Professional Documents

Culture Documents

Rajalakshmi Engineering College ME 1006 Quality Control and Reliability Engineering Lesson Plan SL - No. Topic Unit 1

Uploaded by

Manoj KbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rajalakshmi Engineering College ME 1006 Quality Control and Reliability Engineering Lesson Plan SL - No. Topic Unit 1

Uploaded by

Manoj KbCopyright:

Available Formats

RAJALAKSHMI ENGINEERING COLLEGE

Department of Mechanical Engineering

ME 1006 Quality Control and Reliability Engineering

VI Semester Mechanical Engineering

Lesson Plan

Sl.No.

Topic

1. Introduction, definition of quality, basic concept of quality

Unit

I

2.

Definition of SQC, benefits and limitation of SQC

3.

Quality assurance Steps involved in Quality assurance

4.

Quality cost Types of quality cost

5.

Variation in process- factors process capability

6.

Process capability studies and simple problems

7.

Theory of control chart- uses of control chart

8.

Control chart for variables - X chart, R chart and chart.

9.

Problems in X chart, R chart

10. Problems in X chart and chart

11. Control chart for attributes

II

12. Control chart for proportion or fraction defectives p chart and np chart

II

13. Problems in p chart

II

14. Problems in np chart

II

15. Control chart for defects C and U charts

II

16. Problems in C chart

II

17. Problems in U chart

II

18. State of control and process out of control identification in charts

II

19. Lot by lot sampling types

III

20. Probability of acceptance in single, double, multiple sampling techniques

III

21. Problems in Single sampling

III

22. Problems in double sampling

III

23. Problems in multiple sampling

III

24. O.C. curves producers Risk and consumers Risk.

III

25. AQL, LTPD, AOQL concepts

III

26. Problems in AQL, LTPD, AOQL concepts

III

27. Standard sampling plans for AQL and LTPD

III

28. Uses of standard sampling plans.

III

29. Life testing Objective failure data analysis

IV

30. Mean failure rate, mean time to failure, mean time between failure

IV

31. Problems in MTTF and MTBF.

IV

32. Hazard rate, system reliability

IV

33. Series, parallel and mixed configuration

IV

34. Simple problems in series, parallel and mixed configuration

IV

35. Maintainability and availability

IV

36. Simple problems in maintainability and availability

IV

37. Acceptance sampling based on reliability test

IV

38. Operating Characteristic (OC) curves

IV

Sl.No.

Topic

39. Reliability improvements techniques

Unit

V

40. Use of Pareto analysis

41. Design for reliability

42. Redundancy unit and standby redundancy

43. Optimization in reliability

44. Product design and Product analysis

45. Product development and Product life cycles

TEXT BOOKS

1.

2.

Grant, Eugene .L Statistical Quality Control, McGraw-Hill, 1996.

L.S.Srinath, Reliability Engineering, Affiliated East west press, 1991.

REFERENCES

1.

2.

3.

4.

5.

6.

7.

Monohar Mahajan, Statistical Quality Control, Dhanpat Rai & Sons, 2001.

R.C.Gupta, Statistical Quality control, Khanna Publishers, 1997.

Besterfield D.H., Quality Control, Prentice Hall, 1993.

Sharma S.C., Inspection Quality Control and Reliability, Khanna Publishers,

1998.

Danny Samson, Manufacturing & Operations Strategy, Prentice Hall, 1991

Connor, P.D.T.O., Practical Reliability Engineering, John Wiley, 1993

Narayanamurthy , Baskar, Statistical Quality control and Reliability

Engineering

You might also like

- Technical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesFrom EverandTechnical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesNo ratings yet

- M.E. Quality Engineering and Management SyllabusDocument39 pagesM.E. Quality Engineering and Management SyllabusJoswa CaxtonNo ratings yet

- Puter Integrated Manufacturing SyllabusDocument41 pagesPuter Integrated Manufacturing SyllabusJoswa CaxtonNo ratings yet

- M.E. Industrial Engineering SyllabusDocument46 pagesM.E. Industrial Engineering SyllabusJoswa CaxtonNo ratings yet

- 7th SemDocument17 pages7th SemShankar MukalNo ratings yet

- University Departments: Anna University Chennai:: Chennai 600 025Document42 pagesUniversity Departments: Anna University Chennai:: Chennai 600 025Jeyaram KumarNo ratings yet

- Mtech Se July2011 PDFDocument50 pagesMtech Se July2011 PDFsavitrinaikNo ratings yet

- M.E. CimDocument40 pagesM.E. CimvenkatkrishnaNo ratings yet

- M.E Control and Instrumentation Engineering PDFDocument55 pagesM.E Control and Instrumentation Engineering PDFAmit SaurabhNo ratings yet

