Professional Documents

Culture Documents

WPS MS 01C Rev. 0

Uploaded by

alinor_tnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS MS 01C Rev. 0

Uploaded by

alinor_tnCopyright:

Available Formats

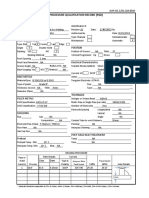

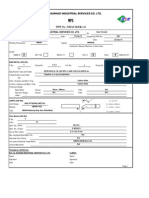

NAWARA PROJECT (PIPELINE)

Contractor

JV BIMS

Client

OMV

WPS

MS-NAWPPL-01C

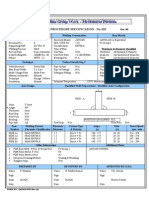

WPQR

MS-NAWPPL-01A

MS-NAWPPL-01B

R.0

R.0

R.0

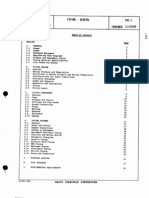

WELDING PROCEDURE SPECIFICATION

APPLICATION Carbon Steel Pipipeline and Related Facilities

TYPE OF WELDING Automatic Welding of Butt Joints - Pipe to Pipe/Fitting DN 20''

WELDING PROCESS GMAW (Gas Metal Arc Welding) LINCOLN INVERTEC STT II + FCAW (Flux Core Arc Welding) with PROTEUS system

STANDARD REFERENCE API 1104 Ed.21st-2013 ; STGP-GEN-OF04-E321-YL-SPE-1006 Rev. 001 - 09 Apr 2013

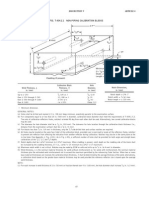

PREPARATION AND ALIGNMENT

BEVEL DESIGN

WELDING SEQUENCE

Preparation Mechanical or thermal cutting

Beveling pipe facing machine

Cleaning Grinding and/or wire brush

Type of Joint Butt weld

Bevel Design V- Groove

t=

s=

g=

=

Allignment Internal pneumatic clamp

Allignment Sys Removal After completion of 100% Root pass

11,91 19,05 mm

1,6 0,2 mm

0,0 mm

18 2

Note

R = 2,4mm

THERMAL CONDITION

BASE MATERIAL

Type

Standard - Material

SMYS - SMTS (MPa)

1 - PIPE

2 - PIPE / FITTING

API 5L X 65 PLS 2

or eq. YS 448MPa

API 5L X 65 / ASTM A694

F65 or eq. YS 448MPa

450

535

450

Heating Oxi-propane Flame

Interpass [T max] 250 C

Measurement Contact Thermomenter or Crayons

535

CE Max %

0,43

0,43

NOMINAL DIAMETER - DN

20''

20''

11,91 19,05 mm

11,91 19,05 mm

NOMINAL THICKNESS - t

PRE-Heat [T min] 75 C - Extention 75 mm both sides of the joint

TECNIQUE

Single or Multipass Multipass

Position - Direction Root 5G - Fill&Caps 5G

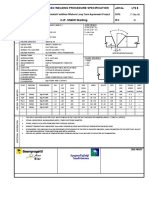

FILLER MATERIAL

Process

SFA Specification

GMAW

FCAW

AWS A 5.18

AWS A 5.20

AWS Classification

Time Lap Root-Hot pass

10 min.

N Passes min.

3 including Caps for th 11,91 mm

5 including Caps for th 17,48 mm

6 including Caps for th 19,05 mm

Type of Passes string or wave

ER70S-6

E71T-9MJ

OERLIKON

KOBELCO

CARBOPIPE 70

FAMILIARC DW-A 55E

Type - Transfer Mode

Wire - STT

Wire - Spray Arc

Welding Unit

STT

Fille Metal Diameter

1.2 mm

1.2 mm

Pass / Layer

Root

2nd

3rd - Ci

Rutile

Angle weld. Torch ()

Oscill. Width (set)

90 6

90 6

90 6

20 - 20

60 - 80

90 - 150

Oscill. Freq (inch)

12,5

9,0 - 9,5

8,0 - 9,5

Dwell Time (ms)

120

90 120

90 120

Manufacturer

Trade Name

Coating/Flux

Batch No.

N Welders / Operators

Backing No

SEMI-AUTOMATIC AND AUTOMATIC WELDING UNITS

GAS

PROTEUS

Side Shielding

Pass

Class. AWS

Composition

Rate (l/min)

15 20

15 20

40%Ar+60%CO2

27 - 35

Nozzle (mm)

Stick-out (mm)

15 20

Root

12 15

12 15

12 15

Filling /Caps

2 - Ci

80%Ar+20%CO2

27 - 35

Number of wire

WELDING PARAMETERS

Passes

Process

1 / Root

GMAW

2 / Hot Pass

FCAW

3 - 4/ Filling

FCAW

5 - n / Filling

FCAW

Ci / Caps

FCAW

Position and

Direction

5G (Fixed H. Axis)

Down-Hill

5G (Fixed H. Axis)

Up-Hill

5G (Fixed H. Axis)

Up-Hill

5G (Fixed H. Axis)

Up-Hill

5G (Fixed H. Axis)

Up-Hill

Filler

Material

Current &

Polarity

Amperage

(A)

Voltage

(V)

Travel Speed

(mm/min)

Wire Speed

(m/min)

H.I.

