Professional Documents

Culture Documents

Design Considerations Kalsan I

Uploaded by

Engr Amir Jamal QureshiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Considerations Kalsan I

Uploaded by

Engr Amir Jamal QureshiCopyright:

Available Formats

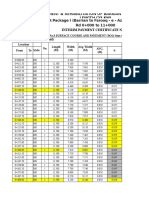

DETAIL OF MAN-DAYS FOR COST ESTIMATION

Sr. No.

1 Excavation

Description

Unit Measure

a- ordinary soil

b- gravelly soil

c- Boulder mix soil

per cft

per cft

per cft

(1:2:4)

(1:4:8)

per cft

per cft

per cft

per cft

per sft

per sft

per kg

per cft

per cft

Man-days

Skilled unskilled

-

0.022

0.016

0.031

2 PCC

3

4

5

6

7

8

9

RCC (1:2:4)

Stone Masonry

Plaster

Pointing

Steel work for RCC

Shingle work

Centring and shuttering for RCC work

0.031

0.031

0.047

0.04

0.013

0.018

0.02

0.113

0.113

0.095

0.09

0.02

0.028

0.01

0.015

0.01

WATSAN

Operational Team

KALSAN- 1

Drinking Water Supply Scheme:

U/C SACHAN

STAND POST

(1.5' X 1.5'X 2.25')

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Pad

4.50

4.50

1.00

1.00

20.25

Cft

stand post

0.75

0.42

1.00

1.00

0.32

Cft

dispose off drain

5.41

1.00

1.00

1.00

5.41

Cft

25.98

Cft

Pad

4.50

4.50

0.33

1.00

6.68

Cft

stand post

0.75

0.42

0.33

1.00

0.10

Cft

dispose off drain

5.41

1.00

0.33

1.00

1.79

Cft

Sand

(cft)

Gravel/

Crush

(cft)

Shingle

Unskilled

Labour

Men-days Men-days

0.57

8.57

Cft

8.57

0.13

P/L PCC (1:4:8)

Pad

4.50

4.50

0.33

1.00

6.68

Cft

stand post

0.75

0.42

0.33

1.00

0.10

Cft

dispose off drain

5.41

1.00

0.33

1.00

1.79

Cft

8.57

Cft

Total

4

Cement

(Bags)

Shingle bed

Total

3

Unit

Excavation (gravelly soil)

Total

2

Quantity

Labour

Skilled

Labour

0.90

4.50

9.00

0.27

0.97

2.60

6.50

13.00

0.39

1.42

0.20

0.40

0.86

3.49

P/L PCC (1:2:4)

Pad

4.00

4.00

0.33

1.00

5.28

Cft

stand post

0.75

0.75

3.42

1.00

1.92

Cft

dispose off drain

6.00

1.00

0.58

1.00

3.48

Cft

pad boundary projection Lond side

4.50

0.25

0.58

2.00

1.31

Cft

Short sides (stand post side)

3.25

0.25

0.48

1.00

0.39

Cft

(Drain side)

3.00

0.25

0.48

1.00

0.36

Cft

1.00

1.00

0.50

1.00

0.50

Cft

13.24

Cft

Seat pad

Total

deduct for drain flow

Net Total

6.00

0.33

0.33

1.00

0.65

Cft

12.59

Cft

GI Pipe 1/2 " dia

10.00

Rft

GI Socket 1/2" dia

No.

GI Elbow 1/2 " dia

No.

Brass tap 1/2"

No.

Quantities for 1 Tap Stand

CRS-Mansehra

3.50

11.00

22.00

8.57

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Quantities for 5 Tap Stand

CRS-Mansehra

17.50

55.00

110.00

42.86

4.28

17.45

Engr. Amir Jamal Qureshi

KALSAN- 1

Drinking Water Supply Scheme:

U/C SACHAN

VALVE CHAMBER

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Quantity

Unit

Excavation (gravelly soil)

4.00

4.00

2.50

1.00

40.00

Cft

P/L PCC (1:4:8) as in Foundation

4.00

4.00

0.25

1.00

4.00

Cft

Stone Masonry in (1:3) CSM

Long Wall

3.50

1.00

2.25

2.00

15.75

Cft

Short Wall

1.50

1.00

2.25

2.00

6.75

Cft

22.50

Cft

6.75

Cft

Total

30% (1:3) CSM

Stone

4

PCC (1:2:4) as coping

Long Wall

Short Wall

Sand

(cft)

1.87

2.50

15.75

Cft

1.00

4.00

Cft

3.50

1.00

0.16

2.00

1.12

Cft

1.50

1.00

0.16

2.00

0.48

Cft

1.60

Cft

0.20

1.00

13.50

Sft

0.23

0.84

2.25

Sft

1.50

Steel Man hole cover 1.5'x1.5' (16

Guage sheet)

1.50

1.50

2.25

4.00

Stone

(cft)

