - Rev intotongopNo ratings yet

- Inbreathing Outbreathing of TanksDocument30 pagesInbreathing Outbreathing of Tanksomesh2008No ratings yet

- Heat Transfer in Packed BedDocument10 pagesHeat Transfer in Packed BedNidhi JainNo ratings yet

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 pagesOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- Study of Dry Ice Formation During Blowdown of CO - CH From CryogenicDocument9 pagesStudy of Dry Ice Formation During Blowdown of CO - CH From CryogenicAbul HassanNo ratings yet

- Fired Heaters - Fired Capital Equipment Key Plant ComponentsDocument4 pagesFired Heaters - Fired Capital Equipment Key Plant ComponentsReyes SanchezNo ratings yet

- 2nd Part of CalculationDocument26 pages2nd Part of CalculationLohith NatarajNo ratings yet

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Lec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerDocument30 pagesLec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerQamar AbbasNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- Gas Spec Cs 2010Document4 pagesGas Spec Cs 2010MauricioNo ratings yet

- Appendix A - DATASHEET - BilectricDocument11 pagesAppendix A - DATASHEET - BilectricChakravarthy BharathNo ratings yet

- TraysDocument23 pagesTraysAmgadNo ratings yet

- PDFDocument164 pagesPDFĐỗ Vũ ThưNo ratings yet

- Progress of Modern Pyrolysis Furnace TechnologyDocument4 pagesProgress of Modern Pyrolysis Furnace TechnologyDavid Rodrigues100% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Methyl Methacrylate MSDSDocument81 pagesMethyl Methacrylate MSDSJeEJyZaNo ratings yet

- Critical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988Document6 pagesCritical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988JeEJyZaNo ratings yet

- A Practical Guide To Rotary ValvesDocument26 pagesA Practical Guide To Rotary ValvesJeEJyZaNo ratings yet

- Donaldson Indust Water Process ChillersDocument6 pagesDonaldson Indust Water Process ChillersJeEJyZaNo ratings yet

- BeaconDocument1 pageBeaconJeEJyZaNo ratings yet

- Discussion Shell and TubeDocument3 pagesDiscussion Shell and TubeFarhah AinNo ratings yet

- CRAsiaebrochure2012 PDFDocument25 pagesCRAsiaebrochure2012 PDFsarathoonvNo ratings yet

- Güntner Info: Variable Aircooler For Industrial RefrigerationDocument5 pagesGüntner Info: Variable Aircooler For Industrial RefrigerationWINNo ratings yet

- Catalog O2 Gen A3 2 PGDocument2 pagesCatalog O2 Gen A3 2 PGDelta DigitronicsNo ratings yet

- Sciencedirect: Configuration and Change Management Approach in Product Variant Design of ChillersDocument6 pagesSciencedirect: Configuration and Change Management Approach in Product Variant Design of ChillersHemonNo ratings yet

- NoteDocument130 pagesNoterkNo ratings yet

- DC-8 - Pneumatic SystemDocument18 pagesDC-8 - Pneumatic SystemGino AcevedoNo ratings yet

- G446 2104 PDS 0150 0027 Rev 02Document14 pagesG446 2104 PDS 0150 0027 Rev 02Magesh VenuNo ratings yet

- ZHF XPXN 0SS02 Omi 101-1Document71 pagesZHF XPXN 0SS02 Omi 101-1Online 4-lifeNo ratings yet

- Select Om at PlenDocument20 pagesSelect Om at PlenAxsel AndrewNo ratings yet

- Me309 2015 11 PDFDocument4 pagesMe309 2015 11 PDFgift mudimuNo ratings yet

- Design 003H AmmoniaSynthesis EconomicAnalysis PDFDocument22 pagesDesign 003H AmmoniaSynthesis EconomicAnalysis PDFEbook DownloadNo ratings yet

- Vitocal 300 ServiceinstructionsDocument176 pagesVitocal 300 ServiceinstructionsAnonymous WVIoHV5Mh7No ratings yet

- Air Cooled: Heat ExchangerDocument8 pagesAir Cooled: Heat Exchangermu khaledNo ratings yet

- Concentric Tube Water-Water Heat Exchanger Study UnitDocument12 pagesConcentric Tube Water-Water Heat Exchanger Study Unitseraj ibramemNo ratings yet

- FD Series Orange BrochureDocument24 pagesFD Series Orange Brochureapi-239567793No ratings yet

- LG VRF Multi V S Brochure - Outdoors OnlyDocument44 pagesLG VRF Multi V S Brochure - Outdoors OnlyInventor SolidworksNo ratings yet

- DBV3 Digital Scroll R410a 50-60Hz MS0328A-0316 NpyDocument60 pagesDBV3 Digital Scroll R410a 50-60Hz MS0328A-0316 NpychiascNo ratings yet

- Andenes Oljekj - Ler KS12-AEP-123 L800Document19 pagesAndenes Oljekj - Ler KS12-AEP-123 L800MaxiwendelNo ratings yet

- Refrigerants CompressorsDocument33 pagesRefrigerants CompressorsAnonymous XybLZfNo ratings yet