(KJ/mm)

1.2 mm

DC +

155

180

15,0

17,0

315

340

3,20

3,60

0,41

0,58

1.2 mm

DC +

195

230

19,5

23,0

240

250

7,00

8,30

0,91

1,32

1.2 mm

DC +

210

250

22,0

24,0

215

230

8,10

8,30

1,21

1,67

1.2 mm

DC +

195

210

23,5

25,0

215

230

7,00

8,30

1,20

1,47

1.2 mm

DC +

185

200

22,0

23,0

220

240

7,00

7,30

1,02

1,25

NOTES

1. After welding of 100% the root pass, pipe can be moved to adapt the welding at the field condition. Welding of the hot pass will start in 10 min from the end of the

root pass.

2. Before to completion, the welding of joints of Thickness > 11,91mm can be interrupted at filling deposition of 10mm wall thickness and left to cool until room

temperature under thermal insulation if the weather conditions require it.

3. The welding joint conditions may require a partial layer "Strip-pass" during filling and more than one pass for the Cap layer

APPROVAL JV: BOUCHAMAOUI Ind. - MAX STREICHER SpA

DATE 27.06.2016

CLIENT OMV TUNISIE

DATE

THIRD PARTY INSPECTION

DATE

You might also like

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Omniscan Techniques For Crack SizingDocument31 pagesOmniscan Techniques For Crack Sizingalinor_tnNo ratings yet

- ISO 6520 Defects Overview PDFDocument27 pagesISO 6520 Defects Overview PDFalinor_tn100% (4)

- Surface Tension Transfer (STT) Pipe WeldingDocument3 pagesSurface Tension Transfer (STT) Pipe WeldingahmedNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WpsDocument6 pagesWpsabhishek198327No ratings yet

- Welders MatrixDocument1 pageWelders Matrixalinor_tn100% (1)

- Master SteelDocument5,118 pagesMaster Steelsabiutayo100% (3)

- DLL Smaw-W1&2Document5 pagesDLL Smaw-W1&2cath borja100% (1)

- ASSENT Prequalification DocumentDocument95 pagesASSENT Prequalification DocumentMostafaAdelMaghrabyNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- 5 Weld MapDocument6 pages5 Weld MapEdha AliNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Weld ProceduresDocument8 pagesWeld Proceduresshifa100% (2)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Stack WeldingDocument76 pagesStack WeldingKatie Ramirez100% (1)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Saipem Wps ListDocument2 pagesSaipem Wps ListookaNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- AWS Classification System SAWDocument5 pagesAWS Classification System SAWperungguNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- ASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Document2 pagesASME Sect. IX WPS & PQR Check List: ! ! ! Cannot Replace The Use of Section IX ! ! !Lora BoydNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPS - 025Document4 pagesWPS - 025MAT-LIONNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- WpsDocument1 pageWpssathi_mechNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Welding Presentation by NoreastDocument78 pagesWelding Presentation by Noreastravi00098No ratings yet

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- IDS For Fiber Optic CableDocument5 pagesIDS For Fiber Optic Cablealinor_tnNo ratings yet

- Technical Data Sheet For Control ValveDocument5 pagesTechnical Data Sheet For Control Valvealinor_tnNo ratings yet

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocument32 pagesHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- Pipeline Hydrotest ProcedureDocument78 pagesPipeline Hydrotest Procedurealinor_tn100% (1)

- Work Method Statement For De-Watering Drying and Purging After HydrotestDocument12 pagesWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnNo ratings yet

- Pipeline Welding Visual Inspection ReportDocument8 pagesPipeline Welding Visual Inspection Reportalinor_tn0% (1)

- Technical Data Sheet For Temperature TransmitterDocument38 pagesTechnical Data Sheet For Temperature Transmitteralinor_tnNo ratings yet

- Sample Test Pack - Piping HydrotestDocument96 pagesSample Test Pack - Piping Hydrotestalinor_tn75% (4)

- Nawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping SupportsDocument21 pagesNawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping Supportsalinor_tnNo ratings yet

- 000 ZA E 09411 Punch List ProcedureDocument17 pages000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- MLE System SubSystem SheduleDocument29 pagesMLE System SubSystem Shedulealinor_tnNo ratings yet

- 000 ZA E 09403 SITE NC MNGMT ProcedureDocument11 pages000 ZA E 09403 SITE NC MNGMT Procedurealinor_tn100% (1)

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDocument251 pages000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnNo ratings yet

- 000-ZA-E-09413 Construction Progress Meas ProcDocument12 pages000-ZA-E-09413 Construction Progress Meas Procalinor_tnNo ratings yet