Unskilled

Labour

Men-days Men-days

5.00

0.12

0.45

0.90

2.03

0.05

0.18

0.18

0.27

7.00

0.25

P/L Plaster 3/4" thick in (1:3) CSM

Gravel/

Crush

(cft)

Labour

Skilled

Labour

0.88

0.50

4.00

Quantities for 1 Valve Chamber

Cement

(Bags)

4.00

Total

(1.5' X 1.5'X 2.25')

15.75

2.00

0.06

2.79

11.34

7.00

15.75

1.31

3.81

WATSAN

Opertaional Team

KALSAN- 1

Drinking Water Supply Scheme:

U/C SACHAN

SOURCE TANK

(4' X 4'X 3')

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Quantity

Unit

Excavation (in hard soil)

7.00

7.00

1.50

1.00

73.50

Cft

P/L PCC (1:4:8) as in Foundation

7.00

7.00

0.50

1.00

24.50

Cft

Stone Masonry in (1:3) CSM

Long Wall

7.00

1.50

3.50

2.00

73.50

Cft

Short Wall

2.00

4.00

3.50

2.00

56.00

Cft

129.50

Cft

30% (1:3) CSM

38.85

Cft

Stone

90.65

Cft

1.00

4.00

Cft

Total

P/L PCC (1:2:4) as in Bed

4.00

Vertical Reinforcement in walls

P/L Plaster 3/4" thick in (1:3) CSM

Stone

(cft)

Labour

Steel

#3 bars

(kg)

Binding

wire (kg)

Skilled

Labour

Unskilled

Labour

Men-days Men-days

2.28

2.50

12.50

10.67

40.00

0.50

2.50

25.00

0.76

2.77

5.18

11.66

0.12

0.45

90.65

0.25

20.00

45.50

kg

4.00

3.50

4.00

56.00

Sft

0.93

3.50

0.73

1.12

P/L Pointing 3/4" in (1:2) CSM

7.00

2.25

4.00

63.00

Sft

0.16

0.39

1.13

1.76

P/L RCC (1:2:4) as in Slab

7.56

7.50

0.33

1.00

18.71

Cft

4.00

10.00

0.88

1.78

Decuction for man hole cover

2.00

2.00

0.33

1.00

1.32

Cft

17.39

Cft

7.50

Net Total

8.2

Sand

(cft)

Steel

#4 bars

(kg)

4.00

(#4 @ 12" c/c all around)

8.1

Cement

(Bags)

Gravel/

Crush

(cft)

5.00

50.00

1.37

20.00

0.46

Steel

(#3 @ 6" c/c as main steel)

7.56

15.00

19.30

kg

(#3 @ 9" c/c as temp. steel)

7.50

10.00

12.80

kg

32.10

kg

18.71

Cft

Total

9

Centring and shuttring

10

Binding wire

2.33

kg

11

GI strainer 2" dia

3.00

12

GI Over flow pipe 1.5" dia

6.00

13

GI wash out pipe 1" dia

5.00

14

GI Plug 1"

1.00

No

15

Steel Man hole cover (2'x2')

4.00

Sft

Quantities for 1 Source Tank

CRS-Mnasehra

7.56

2.00

7.50

2.00

0.33

1.00

38.00

0.96

0.32

0.37

0.19

Rft

0.06

0.12

Rft

0.12

0.24

Rft

0.10

0.20

0.10

18.76

68.89

50.00

90.65

50.00

38.00

2.33

9.56

23.34

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Drinking Water Supply Scheme

KALSAN-I

U/C

ROOF SLAB DESIGN (2000 Gallon Tank)

fc =

compressive strength of concrete= =

3 ksi

Yield Strength of steel

max =

g pcc =

g Steel=

Specific weight of PCC

Specific weight of steel

50 ksi

Max. steel ratio

Long span = L =

Short span =W=

Wall thickness=

fy

SACHAN

0.021

0.15 k/cft

W

490 lb/cft

12.25 ft

9.75 ft

1.5 ft

Design depth of slab, effective depths and design effective lengths

clear

clear

Perime

span

span

ter P

along along W

(ft)

L (ft)

(ft)

8

5.5

44

hmin

(in)

2.93

Effective

depths

Design Le

wall

Proposed

(in)

Clear lengths Le

(ft)

(ft)

thickn

h (in)

along L

along W

along along ess

along along

L

W

(ft)

(1)

(2)

(1)

(2)

L

W

4

2.5

3

1.5

9.5 8.21

7

5.75

9.5

7

Ultimate Load and ultimate moment

depth h

(ft)

0.33

self wt./ft

(k/ft)

0.0495

Ult. Load Ultimate moments Mu

(k-in)

Wu

(k/ft)

along L

along W

0.0693

6.25

3.4

Design Steel Areas per 1 ft span of slab (b=12")

Asmin =

0.002bh =

Along Short span (main steel)

Asmax =

As

(sq.in)

0.096

max

a

(in)

0.16

a/2

(in)

0.08

0.096 sq.in

d=

3 in

bd =

0.742 sq.in

(d-a/2) Design moment Md

(in)

(k-in)

2.92

12.61

Along Long span (transverse steel)

Asmax =

As

(sq.in)

0.096

max

a

(in)

0.16

a/2

(in)

0.08

As

Area of bar Ab

(sq.in) Bar No.