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804Document3 pagesGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804N NandiniNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial Engineeringnandan144No ratings yet

- Mechanical Engineering: University of CalicutDocument20 pagesMechanical Engineering: University of CalicutJacob JoseNo ratings yet

- M.tech (Industrial Safety and Hazards Management) SyllabusDocument34 pagesM.tech (Industrial Safety and Hazards Management) SyllabusRamNocturnalNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial EngineeringRam RenNo ratings yet

- 1i 592 MEPC29 2Document1 page1i 592 MEPC29 2Darshan SoniNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial EngineeringHusni mubsshirNo ratings yet

- M.e.,cim SyllabusDocument44 pagesM.e.,cim SyllabusSiva PrakashNo ratings yet

- Mtech Ie PDFDocument15 pagesMtech Ie PDFAnonymous 1kUvpdbWGNo ratings yet

- Course Code. Course Name L-T-P - Credits Year of IE308 Quality Engineering 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesDocument3 pagesCourse Code. Course Name L-T-P - Credits Year of IE308 Quality Engineering 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesloshidhNo ratings yet

- Affliated Institutions: Anna University of Technology Chennai CHENNAI 600 113Document34 pagesAffliated Institutions: Anna University of Technology Chennai CHENNAI 600 113Maha RajaNo ratings yet

- Design of Hydraulic and Pneumatic SystemsDocument2 pagesDesign of Hydraulic and Pneumatic SystemsGokul raj SNo ratings yet

- Mtech Iem 2013Document12 pagesMtech Iem 2013Jaykrishnan GopalakrishnanNo ratings yet

- Annauniversity ICE VI VIIIDocument48 pagesAnnauniversity ICE VI VIIIismailpasha_1987No ratings yet

- IE401 Reliability EngineeringDocument2 pagesIE401 Reliability EngineeringRoNo ratings yet

- Morton E. Bader (Author) - Practical Quality Management in The Chemical Process Industry-CRC Press (1983)Document160 pagesMorton E. Bader (Author) - Practical Quality Management in The Chemical Process Industry-CRC Press (1983)TewodirosNo ratings yet

- Iem SyllabusDocument2 pagesIem SyllabusC MohanNo ratings yet

- Possible Questions of Graph Theory and Reliability AnalysisDocument1 pagePossible Questions of Graph Theory and Reliability AnalysisShuvodip DasNo ratings yet

- 402050A - Quality & Reliability Engg-sYLLABUSDocument2 pages402050A - Quality & Reliability Engg-sYLLABUSashish RautNo ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- Lbs College of Engineering: KasaragodDocument14 pagesLbs College of Engineering: KasaragodshobithNo ratings yet

- Product Design 1Document10 pagesProduct Design 1elango_mm3307No ratings yet

- 4th Year - II Sem - MechDocument10 pages4th Year - II Sem - MechaareachyuthNo ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- Lesson Plan TQM-NewDocument7 pagesLesson Plan TQM-Newtmuthu123No ratings yet

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word DocumentBala NarayanasamyNo ratings yet

- Industry 4.0 Value Roadmap Integrating Technology and Market Dynamics For Strategy, Innovation A PDFDocument123 pagesIndustry 4.0 Value Roadmap Integrating Technology and Market Dynamics For Strategy, Innovation A PDFXiomara Vidal RamirezNo ratings yet

- 3 Quality-Reliability-Engineering PDFDocument4 pages3 Quality-Reliability-Engineering PDFinGOVA SoporteNo ratings yet

- Metrology & Quality ControlDocument127 pagesMetrology & Quality ControlArnav PandeyNo ratings yet

- Dr. Navalar Nedunchezhiyan College of Engineering B.E ME Sem 7 Total Quality ManagementDocument121 pagesDr. Navalar Nedunchezhiyan College of Engineering B.E ME Sem 7 Total Quality Managementmaruthu100% (1)

- QualityDocument39 pagesQualitysudharshankyNo ratings yet

- Me2037 Maintenance Engineering L T P CDocument1 pageMe2037 Maintenance Engineering L T P CamanpurushothNo ratings yet

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804Document3 pagesGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740804Shailesh PatelNo ratings yet

- Unit 1Document13 pagesUnit 1Vinay LuckyNo ratings yet

- Me Manufacturing Curriculum-2Document11 pagesMe Manufacturing Curriculum-2Arun KumarNo ratings yet

- M.E. Mechatronics SyllabusDocument38 pagesM.E. Mechatronics SyllabusJoswa CaxtonNo ratings yet

- RTPMDocument2 pagesRTPMG. RajeshNo ratings yet

- IV Year - II Semester L T P C 4 0 0 3 Production Planning and ControlDocument13 pagesIV Year - II Semester L T P C 4 0 0 3 Production Planning and Controlrajeshchindu186No ratings yet