- Mechanical Test Specimens PlanDocument3 pagesMechanical Test Specimens Planalinor_tn100% (1)

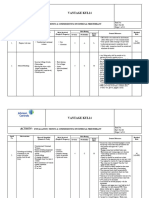

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDocument11 pagesIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnNo ratings yet

- General Procedure For AUTDocument19 pagesGeneral Procedure For AUTalinor_tn100% (2)

- Piping Codes (41-45)Document42 pagesPiping Codes (41-45)Brenda Davis100% (2)

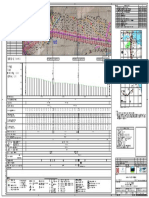

- Raw Gas Pipeline - Alignment Sheet N.407Document1 pageRaw Gas Pipeline - Alignment Sheet N.407alinor_tn100% (1)

- Erection Manual-Pc PipingDocument219 pagesErection Manual-Pc Pipingalinor_tn100% (2)

- Jacobs Standard Specification - Piping Fabrication and ErectionDocument19 pagesJacobs Standard Specification - Piping Fabrication and Erectionalinor_tn100% (1)

- Inspection Plan For Crane PDFDocument3 pagesInspection Plan For Crane PDFalinor_tnNo ratings yet

- PT-MT Kurs NotuDocument300 pagesPT-MT Kurs NotuBahadir TekinNo ratings yet

- TeknosDocument76 pagesTeknosMartin LafonNo ratings yet

- Piping Notes 1Document47 pagesPiping Notes 1sanjay421100% (1)

- ASME CalculationDocument25 pagesASME Calculationalinor_tn100% (1)

- Risk Assessment Fire Hydrant Installation Testing CommissioningDocument11 pagesRisk Assessment Fire Hydrant Installation Testing CommissioningAmie GTunedNo ratings yet

- Manual 19 PDFDocument9 pagesManual 19 PDFyury1102No ratings yet

- Design World Robotics Handbook 11 2023Document60 pagesDesign World Robotics Handbook 11 2023ql yuanNo ratings yet

- Electrode Material SelectionDocument1 pageElectrode Material SelectionJoel BrasilBorgesNo ratings yet

- Sabater-Fundimol Catalog p32-33 PDFDocument2 pagesSabater-Fundimol Catalog p32-33 PDFSağlam RasimNo ratings yet

- Fire Safety During Construction and MaintenanceDocument32 pagesFire Safety During Construction and MaintenanceYahya AhmedNo ratings yet

- Curriculum Vitae: Prakriti Kumar GhoshDocument41 pagesCurriculum Vitae: Prakriti Kumar GhoshaNo ratings yet

- ME6302-Manufacturing Technology-I PDFDocument10 pagesME6302-Manufacturing Technology-I PDFpraveen mithunNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Piping Volume of WorkDocument13 pagesPiping Volume of WorkRagerishcire Kanaalaq50% (2)

- Ruud Optimal SecuringDocument28 pagesRuud Optimal SecuringStian Eikanger SkålevikNo ratings yet

- BR Company ProfileDocument31 pagesBR Company ProfilearefNo ratings yet

- Saudiaramcostandards 140726082837 Phpapp01Document12 pagesSaudiaramcostandards 140726082837 Phpapp01RakeshNo ratings yet

- Ansi GPTC z380 1 - 2018 Addendum 2 02 - 19 - 19Document212 pagesAnsi GPTC z380 1 - 2018 Addendum 2 02 - 19 - 19Melele MuNo ratings yet

- ANSI-NEMA GR1-2007 - FinalDocument27 pagesANSI-NEMA GR1-2007 - FinalJunior AvalosNo ratings yet

- En 1057 PDFDocument37 pagesEn 1057 PDFdeea19sNo ratings yet

- Br20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesDocument2 pagesBr20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesBashu Dev SanjelNo ratings yet

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- Table QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023Document1 pageTable QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023ahmadrizkiqcNo ratings yet

- Erico Cadweld Plus Installation Guide - E297lt17wwen - LRDocument56 pagesErico Cadweld Plus Installation Guide - E297lt17wwen - LRJoel AlcantaraNo ratings yet

- Spanish Model III BrochureDocument6 pagesSpanish Model III BrochureMaFher JimenezNo ratings yet

- Introduction To Acoustic Emission TestingDocument19 pagesIntroduction To Acoustic Emission TestingkingstonNo ratings yet

- 02 DRP Cat Side Pin AdaptDocument12 pages02 DRP Cat Side Pin AdaptNicoleta CosteaNo ratings yet

- Acception of ImperfectionDocument3 pagesAcception of ImperfectionAnonymous 7yN43wjlNo ratings yet

- Welding and Materials-At A Glance06,07,2013Document65 pagesWelding and Materials-At A Glance06,07,201355312714No ratings yet

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza PradaNo ratings yet

- Guideline Dvs 2206 4 09 2011Document2 pagesGuideline Dvs 2206 4 09 2011Zheng YuNo ratings yet