(sq.in)

3

4

W=

0.9

0.5

Along Long span (transverse steel)

0.096

0.096

CRS-Mansehra

3

4

Remarks

Greater than Mu=3.4 k-in

Proposed

9.75 ft

Bar length

#

length

#

bars

of

# bars in propo in full bars

1ft span

sed span

(ft)

0.11

0.196

As

Area of bar Ab

(sq.in) Bar No.

(sq.in)

Proposed

2.5 in

bd =

0.618 sq.in

(d-a/2) Design moment Md

(in)

(k-in)

2.42

10.45

Rebar sizes and spacings

Along Short span (main steel)

0.096

0.096

d=

Remarks

Greater than Mu=6.25 k-in

2

1

20

10

245

122.5

L= 12.25 ft

#

length

#

bars

of

# bars in propo in full bars

1ft span

sed span

(ft)

12.25 ft

wt. of

steel

(kg)

42

37

Remarks

Proposed

bars @ 6" c/c)

Bar length= 9.75 ft

wt. of

steel

(kg)

0.11

0.9

2 24.5 238.88

41

0.196

0.5

1 12.25 119.44

36

Total steel (#3 bars) required =

83 kg

SAY

=

95 kg

= L

(#3

= W

Remarks

Proposed

bars @ 6" c/c)

(#3

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

DRINKING WATER SUPPLY SCHEME

KALSAN-I

U/C

Detail of Quantities

Sub

Head

No

Description

Excavation (gravelly soil, not requiring blasting)

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Unit

Long Wall

12.17

48.68

Cft

5.67

22.68

Cft

Plinth/Apron

11.67

0.5

17.51

Cft

Shingle bed

12.17

5.67

0.5

34.50

Cft

123.37

Cft

Shingle as in Bed

P/L PCC (1:4:8) as in Foundation

12.17

5.67

0.5

34.50

Cft

MAIN STORAGE TANK

Detail of Materials

Cement

(Bags)

Sand

(cft)

Gravel/

Crush

(cft)

Stone

(cft)

Shingle

(cft)

2000 GALLON (US)

Labour

Skilled

Steel

#3 Steel

#4

Binding wire Labour

bars (kg) bars (kg)

(kg)

Men-days

Unskilled

Labour

Men-days

2.71

34.50

0.52

Long Wall

12.17

0.5

24.34

Cft

Short Wall

5.67

0.5

11.34

Cft

Plinth/Apron

11.67

0.5

17.51

Cft

Bed

8.67

6.17

0.67

35.84

Cft

89.03

Cft

8.90

44.50

89.00

2.76

10.06

17.65

Cft

3.60

9.00

18.00

0.83

1.68

Total

P/L RCC (1:2:4) as in Bed

8.67

6.17

0.33

Steel

along long walls(#3@6"c/c)

10.67

13

23.60

kg

along short walls(#3@6"c/c)

8.17

18

25.00

kg

48.60

kg

Total

5

Quantity

Short Wall

Total

SACHAN

55.00

1.46

0.49

Ring Beam (18"X12")

5.1 RCC (1:2:4)

Long sides

11.67

1.5

35.01

cft

Short sides

6.17

1.5

18.51

cft

53.52

cft

Total

10.80

27.00

54.00

2.52

5.08

5.2 Steel

Main steel (4, #4 bars)

200

Shear stirrups (#3@ 12" c/c)

4.25

5.3 Centring and shuttering

6

60.60

kg

40

28.90

kg

17.84

1.5

53.52

Cft

Long Wall

11.67

1.5

6.83

239.12

Cft

Short Wall

6.17

1.5

6.83

126.42

Cft

Total

365.54

Cft

Deduct for 2 seismic bands

35.32

Cft

Net Total

330.22

Cft

30% (1:6) CSM

99.07

Cft

Stone

231.16

Cft

38

138.20

kg

70.00

35.00

1.82

0.61

0.87

0.29

1.07

0.54

13.21

29.72

CR Stone Masonry in (1:6) CSM

Vertical Reinforcement in walls

Seismic Bands

(#4 @ 12" c/c all around)

12

13.33

100.00

231.16

150.00

4.15

1.38

8.1 @ 2'-2" from top of ring beam

8.11 RCC (1:2:4)

Long sides

11.67

1.5

0.33

11.55

cft

short sides

6.17

1.5

0.33

6.11

cft

17.66

cft

Total

3.60

9.00

18.00

0.83

1.68

8.12 Steel

Main steel (2,#4) bars

72

21.80

kg

Shear stirrups(#3 @ 12"c/c)