- Syallabus Me & orDocument2 pagesSyallabus Me & ortamil thendralNo ratings yet

- Production Planning & ControlDocument2 pagesProduction Planning & ControlJobin AbrahamNo ratings yet

- knrS7 & S8Document94 pagesknrS7 & S8Raavan LankaNo ratings yet

- Industrial BiotechDocument50 pagesIndustrial BiotechlmnmpnsNo ratings yet

- Me Manufacturing CurriculumDocument37 pagesMe Manufacturing CurriculumJeyaram kumarNo ratings yet

- Ee404 Industrial Instrumentation and AutomationDocument3 pagesEe404 Industrial Instrumentation and AutomationArya RahulNo ratings yet

- Electrical and Electronics Engineering Vii Semester: Course Theory/Lab L T P C CodeDocument66 pagesElectrical and Electronics Engineering Vii Semester: Course Theory/Lab L T P C Codejitendra jhaNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3jpbhimaniNo ratings yet

- Jntua B.tech 4-2 Me r15 SyllabusDocument13 pagesJntua B.tech 4-2 Me r15 SyllabusDileep KumarNo ratings yet

- Instrumentation EngineeringDocument34 pagesInstrumentation Engineeringvaithy1990No ratings yet

- Pie Chart1Document35 pagesPie Chart1Manoj KbNo ratings yet

- Mechanics of Materials Syllabus For ME 3 Sem 2010 Scheme - Vtu Syllabus PDFDocument3 pagesMechanics of Materials Syllabus For ME 3 Sem 2010 Scheme - Vtu Syllabus PDFManoj KbNo ratings yet

- Kerala - Wikipedia, The Free EncyclopediaDocument24 pagesKerala - Wikipedia, The Free EncyclopediaManoj KbNo ratings yet

- Logarithm ProblemsDocument8 pagesLogarithm ProblemsvaranasilkoNo ratings yet

- Adjectives PDFDocument3 pagesAdjectives PDFManoj KbNo ratings yet

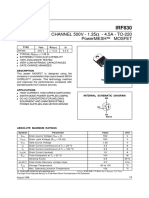

- N - Channel 500V - 1.35 - 4.5A - To-220 Powermesh Mosfet: DescriptionDocument9 pagesN - Channel 500V - 1.35 - 4.5A - To-220 Powermesh Mosfet: DescriptionManoj KbNo ratings yet

- SpontaneityDocument1 pageSpontaneityPayal SarkarNo ratings yet

- Great DayDocument1 pageGreat DayManoj KbNo ratings yet

- SpontaneityDocument1 pageSpontaneityPayal SarkarNo ratings yet

- SpontaneityDocument1 pageSpontaneityPayal SarkarNo ratings yet

- NotesDocument1 pageNotesManoj KbNo ratings yet

- NiceDocument1 pageNiceManoj KbNo ratings yet

- List of Basic Terms For Mechanical EngineeringDocument10 pagesList of Basic Terms For Mechanical EngineeringvinothenergyNo ratings yet

- Tide and Time Waits For NoneDocument1 pageTide and Time Waits For NoneManoj KbNo ratings yet

- Me09704 Nov13Document2 pagesMe09704 Nov13varunNo ratings yet

- Mi 1st ModuleDocument3 pagesMi 1st ModuleManoj KbNo ratings yet

- Me09701 Nov13Document2 pagesMe09701 Nov13Manoj KbNo ratings yet

- Part ADocument13 pagesPart AManoj KbNo ratings yet

- ME 09 706 L25 Energy Engineering and Management NOV 2014Document2 pagesME 09 706 L25 Energy Engineering and Management NOV 2014Manoj KbNo ratings yet

- Mi 2nd ModuleDocument3 pagesMi 2nd ModuleManoj KbNo ratings yet

- Me09l07 Jun13Document2 pagesMe09l07 Jun13Manoj KbNo ratings yet

- Mi 4th ModuleDocument3 pagesMi 4th ModuleManoj KbNo ratings yet

- ME 09 706 L25 Energy Engineering and Management NOV 2014Document2 pagesME 09 706 L25 Energy Engineering and Management NOV 2014Manoj KbNo ratings yet

- ME 09 705 L07-Automobile EngineeringDocument2 pagesME 09 705 L07-Automobile EngineeringManoj KbNo ratings yet

- Unit 1 Metro LogyDocument9 pagesUnit 1 Metro LogyMuthuvel M100% (1)

- 1.3 Energy Management & AuditDocument25 pages1.3 Energy Management & AuditEdd GithaeNo ratings yet

- ME 09 706 L25 Energy Engineering and Management APR 2014Document1 pageME 09 706 L25 Energy Engineering and Management APR 2014Manoj KbNo ratings yet