1.75

38

11.30

kg

corner reinforcement

(1,#4 bar 2' ovelap with main steel at each

corner)

5.25

6.40

kg

11.55

cft

25.00

15.00

10.00

0.65

0.22

0.34

0.11

0.19

0.06

8.2 @ 2' from top of 1st seismic band

8.21 RCC (1:2:4)

Long wall

CRS-Mansehra

11.67

1.5

0.33

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

short wall

6.17

Breadth

in ft

1.5

Depth/Ht

in ft

No of

Units

Quantity

0.33

6.11

cft

17.66

cft

Total

Unit

Cement

(Bags)

3.60

Sand

(cft)

9.00

Gravel/

Crush

(cft)

Stone

(cft)

Shingle

(cft)

Labour

Skilled

Steel

#3 Steel

#4

Binding wire Labour

bars (kg) bars (kg)

(kg)

Men-days

18.00

0.83

Unskilled

Labour

Men-days

1.68

8.22 Steel

Main steel (2,#4) bars

72

21.80

kg

Shear stirrups(#3 @ 12"c/c)

corner reinforcement (1,#4 bar 2' ovelap with

main steel at each corner)

1.75

38

11.30

kg

5.25

6.40

kg

25.00

15.00

10.00

0.65

0.22

0.34

0.11

0.19

0.06

9.1 RCC (1:2:4) as in core wall

Long wall

8.67

0.33

40.06

cft

Short wall

5.5

0.33

25.41

cft

65.47

cft

Total

9.2 Steel

13.20

33.00

66.00

3.08

6.22

Horizontal(#3 @6"c/c)

along long wall

10

28

47.60

kg

along short wall

7.5

28

35.70

kg

along long wall

32

49.00

kg

along short wall

22

33.70

kg

166.00

kg

Vertical (#3 @6"c/c)

Total

10

10.1 RCC (1:2:4)

2.5

10.2 Steel

12

11.25

cft

Main steel(#3 bars)

7.83

1.5

0.25

12

16.00

kg

shear stirrups(#3)

1.75

24

Total

11

175.00

4.98

1.66

RCC corner strips

(above and below seismic bands)

7.10

kg

23.10

kg

2.40

6.00

12.00

0.53

30.00

0.69

1.07

0.23

P/L Pointing (0.75") in (1:2) CSM

Long walls

11.67

6.17

144.01

Sft

short walls

9.17

6.17

113.16

Sft

257.17

Sft

39.19

Cft

Total

12.1 P/L RCC (1:2:4) as in Slab

Decuction for manhole cover

12.17

9.67

0.333

0.333

Net Total

Steel (#3 @ 6" c/c) as per detail

12.2 Centring and shuttering

12.17

9.67

0.333

0.64

1.61

7.60

19.00

4.63

7.20

1.78

3.60

1.33

Cft

37.86

Cft

83.00

kg

39.19

Cft

0.78

0.39

38.00

95.00

2.49

0.95

13

GI over flow pipe 1.5" dia.

12

Rft

0.24

0.48

14

GI wash out pipe 1.5" dia

Rft

0.12

0.24

15

GI Plug 1.5 "

No.

16

Steel man hole cover (2'x2')

4.00

Sft

33.20

79.25

Quantities for 1 Tank

CRS-Mansehra

67.68

258.11

313.00

231.16

34.50

420.00

290.00

18.82

Engr. Amir Jamal Qureshi

Hydraulic Statement of DWSS Kalsan 1

S.NO

Length of

Name of

pipe

in

Line

" ft "

Sector

Zone

Projected

Population

(persons)

Design Q in

US GAL

Proposed dia Velocity in

Head

of G.I pipe in

" Loss per

" inches"

ft/sec "

1000 ft

Total

Head

Losss

Hydraulic Grade

U/End

L/End

Ground

Level

Terminal

Pressrure in

ft of water

Remarks

Supply Main

1

CC-WST

520

230

1.92

0.75

1.20

19.00

9.88

5118

5108.12

5063

45.1

Proposed

5063

5058.8

5035

23.8

Proposed

5063

Distribution NetWork

1

WST-1

200

68

0.85

0.5

1.06

21.00

4.20

WST-2

100

162

2.03

0.75

1.20

19.30

1.93

5061.07

5020

41.1

Proposed

2 --3

360

135

1.69

0.75

1.20

19.30

6.95

5061.1 5054.15

4960

94.2

Proposed

3 -- 4

100

27

0.34

0.5

0.53

5.82

0.58

5054.2 5053.62

4950

103.6

Proposed

3--5

100

68

0.85

0.5

1.06

21.00

2.10

5054.2

5052.1

4945

107.1

Proposed

3 -- 6

360

41

0.51

0.5

1.58

44.40

15.98

5054.2 5038.22

4942

96.2

Proposed

Peaking Factor 1.5

WATSAN

Operational Team

KALSAN-I

DRINKING WATER SUPPLY SCHEME

DESIGN PERIOD

Design Period

U/C SACHAN

20 years

DESIGN POPULATION

No. of persons/H.H for present population

Design growth rate

Design growth rate factor G.R.F

=

=

=

7.5

3%

1.8

SECTOR NO. 1

Sr. # Zone Name

1 ZONE 1

Present population

# of persons/

(July 2006)

G.R.F

H.Hs H.H

Persons

17

7.5

128

1.8

Design

population

(July 2026)

Persons

230

TOTAL

TOTAL DESIGN POPULATION

230

230 Persons

DESIGN WATER DEMAND

Water requirement of design population @ 10 gpcd =

2300 GPD (Imp)

1.92 GPM (US)

Additional water requirement

1 Schools

NO. # students in 2006

(No school exists)

1

2 Mosques

NO.

# students in

2026

taking half as

outsiders

0

# attending

Daily req. @ 3

Population in 2026 mosques (10%) gpcd GPD (Imp)

1

230

23

69

TOTAL

3 Animals

Large animals

No.

# in

2026

# in 2006

1

Small animals

Daily req. @ 2.5

gpcd GPD (Imp)

0

0

TOTAL

0

No.

47

# in

2026

# in 2006

1

Total additional water requirements =

Design Water Demand of community

69

daily

requirement @

12 GPD (Imp)

71 852

daily

requirement @ 6

GPD (Imp)

3 18

939 GPD (Imp)

0.78 GPM (US)

=

2.70 GPM (US)

FLOWS AND CONSUMPTIONS

Safe Yield of source(s)

=

12 GPM (US)

Design water consumption =

2.70 GPM (US)

MAIN STORAGE TANK CAPACITY

Design water consumption of community =

2.70 GPM (US)

3888 GPD (US)

Total water storage per day =

3888 GALLONS (US)

Taking half day storage,

Design storage capacity of tank =

1944 GALLONS (US)

SAY

2000 GALLONS (US)

PROPOSED

CRS-Mansehra

2000 GALLONS (US) MAIN STORGE TANK

Engr. Amir Jamal Qureshi

WATSAN

CRS-Mansehra

Operational Team

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

DRINKING WATER SUPPLY SCHEME

KALSAN-I

U/C

SACHAN

TRANSPORTATION COST

TRANSPORTATIN COST UP TO NEAREST ROAD SITE

Total

Sr.#

Item Description

quantity Unit Transp. Rate (PKR)

1 Cement

108 Bags

75 per bag

2 Sand

410 cft

0 per cft

3 Gravel

480 cft

25 per cft

4 Shingle

78 cft

25 per cft

5 Steel & Binding wire

819 kg

5 per kg

6 Stone

338 cft

25 per cft

7 Pipe materials

1 LS

4500 per job

8 Steel manhole cover

3 No.

150 per No.

TOTAL

12 % of Total Cost

Amount

Amount

(PKR)

(USD)

8100

135

0

0

12000

200

1950

32.5

4095

68.3

8450

140.8

4500

75

450

7.5

39545

659.08

TRANSPORTATIN COST OF JEEPABLE CARRIAGE

Total

quantity Unit Transp. Rate (PKR)

Sr.#

Item Description

1 Cement

108 Bags

per bag

2 Sand

410 cft

per cft

3 Gravel

480 cft

per cft

4 Shingle

78 cft

per kg

5 Steel & Binding wire

819 kg

per cft

6 Stone

338 cft

per cft

7 Pipe materials

1 LS

per job

8 Steel manhole cover

3 No.

per No.

TOTAL

0 % of Total Cost

Amount

Amount

(PKR)

(USD)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

TRANSPORTATIN COST OF DONKEY CARRIAGE

Total

quantity Unit Transp. Rate (PKR)

Sr.#

Item Description

1 Cement

108 Bags

per bag

2 Sand

410 cft

per cft

3 Gravel

480 cft

per cft

4 Shingle

78 cft

per kg

5 Steel & Binding wire

819 kg

per cft

6 Stone

338 cft

per job

7 Pipe materials

1 LS

8 Steel manhole cover

3 No.

per No.

TOTAL

0 % of Total Cost

Amount

Amount

(PKR)

(USD)

0

0

0

0

0

0

0

0

0

0

0

0

TRANSPORTATIN COST OF MANUAL CARRIAGE

Total

quantity Unit Transp. Rate (PKR)

Sr.#

Item Description

1 Cement

108 Bags

50 per bag

2 Sand

410 cft

50 per cft

3 Gravel

480 cft

50 per cft

Shingle

78 cft

50 per cft

4 Steel & Binding wire

819 kg

5 per kg

5 Stone

338 cft

50 per cft

24 % of Total Cost

Amount

Amount

(PKR)

(USD)

5400

90

20500

341.7

24000

400

3900

65

4095

68.3

16900

281.7

6 Pipe materials

8 Steel manhole cover

1 LS

3 No.

4000 per job

80 per No.