- ME 09 706 L25 Energy Engineering and Management NOV 2013Document2 pagesME 09 706 L25 Energy Engineering and Management NOV 2013Manoj KbNo ratings yet

- Production Drawing: 3 Basic Principles of Dimensioning in Production DrawingsDocument5 pagesProduction Drawing: 3 Basic Principles of Dimensioning in Production DrawingsManoj KbNo ratings yet

- The Dark RoomDocument8 pagesThe Dark RoomCarlos muñozNo ratings yet

- A Systematic Literature Review of Methods and Datasets For Anomaly Based Network Intrusion DetectionDocument20 pagesA Systematic Literature Review of Methods and Datasets For Anomaly Based Network Intrusion DetectionAd AstraNo ratings yet

- Iterative ModelDocument9 pagesIterative ModelasadNo ratings yet

- 924-Article Text-1321-1-10-20180531Document16 pages924-Article Text-1321-1-10-20180531Nur AbdillahNo ratings yet

- Gantt ChartDocument9 pagesGantt ChartvishwassaimsNo ratings yet

- Traffic Signs RecognitionDocument20 pagesTraffic Signs RecognitionSakshi Singh0% (1)

- T1 Decomposition and AbstractionDocument26 pagesT1 Decomposition and AbstractionrukhNo ratings yet

- LQR Based Optimal Tuning of PID Controller For Tra PDFDocument11 pagesLQR Based Optimal Tuning of PID Controller For Tra PDFFrancisco A Torres VNo ratings yet

- Chap12-Practical Database Design Methodology and Use of UML DiagramsDocument8 pagesChap12-Practical Database Design Methodology and Use of UML Diagramsnomaddarcy100% (1)

- Experiment 4Document13 pagesExperiment 4Usama NadeemNo ratings yet

- Epics in Agile - The Ultimate Guide To Mastering Your WorkflowDocument10 pagesEpics in Agile - The Ultimate Guide To Mastering Your WorkflowFaizan Bashir Sidhu100% (2)

- VU - Software Testing March 21Document17 pagesVU - Software Testing March 21Srikanth MarepalliNo ratings yet

- Introduction To PID ControlDocument115 pagesIntroduction To PID Controlمحمد القدوميNo ratings yet

- Welcome: Machine LearningDocument31 pagesWelcome: Machine LearningBùi Hữu ThịnhNo ratings yet

- OSSP - CCA-1 Individual Assignment SOB 2023Document6 pagesOSSP - CCA-1 Individual Assignment SOB 2023Gangane HomeNo ratings yet

- Operational Efficiency: Improvement TermsDocument56 pagesOperational Efficiency: Improvement TermsLuis Javier0% (1)

- Principles of Testing Istqb 6Document155 pagesPrinciples of Testing Istqb 6CedricNo ratings yet

- Updated SRSDocument5 pagesUpdated SRSbc190205729 ALVIA KHANNo ratings yet

- Intelligent Software AgentsDocument39 pagesIntelligent Software AgentsHassan VilniusNo ratings yet

- CH 17Document45 pagesCH 17amarmudirajNo ratings yet

- A Gentle Introduction To Neural Machine TranslationDocument14 pagesA Gentle Introduction To Neural Machine TranslationDragan ZhivaljevikjNo ratings yet

- ISO 9001 2015 中文版 (繁)Document25 pagesISO 9001 2015 中文版 (繁)a0931474125No ratings yet

- Done - 2 - Develop Good Decision Models To Succeed at Decision Management Done 21 NovDocument15 pagesDone - 2 - Develop Good Decision Models To Succeed at Decision Management Done 21 Novmeghraj gurjarNo ratings yet

- Arabic Aspect Based Sentiment Analysis Using Bidirectional GRUDocument11 pagesArabic Aspect Based Sentiment Analysis Using Bidirectional GRUperpetualNo ratings yet

- Control System TheoryDocument60 pagesControl System TheoryNishant SaxenaNo ratings yet

- Reliability in Automotive and Mechanical Engineering - Determination of Component and System Reliability PDFDocument7 pagesReliability in Automotive and Mechanical Engineering - Determination of Component and System Reliability PDFClaudiu Marius R100% (1)

- Neutral Network Model Predictive ControlerDocument10 pagesNeutral Network Model Predictive ControlerNimai KowlessurNo ratings yet

- Project ManagementDocument2 pagesProject ManagementpradeepNo ratings yet

- 1987 - Adaptive Feedback Control - AstromDocument33 pages1987 - Adaptive Feedback Control - Astromademargcjunior100% (1)

- RNN Vanishing Gradients LSTM CompressedDocument53 pagesRNN Vanishing Gradients LSTM CompressedSmruti PatroNo ratings yet