TOTAL

TOTAL TRANSPORTATION COST

CRS-Mansehra

0

0

Remarks

will be arranged locally

from Ichrian by trolly

from Ichrian by trolly

from Sachan by trolly

Remarks

Remarks

0

0

4000

240

66.7

4

79035

1317.25

118,580.00

1,976.33

Remarks

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

36

% of Total Cost

Amir Jamal Qureshi

KALSAN-I

DRINKING WATER SUPLLY SCHEME

U/C

SACHAN

FITTINGS AND FIXTURES DETAILS

NEW INSTALLATION

Sr

#

Item Description

1 Sockets 3/4"

2

3

4

5

6

7

1

2

3

4

5

6

Sr

#

1

2

3

4

Sockets1.5"

(wash out main tank)

Unions 3/4"

Ball valve 3/4"

GI Elbows 3/4" ( 90 deg)

GI Elbows 1.5" ( 90 deg)

GI T 2"-3/4"(source tank)

Total length

(RFt)

520

Qty/100

Rft (No.)

Total

Qty

(No.)

SAY

(No.)

Unit cost

(PKR)

Total Cost

(PKR)

21

25

17

425

45

90

8

1

3

3

2

56

204

21

62

122

448

204

63

186

244

25

8

35

12

7

1

17

56

13

45

26

204

425

448

455

540

182

204

SAY

(NO.)

Unit cost

(PKR)

Total Cost

(PKR)

60

15

8

8

32.75

13

13

85

1965

195

104

680

6,858

Total

Cost

(PKR)

398

SUPPLY MAIN

4

520

5

1

2

2

1

DISTRIBUTION SYSTEM

Sockets 3/4"

460

4

18

Unions 3/4"

460

1

5

Sockets 1/2"

760

4

30

Unions 1/2"

760

1

8

GI T's (3/4"-1/2")

4

Ball valve 3/4"(out let)

1

TAP STANDS

Qty/tap

Total

Total Tap

Item Description

stand

Qty

stands

(No.)

(No.)

GI pipe 1/2" dia

5

10

50

5

2

10

GI Elbows 0.5"(90 deg)

Sockets 1/2"

5

1

5

Brass Taps 1/2 "

5

1

5

TOTAL FOR FITTINGS AND FIXTURES

ACCESSORIES DETAIL

Location

Quantity

1 GI strainer 2" dia

source tank

RFt

Unit

cost

(PKR)

132.65

2 GI Over flow pipe 1.5" dia

source tank

RFt

93.9

563

3 GI wash out pipe 1" dia

source tank

RFt

62.35

312

No.

30

30

12

RFt

93.9

1127

main tank

wash out main

tank

Source tank,

main tank

RFt

93.9

563

No.

45

45

No.

600

1200

Valve chamber

No.

350

350

source tank

100

Ft

3.35

335

Sr

#

Item Description

GI Plug 1"

4 GI Over flow pipe 1.5" dia

5 GI wash out pipe 1.5" dia

6 GI Plug 1.5"

Steel Man hole cover

7 (2'x2')

Steel Man hole cover

8 (1.5'x1.5')

9 Barbed wire

wash out

source tank

main tank

unit

Remarks

TOTAL FOR ACCESSORIES

4,923

KALSAN-I

DRINKING WATER SUPPLY SCHEME

SACHAN

SUMMARY OF OVER ALL PROJECT COST

MATERIAL COST

Sr.#

A

1

2

3

4

5

6

7

8

9

Item Description

Quantity

CIVIL WORKS

Cement

108

Sand

410

Gravel

480

Shingle

78

Stone

338

Steel (#4 bars)

340

Steel (#3 bars)

458

Manhole Cover

10.25

Steel Binding wire

8

SUB TOTAL - A

Unit

Bags

cft

cft

cft

cft

kg

kg

sft

kg

PIPE WORKS

1 Supply main

3/4" dia

520

Rft

2 Distribution mains

3/4" dia

460

Rft

1/2" dia

760

Rft

Fitting & fixtures

3 (as per detail)

1

L.S.

4 Accessories (as per detail)

1

L.S.

SUB TOTAL- B

SUB TOTAL MATERIAL COST

Unit

Amount Amount

Rate

(PKR)

(USD)

(PKR)

370

48

48

150

48

Remarks

39960

666

0

0

0

0

0

0

0

0

16320

272

21984

366.4

1538 25.63333

384

6.4

80,186

1,336

35

18200

303

35

26.75

16100

20330

268

339

6858

4923

6858

4923

66,411

146,597

114

82

1,106

2,442

TRANSPORTATION COST

Sr.#

1

2

3

4

5

6

7

8

Item Description

Cement

Sand

Gravel

Shingle

Steel & Binding wire

Stone

Pipe materials etc

steel manhole covers

Donkey Manual

up to nearest road

Jeepable

carriage carriage

site (PKR)

carriage (PKR) (PKR)

(PKR)

8100

0

0

5400

0

0

0

20500

12000

0

0

24000

1950

0

0

3900

4095

0

0

4095

8450

0

0

16900

4500

0

0

4000

450

0

0

240

SUB TOTAL TRANSPORTATION COST

Total

Amount

(PKR)

13500

20500

36000

5850

8190

25350

8500

690

118,580

Amount

(USD)

225

342

600

98

137

423

142

12

1,979

LABOR COST

Sr.#

Category

Quantity

unit

1 Unskilled Labor

124

man-days

2 Skilled Labour

49

man-days

3 Plumber

30

man-days

SUB TOTAL LABOR COST

Rate Amount Amount

(PKR) (PKR)

(USD)

250

31000

517

450

22050

368

450

13500

225

66,550

1,110

9

7

4

20

Remarks

% of Total Cost

% of Total Cost

% of Total Cost

% of Total Cost

TOTAL COST

CONTINGENCIES CHARGES @ 2.5% OF TOTAL COST

PKR 331,727

PKR 8,293

USD

USD

5,529

138

GRAND TOTAL

PKR 340,020

USD

5,667

You might also like

- BR-,3a.dwg A3Document1 pageBR-,3a.dwg A3Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 04+200 TO STA. 04+550Document1 pagePlan and Profile STA. 04+200 TO STA. 04+550Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile Sta 04+550 to 04+900Document1 pagePlan and Profile Sta 04+550 to 04+900Engr Amir Jamal QureshiNo ratings yet

- Plan Profile Stations 03+150 to 03+500Document1 pagePlan Profile Stations 03+150 to 03+500Engr Amir Jamal QureshiNo ratings yet

- Plan Profile Stations 03+150 to 03+500Document1 pagePlan Profile Stations 03+150 to 03+500Engr Amir Jamal QureshiNo ratings yet

- ABOpp 13b PDFDocument1 pageABOpp 13b PDFEngr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 03+850 TO STA. 04+200Document1 pagePlan and Profile STA. 03+850 TO STA. 04+200Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 04+450 TO STA. 04+800Document1 pagePlan and Profile STA. 04+450 TO STA. 04+800Engr Amir Jamal QureshiNo ratings yet

- Location Map Thanidani Nathiagali 1Document1 pageLocation Map Thanidani Nathiagali 1Engr Amir Jamal QureshiNo ratings yet

- Slab, Diaphragm and Exp JT D PDFDocument1 pageSlab, Diaphragm and Exp JT D PDFEngr Amir Jamal QureshiNo ratings yet

- Abopp 9Document1 pageAbopp 9Engr Amir Jamal QureshiNo ratings yet

- Typical Cross Section For Cut and Fill Area: Annex 2 - 2Document3 pagesTypical Cross Section For Cut and Fill Area: Annex 2 - 2Engr Amir Jamal QureshiNo ratings yet

- General Arragement - DWG LayoDocument1 pageGeneral Arragement - DWG LayoEngr Amir Jamal QureshiNo ratings yet

- Summary of The Chief Minister KPK DraftDocument2 pagesSummary of The Chief Minister KPK DraftEngr Amir Jamal QureshiNo ratings yet

- BR-R 000.Dwg Layout1Document1 pageBR-R 000.Dwg Layout1Engr Amir Jamal QureshiNo ratings yet

- Asphaltic Wearing Course Calculation Sheet PK-1Document52 pagesAsphaltic Wearing Course Calculation Sheet PK-1Engr Amir Jamal QureshiNo ratings yet

- HARI PUR BYPASS Alignment With DetailsDocument1 pageHARI PUR BYPASS Alignment With DetailsEngr Amir Jamal QureshiNo ratings yet

- Location Map Thanidani Nathiagali 3Document1 pageLocation Map Thanidani Nathiagali 3Engr Amir Jamal QureshiNo ratings yet

- Khyber Pakhtunkhwa Highway Authority addresses improper road workDocument1 pageKhyber Pakhtunkhwa Highway Authority addresses improper road workEngr Amir Jamal QureshiNo ratings yet

- Location Map Thanidani Nathiagali 2Document1 pageLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNo ratings yet

- SING BOARDS List SpecimensDocument25 pagesSING BOARDS List SpecimensEngr Amir Jamal QureshiNo ratings yet

- PLOT Sizes For Fuel and CNGDocument1 pagePLOT Sizes For Fuel and CNGEngr Amir Jamal QureshiNo ratings yet

- Haripur Bypass Flyovers Progress ReportDocument3 pagesHaripur Bypass Flyovers Progress ReportEngr Amir Jamal QureshiNo ratings yet

- Location Map Thanidani Nathiagali 2Document1 pageLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNo ratings yet

- Draft MOM - DD 25-7-16Document4 pagesDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNo ratings yet

- Draft MOM - DD 25-7-16Document4 pagesDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNo ratings yet

- Progress Report-April 2016Document4 pagesProgress Report-April 2016Engr Amir Jamal QureshiNo ratings yet

- NWFP Public Propert (Removal of Encroachment) Act 1977Document6 pagesNWFP Public Propert (Removal of Encroachment) Act 1977Engr Amir Jamal QureshiNo ratings yet

- Letter To Consultants For Mobilization at SiteDocument2 pagesLetter To Consultants For Mobilization at SiteEngr Amir Jamal Qureshi57% (7)

- KPK GOVT APPROVES RETAIL OUTLET NOCDocument1 pageKPK GOVT APPROVES RETAIL OUTLET NOCEngr Amir Jamal QureshiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BOQ - EGB BoilerDocument4 pagesBOQ - EGB BoilerNadira PervinNo ratings yet

- Standard Drawings Complete 2012Document257 pagesStandard Drawings Complete 2012AdrianNo ratings yet

- Alarm Check Valve VictulicDocument12 pagesAlarm Check Valve Victulicمحمود السعيدNo ratings yet

- HyperMAX Damper FansDocument2 pagesHyperMAX Damper Fansrossi.enzo.bsNo ratings yet

- Chandigarh University: Topic - Vernacular Architecture of Indian Village (Menavali Village, Satara Maharashtra)Document18 pagesChandigarh University: Topic - Vernacular Architecture of Indian Village (Menavali Village, Satara Maharashtra)Naitik JaiswalNo ratings yet

- Second Floor Plan LayoutDocument1 pageSecond Floor Plan Layoutmohamed abuthalibNo ratings yet

- Mike C Map Install NoteDocument26 pagesMike C Map Install NoteAlejandro Canul TurrizaNo ratings yet

- The The: Evolution of Warren, or Triangular, TrussDocument1 pageThe The: Evolution of Warren, or Triangular, TrussMr. DreamNo ratings yet

- Mal Ware Bytes 1Document27 pagesMal Ware Bytes 1asimNo ratings yet

- Veritas InfoscaleDocument223 pagesVeritas InfoscaleShanmuga Babu TamilarasanNo ratings yet

- NDT-Verify Steel WeldsDocument1 pageNDT-Verify Steel Weldskinglordofato100% (1)

- IEC 61850 Based Substation Automation System (SAS) - PPT 1Document21 pagesIEC 61850 Based Substation Automation System (SAS) - PPT 1ChanderSinghWarkade100% (5)

- 01 - IntroductionDocument19 pages01 - IntroductionchamindaNo ratings yet

- Revetment Wall Design Along Bacao BridgeDocument19 pagesRevetment Wall Design Along Bacao BridgeAngelo MoralNo ratings yet

- CP MoyaShield BEDocument3 pagesCP MoyaShield BEGanesh MurthyNo ratings yet

- PHPDocument4 pagesPHPRaviNarayanaNo ratings yet

- Lecture 46 Vernacular Architecture - I PDFDocument17 pagesLecture 46 Vernacular Architecture - I PDFnikita chawlaNo ratings yet

- Lime & Tiles: Presentation ONDocument47 pagesLime & Tiles: Presentation ONsanjeev kumarNo ratings yet

- Manual OpenKmDocument22 pagesManual OpenKmHoracio Jose Menendez HernandezNo ratings yet

- Piazza NovonnaDocument14 pagesPiazza NovonnaSwathiNo ratings yet

- Sikatop 107 Plus Pds enDocument3 pagesSikatop 107 Plus Pds enaostiwaNo ratings yet

- Total HousingDocument71 pagesTotal Housingvampir092% (13)

- Pisa SpecDocument9 pagesPisa SpecCarlos do PradoNo ratings yet

- Work Inspection RequestDocument1 pageWork Inspection RequestMohammed JavidNo ratings yet

- Service Manual P3Document159 pagesService Manual P3kulilin10% (2)

- EDCHDocument34 pagesEDCHjohnsonsemNo ratings yet

- BB FormworkDocument66 pagesBB Formworkshingkeong100% (1)

- Array Processors: SIMD Computer OrganizationDocument45 pagesArray Processors: SIMD Computer OrganizationArshad Matin100% (1)

- XVME-689-VR7 VME - XembeddedDocument94 pagesXVME-689-VR7 VME - XembeddedKevin BudzynskiNo ratings yet

- Concise installation guide for Panasonic ventilation fan models FV-08VQL6, FV-11VQL6, FV-15VQL6Document12 pagesConcise installation guide for Panasonic ventilation fan models FV-08VQL6, FV-11VQL6, FV-15VQL6tylerdurdaneNo ratings yet